I tried yoga once but got kicked out of the classes for excessive farting.

(As a result I don’t think I want to sit on my own face 🤡 )

(As a result I don’t think I want to sit on my own face 🤡 )

Trying to come up with a way to hold this and other drivers for the DATS runs. The largest driver is 17kg

How would bollard type job go for these smaller drivers? A vertical post on a sturdy base like a cat scratcher post. Some machined MDF interfaces to mate post to magnet. A hollow post with window would take care of vented drivers too. Would this have cons?

How would bollard type job go for these smaller drivers? A vertical post on a sturdy base like a cat scratcher post. Some machined MDF interfaces to mate post to magnet. A hollow post with window would take care of vented drivers too. Would this have cons?

Dunno, but FWIW I DIYed an inverted 'A' frame to ' slide' them snugly into place and for thinner flanges just used scrap shims.

I think I have it. A tall stand with a sturdy base and a small, narrow top. The top would have a row of holes for various sized U-clamps

The same stand can mount a complete box for testing later by screwing the box on using the existing holes in the top plate

The same stand can mount a complete box for testing later by screwing the box on using the existing holes in the top plate

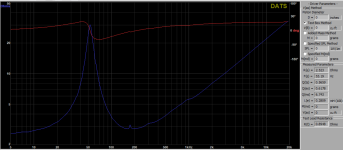

Odd, the test lead resistance has dropped by only 0.006 ohms with better clips, and is still nearly 1 ohm, a lot of series resistance.Measured on Datsv3 using the new heavy duty steel stand and Datsv3 leads refitted with better alligators.

"Typically", the test leads are ~0.17 ohms.

Not sure of the test lead gauge, but 100 feet (30.7 meters) of 18AWG would only be ~0.65 ohms resistance.

The driver impedance has gone up by .08 ohms.

Was it the same driver as the first test?

I find this odd too. It is the same driver. It seems to be the alligators or leads. Even the calibration steps with shorting. Even the new clips struggle to get a good contact. I still don't feel that I am getting accurate results. For example, the qts reads over 0.69 if the clips are just applied to the solder tabs. If the clips are jammed in through the hole in the tab, the qts drops to 0.56x, but not consistent during reruns. Feels like the contact is still dodgy

Alligator clips must also be vibrating during the Datsv3 pulse. Will try to create a better connection today and remeasure

Alligator clips must also be vibrating during the Datsv3 pulse. Will try to create a better connection today and remeasure

FWIW, since grounding is nearly 'everything' in electrical wiring, all my XOs/whatever grounds all go individually to a bus bar like in a home's distribution panelboard where the clips can get a good grip or at least a UL/CSA terminal strip with needle leads and clamp them.

How about drilling some alligators through and fit an M3 bolt and wing nut to enable locking down

Sure! Anything to make for an excellent joint. Also recommend using conductive joint compound if in a humid area such as I do/did, though Vaseline is fine if not hot enough for it to start/going liquid and if you can get access to the type of hydraulic brake fluid designed for planes that spend time in the arctic circles, mix a bit in to tint it red and you'll have a mix that can withstand much more extreme weather than humans long term.

Got lucky with this one. Found it at the reuse centre for $10. Is strong enough to serve as an anvil too. Will remove the hook and replace with a bolt-onable steel square top for holding complete cabs. The 38kg AGM work bench battery sits over the base strap well! I will make a battery holder there. The outrigger leg pair looks fit for a pair of trolley wheelsNice stand!

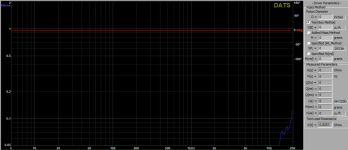

Stock cables with the alligators cut off and wires twisted togetherResistance is still far too much unless your cables are very long.

Anyway, I would have thought that Datsv3 would be smart enough to actually use the calibration results. I.e, once in range which it appears to be, then correct for it automatically

Hooked up to the z623 amp and breaking it in. Bass is boosted to work the driver over a day or two

- Home

- Loudspeakers

- Subwoofers

- Racer 8