Those who install dust covers argue their position with something, covers are an intermediary in sound.That is why there are dust covers on ALL Quad ESL models. No other brand has dust protection. Mylar by itself attracks dust because it is very easily positively charged. Look at old dust covers and you know.

Electrostatic already has a very weak motor, that is, it is not capable of creating any proper sound pressure, and then they also enclose it in a "cocoon", as a result, half of the sound pressure is lost in order to make the "cocoon" itself vibrate.

In short, the tail is put on, the head falls.

the stator side layer is completely isolated from the plastic frame, it floats to prevent leakage

So this would neatly match the picture I already posted before. And then, I possibly would have stripped this layer apart from the Mylar base. In the end, one sub-foil of Mylar, the other Nylon? Interesting. About the finding of these two sub-foils, I was uniquely thinking of some damping purpose/effect of this stripped-off (Nylon?) layer for the intrinsic nervous "Eigensound" of the Mylar. So maybe it's both altogether: An additional layer of Nylon to keep electrostatic charge and damp the Mylar? This would be rather ingenious.

About the induction story: There indeed is the mechanism of disconnection: The neon recharger. Maybe it's also in this term a double purpose goodie?

these are my findings after many years and many dozens of sets of Quad ESL's rebuilds

I saw your site. Beautiful work!

Last edited:

Tried that, done that.So maybe it's both altogether: An additional layer of Nylon to keep electrostatic charge and damp the Mylar? This would be rather ingenious.

The simple answers is no. Two electrostatic layers (nylon) on both sides of the Mylar give extremely high distortion, so that is a no go.

We also thought a second layer would help, but it did completely the opposite.

Mechanical damping has been mentioned by others. I doubt it, but who knows. I will stick with adhesion for now.

3 micron thin Mylar has hardly any "eigensound" as you call it, the thicker it gets, the more it does. Take 12 micron for instance and you can hear it very clearly.

There can also difference in "eigensound" between Mylar and other brands of PET film like Hoechst Hostphan.

Sorry to say, but that is utter nonsense.Those who install dust covers argue their position with something, covers are an intermediary in sound.

Electrostatic already has a very weak motor, that is, it is not capable of creating any proper sound pressure, and then they also enclose it in a "cocoon", as a result, half of the sound pressure is lost in order to make the "cocoon" itself vibrate.

In short, the tail is put on, the head falls.

Measured dozens and dozens of ESL's with and without dust covers and the difference is very minimal, only a small drop off in the high frequencies.

What is proper sound pressure? I listen at 90+ dB sound level peaks in a room 8x12 meters , 4 meters from the speakers and the speaker 3 meters apart.

If you want your pants to flap, indeed you should not look for an electrostatic loudspeaker, that is not what they are meant for.

Measured frequency response of a Quad ESL-63 from 30 Hz to 24 kHz with plus 3,3 dB and minus 3,5 dB measured in my own room with REW and MiniDSP UMIK2 on axis @ 1 meter 75 dB setting at 1 kHz with ERB smoothing. It is only down 2 dB at 24 kHz. All this WITH dust covers, grilles and speaker cloth in place.

The pulse and step look very good and distortion is extremely low with all below 0,1% THD (2nd - 9th) from 200 Hz up and never above 1% down to 30 Hz. All distortion below the noise floor measured again @ 75 dB.

Last edited:

What nonsense(?), these are elementary things, I have done this dozens of times not only with speakers, but also with headphones.

The bass component is sharply reduced, all the plucking of the double bass and the blows of the beater on the drum become "caressing-licking", the energy of the sound is lost for obvious reasons.

The only advantage of a speaker in a "cocoon" is that the air mass located in the "cocoon" is attached to the membrane and the membrane is damped, but of course it loses.

The bass component is sharply reduced, all the plucking of the double bass and the blows of the beater on the drum become "caressing-licking", the energy of the sound is lost for obvious reasons.

The only advantage of a speaker in a "cocoon" is that the air mass located in the "cocoon" is attached to the membrane and the membrane is damped, but of course it loses.

My measurements and hearing say otherwise. Maybe we can agree to disagree.What nonsense(?), these are elementary things, I have done this dozens of times not only with speakers, but also with headphones.

The bass component is sharply reduced, all the plucking of the double bass and the blows of the beater on the drum become "caressing-licking", the energy of the sound is lost for obvious reasons.

The only advantage of a speaker in a "cocoon" is that the air mass located in the "cocoon" is attached to the membrane and the membrane is damped, but of course it loses.

1) You are going about it wrong. You apply the film to the frames out of the speaker and untensioned. Then you snap the dust cover into place and heat shrink. Works great and is easy.I have completely finished one speaker and the second one 95% finished. I discovered that its fuse holder was broken last night when I was going to test the speaker. I have ordered new fuse holders and will replace them in both speakers, and finish off the second speaker tomorrow.

I have some serious criticism of the design/manufacture of these speakers.

1) The dust covers are ridiculous. The frame isn't solid until you snap it into the speaker, but you can't put the film on while the frame is on the speaker because it sits inside the rest of the driver frame. There's no way to put the film on the frame when it's off the speaker and know that it won't be wrinkled when you move it to the speaker. The drivers mount on two aluminum L brackets, and that assembly can be dropped into the driver housing. That assembly should have included frames for the dust covers, or maybe dust covers should have been a part of each driver.

2) Too much use of foam tape. I spent at least 3 full days cleaning the rotted foam and the adhesive residue out of these speakers. Some of it seems entirely unnecessary, such as the strips on the aluminum L brackets where the drivers mount. They don't cover the whole surface of the driver's edges, so what's the point of it?

3) Adhesive that doesn't bond to the diaphragms. The stuff has zero peel strength, so they are relying on shear strength of the very weak "bond". It's no wonder they fail.

4) Overly complicated and flimsy driver enclosure frame - plastic top and bottom pieces and thin aluminum extrusions on the sides, with 4 aluminum sticks near the center. What were they thinking?

5) The electronics housing is a thin plastic box!

6) Steel protective grids fit into slots in the aluminum side pieces, but are taped to the frame at the top and bottom. Why wouldn't they have screwed them to those top and bottom pieces? I think they were trying to bolster the flimsy construction of the driver enclosure by taping the grids to them.

I don't know how they managed to ship these things and have them work properly when they arrived at their destination. It seems like Quad didn't have any manufacturing engineers on staff or these things would have never made it to production.

2) Yes, the foam tape is sad, but honestly its a grate way to gently hold the thin dust cover material. As for the foam, it was looney. None of the internal foam is needed or should be replaced.

3) the adhesive for the diaphragms changed over time. The 15000ish speakers had good stator glue and bad diaphragm glue. But honestly for the vast majority of the production run of any of these modern quads, the stator glue is the issue not the diaphragm glue.

4) they were thinking that there 2 grams of moving mass, so anything more is not needed.

5) it's a thick plastic box.. 😉 And UPS loves to smash them.

6) all layers of the construction just keeps making the unit more stiff. But it's not an aerospace design by any means. 988 and later screws the grilles on.

Sheldon

The dust cover acts like a first order low pass filter. The corner frequency is above 25khz in these speakers assuming the material is thinner than 4um mylar. At lower frequencies it is transparent.Those who install dust covers argue their position with something, covers are an intermediary in sound.

Electrostatic already has a very weak motor, that is, it is not capable of creating any proper sound pressure, and then they also enclose it in a "cocoon", as a result, half of the sound pressure is lost in order to make the "cocoon" itself vibrate.

In short, the tail is put on, the head falls.

Nice work! I find your jig and resonance testing very clever! My only worry with Lycron is how long it lasts, mass is inconsequential. And if it needs refreshed in a few years, you may be able to splat your panels without damage and recoat.It's not rocket science. Licron Crystal works fine.

I am finished:

<nice pic snipped>

Yes, they sound great!

Sheldon

There were more important things that Peter Walker was unhappy about on commercial ESL 63s. The biggest was the dust covers.They had a weight constrain. I read an article that they managed to reduce the weight from the earlier prototypes with almost half! So they could ship them much much cheaper.

I guess Walker was not 100% happy...

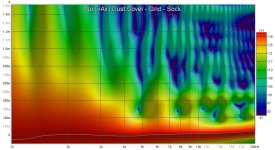

He told me the supa dupa curve in his AES paper was without dustcovers. With the dustcovers, the 'waterfall' becomes quite ropy above about 5kHz. I think I was the first to do this for ESL 63. KEF were the only other people who could do 'waterfalls' (their Cumulative Decay Spectra) in dem days. They invented 'waterfalls'.

But an electrostatic without dustcovers only lasted a couple of months without needing a full top end service probably including new diaphragms.

This is certainly NOT what Peter Walker told me. I measured in a very early one. Can you show your measurements of with & without? What equipment did you use? Can you post the raw Impulse responses?Sorry to say, but that is utter nonsense.

Measured dozens and dozens of ESL's with and without dust covers and the difference is very minimal, only a small drop off in the high frequencies.

If you guys want measurements, I can do that next pair of 63's I'm working on. You tell me what you want and I'll do my best to provide it. I make measurements on every speaker I rebuild, but I take very specific sorts of measurements to verify proper function of the panels and the electronics, not to get an actual response plot for the speaker itself. In my quad measurement folder I currently have 237 sets of speaker measurements.

Here's a pair of 63's that I rebuilt in January. These measurements are not windowed (because I use the low frequency information to diagnose the electronics and panel issues). The red plot is without dust cover, and the blue plot is with dust covers and grilles. Sadly the speaker and mic are not in exactly the same positions, but they are close

Note that the resonant point of the set of four panels has dropped a little as the diaphragms break in. The red curve was taken soon after the diaphragms were installed and the blue curve was a day or so later.

Here's a waterfall without dust cover:

Here's with the dust covers and grilles with the same settings:

I will continue to state that the dust cover acts like a first order low pass filter, with the corner frequency in the 25KHz region or higher. Any difference you see in those two plots are more about the grilles than the dust covers IMHO.

Again, I want to reiterate that these measurements are for my quality control and are taken specifically to check out specific aspects of speaker performance during and after my rebuild process, I generated these impulse response plots and waterfalls for this discussion, and they are not windowed and no effort was made to remove room interactions in the original data.

Sheldon

Here's a pair of 63's that I rebuilt in January. These measurements are not windowed (because I use the low frequency information to diagnose the electronics and panel issues). The red plot is without dust cover, and the blue plot is with dust covers and grilles. Sadly the speaker and mic are not in exactly the same positions, but they are close

Note that the resonant point of the set of four panels has dropped a little as the diaphragms break in. The red curve was taken soon after the diaphragms were installed and the blue curve was a day or so later.

Here's a waterfall without dust cover:

Here's with the dust covers and grilles with the same settings:

I will continue to state that the dust cover acts like a first order low pass filter, with the corner frequency in the 25KHz region or higher. Any difference you see in those two plots are more about the grilles than the dust covers IMHO.

Again, I want to reiterate that these measurements are for my quality control and are taken specifically to check out specific aspects of speaker performance during and after my rebuild process, I generated these impulse response plots and waterfalls for this discussion, and they are not windowed and no effort was made to remove room interactions in the original data.

Sheldon

Attachments

I have some drivers that I coated with Licron (before Crystal was available) in the early/mid 90s (IRIC) and they still test at 10^8 Ohms per square. The 4693H glue I used on them is still holding fast, too. I don't think longevity is an issue. Those drivers have been in storage for about 20 years, waiting for me to put them to use. I wasn't measuring the resonance when I put the diaphragms on, so I'll probably redo it soon, and then build up some 989s using the bass panels. It's entirely possible that the stators have let go while they've been stored.Nice work! I find your jig and resonance testing very clever! My only worry with Lycron is how long it lasts, mass is inconsequential. And if it needs refreshed in a few years, you may be able to splat your panels without damage and recoat.

Sheldon

Regarding dust covers... operating without them might be OK for some, but I have a cat. Her hair will find its way into the drivers very quickly without dust covers (so will bugs and dust). I did the rebuild in my work room that the cat is kept out of, and vacuumed everything thoroughly at multiple steps in the rebuild process, and I still see a few hairs inside the dust covers. It floats in the air and sticks to my clothes, so I probably brought it into the work room. I don't want to think about how much cat hair is lodged in my lungs...

Like them or not, a speaker with dust covers that works sounds a lot better than one that hisses and whines.

Thanks for these stokessd. Your response is sorta what I expected to see but there's insufficient resolution.Here's a pair of 63's that I rebuilt in January. These measurements are not windowed (because I use the low frequency information to diagnose the electronics and panel issues). The red plot is without dust cover, and the blue plot is with dust covers and grilles. Sadly the speaker and mic are not in exactly the same positions, but they are close

View attachment 1448884

Note that the resonant point of the set of four panels has dropped a little as the diaphragms break in. The red curve was taken soon after the diaphragms were installed and the blue curve was a day or so later.

Here's a waterfall without dust cover:

View attachment 1448886

Here's with the dust covers and grilles with the same settings:

View attachment 1448887

What's the time resolution on your 'waterfalls'? Are the numbers msecs? ie Is your waterfall between 0 & a bit less than 4 seconds?

Do you know if the tension in the Dustcovers changed? It was pretty tight in my early ESL 63

... When were your speakers made? Maybe they made some change to later models?

@ Mark Rehorst: Sorry, I currently am away from the serial numbers of my Quads. This will change in some days. I will remember then your quest for date-of-birth

@ Mark Rehorst: Ok, now I am close to them: SN 023809 and SN 023810

Any difference you see in those two plots are more about the grilles than the dust covers IMHO.

While refurbishing and finishing my ESL63, I looked at the effects of the grilles (G), the sock (S), and two variants of dust protecions (B = BOPP / V= Vliesseline). I tested the finished assembly using wavelet transform.

AAA = Air / Air / Air. No dust cover, no grilles, no sock.

AAS = Air / Air / Sock. No dust cover, no grilles, sock only.

AGA = Air / Grille / Air. No dust cover, grill mounted, no sock.

AGS = Air / Grille / Sock. No dust cover, grill mounted, sock also.

BGS = BOPP / Grille / Sock

VGS = Vliesseline / Grille / Sock

AAA vs. AAS vs. AGA vs. AGS:

The four first measurements are without any dust protection (Axx = Air). Look at the effects of the grilles and the sock

AGS vs. BGS vs. VGS:

It was clear to me that I would not operate the ESL63 without the grilles. Therefore I measured the dust protection variants with the grill and sock mounted.

As a result it seems that the grilles account for some artefacts, especially around 800u (lambda 0.8ms = 280mm) and above 10kHz. BOPP seems to add another layer of artefacts (!). Vliesseline as a dust cover instead seem to account for some slight damping of the artefacts at 400uS (lambda 0.4ms == 140mm).

Very unfortunately I have no comparative measurements of the dust protection variants alone, without the grilles and the sock This would have given a certainly interesting series like AAA vs. BAA vs. VAA. Maybe it would be worth to assess wavelet transform artefacts of further different dust protection materials. BOPP does not seem to be acoustically completely inert.

With my Vliesseline type of dust protection I am very happy. Vliesseline, when moved, is acoustically dead. It has no "Eigensound". Main drawback with Vliesseline seems to be a slight sensitivity loss for higher frequencies due to energy absorption inside the Vliesseline felt layers. And of course ... very fine dust still can pass between the fibre layers, which is not the case for a BOPP dust protection. Time will tell.

Attachments

I have been running mine without dustcovers since the 90ties.... depends on the cleanliness "inna da hause" I guessThere were more important things that Peter Walker was unhappy about on commercial ESL 63s. The biggest was the dust covers.

He told me the supa dupa curve in his AES paper was without dustcovers. With the dustcovers, the 'waterfall' becomes quite ropy above about 5kHz. I think I was the first to do this for ESL 63. KEF were the only other people who could do 'waterfalls' (their Cumulative Decay Spectra) in dem days. They invented 'waterfalls'.

But an electrostatic without dustcovers only lasted a couple of months without needing a full top end service probably including new diaphragms.

Friends, can I interject something sideways?

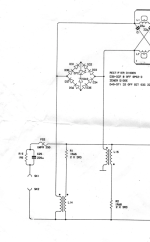

In some of the '63-s there are what looks like a fuse in series with the audio input, see pic.

Looks like 'FS2; UMFR250'. Are these actual fuses or one of those chemical/resttable things?

Any info about them? Just curious.

Edit: there exists a type 'UMF 250' which is an SMD 250V fuse, maybe the SMD version of the UMFR?

Jan

In some of the '63-s there are what looks like a fuse in series with the audio input, see pic.

Looks like 'FS2; UMFR250'. Are these actual fuses or one of those chemical/resttable things?

Any info about them? Just curious.

Edit: there exists a type 'UMF 250' which is an SMD 250V fuse, maybe the SMD version of the UMFR?

Jan

Attachments

Last edited:

Yes, that is a polyfuse. A resettable fuse. Added late in the clamp circuit variants for the 63's and has been present in every modern quad since. That will trip if the clamp circuit is clamped and the amp keeps powering energy into the clamp circuit. It is going to limit the stress on the triac, as the thermal mass and time constant are less than the triac plus heat sink.

The fact that the solution to speaker problems is to short out the amp is absolute lunacy to me. But here we are.

Sheldon

The fact that the solution to speaker problems is to short out the amp is absolute lunacy to me. But here we are.

Sheldon

Now the question is: what is the purpose of the diode bridge that drives the LED? The LED is inside the electronics enclosure and isn't visible during operation of the speakers. Is it there for test purposes?

- Home

- Loudspeakers

- Planars & Exotics

- QUAD ESL-63 rebuild