I use photo paper now much easier to mount and tension said diaphragm. Using double sided tape, although you have to be very careful to line up the diaphragm correctly. Been rebuilding all my old designs about 30 up to now, a few more left to do, and 2 pairs of headphone designs!

Henry,

Would this be good for the diaphram?

HP Designjet Large Format Instant Dry Gloss Photo Paper Roll 24 x 100 by Office Depot & OfficeMax

Scott

Would this be good for the diaphram?

HP Designjet Large Format Instant Dry Gloss Photo Paper Roll 24 x 100 by Office Depot & OfficeMax

Scott

I'm using 20 um at the moment, I am not sure but that is thinner I think. So up to you how thick you use. I am quite happy with 20 um. I don't like it too thin as it is too noisy as I found out when I used the mylar! That is why I stopped using it.

Henry,

Like many others I have read through your journey with great interest. Thank you for sharing. May I ask what paper you are using? Also, how does the sound compare to your favorite film versions?

Walter

Like many others I have read through your journey with great interest. Thank you for sharing. May I ask what paper you are using? Also, how does the sound compare to your favorite film versions?

Walter

latest planar designs using pics!

Just as good and easier to build, I also use my version of the epsilon layout, using 3, 5, and 6 mm wide tape depending on the width of your magnets. I have got 18,22, and 25 width wide magnets so use different tape widths to fit, using my version of the epsilon layout. Have nearly finished my rebuilds . Will only use ferrites on the smaller 60 x 40 cm versions the 4' x 2' ones are too heavy for my age (77). Will use neos on this size.

Just as good and easier to build, I also use my version of the epsilon layout, using 3, 5, and 6 mm wide tape depending on the width of your magnets. I have got 18,22, and 25 width wide magnets so use different tape widths to fit, using my version of the epsilon layout. Have nearly finished my rebuilds . Will only use ferrites on the smaller 60 x 40 cm versions the 4' x 2' ones are too heavy for my age (77). Will use neos on this size.

Attachments

One additional question

Thank you for the info on the paper. I think traditional speakers sound better with paper cone. Somehow I expect the same here.

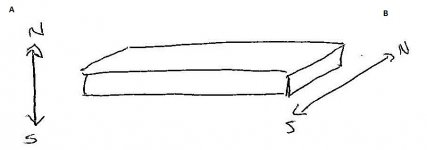

I confess I remain confused about the magnet field orientation. See my sketch below. I found a local source of 25x8x3mm neos. But they have orientation as in A below. If I understand the ones you use they would be oriented like B. Mine have north all across the big flat side that is 25x8 and south is on the bottom. Which way should it be? Sorry to be slow on this.

Thank you for the info on the paper. I think traditional speakers sound better with paper cone. Somehow I expect the same here.

I confess I remain confused about the magnet field orientation. See my sketch below. I found a local source of 25x8x3mm neos. But they have orientation as in A below. If I understand the ones you use they would be oriented like B. Mine have north all across the big flat side that is 25x8 and south is on the bottom. Which way should it be? Sorry to be slow on this.

Attachments

Last edited:

Hi there.

After testing real Magnepans 2.7 and MMGs in my house, I decided to lazily collect some info on how to make my own, better magneplanar speakers. This topic is a good start, definitely.

The very first question is: why cut&glue aluminum tape if one can buy a roll of foiled PET (used for flexy PCBs and ribbon cables) and just etch the traces as we do on our homebrew boards? This is much more precise, strong and lightweight (even with copper), compared to handmade alu tape and lots of glue. Well, yes, you need a barrel of chlorine iron and some spacers to fit the roll evenly into that barrel, but the total amount of sweat is going to be much less?

Or not?

After testing real Magnepans 2.7 and MMGs in my house, I decided to lazily collect some info on how to make my own, better magneplanar speakers. This topic is a good start, definitely.

The very first question is: why cut&glue aluminum tape if one can buy a roll of foiled PET (used for flexy PCBs and ribbon cables) and just etch the traces as we do on our homebrew boards? This is much more precise, strong and lightweight (even with copper), compared to handmade alu tape and lots of glue. Well, yes, you need a barrel of chlorine iron and some spacers to fit the roll evenly into that barrel, but the total amount of sweat is going to be much less?

Or not?

Hi there.

After testing real Magnepans 2.7 and MMGs in my house, I decided to lazily collect some info on how to make my own, better magneplanar speakers. This topic is a good start, definitely.

The very first question is: why cut&glue aluminum tape if one can buy a roll of foiled PET (used for flexy PCBs and ribbon cables) and just etch the traces as we do on our homebrew boards? This is much more precise, strong and lightweight (even with copper), compared to handmade alu tape and lots of glue. Well, yes, you need a barrel of chlorine iron and some spacers to fit the roll evenly into that barrel, but the total amount of sweat is going to be much less?

Or not?

if you can find it anywhere 🙂 i searched high and low for this stuff. for years. its either you buy a few Km of the stuff or pay major dollars/euro's

getting the right thickness alu/pet is pretty hard as well.

Oh also i etched PCB copper etc. but alumnium seems to let go of every etch resist i tried. maybe you got an idea?

As the first try I found copper-foiled PET, 50um thick (must be a bit too heavy?) with 35um copper, in widths from 40cm to 1.2m. No aluminum found, but see my message above. The main questions before I get broke for a roll, are thickness of the base and the ability to tension it right. Copper is way better in bending then aluminum, but mind the layer of glue...

I always use aluminium foil 3, 5, and 6 mm wide glued already! Have used 1,00's of meters no problems, even at my age (77)!

Henry, you must be far far away from Moscow as I suspect. We have no circuit-based alarm systems for 20++ years already, so I'm unable to find any more self-adhesive alu tape. Instead, military grade foiled PET in 50um can be found with no real problem. The question is - is it worth the effort. Or am I riding the wrong way.

full range planar 24 x 16 inches

Have redesigned my planar speakers again and again, use less magnets now just as sensitive as before also have increased the gap to 5 mm, this has got rid of the funny noises on some of the songs I have played on them, only use ferrites now.Also use a lot less aluminium foil as well.A lot easier especially for someone my age 83.As I said before the pictures are easier to place in position. You don't have to stretch the diaphragm, nice and tight. Also use the cut outs to make a slightly bigger one, saves money for wooden surround.

Have redesigned my planar speakers again and again, use less magnets now just as sensitive as before also have increased the gap to 5 mm, this has got rid of the funny noises on some of the songs I have played on them, only use ferrites now.Also use a lot less aluminium foil as well.A lot easier especially for someone my age 83.As I said before the pictures are easier to place in position. You don't have to stretch the diaphragm, nice and tight. Also use the cut outs to make a slightly bigger one, saves money for wooden surround.

- Home

- Loudspeakers

- Planars & Exotics

- Planar speaker - first try