I think about some comparative testing of different materials for the ESL63 dust protection purpose.

Background: Quite many posts in different threads are related to the dust protection film and it's potential impact on the impulse response of the assembled ESL63 speaker. Some advocate to omit this dust protection altogether, some claim no influence of the two film sheets, some fit them hands down for practical reasons while trading in a potential slight sonic drawback. I therefore would like to perform some comparative, more theoretical, yet systematic testing of some standard and also of some non-standard materials for dust protection. If the test succeeds, then a more precise weighting/compromizing might become possible for every of the tested materials.

For my refitted ESL63, I used Vliesseline stich n tear, which showed some quite pleasing results while measuring. I do not claim that it is the best compromize, and I don't know how it performs against other options. So I would like to test this product against some experimantal 100% PET felt sheets/panels and of course also against different brands and strengths of standard film ("standard" == routinely used as dust protection). It would also be interesting to test some, say 3 different brands and strengths of standardly fitted films one against the other.

To perform these tests, I need some samples. So my question/request to the pro ESL63 rebuilders here in this forum is: Are some of you experts willing to send me 1.5m of yours preferred and routinely fitted dust protection film? Of course I would pay for the material and shipping. Please contact me per PM for my shipping address and for the mode of payment. I will perform this test if I can get 2 or 3 samples.

Test setup would include the absorbtive and the reflective property of each dust protector candidate (DPC) under test. I imagine to place everything into a line:

Sound source - Mic - DPC - Flat/plane surface as near-perfect acoustic reflector. The mic would therefore catch first the wavefront of the direct sound, then the wavefront reflected by the DPC, then the reflected and twice partly absorbed wavefront. Reflected by the acoustic reflecting plane, absorbed by the DPC.

Any comments welcome.

Background: Quite many posts in different threads are related to the dust protection film and it's potential impact on the impulse response of the assembled ESL63 speaker. Some advocate to omit this dust protection altogether, some claim no influence of the two film sheets, some fit them hands down for practical reasons while trading in a potential slight sonic drawback. I therefore would like to perform some comparative, more theoretical, yet systematic testing of some standard and also of some non-standard materials for dust protection. If the test succeeds, then a more precise weighting/compromizing might become possible for every of the tested materials.

For my refitted ESL63, I used Vliesseline stich n tear, which showed some quite pleasing results while measuring. I do not claim that it is the best compromize, and I don't know how it performs against other options. So I would like to test this product against some experimantal 100% PET felt sheets/panels and of course also against different brands and strengths of standard film ("standard" == routinely used as dust protection). It would also be interesting to test some, say 3 different brands and strengths of standardly fitted films one against the other.

To perform these tests, I need some samples. So my question/request to the pro ESL63 rebuilders here in this forum is: Are some of you experts willing to send me 1.5m of yours preferred and routinely fitted dust protection film? Of course I would pay for the material and shipping. Please contact me per PM for my shipping address and for the mode of payment. I will perform this test if I can get 2 or 3 samples.

Test setup would include the absorbtive and the reflective property of each dust protector candidate (DPC) under test. I imagine to place everything into a line:

Sound source - Mic - DPC - Flat/plane surface as near-perfect acoustic reflector. The mic would therefore catch first the wavefront of the direct sound, then the wavefront reflected by the DPC, then the reflected and twice partly absorbed wavefront. Reflected by the acoustic reflecting plane, absorbed by the DPC.

Any comments welcome.

I had 63's for many years - rebuilt a slew of panels to keep them going. One thing NOT mentioned in discussion was that ti me it's MANDATORY to have them in an air-conditioned environment, AND turn them off if your not going to listen for a while. The conductive coatings are hydroscopic and will accumulate charge hot spots if left on in a humid environment.

That said, if you are in a relatively dry environment and don't smoke, you can easily get by WITHOUT the dust covers. If need be, brush the surface every so often with a soft/clean cloth.

That said, if you are in a relatively dry environment and don't smoke, you can easily get by WITHOUT the dust covers. If need be, brush the surface every so often with a soft/clean cloth.

Your post is completely off-topic, but maybe it's a bit also by my fault. My fault, because I unfortunately wrote, as the very last sentence of my first post:

"any comments welcome".

Obviously, I should not have done so. Because, as written, it's an way too general invitation, agreed. It's an invitation maybe also to talk about anything from the kitchen sink design to the fakeness or not of the apollo program. Why not ...

The subject you rise of omitting the dust protection is also not new. It has been discussed over and over and over again in other threads. But you rise a point which is new to me: The assumption about the hygroscopic properties of the coatings, which indeed might be interesting as such. I will not comment on that one, because, once again, this topic is not in the center of interest here. I do not intend a discussion about coatings. So you may please open another and own thread to discuss eventual hygroscopic properties of coatings and the best potential workarounds.

I am purposely very direct in writing so and hope this is not offending. I simply don't want this thread bloated with exostuff right from the beginning. And I hope this directness of mine is not intimidating any potential posters interested in and wanting to contribute to the subject I rose.

So let me be have a 2nd try and thereby be a bit more precise:

Comments about the utility of acoustically test assessing dust protection film materials for ESL's and comments about the mentionned test setup are welcome (what a mouthful of a sentence ...).

🙂

"any comments welcome".

Obviously, I should not have done so. Because, as written, it's an way too general invitation, agreed. It's an invitation maybe also to talk about anything from the kitchen sink design to the fakeness or not of the apollo program. Why not ...

The subject you rise of omitting the dust protection is also not new. It has been discussed over and over and over again in other threads. But you rise a point which is new to me: The assumption about the hygroscopic properties of the coatings, which indeed might be interesting as such. I will not comment on that one, because, once again, this topic is not in the center of interest here. I do not intend a discussion about coatings. So you may please open another and own thread to discuss eventual hygroscopic properties of coatings and the best potential workarounds.

I am purposely very direct in writing so and hope this is not offending. I simply don't want this thread bloated with exostuff right from the beginning. And I hope this directness of mine is not intimidating any potential posters interested in and wanting to contribute to the subject I rose.

So let me be have a 2nd try and thereby be a bit more precise:

Comments about the utility of acoustically test assessing dust protection film materials for ESL's and comments about the mentionned test setup are welcome (what a mouthful of a sentence ...).

🙂

Last edited:

I woud be interested in the linearity of damping materials (in regards to amplitude). I think that it might explain the perception of dull sound some people experience with (over?-) dampened panels.

Https://www.mdpi.com/2076-3417/11/16/7713

This research paper hints to nonlineair behaviour of airchannels etc. Closer to the soundsource, like the mesh in quad speakers, the effect may be more pronounced.

This research paper hints to nonlineair behaviour of airchannels etc. Closer to the soundsource, like the mesh in quad speakers, the effect may be more pronounced.

You raise an interesting subject. ESL63 are a quite complex sandwich in terms of reflections and absorbtion (== damping):

First the central membrane

Then a situatively both symmetric and asymmetric cushion of air of variable thickness of approx. symmetric 2mm when idle and approx. asymmetric 0.5mm/3.5mm when at max. amplitude.

Then the asymmetrically meshed/non meshed perforated stators, leading to a compression ratio of approx. 1:2 and trapping some air in holes of lenghts of 1.2mm (== thickness of the stator)

Then the array of all the multiple sqare and open pipes of approx. 25mm lenght formed by the stator carriers structure

Then a layer of air

Then the dust protection film

Then another layer of air

Then the metal grid

Then the textile sock

Then finally the free ambient air

So where occurs "panel damping"? I guess and potentially bit everywhere. And also reflections might occur a bit everywhere within this complex sandwich. Think all these abrupt changes of acoustic impedance on the first +-7cm (centerline) to +-4cm (laterally) of the wave's pathway. This is way too complex for me to understand at once and as a whole, and this is why I would understand at least the acoustic properties of one single of all these structures: The behavior of the dust protector. In an acoustically more or less linear, simple and isolated environment such as in the mentionned test setup.

If by choosing a best suited material for the dust protection you could, in interaction with the other parts of the sandwich further linearize the whole sound wave transfer, then it could have been worth the effort to investigate on this single pair of sandwiched dust protective films or structures.

First the central membrane

Then a situatively both symmetric and asymmetric cushion of air of variable thickness of approx. symmetric 2mm when idle and approx. asymmetric 0.5mm/3.5mm when at max. amplitude.

Then the asymmetrically meshed/non meshed perforated stators, leading to a compression ratio of approx. 1:2 and trapping some air in holes of lenghts of 1.2mm (== thickness of the stator)

Then the array of all the multiple sqare and open pipes of approx. 25mm lenght formed by the stator carriers structure

Then a layer of air

Then the dust protection film

Then another layer of air

Then the metal grid

Then the textile sock

Then finally the free ambient air

So where occurs "panel damping"? I guess and potentially bit everywhere. And also reflections might occur a bit everywhere within this complex sandwich. Think all these abrupt changes of acoustic impedance on the first +-7cm (centerline) to +-4cm (laterally) of the wave's pathway. This is way too complex for me to understand at once and as a whole, and this is why I would understand at least the acoustic properties of one single of all these structures: The behavior of the dust protector. In an acoustically more or less linear, simple and isolated environment such as in the mentionned test setup.

If by choosing a best suited material for the dust protection you could, in interaction with the other parts of the sandwich further linearize the whole sound wave transfer, then it could have been worth the effort to investigate on this single pair of sandwiched dust protective films or structures.

Last edited:

I agree with you that the situation is quite complex when considering all the elements. When limiting to dustcovers I invite you to do a simple subjective experiment. It requires making a frame with Mylar glued on. Put it in front of any source ( can be a dynamic loudspeaker, or a real instrument, noise of the street or whatver is continous and conveniant) and listen. Then remove and keep on listening. Do you hear a difference? I did this once....I found the single sheet 6 micron Mylar acoustically transparant except from som bass resonance. So the tension of the dustcover is another variable which has to be taken into account. To make it complex again added damping will change the Q of the resonance. Anyway it is very positive that someone takes the effort to investigate this subject .

Good news. The tests might get interesting.

Until now, I will get five (!) distinctly different brands/types of films with quite individual properties, all of them suited and used for dust protection to test one against the other. Dupont Mylar 3u, also standardly used as a dust protecive film by some ESL63 refitters however is still missing amongst this collection.

Until now, I will get five (!) distinctly different brands/types of films with quite individual properties, all of them suited and used for dust protection to test one against the other. Dupont Mylar 3u, also standardly used as a dust protecive film by some ESL63 refitters however is still missing amongst this collection.

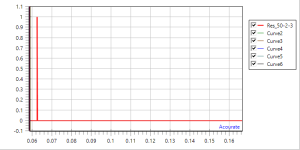

Imagine a very simplified model including the driving membrane between two (experimentally very highly) reflective dust protector films only.

Black is the resulting sum of all three pulses.

Remember: This is an exagerated model. In reality the films will be much less reflective, or eventually not at all. Hopefully, real-life tests later on might show.

Pulse response:

Step response:

Frequency (Magnitude) response:

- No stators in between then, no stator damping mesh, no stator supporting structures, no structures behind and in front the two films.

- The films are assumed to be way too highly reflective with a -10dB of reflected SPL for better effects demonstration purposes

- The films are assumed to be uniformly reflective over the whole frequency band

- No secondary reflections are included which in reality do occur

- This very simple model includes reflections only, not taking in account potential absorbtive and delaying (due to energy storage) properties.

- Red, the front pulse from the diaphagm, directly travelling though the front membrane (the transfer loss because of the reflection and thus lost energy is not accounted for in this model!)

- Green, the front pulse, but then at -20dB having been reflected twice with losses of -10dB each on both front first, then back protector films

- Brown, the negative pulse at -10dB stemming from the back of the diaphragm (therefore with negative polarity), having been reflected with an attenuation of -10dB by the back protector film.

Black is the resulting sum of all three pulses.

Remember: This is an exagerated model. In reality the films will be much less reflective, or eventually not at all. Hopefully, real-life tests later on might show.

Pulse response:

Step response:

Frequency (Magnitude) response:

Last edited:

Yesterday I got five neat, different samples of film from ErAudio, Australia. Thank you Rob for your prompt handling and delivery!

And meanwhile I also set up the test bench for the films.

The picture shows a 85cm x 160cm hanging frame with a reflective plate on the back and an omnidirectional microphone at the front. The films will be attached at the frontal rim of the frame. There is a sound source (it's a single Cabasse Sampan loudspeaker stacked onto an other (mute) one to get some frame-matching elevation of the sound source) placed at 2m from the film plane, emitting the test signal. Midway between the frame and the loudspeaker there is a PET absorber to partially cancel the floor's reflection pathway.

Sound incoming from the front will be reflected back by this rear aluminium coated plate, depending of the frequency of the incoming signal. As this plate is 85cm x 110cm, so roughly taking lambda/2 as a threshold value we can expect frequencies above 343m/s / (2*0.85m) = 200Hz starting to be reflected. Therefore, a sinesweep between 500Hz ... 24kHz will be chosen for all tests.

Both the plate and the microphone are placed at a distance of 17.2cm from the film plane. Therefore, incoming sound from the front will first arrive at the microphone, then take 0.5ms to reach the film, then take another 0.5ms to reach the plate and being reflected back there, then take another 1ms to pass trough the film again and travel back to the microphone. While this pathway takes 2ms, any sound being potentially reflected by the film will take only 1ms to travel back to the microphone.

Test signal was a 10 seconds duration sinesweep 500Hz ... 24kHz, sampling rate was 192kHz. The picture shows the 2ms delayed reflected impulse response of the frame without any film fitted. Any film reflection will/would be seen in the yellow marked region at a delay of 1ms.

Notice: The partitally visible, red curve is without the PET absorber and shows a disturbing floor reflection (amongst others), while the green curve is with the interposed PET absorber. It's evident that the floor reflection will not interfere with the first film reflection (mic - membrane - mic) . But it certainly will interfere with a secondary film reflection (mic - plate - film - plane - mic) potentially arriving with a delay of 3ms. Therefore, the PET absorber may help if there will be any secondary reflection.

As mentionned before, this is a "void" measurement to test the validity of this frame setup only. "Real" tests with a film fitted have not yet been performed. So then, make your best bet. Will there any visible film effect in this setup? We will see ... My odds is that if there is any, then only minimally so.

Last edited:

1st round: Vliesseline Stickflies vs. 4.2um Mylar C

The party has started. And it starts with an unexpected surprize ...

By the time I reworked my ESL63, I opted for a material called Vliesseline Stickvlies as a dust protection. Mainly because it is acoustically dead and because it's handling was more conventient to me than the handling of a PET film. Long story short: It seems that I might have been not completely wrong in doing so.

But first, as for the test series, I had to make some slight apparative modifications on my test frame to ensure a more convenient handling when fitting a film. During preliminary measurements quality tests, I made the experience that the setup is rather sensible in terms of consistency from measurement to measurement. Everytime I fit, tension or remove a film, inevitably there are forces acting on the frame which potentially displace the whole setup by some millimeters: If the geometry between two tests is not near-equal, then the impule subtraction (film - naked = film artefacts) will show too much false artefacts. So finally I ended with a near undamped, freely hanging frame, and good old Sir Newton does it's very best to re-place everything after each invervention. All you have to do between tests is to provide some patient time waiting for the pendulums to loose theirs energy.

For the first "live" tests, I chose Vliesseline and 4.2um Mylar C. For practical reasons: I am familiar with the handling of both, so it's best to begin with something familiar. The test setup is the same as described as in the former post: 10 seconds of sinesweep 500Hz ... 24kHz, SR = 192kHz. The two following graphs show some 0.5ms before and 5ms after the pulse. Blue is naked (without film) response, Black is with the Vliesseline/Mylar fitted, Red is the difference fit minus naked.

First test, then: Naked vs. Vliesseline Stickvlies:

I was very happy to see a reflection 1ms after the direct impulse (pointed out with the markers) as a proof of concept for my setup. And there is another cute wiggle at 0.0655 which could match with a secondary reflection. But then, I also was disappointed about seing all these reflections at all ... naively besting my own choice ... until the next test, at least ...

And now for the obvious big (!) surprize: Naked vs. 4.2um Mylar C:

I tensioned the film as I would have done so for a dust protection. Compared to Vliesseline Stickflies, there is a huge direct 1ms reflection from this film. The reflected energy is of magnitude +0.45/-0.4 which nearly corresponds to the regular one coming back from the aluminium plane. Then there is a distinct 2nd order reflection and even a 3rd order one. No good ...

It seems that at least for this case of 4.2 um Mylar C all those were right who blamed a potential sonic influence emerging from a dust cover film.

Let's then see how the other films will behave. For today, sorry, we're closed.

The party has started. And it starts with an unexpected surprize ...

By the time I reworked my ESL63, I opted for a material called Vliesseline Stickvlies as a dust protection. Mainly because it is acoustically dead and because it's handling was more conventient to me than the handling of a PET film. Long story short: It seems that I might have been not completely wrong in doing so.

But first, as for the test series, I had to make some slight apparative modifications on my test frame to ensure a more convenient handling when fitting a film. During preliminary measurements quality tests, I made the experience that the setup is rather sensible in terms of consistency from measurement to measurement. Everytime I fit, tension or remove a film, inevitably there are forces acting on the frame which potentially displace the whole setup by some millimeters: If the geometry between two tests is not near-equal, then the impule subtraction (film - naked = film artefacts) will show too much false artefacts. So finally I ended with a near undamped, freely hanging frame, and good old Sir Newton does it's very best to re-place everything after each invervention. All you have to do between tests is to provide some patient time waiting for the pendulums to loose theirs energy.

For the first "live" tests, I chose Vliesseline and 4.2um Mylar C. For practical reasons: I am familiar with the handling of both, so it's best to begin with something familiar. The test setup is the same as described as in the former post: 10 seconds of sinesweep 500Hz ... 24kHz, SR = 192kHz. The two following graphs show some 0.5ms before and 5ms after the pulse. Blue is naked (without film) response, Black is with the Vliesseline/Mylar fitted, Red is the difference fit minus naked.

First test, then: Naked vs. Vliesseline Stickvlies:

I was very happy to see a reflection 1ms after the direct impulse (pointed out with the markers) as a proof of concept for my setup. And there is another cute wiggle at 0.0655 which could match with a secondary reflection. But then, I also was disappointed about seing all these reflections at all ... naively besting my own choice ... until the next test, at least ...

And now for the obvious big (!) surprize: Naked vs. 4.2um Mylar C:

I tensioned the film as I would have done so for a dust protection. Compared to Vliesseline Stickflies, there is a huge direct 1ms reflection from this film. The reflected energy is of magnitude +0.45/-0.4 which nearly corresponds to the regular one coming back from the aluminium plane. Then there is a distinct 2nd order reflection and even a 3rd order one. No good ...

It seems that at least for this case of 4.2 um Mylar C all those were right who blamed a potential sonic influence emerging from a dust cover film.

Let's then see how the other films will behave. For today, sorry, we're closed.

Last edited:

I run without dustcovers since over 25 years ago. I remember by that time that it sounded better without.

But maybe 3um film will be more transparent? Probably... Would be interesting to do a listening test of ordinary speakers, with and without a 3um mylar barrier for a blind test.

But maybe 3um film will be more transparent? Probably... Would be interesting to do a listening test of ordinary speakers, with and without a 3um mylar barrier for a blind test.

Nice work presented here!

Could it be that the reflection of the Mylar actually is its resonance behaviour?

Could it be that the reflection of the Mylar actually is its resonance behaviour?

Rob Mackinlay provided me with Toray 3.2um PET film, pending to be tested. Let's hope this 0.2um bias will match into your tolerance 🙂.... maybe 3um film will be more transparent ... listening test of ordinary speakers, with and without a 3um mylar barrier for a blind test.

For the blind subjective hearing test: Rob Mackinlay also pointed me to an interesting and potential unwanted effect in case of a non-100% transparent dust cover film within an ESL: Doppler distortion. Doppler might unpleasently add to the otherwise harmless linear frequency response changes. So it might eventually be rather Doppler distortion contents which makes people omit theirs dust protection? Some weak comb filtering effects due to a reflection certainly does not make a speaker sound "bad". Instead, more so Doppler distortion.

Good point! In time domain indeed the impulse response of a resonance at fist sight appears like a dirac-like pulse of lenght 1 (corresponding to a linear SPL in frequency domain).Could it be that the reflection of the Mylar actually is its resonance behaviour?

Take a resonance, f_res= 50Hz, Q=2 and peaking at +3dB which might be a bit on the highish side for a dust protection film within a Quad63.

Frequency domain:

Time domain:

It's not a dirac at all. In only looks like a dirac in "standard" Y-axis resolution. X-axis shows 0.1s of the response after the initial pulse.

Now then - is it a reflection or a Mylar resonance in the case of the 4.2um Mylar C test I presented in the former post?

From the test setup, we must assume that it's a resonance. F_res of the film certainly was far below 50Hz. Instead, the sinesweep, as described before in this tread, started at 500Hz and whistled up to 24kHz. Therefore, we might exclude the excitation of any 1st order film resonance.

Thank you for your input. It lead me to a nice and revealing sightseeing tour! I was not aware before that in time domain the impulse of a resonance first-sight can look like the one of a perfectly linear frequency response in time domain.

Attachments

Last edited:

ERRATUM:

Should say: From the test setup, we must assume that it is not a resonance.

From the test setup, we must assume that it's a resonance.

Should say: From the test setup, we must assume that it is not a resonance.

I am still puzled by this seemingly reflection as a believed that the mylar would move just along with the soundwave. If we excite the mylar film not uniformly we could create reflections on the mylar itself. If I understad correctly you excite with a pointsource instead of a planar wave perpendicular on the mylar?

Remember that in a Quad63 only the lowermost and the uppermost panel get excited uniformly. Instead, both mid panels are excited inclreasingly delayed from one lateral center to the opposite periphery in order to overall mimic an approximated point source 1.5m behind the panels assembly. So there is also no uniform excitement in a Quad63.

In my test, the monopole (point?) source is placed 200cm away from the film. The film measures 65cm by 80cm. With these values, the largest extent of the film is it's diagonal which is 103cm. The smalles extent is 65cm. Taking the curved sound front into account, this makes a max. distance of 206.5cm from the sound source to the corners of the film, and a min. distance of 202.6 to the mid of the long side.

For the max. periphery excitement delay (corner/diagonal) then, we get a pathways difference delay of

206.5cm - 200cm = 6.5cm = 0.19ms = 5.25kHz.

For the shortest periphery excitement delay (center of long side) we get a difference of

202.6cm - 200cm = 2.6cm = 0.08ms = 13.1kHz.

Therefore it might be interesting to also assess the behavior of the film within a narrow frequency band signal between 500Hz and 1kHz in order to rule out any longitudinal or other possible resonances excitement. We'll see.

I also did not expect such an intense reflection. Or shoud I better and more cautiously say peak, ruling out any misinterpretation? Still, as this 1ms delayed peak strongly resembles the direct sound's initial peak in it's shape, I strongly guess that it is a wideband reflective one.

In my test, the monopole (point?) source is placed 200cm away from the film. The film measures 65cm by 80cm. With these values, the largest extent of the film is it's diagonal which is 103cm. The smalles extent is 65cm. Taking the curved sound front into account, this makes a max. distance of 206.5cm from the sound source to the corners of the film, and a min. distance of 202.6 to the mid of the long side.

For the max. periphery excitement delay (corner/diagonal) then, we get a pathways difference delay of

206.5cm - 200cm = 6.5cm = 0.19ms = 5.25kHz.

For the shortest periphery excitement delay (center of long side) we get a difference of

202.6cm - 200cm = 2.6cm = 0.08ms = 13.1kHz.

Therefore it might be interesting to also assess the behavior of the film within a narrow frequency band signal between 500Hz and 1kHz in order to rule out any longitudinal or other possible resonances excitement. We'll see.

I also did not expect such an intense reflection. Or shoud I better and more cautiously say peak, ruling out any misinterpretation? Still, as this 1ms delayed peak strongly resembles the direct sound's initial peak in it's shape, I strongly guess that it is a wideband reflective one.

Last edited:

Once a wave hits the mylar I assime iit travels with a certain speed away, just like the ripples of water after throwing a stone in the water. Then it may bounce agains the edge of the frame, reflect interfere etc so the actual situation may be quite complex. If I remember correctly P.Walker realizid there could be reflections on the Mylar and there is some electric damping provided. Also the decay plot of the quad is quite hashy just like most other esls. In case of ESLs the protective sheet is always larger than the sound producing elements , specially high frequencies, so we should see similar effects. That makes your setup ractually kind of ealistic. Not exactly the same but it is comparative so doesnt matter. Ps adding some tape at the edge of the mylar reduces reflections. Maybe you could try if you see a difference

WHen i glue the mylar I let the elastic glue extend some mm in to the membrane. My gut feeling many years ago was that the sharp edge of the frame could rip the membrane, thats why I started to add extra glue several mm extra. No side effects has been observed. And the added mass is no problem since the movement is almost zero this close to the edge. Adding some tape is a good idea, on the short sides. It will break up and damp standing wave reflections.

- Home

- Loudspeakers

- Planars & Exotics

- QUAD ESL63 dust protection comparative testing