@djim few posts back in the 3d pic u can see some bracing.

there should be no more than 12 " whitout bracing.

@olsound

we could put "bild up "handles on it instead of bild in.

then we could take away panel 9a/b, shorten 4 and 3,this would save weight +you could fit bigger casters on it.

just another brainfart😛

there should be no more than 12 " whitout bracing.

@olsound

we could put "bild up "handles on it instead of bild in.

then we could take away panel 9a/b, shorten 4 and 3,this would save weight +you could fit bigger casters on it.

just another brainfart😛

@olsound

we could put "bild up "handles on it instead of bild in.

then we could take away panel 9a/b, shorten 4 and 3,this would save weight +you could fit bigger casters on it.

just another brainfart😛

[/QUOTE]

[/QUOTE]

that sound good

we could put "bild up "handles on it instead of bild in.

then we could take away panel 9a/b, shorten 4 and 3,this would save weight +you could fit bigger casters on it.

just another brainfart😛

that sound good

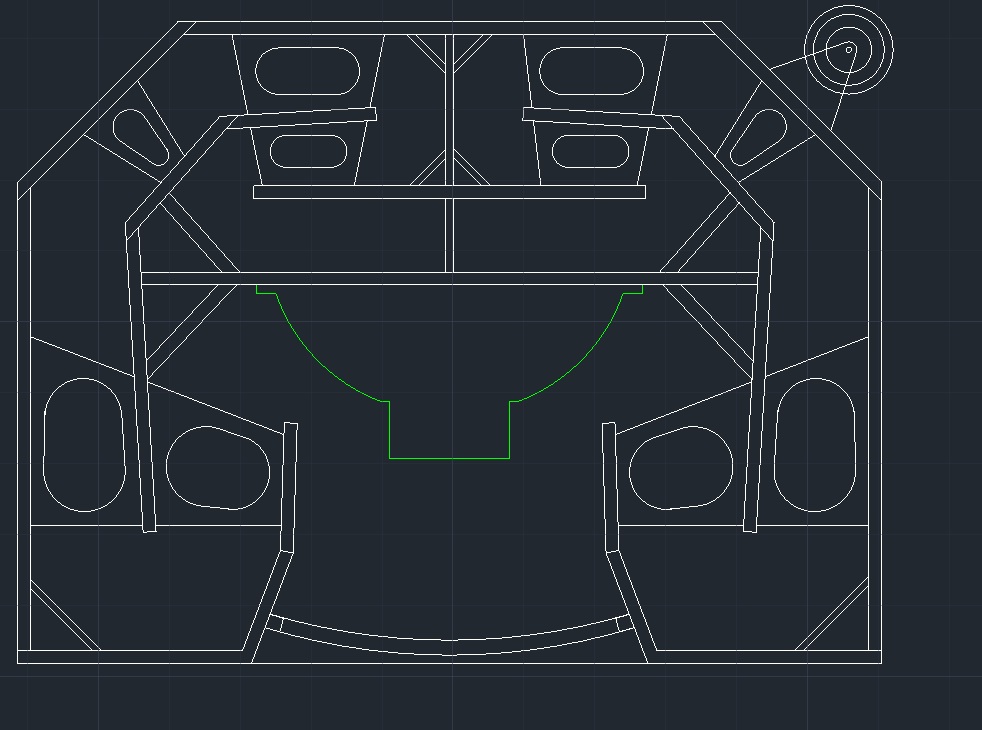

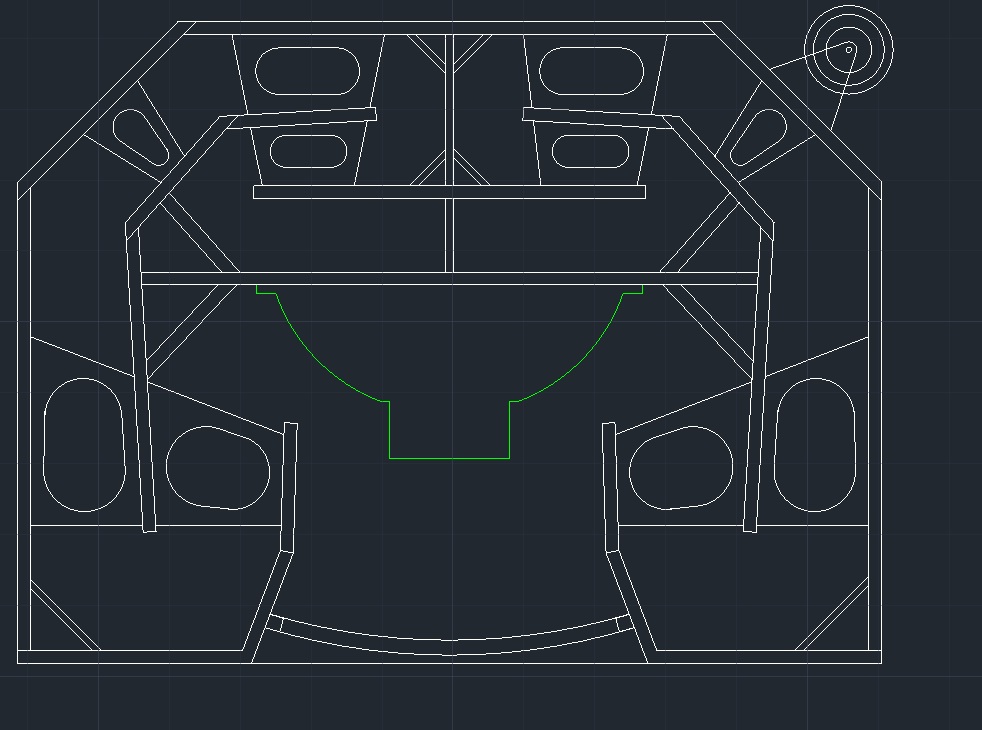

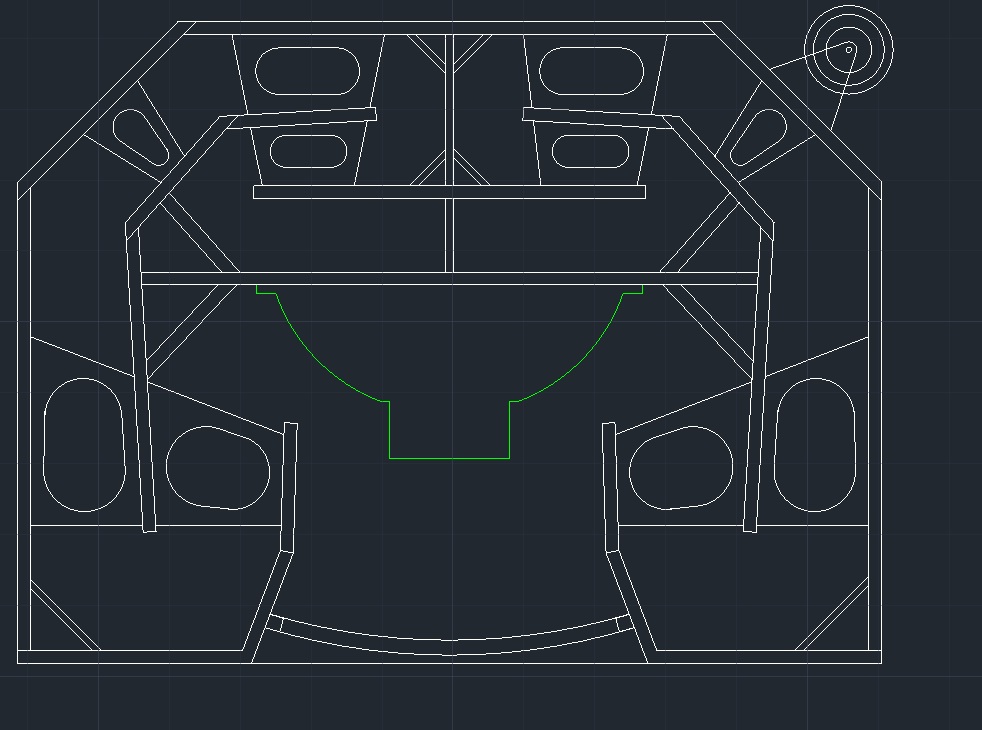

The problem is not the distance but it doesn't support enough surface. Also I think your mouth could benefit from extra bracing (dual layering) and the corners in front could benefit from extra support for durability reasons.@djim few posts back in the 3d pic u can see some bracing.

there should be no more than 12 " whitout bracing.

The panels Olsound is referring to with arrows you can simplify by just using 1 panel. Because it is in the end of the path it wont make a difference in response and makes it easier to build.

Last edited:

the ones on the side could be a bit wider , i agree.i was considering that.

@olsound i was thinking makeing it 3* 9mm,but maybe i.m abit to precise.

agreed with jim ,at the end of the horn it doesn't make much difference.

we might aswel make it one 18 mm panel.

i wil continue drawing tomorow.

at the mouth i was tinking a curved perforated sheet to brace top and bottem pannel.

@olsound i was thinking makeing it 3* 9mm,but maybe i.m abit to precise.

agreed with jim ,at the end of the horn it doesn't make much difference.

we might aswel make it one 18 mm panel.

i wil continue drawing tomorow.

at the mouth i was tinking a curved perforated sheet to brace top and bottem pannel.

Epa, if you send me a drawing (from above) without panel labels I could draw some suggestion in if you want.

damn, they stole my idea😀

i came up with this one as it evolved from many try's over time.

i think the longer l4>l5 and the taper wil be an improvement

i came up with this one as it evolved from many try's over time.

i think the longer l4>l5 and the taper wil be an improvement

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

The vertical corner bracing will extend the support function of the backwall and the panel which directly receives the pressure from the cone.

The left front corner shows how the extension of your bracing will back up the support for the corner. That makes the cab better 'roadproof'.

On the right front corner another example of making the cab stronger but also has the advantage of correcting the corner volume.

For the rest your bracing is optimal but make it all double at 1/3 and 2/3 distance.

Last edited:

[QUOTE 225755[/ATTACH]

The vertical corner bracing will extend the support function of the backwall and the panel which directly receives the pressure from the cone.

The left front corner shows how the extension of your bracing will back up the support for the corner. That makes the cab better 'roadproof'.

On the right front corner another example of making the cab stronger but also has the advantage of correcting the corner volume.

For the rest your bracing is optimal but make it all double at 1/3 and 2/3 distance.[/QUOTE]

I like this angle on the right

The vertical corner bracing will extend the support function of the backwall and the panel which directly receives the pressure from the cone.

The left front corner shows how the extension of your bracing will back up the support for the corner. That makes the cab better 'roadproof'.

On the right front corner another example of making the cab stronger but also has the advantage of correcting the corner volume.

For the rest your bracing is optimal but make it all double at 1/3 and 2/3 distance.[/QUOTE]

I like this angle on the right

Attachments

beta 4

tnx jim

anyone else want to contribute?

olsound ,i wouldn't take that cornr of.

a biger front wil improve lows and directivety.

tnx jim

anyone else want to contribute?

olsound ,i wouldn't take that cornr of.

a biger front wil improve lows and directivety.

beta 4

tnx jim

anyone else want to contribute?

olsound ,i wouldn't take that cornr of.

a biger front wil improve lows and directivety.

Lows and directivety sounds good

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- R evenge C omes with F orce