Use this: https://www.usaindustrialsupply.com/index.php?dispatch=products.view&product_id=34380Any special methods and adhesives?

Please mention those.

That between each sheet of bendable plywood or MDF would make for a very damped structure. Use the trowel I've attached.

Attachments

I would just use the adhesive I posted above. I you look at my tests I put a middle layer of cork and XPS foam in the middle and it wasn't better than the simple CLD I ended up recommending. So I'm not sure using rubber would be much better either. It might be like the Nidacore where it was ever-so-slightly better, but way more of a hassle to build.or should I glue a layer or carpet with rubber underlay in between?

A few thoughts, as I use mdf and BB.

BB is nice, not perfect (could be voids) and rough on saw blades / router bits.

MDF, so many grades out there. A large box store chain ad cut/pasted a premium grade photo on their website and I went running down there.

Getting a good laugh now because it was the worst recycled cardboard product I've ever seen.

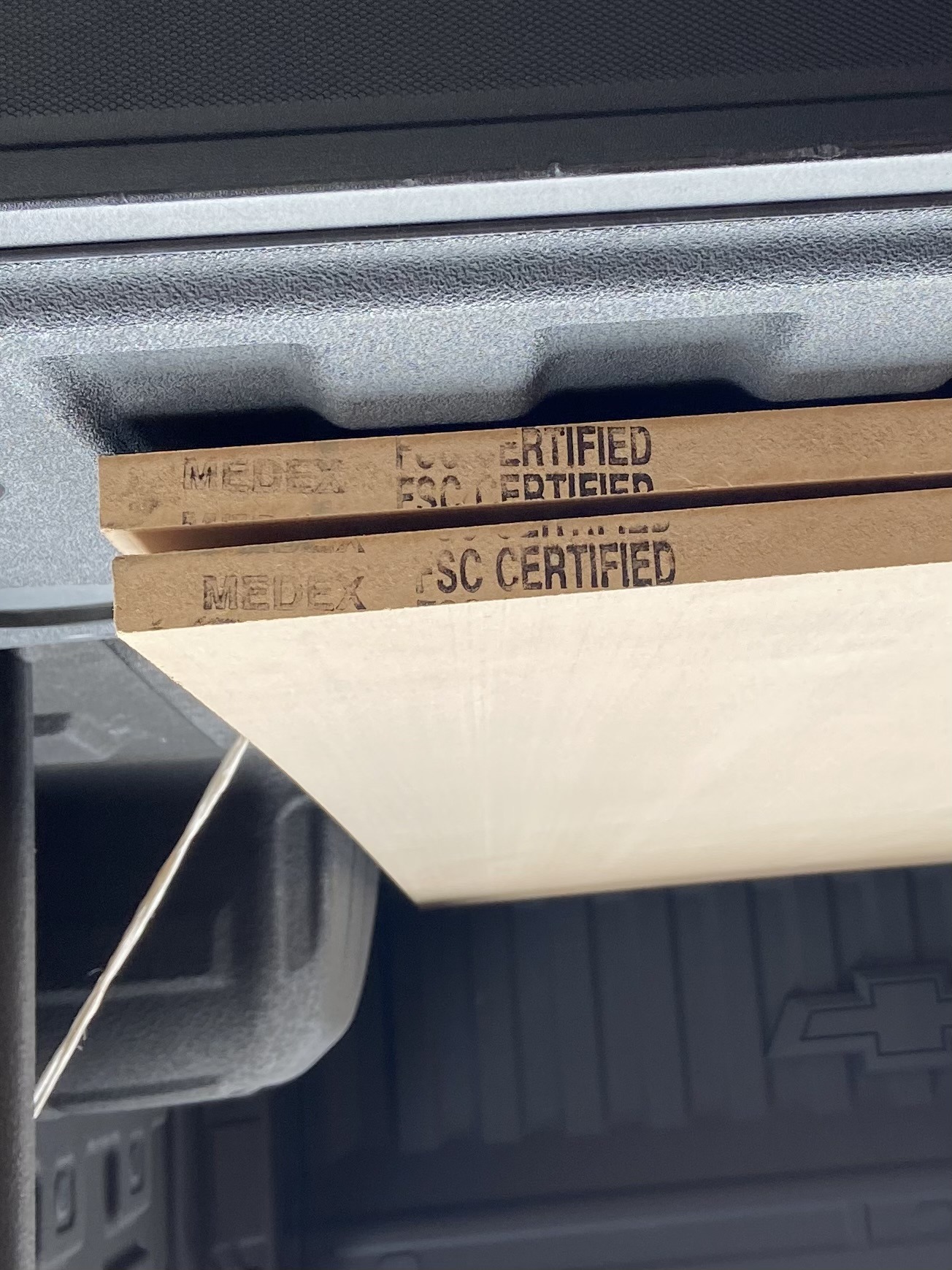

That was enough for me to order this wonderful product, MEDEX

Cost $111 vs the box store recycled cardboard at $59

[Was able to squeak out 4 boxes from one sheet]

There is a mom/pop lumber yard around the corner, they were sell a high grade mdf shelving board 12" and 16", almost as good as this.

They may have sold it all by now, next week I'm going back up and look for old stock, sample in hand!

BB is nice, not perfect (could be voids) and rough on saw blades / router bits.

MDF, so many grades out there. A large box store chain ad cut/pasted a premium grade photo on their website and I went running down there.

Getting a good laugh now because it was the worst recycled cardboard product I've ever seen.

That was enough for me to order this wonderful product, MEDEX

- Moisture resistant

- Full 3/4"

- A solid/dense product

- Machines beautifully

- 1" oversized

Cost $111 vs the box store recycled cardboard at $59

[Was able to squeak out 4 boxes from one sheet]

There is a mom/pop lumber yard around the corner, they were sell a high grade mdf shelving board 12" and 16", almost as good as this.

They may have sold it all by now, next week I'm going back up and look for old stock, sample in hand!

As MDF, this product appears to be carcinogenic. You had better take precautions re. breathing the dust.

Wear an N 95 3M, and well ventilate that room $0.02.

There is something I do dislike about ply woods. The slivers are wicked and plentiful after cutting and before you edge sand. If its covered with wood veneer especially. Even when being carful your bound to get nailed by at least one.

There is something I do dislike about ply woods. The slivers are wicked and plentiful after cutting and before you edge sand. If its covered with wood veneer especially. Even when being carful your bound to get nailed by at least one.

You need to use better quality saw blades and/or a better quality saw...the edge of a high grade plywood panel either ripped or crosscut should be smooth and splinter free and ready for glue up.The slivers are wicked and plentiful after cutting and before you edge sand

Its not my first time with a table saw or cutting plys. In this case its more a combination of the hardness and type of the species combined with the way the acrylic cuts. Everyone's a comedian. Owell, shrugs.You need to use better quality saw blades and/or a better quality saw...the edge of a high grade plywood panel either ripped or crosscut should be smooth and splinter free and ready for glue up.

If your saw blade is sharp and this is still happening, you might want to check your table saw blade alignment with the fence. Misalignment can sometimes cause this problem.

Just trying to be helpful, not smart 🙂

Just trying to be helpful, not smart 🙂

Another trick I was told (a long time ago), wich is tricky by itself, is to precut the veneer with a good knife along the cutting line… this must be done very precisely but gives an absolutely splinterfree edge. Since it is lacquered, you could put a masking-tape for better visibility of the marking without risking to „rip off“ the veneer when removing that tape…

@wasabii I had no intention of introducing comedy to a serious woodworking discussion. This is an issue of both productivity and safety. A ragged cut suggests either a dull/chipped blade or one mismatched to the cut and material, a saw arbor with runout or alignment problems, a misalignment between blade and fence, or an inappropriate feed rate. Prefinished ply should cut as well or better than raw ply. Addressing the underlying causes can both improve safety and eliminate the extra steps required to clean up the edges. It's tempting to just push through with the work but when a tool talks to you by producing substandard results it makes sense to listen by getting to the bottom of the root cause and fixing it.

Has anybody tried oriented strand board? IIt might be a cheap alternative, half way between MDF and plywoodI have been thinking about it for my next project.

It has been used. In particular i recall Variac’s big BOFU BIB(?). It could have been one of the other big BOFU boxes.

dave

dave

I have followed a variety of speaker builds for quite a few years and have seen that over the past few years Densified Wood Boards are becoming more popular as a Baffle Material.

I have not seen a reference to it in this thread and have chose to add it to the materials being made known.

The link and a Google Search will show more of its usage.

The material is not for those on a tight budget, as it is most likely the most expensive option, but it does show up as used material from time to time as it is used in various industries.

Densified Wood Products such a Panzerholz and Permali are being used both Commercially and in DIY projects, it does appear to have a properties that suits being used as a front baffle.

https://www.monoandstereo.com/2014/11/interview-with-rainer-weber-of-kaiser.html

I have not seen a reference to it in this thread and have chose to add it to the materials being made known.

The link and a Google Search will show more of its usage.

The material is not for those on a tight budget, as it is most likely the most expensive option, but it does show up as used material from time to time as it is used in various industries.

Densified Wood Products such a Panzerholz and Permali are being used both Commercially and in DIY projects, it does appear to have a properties that suits being used as a front baffle.

https://www.monoandstereo.com/2014/11/interview-with-rainer-weber-of-kaiser.html

Last edited:

I have heard osb tends to not be airtight. So it may need some kind of airtightening (lacquer).oriented strand board

I have old ESM speakers, The Energy woofer and tweeter are long gone. It sports a Kenwood Trio (from LS-P7000X speakers) woofer and seas H123 tweeter, a friend who ran a repair business did up the crossovers. Perfect speakers but the veneer was pealing so i took it all off. Particle board the cabinets. I wonder how it fares against MDF. The Bunnings (retail hardware chain here in Australia) sells MDF, plywood not birch, but pine based,

I remember an article once, online mentioning that BB (may have been TNT audio) is great for acoustics, that sort of thing, and MDF had more bass, but the reviewer thought thicker BB had as much bass as MDF, and the benefits of better audio

My coral speakers, are a mix of ply and particle board, the celestion SL-6 )not sure could be ply or mix, and the Technics are particle board . I do remeber some old 70s technics speakers i had were ply (wish i kept them).

Found it

https://www.tnt-audio.com/clinica/cabinet_walls_e.html

Back to my bookshelves instead of painting the particle board, i am thinking a thin plywood cover and stain. I am tempted to get plywood boxes made instead. As another Aussie found shipping is steep. Some marine plywood on gumtree (like craigslist) in my city, they state it as "Our plywood is made from ethically sourced Eucalyptus hard wood core and an Okoume hard wood veneer AA bonded together with A Bond Phenolic WBP glue.

https://www.gumtree.com.au/s-ad/nerang/building-materials/bs1088-marine-plywood/1267399332

I remember an article once, online mentioning that BB (may have been TNT audio) is great for acoustics, that sort of thing, and MDF had more bass, but the reviewer thought thicker BB had as much bass as MDF, and the benefits of better audio

My coral speakers, are a mix of ply and particle board, the celestion SL-6 )not sure could be ply or mix, and the Technics are particle board . I do remeber some old 70s technics speakers i had were ply (wish i kept them).

Found it

https://www.tnt-audio.com/clinica/cabinet_walls_e.html

Back to my bookshelves instead of painting the particle board, i am thinking a thin plywood cover and stain. I am tempted to get plywood boxes made instead. As another Aussie found shipping is steep. Some marine plywood on gumtree (like craigslist) in my city, they state it as "Our plywood is made from ethically sourced Eucalyptus hard wood core and an Okoume hard wood veneer AA bonded together with A Bond Phenolic WBP glue.

https://www.gumtree.com.au/s-ad/nerang/building-materials/bs1088-marine-plywood/1267399332

As a general rule, ~half of the acoustic power is < ~500 Hz, so we want rigid construction (high MOE) to push cab's resonance above its intended passband and > ~500 Hz we want massive to push it down (low MOE), so the 3/4" no void marine grade I used proved an excellent choice for all manner of (sub/mid) bass, full range cabs. Regardless, get some specs of what all's available and do the math to get the best overall choice for your app if wanting to save $$, have least weight.

Calculating thickness comparison, equivalents.

Calculating thickness comparison, equivalents.

Last edited:

I've used It. Much more rigid than mdf, close to plywood. There are different grandes, the best is OSB 5.Has anybody tried oriented strand board? IIt might be a cheap alternative, half way between MDF and plywoodI have been thinking about it for my next project.View attachment 1045686

Main problem is finishing, especially the edges. Routing and sanding carefully helps.

If you dont mind a rustic finish, go for It.

Thank you GM for the help. I just followed your link so 40mm PB to match the BB at 19mm. The PB is quite thin on the ESM bookself 12mm on the sides. From memory the front where the woofer and tweeter is place was thicker, maybe 25mm.As a general rule, ~half of the acoustic power is < ~500 Hz, so we want rigid construction (high MOE) to push cab's resonance above its intended passband and > ~500 Hz we want massive to push it down (low MOE), so the 3/4" no void marine grade I used proved an excellent choice for all manner of (sub/mid) bass, full range cabs. Regardless, get some specs of what all's available and do the math to get the best overall choice for your app if wanting to save $$, have least weight.

Calculating thickness comparison, equivalents.

- Home

- Design & Build

- Construction Tips

- Plywood VS MDF for speaker construction