I paint the insides of my cabs with this stuff: EVERBUILD® BLACK JACK® 908 D.P.M. - everbuild-black-jack908dpm.pdf

It is a water-based bitumen-enriched rubber compound which is odourless and black once dry. I suppose you could also use to make CLD panels.

If you want it thicker just use more coats and you can use it to fix any damping material.

It is a water-based bitumen-enriched rubber compound which is odourless and black once dry. I suppose you could also use to make CLD panels.

If you want it thicker just use more coats and you can use it to fix any damping material.

Great. This is pioneering SOTA research. 🙂 Lends more credence to baffle-less dipoles for mids and treble, too.That's the key question, because it really does depend on the pass band. I'm not an acoustic engineer, so forgive the layman's description, but I break up the behavior of any cabinet into 3 regimes. Using the example above, below the first panel resonances, say below 400hz, the panels are not resonating, just flexing. Here a lot of bracing is the way to go, since this drops the output of the panels a lot (see my bracing tests). Panel material or construction doesn't matter near as much as bracing, so I can see why some people like Bill F. use 1/2" plywood heavily braced for subwoofer cabinets. Than we get to the panel resonance regime, in my speaker about 400hz to 2khz. If you could laser scan the panel you would probably see it breaking up chaotically like those laser scans of speaker cones we've all seen. I've been told at resonance, the panel is almost "transparent" to sound, and I think my measurements show that. This is the area most benefiting from CLD construction, Resonix-type tiles, and driver isolation. Above this region, it is more simple transmission of sound through the panel, which steadily declines with increasing frequency. I'd have to look over my data again to be sure, but in this area it was just the material used the defined the behavior. For example, while the slope and shape were the same, MDF was a few dB lower than plywood in this regime. In the CLD vs plywood example above, you can see they are basically the same. I don't think I would worry too much about this area as the levels quickly drop.

I'm going out to look for material today. I'm limited to using plywood, MDF wouldn't be good for a flexy rack.

I wonder if I'm in for more sticker shock. I have not shopped for any DIY supplies in several weeks. Everything has gone up. Metal wood, tool bits, rockwool...

I wonder if I'm in for more sticker shock. I have not shopped for any DIY supplies in several weeks. Everything has gone up. Metal wood, tool bits, rockwool...

Car panels are curved for stiffness among other things, so yes a curved ply or anything similar will be stiffer...

How many of us have the machines to do that?

Curved ply Scandinavian chairs were steam bent from sheets.

Boiler, presses, tooling?

Who has those?

How else can you bend ply?

How many of us have the machines to do that?

Curved ply Scandinavian chairs were steam bent from sheets.

Boiler, presses, tooling?

Who has those?

How else can you bend ply?

so the resonances are above 5khz?

500-1000 hz is suffiecient. Getting it up that high is not easy.

dave

…with driver isolation as I mentioned above...

Did you get a measure of the loss of information from decoupling the driver from the box?

It will reduce the energy transferred to the box making for a basket that moves more while music is playing, with a loss of information from that.

In those measures, the resonances ar ehigh enuff they should not be an issue. With music.

dave

I would really try out the CLD method. It is simple to do...

It is?

dave

Buy flexible ply and layer it yourself to the thickness you need.

That is what we ended up doing. Plus a layer of masonite to veneer over.

dave

Did you get a measure of the loss of information from decoupling the driver from the box?

It will reduce the energy transferred to the box making for a basket that moves more while music is playing, with a loss of information from that.

In those measures, the resonances ar ehigh enuff they should not be an issue. With music.

dave

No I haven't checked that. I'm not sure I would use driver isolation for a woofer being used below the panel resonances for exactly the reason that you would probably want a heavy frame/magnet tightly attached to the speaker. I doubt you will see any difference at higher frequencies using driver isolation, and I'm sure I've seen someone do that exact test around here. Can't remember who. Linkwitz maybe?

My CLD is no more difficult than gluing any two panels together. Just be sure the constrained layer is 1/32" thick using either my 3D-printed trowel. Or a 1/16" square tooth trowel and slide the panels sideways to collapse the beads and expel the air. Just like laying tile.

What do you do at the joins? If you are only CLDing the panels and not where they join the job is unfinished.

dave

dave

Using the same adhesive as the constrained layer. At first I did box-within-a-box, so the inner box was isolated from the outer. But that is a big pain to build so I moved to gluing up the panels, then cutting them and attaching them as you would any box. I didn't see any obvious reduction in benefit, so it's nice to know even simple methods can be very effective.

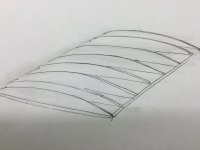

I’m more interested in bookshelf size enclosures rather than the large floor standing ones in Dave’s pics. I would cut a number of ribs and cut the desired radius on one edge, attach these to a board (something like the rough sketch below) the size of the former needs to be larger than the finished piece. I would include a timber strip along the underside of the curved edges so the clamps won’t slip off.Car panels are curved for stiffness among other things, so yes a curved ply or anything similar will be stiffer...

How many of us have the machines to do that?

Curved ply Scandinavian chairs were steam bent from sheets.

Boiler, presses, tooling?

Who has those?

How else can you bend ply?

The actual laminating will take a bit of experimenting, my first thought would be to laminate the layers together flat, clamp one edge on the jig and work the ply over to the other edge while the glue still has slip. Two pairs of hands would definitely be required plus a lot of clamps.

Alternatively, layers could be applied separately by screwing them along the edges, offsetting the screws and allowing cutouts for final disassembly.

Steve

Attachments

Just picked up some 12mm baltic 9 ply for making a little pair of PU5 style boxes for CHN50s. I was going to dove tail the joints bit for this first pair I'll go simple, however https://www.somasonus.net/box-construction-methods got me thinking about the joint bonds. I was considering using a rock hard epoxy style sealant inside the speaker box - I used it to seal my slates outside, it also required a 4lb lump hammer to remove the wood pallet from the garage floor due to a spil. I would then scratch and put felt inside. Suppose I'm overthinking this.

I Have Experienced both and I Think MDF gives Better Bass And Sound It Depends on Thickness And MDF Is Good For 4 to 8 Inches Speakers But If You Want To Use Bigger Speakers than Probably you Should Use Plywood 1 To 1.5 Inches Thickness And MDF will More Expensive Than Plywood Or winboardThis is a reference video on Plywood VS MDF for speaker enclosures.....In a hurry, go to 25:00 minutes in and at 28:00 he says MDF is half as stiff as standard construction grade plywood.....Who knew! https://www.youtube.com/watch?v=EEh01PX-q9I

Dovetails look great if they are executed properly, have you done them previously? I have some experience, I have a router jig but it only does half blind dovetails. I have done hardwood, but never tried plywood. I would imagine that edges could splinter if you weren’t careful.Just picked up some 12mm baltic 9 ply for making a little pair of PU5 style boxes for CHN50s. I was going to dove tail the joints bit for this first pair I'll go simple, however https://www.somasonus.net/box-construction-methods got me thinking about the joint bonds. I was considering using a rock hard epoxy style sealant inside the speaker box - I used it to seal my slates outside, it also required a 4lb lump hammer to remove the wood pallet from the garage floor due to a spil. I would then scratch and put felt inside. Suppose I'm overthinking this.

With regard to the epoxy, that’s not a bad idea, but as you say you would need to stop reflection.

BB prices are becoming more insane..

If stiff is important and mass adds no performance value? - This makes a light weight speaker appealing, especially larger speakers for moving around, on a ladder outdoors for measuring etc.. Contemplating other options for stiff and light construction🤔

If stiff is important and mass adds no performance value? - This makes a light weight speaker appealing, especially larger speakers for moving around, on a ladder outdoors for measuring etc.. Contemplating other options for stiff and light construction🤔

Many years ago, after painstakingly building my first speaker baffle to the cabinet with glue AND screws, I decided to test whether PVA glue alone was enough.

so I did a test-

MDF panels glued via PVA glue versus

MDF panels glued with PVA glue + reinforced with self tapping wood screws.

this was an ordinary butt joint.

I’d leave them for 24 hours; then I tried to snap to panels at the joint line.

The panels broke; but not at where the glue lines were! The MDF panel snapped.

So needless to say; I stopped using screws when building cabinets.

These empirical measurements by Brandon make me think about going back to MDF sheets and gluing them.

I don’t have time to laminate 9 layers of MDF together, but I will buy whatever thickness of MDF is available; and glueing them together to my desired thickness.

sometimes you want a thicker front panel, but you don’t want to buy a whole (8x4’) sheet of 1” or 1.25” MDF. Or you have some leftover pieces. Or depending on supply/demand and what are you available at the times; 1/2” is less than half the price if 1” MDF etc.

Or 1/2” or 3/4” MDF may be on clearance etc,

Just go ahead and glue the layers together with confidence!

or should I glue a layer or carpet with rubber underlay in between?

Possibilities possibilities…

so I did a test-

MDF panels glued via PVA glue versus

MDF panels glued with PVA glue + reinforced with self tapping wood screws.

this was an ordinary butt joint.

I’d leave them for 24 hours; then I tried to snap to panels at the joint line.

The panels broke; but not at where the glue lines were! The MDF panel snapped.

So needless to say; I stopped using screws when building cabinets.

These empirical measurements by Brandon make me think about going back to MDF sheets and gluing them.

I don’t have time to laminate 9 layers of MDF together, but I will buy whatever thickness of MDF is available; and glueing them together to my desired thickness.

sometimes you want a thicker front panel, but you don’t want to buy a whole (8x4’) sheet of 1” or 1.25” MDF. Or you have some leftover pieces. Or depending on supply/demand and what are you available at the times; 1/2” is less than half the price if 1” MDF etc.

Or 1/2” or 3/4” MDF may be on clearance etc,

Just go ahead and glue the layers together with confidence!

or should I glue a layer or carpet with rubber underlay in between?

Possibilities possibilities…

Last edited:

- Home

- Design & Build

- Construction Tips

- Plywood VS MDF for speaker construction