Aleph_4 conversion to Aleph_J finished

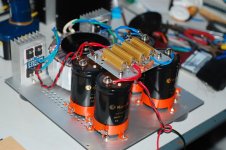

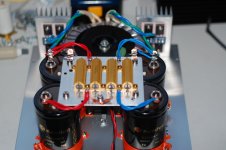

Please find below pics for my recently upgraded A_4 to A_J.

Those are mono blocs versions.

New mainboards are pro. factory custom made.

Other than mainboard, only change needed was the xformer, 18V/450VA per bloc.

Fuse 240V is 500 mA and holds with 2 CL60 in series.

Current is 2,3 amps as per schematic values on +/- 23,4V average. Offset 40 mV cold to 20mV idle.

Power resistors are Welwyn 3W vitreous wirewound 5% 75PPM.

Other resistors are DALE RN55 series. Onboard caps are Nichicon Audio.

Sinks 48-49 celsius at idle.

More, sound is marvelous 🙂 I second Neslon when he says that A_J is the best of Aleph series 😎

Best,

nAr

Please find below pics for my recently upgraded A_4 to A_J.

Those are mono blocs versions.

New mainboards are pro. factory custom made.

Other than mainboard, only change needed was the xformer, 18V/450VA per bloc.

Fuse 240V is 500 mA and holds with 2 CL60 in series.

Current is 2,3 amps as per schematic values on +/- 23,4V average. Offset 40 mV cold to 20mV idle.

Power resistors are Welwyn 3W vitreous wirewound 5% 75PPM.

Other resistors are DALE RN55 series. Onboard caps are Nichicon Audio.

Sinks 48-49 celsius at idle.

More, sound is marvelous 🙂 I second Neslon when he says that A_J is the best of Aleph series 😎

Best,

nAr

Attachments

Nice work Nar. Are you likely to make the boards available?

Thank you 😀

Hey. Those are private builds, but tested and bugfree.

I did this as a hobby, working on Gerber files and so on, with the precious help of Pierre my canadian friend 🙂 it took time and efforts to get the real thing.

Those were done on a small batch ordrer; I only have 1 board left ATM, because the left ones are reserved for friends.

So quantity is very limited 🙁 But for anyone interested, feel free to contact me by PM. Depending on interest, I may study possibility of having a new batch made, maybe in bigger volume if needed.

Please do understand my use of the word may ... As I also have a life out of DIY and must make a living. Those boards were just for fun. And they worked as expected 😎

Best,

nAr

Nice caps. Your build is almost a BoZoaC.

I guess. I used 2x 4700uf filter caps. I couldn't fit any more in my case.

here it is my freshly minted f-5. Thanks to Mr. Pass for this design, and all that have posted before me who answered my questions before I had them.

Attachments

Simply superb! Salute to your wonderful idea to build the chassis with wood and mastery over wood working skills.

Enjoy

Enjoy

@ preamp: Yes, partly. I use these heatsinks for industrial power rectifiers.

@ Jacco: Thank you. I was just too lazy to take photos, the A75 is working for three years now. In the meantime i built a B1/Pearl-Preamp, which i will upgrade to the Pearl II. Maybe i take some pics in a year or three.

Did you mean the four black circular things by uncommon rectifier diodes ? These are fuse holders, the rectifier modules can only be seen vaguely, they´re mounted on the bottom plate, where the red and black wires go to.

Hello evanc, very beautiful enclosure and superbly crafted. What kind of wood is it?

@ Jacco: Thank you. I was just too lazy to take photos, the A75 is working for three years now. In the meantime i built a B1/Pearl-Preamp, which i will upgrade to the Pearl II. Maybe i take some pics in a year or three.

Did you mean the four black circular things by uncommon rectifier diodes ? These are fuse holders, the rectifier modules can only be seen vaguely, they´re mounted on the bottom plate, where the red and black wires go to.

Hello evanc, very beautiful enclosure and superbly crafted. What kind of wood is it?

Last edited:

Thanks

The case is cherry.....a 2.5" thick piece left over from some paying project. The top is cheap 1/2" plywood veneered with curly sycamore....another leftover.

The finish is shellac. Applied with a rag and polished. Easy enough on a piece this small.

The case is cherry.....a 2.5" thick piece left over from some paying project. The top is cheap 1/2" plywood veneered with curly sycamore....another leftover.

The finish is shellac. Applied with a rag and polished. Easy enough on a piece this small.

6L6 thanks....your build guide was a nice reference to have as I built my amp. Very well documented. Your time is appreciated.

Evan

Evan

here it is my freshly minted f-5. Thanks to Mr. Pass for this design, and all that have posted before me who answered my questions before I had them.

Nice!! Only think be careful not to cook the caps. It will be hot inside, as there is no ventilation. I had to make holes in summer. You can make a "summertime" cover 🙂

D.

I have a thermometer in the case as we speak. Less then 100 degrees F. The wood will certainly not catch fire...as far as the cap go I'm not sure what is OK.

Mhouston, yes it sounds good, but I am only a trained monkey.....

Mhouston, yes it sounds good, but I am only a trained monkey.....

here it is my freshly minted f-5. Thanks to Mr. Pass for this design, and all that have posted before me who answered my questions before I had them.

Chapeau!

I certainly found with my Aleph 4 that it would run beautifully cool in the winter with temperatures inside the case at about 45 degrees C. However, in the summer the internals would run at closer to 55 degrees.

The simple solution was to fit a pair of 50mm fans (12V) but running them in series. The result is virtually silent and the temperatures keep the caps well below 50 degrees C.

The fans are above the cap banks with large holes drilled in the base around the caps.

The simple solution was to fit a pair of 50mm fans (12V) but running them in series. The result is virtually silent and the temperatures keep the caps well below 50 degrees C.

The fans are above the cap banks with large holes drilled in the base around the caps.

Just finished my F5. Thank you Mr. N. Pass and to DiyAudio for sharing this Brilliant amplifier.

Attachments

- Home

- Amplifiers

- Pass Labs

- Pictures of your diy Pass amplifier