Also, any thoughts about the new RD6018W ? 60v 18A with wifi etc... not sure if the resolution is comparable with the 6012, but you would never need more current capability!

Sure!

I used pypsucurvetrace withe a Riden 6012P and a 6006P for the recent data in my Sony VFET batch (see link in my signature).

My need for testing / validating power transistors was the motivation to implement the temperature/heat control in pypsucurvetrace. I still need to improve the documentation for this to make it useful for everyone.

I used pypsucurvetrace withe a Riden 6012P and a 6006P for the recent data in my Sony VFET batch (see link in my signature).

My need for testing / validating power transistors was the motivation to implement the temperature/heat control in pypsucurvetrace. I still need to improve the documentation for this to make it useful for everyone.

Great stuff! I look forward to building the heat station once you've shared the design. I'd be interested to see some curve results with audio power BJTs - am I right in understanding there is no need for any resistors in the test configuration?

You need a gate/grid/base resistor resistor to prevent oscillation, and for conversion of base current when testing BJTs.

See here: https://pypsucurvetrace.readthedocs.io/en/latest/curvetrace/curvetrace.html

The heater block for temperature control uses resistors as heater elements, but these are not part of the test circuit.

See here: https://pypsucurvetrace.readthedocs.io/en/latest/curvetrace/curvetrace.html

The heater block for temperature control uses resistors as heater elements, but these are not part of the test circuit.

The 6018 should work out of the box. 18 A is a lot for audio...Also, any thoughts about the new RD6018W ? 60v 18A with wifi etc... not sure if the resolution is comparable with the 6012, but you would never need more current capability!

See attached curves from a NJW0281G. The data are here.I'd be interested to see some curve results with audio power BJTs

Attachments

For what it's worth, Reichelt seem to have received a container of Korads, they are all back in stock.

The KA3005P is at € 109, while the KD3005P is on "sale" for € 70. As far as I can tell, the only difference between the two is that the KD lacks the keypad and hence the ability to define and store settings.

- Is there any reason to believe the KD will not work with your software?

- Is there any reason to still prefer the Korads over the 6006P? Pro Korad: linear power supply. Pro Riden: 0.1 mA resolution. Or do the Korads give you an extra digit via USB?

The KA3005P is at € 109, while the KD3005P is on "sale" for € 70. As far as I can tell, the only difference between the two is that the KD lacks the keypad and hence the ability to define and store settings.

- Is there any reason to believe the KD will not work with your software?

- Is there any reason to still prefer the Korads over the 6006P? Pro Korad: linear power supply. Pro Riden: 0.1 mA resolution. Or do the Korads give you an extra digit via USB?

I have a KA3005P, and it works well with pypsucurvetrace. The KD variant should also work, but I don't have one to test/confirm.

The Korads are great, and I do recommend them. My gut feeling is that curve tracing is a wee bit faster with the Korads than with the Ridens (but I have not measured this). The higher resolution of the Ridens is nice for testing at low currents, though.

The Korads are great, and I do recommend them. My gut feeling is that curve tracing is a wee bit faster with the Korads than with the Ridens (but I have not measured this). The higher resolution of the Ridens is nice for testing at low currents, though.

Hmmm... I simply followed the specified current resolution when I wrote the code for the Korads. I haven't thought of trying to squeeze out more resolution from the readings, but will look into this when I find the time.

The documentation now has some information on the heater block to control DUT temperature during curve tracing:

https://pypsucurvetrace.readthedocs.io/en/latest/heaterblock/heaterblock.html

https://pypsucurvetrace.readthedocs...examples.html#examples-curvetrace-heaterblock

It's not yet perfect, but...

https://pypsucurvetrace.readthedocs.io/en/latest/heaterblock/heaterblock.html

https://pypsucurvetrace.readthedocs...examples.html#examples-curvetrace-heaterblock

It's not yet perfect, but...

Thanks Matthias. The heating block docs are great. Where did you buy that toggle clamp, or did you make it ?

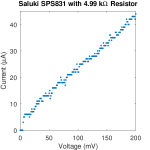

I've got a new toy: the Saluki SPS831 programmable power supply (30 V / 1 A) is specified with a superb 1 µA resolution on the current readback. I tested the SPS831 with with PyPSUcurvetrace using a 4.99 kOhm resistor as a load for the Saluki. Take a look at the attached plot: the resolution really is 1 µA, and the accuracy is about 3 µA or so (this depends on the quality of the internal auto zero for the current readings).

This is a very nice tool for curve tracing of low-power DUTs with PyPSUcurvetrace!

This is a very nice tool for curve tracing of low-power DUTs with PyPSUcurvetrace!

Attachments

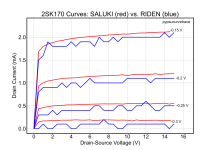

Here's a comparison of the curves from a 2SK170 measured with the Saluki SPS831 and a RIDEN6012P. The better current resolution of the Saluki is great for this application. What you don't see on the figure is that the Saluki is also a bit faster for curve tracing.

Attachments

Last edited:

Have you tried working with PyPSUcurvetrace? Would be cool to get some feedback, especially on the documentation. I am sure there are some rough spots where people run into issues, and I'd be happy to sort them out (if possible).

Maybe one day. Other projects take up all my time right now. Just wanted to share appreciation for what you've done!

Well, I bought two 6006P PSUs beginning of 2023, expressly with the intention of tryying PyPSU. The challenge for me will be getting it to run on Windows and never having used Python. Or set up a dedicated Linux PC with no experience in Linux...

Open source code for curve tracing is very interesting to me.

Running under something other then windows is also very interesting as churn in win10,11,12,13,,,,, drives me crazy supporting test equipment that is dependent on windowsXX.

Currently I use a uTracer3+ to measure data on vacuum tubes and always been very happy with the system.

This I purchased from DOS4EVER years ago and it has been a very solid if not a bit limited unit.

I also purchased a uTracer6 from DOS4EVER that sadly I do not use due to a number of hardware and software issues that render results lacking in accuracy for measurements below 100V and currents above 500mA. This is a main are of interest that I purchased the system for.

I have identified some areas in the uTracer6 hardware that needs improvement BUT it would require very small software changes to implement.

Closed code means no can do.

I have also identified errors in the GUI that returns wildly incorrect results but again closed code, so no way to fix it and the author is too busy in other areas so he has not had time to address the issue(s) yet.

The result is I have been thoroughly frustrated and so thinking a lot on how to get myself a more capable uTracer and that closed code in test equipment is a bad idea to buy into.

PYPSU using standard power supplies is a excellent idea (brilliant?) but without any ability for pulsed measurements there is a lot that can not be measured on higher power devices.

The uTracer platform is a pulsed measurement system.

For me to start curve tracer code from scratch has always seemed far too big a learning curve and likely to fail.

However adapting the PYPSU code base to drive a current uTracer seems a very doable task.

That would immediately allow PYPSU to be used in pulse measurements for vacuum tubes.

It would also allow for some changes to uTracer hardware to improve the system.

It would open the door to developing open source uTracer like pulsed measurement system projects where the hardware and all the firmware are open source. That to me sounds like a fun and useful project.

I plan to dig into the PYPSU code base to see if adaption to run a uTracer is a doable task for me.

Running under something other then windows is also very interesting as churn in win10,11,12,13,,,,, drives me crazy supporting test equipment that is dependent on windowsXX.

Currently I use a uTracer3+ to measure data on vacuum tubes and always been very happy with the system.

This I purchased from DOS4EVER years ago and it has been a very solid if not a bit limited unit.

I also purchased a uTracer6 from DOS4EVER that sadly I do not use due to a number of hardware and software issues that render results lacking in accuracy for measurements below 100V and currents above 500mA. This is a main are of interest that I purchased the system for.

I have identified some areas in the uTracer6 hardware that needs improvement BUT it would require very small software changes to implement.

Closed code means no can do.

I have also identified errors in the GUI that returns wildly incorrect results but again closed code, so no way to fix it and the author is too busy in other areas so he has not had time to address the issue(s) yet.

The result is I have been thoroughly frustrated and so thinking a lot on how to get myself a more capable uTracer and that closed code in test equipment is a bad idea to buy into.

PYPSU using standard power supplies is a excellent idea (brilliant?) but without any ability for pulsed measurements there is a lot that can not be measured on higher power devices.

The uTracer platform is a pulsed measurement system.

For me to start curve tracer code from scratch has always seemed far too big a learning curve and likely to fail.

However adapting the PYPSU code base to drive a current uTracer seems a very doable task.

That would immediately allow PYPSU to be used in pulse measurements for vacuum tubes.

It would also allow for some changes to uTracer hardware to improve the system.

It would open the door to developing open source uTracer like pulsed measurement system projects where the hardware and all the firmware are open source. That to me sounds like a fun and useful project.

I plan to dig into the PYPSU code base to see if adaption to run a uTracer is a doable task for me.

Last edited:

- Home

- Design & Build

- Equipment & Tools

- PyPSUcurvetrace: a flexible, open-source curve tracer using programmable power supplies