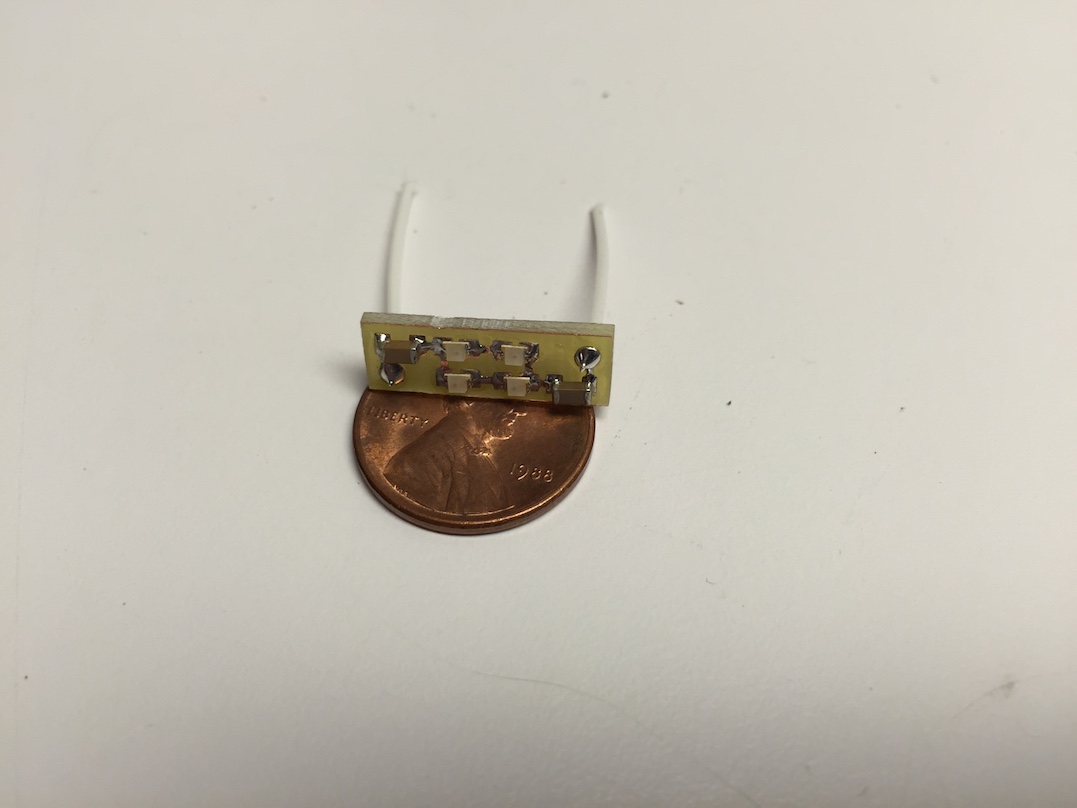

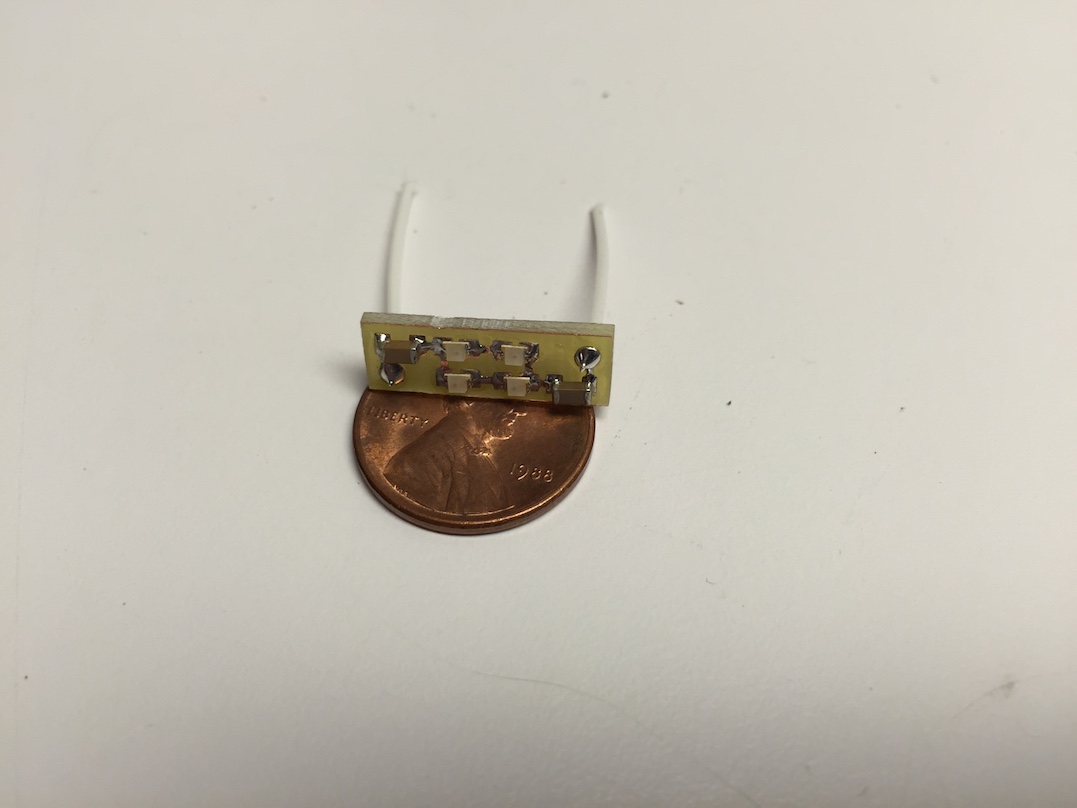

I also replace the neon bulbs, but lately I've switched to LED's. Here's my prototype. Those things should outlive me.

Sheldon

quadesl.com

Sheldon

quadesl.com

Very nice, indeed!

I also replace the neon bulbs, but lately I've switched to LED's. Here's my prototype. Those things should outlive me.

Sheldon

quadesl.com

...now the panels

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Unfortunately, one panel's terminal tag had been broken but I managed to acquire some unused of those.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

I do not have better glue for the process than a bicycle inner tube repairer.

I am a bit worried if it is necessary to 'pre-tension' the dustcover as the one I've been supplied is very rumpled. Should I only straighten the creases out with cellotape on the table and the hair dryer will do the rest?

I am a bit worried if it is necessary to 'pre-tension' the dustcover as the one I've been supplied is very rumpled. Should I only straighten the creases out with cellotape on the table and the hair dryer will do the rest?

The dust cover material that I use is:

Treble panels: Mylar 6um or thinner, and requires a bit more heat than a hair dryer to shrink

Bass panels: A heat shrink saran material that a hair dryer shrinks nicely.

I'm not sure what materials you have though, so I can't really advise.

Sheldon

quadesl.com

Treble panels: Mylar 6um or thinner, and requires a bit more heat than a hair dryer to shrink

Bass panels: A heat shrink saran material that a hair dryer shrinks nicely.

I'm not sure what materials you have though, so I can't really advise.

Sheldon

quadesl.com

The material's 'approved' because I sourced both from One Thing Audio.

The treble material and bass material differs for the touch. The treble dustcover seems more 'brittle' and 'noisy' (?).

Indeed, the materials shrink differently as you mentioned. I had hard time shrinking the treble-material on my testing dummy-frame with the hair-dryer, but it shrunk slowly.

The treble material and bass material differs for the touch. The treble dustcover seems more 'brittle' and 'noisy' (?).

Indeed, the materials shrink differently as you mentioned. I had hard time shrinking the treble-material on my testing dummy-frame with the hair-dryer, but it shrunk slowly.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

There are better methods probably, but I hope this will do

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

My experiences so far: the TIP-TOP bicycle inner tube-repairer glue isn't the best choice for this type of film. It seemed nice for the bass panel's saran (?), as it 'melted' the foil and gave an excellent hold on my test-frame. But in this case, I can tear the film off with almost no effort. It's there however, see the pics. As this is my first try, I am sure that I will puncture the dustcover when I'm going to try to cellotape it together ...I thing I need a better and less fussy dustcover glueing technique... Should I source some double sided tape?

Hi, I used PVA wood glue. Lay down the foil on a flat surface, e.g glass. Apply PVA to the frame, place it on the foil, and weight it around with some books until it gets dried.

Despite the dismay caused by the tube glue first, I decided to stay with it as it looked OK after some days of drying.

Looks like I successfully managed to cellotape the treble panel together.

Here are the pics:

Looks like I successfully managed to cellotape the treble panel together.

Here are the pics:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Tools I used for the procedure:

-Cheap soldering iron for melting the foil

-Thick 50mm wide PE window seal tape

-Some ,,parallel pinchers"

-70% Alcohol for cleaning off the remains of grease at the perimeter

Bass panel's frame being glued:

An externally hosted image should be here but it was not working when we last tested it.

Weighting down:

The adjacent frame has the concave curvature, so I had to flip the DVD player and put on some more weight to obtain even stress at the whole surface of the frame

An externally hosted image should be here but it was not working when we last tested it.

The adjacent frame has the concave curvature, so I had to flip the DVD player and put on some more weight to obtain even stress at the whole surface of the frame

An externally hosted image should be here but it was not working when we last tested it.

And finally, after left it to dry for 20 minutes, I melt the excess film off the frames with the iron:

An externally hosted image should be here but it was not working when we last tested it.

The last sides ready to be melted away with the iron:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Completed covers:

An externally hosted image should be here but it was not working when we last tested it.

- Home

- Loudspeakers

- Planars & Exotics

- QUAD ESL 57 A little work on the loudspeaker