I also suspect as I get closer to optimum with the 465C that there is very little difference sonically speaking between these different cartridges. I originally thought the 451C won on sound quality, but I think they are about on par.

The 450CII is supposed to be special compared to the others. I was going to bid on one but decided to give someone else (probably someone with my kit pre-amp) a chance at getting a cartridge. I'll try a bit later.

The 450CII is supposed to be special compared to the others. I was going to bid on one but decided to give someone else (probably someone with my kit pre-amp) a chance at getting a cartridge. I'll try a bit later.

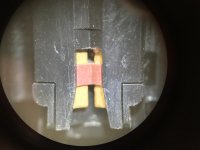

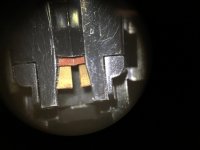

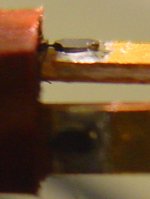

Looking at these under a scope, the only difference between the 450 c2 and 451 is how the plastic body comes forward and covers the damping blocks on the 451

At first it looks like it slightly touches them but not so. There is some space separating them.

From here, the elements look similiar to me.

That body must go and next thing to get reworked..

I will have to add the blob next session.

Regards

David

At first it looks like it slightly touches them but not so. There is some space separating them.

From here, the elements look similiar to me.

That body must go and next thing to get reworked..

I will have to add the blob next session.

Regards

David

Attachments

The shape of the opening is appreciably different too. I will have to take a look at mine the next time I have a good opportunity to do so.

Looking again under the scope, both measure about .0184" from edge to edge between the SG elements

Looking down on the ends, I put a square edge as close as I could get to parallel the elements and both versions are at the same angles on mine. 45/45 degrees.

If someone has a picture of Sound smiths SG with the needle removed, it would interesting to see how they capture the needle assembly in comparison and the view inside the elements

Their specs show better channel separation from the same overall design..,.

Regards

David

Looking down on the ends, I put a square edge as close as I could get to parallel the elements and both versions are at the same angles on mine. 45/45 degrees.

If someone has a picture of Sound smiths SG with the needle removed, it would interesting to see how they capture the needle assembly in comparison and the view inside the elements

Their specs show better channel separation from the same overall design..,.

Regards

David

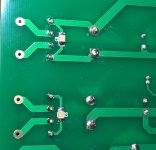

Check to make sure that no tabs are grounded on the heat sinks (but looks OK) - don't forget to remove one instance of the C8 capacitors (does not matter which one) on the filament bypass. Only one should be installed.

Edit: Double check soldering on R3 on the audio PCB on the left.

Kevin,

The C8 you are talking about is on the back of PS board? I checked everything else. They are all fine.

Thanks!

Jim

Attachments

No C8 on the audio board as previously noted. Please remove one of them (not both) Only one needs to be installed per pair of boards. (47uF electrolytic on the filament circuit)

The black plate is similiar to the distance covering the damping material on the 451. Slight gap without touching

Other than the ruby cantilever , the donut and aluminum looks panasonic.

Their SG -230 system is 13k now 😡😎

Other than the ruby cantilever , the donut and aluminum looks panasonic.

Their SG -230 system is 13k now 😡😎

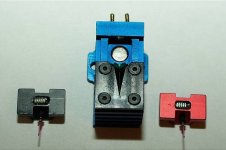

A set screw pushes the needle assembly forward locking it in place.

Looks like a magnet insert ?

That rectangular area looks like a damping substance maybe ?

Need to see how the rubber end holding the cantilever is glued to its housing

The stock panasonic just sits in a glued half circle trough. No full circle capture

Regards

David

Looks like a magnet insert ?

That rectangular area looks like a damping substance maybe ?

Need to see how the rubber end holding the cantilever is glued to its housing

The stock panasonic just sits in a glued half circle trough. No full circle capture

Regards

David

If we can find the strain gauges produced by modern technology, it is very possible to build a cartridge ourselves.

This is exactly the idea I'm currently investigating.

I'm following this thread for quite a while now and in the meanwhile was able to get two EPC-460 cartridges with identical styli.

First of all a big 'thank you' to Kevin to have brought this non mainstream technology to our attention.

I just finished the preamp and will first try to optimize the sound with the tweaks already mentioned by Kevin. I fully agree that the Panasonic cartridge body is a flimsy piece of thin plastic that most probably is not able to deliver the sound quality this technology may be able to deliver.

Next step will be to dismantle one of my cartridges, build a completely new cartridge body from wood (most probably african blackwood) and remount the SGs including the damper sleeves. My hope is to directly (maybe with a different equalizer in the preamp) compare the stock version to the version with a much more rigid and resonant free body.

IF successful, the next step will be to find a source for suitable modern semiconductor strain gauge elements to replace the original Panasonic parts. I already identified two potential (non chinese) suppliers that may be able to deliver the parts I have in mind for a reasonable price tag.

So, lets see how far I can go ...

I'm following this thread for quite a while now and in the meanwhile was able to get two EPC-460 cartridges with identical styli.

First of all a big 'thank you' to Kevin to have brought this non mainstream technology to our attention.

I just finished the preamp and will first try to optimize the sound with the tweaks already mentioned by Kevin. I fully agree that the Panasonic cartridge body is a flimsy piece of thin plastic that most probably is not able to deliver the sound quality this technology may be able to deliver.

Next step will be to dismantle one of my cartridges, build a completely new cartridge body from wood (most probably african blackwood) and remount the SGs including the damper sleeves. My hope is to directly (maybe with a different equalizer in the preamp) compare the stock version to the version with a much more rigid and resonant free body.

IF successful, the next step will be to find a source for suitable modern semiconductor strain gauge elements to replace the original Panasonic parts. I already identified two potential (non chinese) suppliers that may be able to deliver the parts I have in mind for a reasonable price tag.

So, lets see how far I can go ...

I was hoping to spark enough interest that someone would be interested in making a modern version at an affordable price point, perhaps selfishly married to one of my pre-amp designs.

The technology has a lot of promise, and the achilles heal of the old Panasonic is the inexpensive packaging used to put it at a price point of the mass market in the 1970s. Those choices I suspect prevented it from being taken very seriously by the high end audiophile community from quite an early date where unfortunately most of the discretionary money for a hobby like this will be found.

Other examples of stereo era SG technology were pretty unreliable which also did not help.

This of course all started as the result of a challenge received from my close friend GTHICM who deserves the credit for getting me started down this path. Previously I had dismissed these cartridges and the underlying technology as a poorly performing curiosity based on what I had heard elsewhere. (Basically it was a cost effective way to play CD-4 records with the matching decoders)

The technology has a lot of promise, and the achilles heal of the old Panasonic is the inexpensive packaging used to put it at a price point of the mass market in the 1970s. Those choices I suspect prevented it from being taken very seriously by the high end audiophile community from quite an early date where unfortunately most of the discretionary money for a hobby like this will be found.

Other examples of stereo era SG technology were pretty unreliable which also did not help.

This of course all started as the result of a challenge received from my close friend GTHICM who deserves the credit for getting me started down this path. Previously I had dismissed these cartridges and the underlying technology as a poorly performing curiosity based on what I had heard elsewhere. (Basically it was a cost effective way to play CD-4 records with the matching decoders)

So as mentioned above getting replacement strain gauges is a big factor in all this.

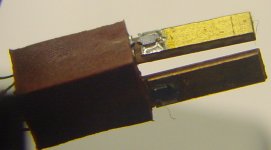

And as I mentioned before one of the strain gauges went open in one sample I have so I went ahead and disassembled it to investigate further and snapped a few photos on the way.

And as I mentioned before one of the strain gauges went open in one sample I have so I went ahead and disassembled it to investigate further and snapped a few photos on the way.

Attachments

Impressive pics Dave !

Didn't realize this was under the element holder

Can you pull it out completely and possibly repair it or at least resolder and see what happens ? Nothing to lose at this point

If you could take another pic (if you pull it out entirely) that would be interesting to see and maybe someone will know where abouts to get a suitable replacement SG

Regards

David

Didn't realize this was under the element holder

Can you pull it out completely and possibly repair it or at least resolder and see what happens ? Nothing to lose at this point

If you could take another pic (if you pull it out entirely) that would be interesting to see and maybe someone will know where abouts to get a suitable replacement SG

Regards

David

Looks like the SG element is made from a piece of phenolic electronic base board material milled into shape with a small groove underneath the semiconductor element.

The semiconductor strain gauge resistor seems to be the small cylinder shaped part with two larger 'feet' soldered to the gold plated copper layer. The entire semiconductor part is quite big - must have been expensive. Todays semiconductor strain gauge elements are much more smaller and are extremely thin.

One potential source for modern replacement parts I identified could be Kulite, based in New Jersey. They produce semiconductor strain gauge based pressure sensors for a wide range of industries. Kulite's product portfolio lists semiconductor strain gauges of various sizes, shapes and resistance values already bonded to small stripes of FR4 electronic board material. On their website, they have a pdf brochure describing all the basics and the properties including datasheets.

The semiconductor strain gauge resistor seems to be the small cylinder shaped part with two larger 'feet' soldered to the gold plated copper layer. The entire semiconductor part is quite big - must have been expensive. Todays semiconductor strain gauge elements are much more smaller and are extremely thin.

One potential source for modern replacement parts I identified could be Kulite, based in New Jersey. They produce semiconductor strain gauge based pressure sensors for a wide range of industries. Kulite's product portfolio lists semiconductor strain gauges of various sizes, shapes and resistance values already bonded to small stripes of FR4 electronic board material. On their website, they have a pdf brochure describing all the basics and the properties including datasheets.

- Home

- Source & Line

- Analogue Source

- Playing With Panasonic Strain Gauge Cartridges (And A Dedicated Phono Stage)