Another big issues with most PR's, is that the Kms(x) is non-linear like most other woofers.

This is the stiffness (compliance) as function of cone excursion.

Which makes the tuning frequency shift.

This is the stiffness (compliance) as function of cone excursion.

Which makes the tuning frequency shift.

The PR Fb drops slightly in frequency at high excursions, a bass reflex Fb rises slightly at high drive level.Which makes the tuning frequency shift.

An undersized port Fb will shift more than a decent PR.

That said, a DIY PR is not likely to have as linear Kms(x) as a decent PR 😉

Bit smallPrice performance, but too small for project:

Just found this amazing item on AliExpress. Check it out!

DKK2.87 15%OFF | YUXI 50*65mm Woofer Radiator Bass Passive Speaker Low Frequency Loudspeaker Diaphragm Vibration Plate DIY

https://a.aliexpress.com/_Exyw8vR

Goole seach for this term is empty, is it a real term? What does it mean?Kms(x)

See above. What is the basis for you setting these limits?That said, a DIY PR is not likely to have as linear Kms(x) as a decent PR

Try using Google 😉Goole seach for this term is empty, is it a real term? What does it mean?

https://fohonline.com/articles/tech-feature/klippel-plots-going-beyond-the-thiele-small-parameters/

Figure 1: Bl (X)

Figure 2: Kms (X)

"Kms (X) is the mechanical analog of Bl (X). It characterizes the uniformity of the restoring force applied to the cone by the driver’s mechanical elements like the spider and surround. Driver manufacturers don’t necessarily want the restoring force to be uniform throughout the driver’s excursion. It can be a useful tool to improve the overall combined linearity, mechanical plus electrical, of the driver. Generally the more symmetric the Kms (X) plot, the better the driver’s distortion performance will be due to mechanical considerations. Again, as in the Bl (X) graph, the dashed grey line in Fig. 2 represents the idealized symmetric Kms (X) curve for the driver in question. Suspension materials and configurations that remain symmetric over a wide range of excursions are part of the closely held intellectual property important to a loudspeaker driver manufacturer."

You have not demonstrated how your "pipe dream" works, so I have no comment on it's linearity.What would be non-linear about the PR plug riding on a rod with ferrofluid lube/suspension?

Diagram how your systems magnets are arranged to allow the radiator "plug" riding on a rod to maintain an inner and outer airtight seal.

Then diagram how the airtight seal provides a uniform restoring force to center the radiator in the piston.

Cheers,

Art

Last edited:

I quite literally explained it in the same post:Bit small

Goole seach for this term is empty, is it a real term? What does it mean?

See above. What is the basis for you setting these limits?

This is the stiffness (compliance) as function of cone excursion.

Which makes the tuning frequency shift

But a good search would be for a excellent paper from Klippel, called loudspeaker non-linearities.

I have seen drivers (even good quality ones) with pretty bad Kms(x).The PR Fb drops slightly in frequency at high excursions, a bass reflex Fb rises slightly at high drive level.

An undersized port Fb will shift more than a decent PR.

That said, a DIY PR is not likely to have as linear Kms(x) as a decent PR 😉

But the real issue here, is that you'll get the PR non-linearities on top of the woofer non-linearities.

We can actually simulate this.

Could we not trade the limitations of the surround and spider for greater excursion by riding the rod with a very slight leak forming air bearings where the surrounds would be? Return to rest at idle can be taken care of by a more linear compliant mechanism such as some NiTi wands. The leak can be further tamed with a bristle surround doped with silicone oil. The main prob that I can think off would be any air noises from the leak. Ferrofluid on rod should be quite enough, never heard of any noise issues with that

Ordered 6 more pairs of PRs today in various sizes but still cant decide on one for the 12 active driver. Some of these are basket less types for experiments sandwiching a plug between a pair

Would there be any interest in development work for a DIY PR driver - I have come up with a feasible means of setting up a pair of back to back glass cones attached at the apex and FAT roll surrounds at either side in a DIY basket? I have worked out the DIY workflow and think we can make a better performing unit than the SLAPS system for a lot less cost

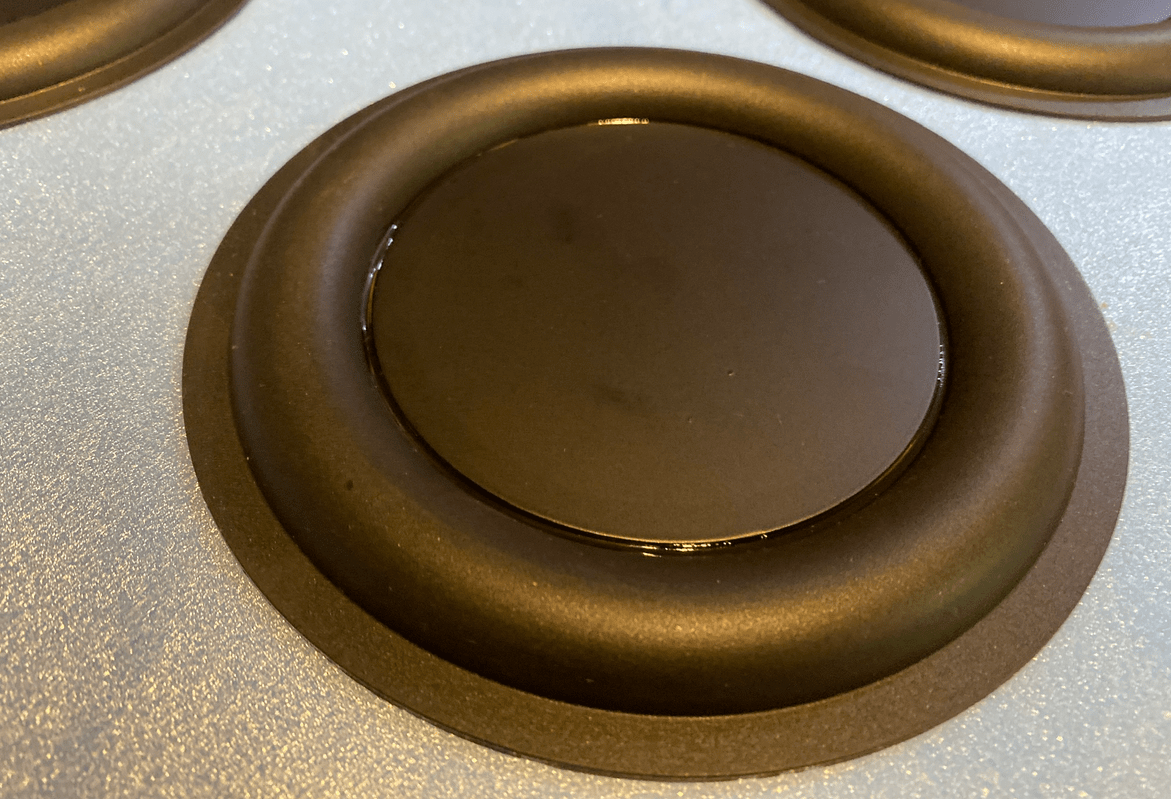

Time for an update on this. Starting development of a DIY 6" PR unit. Pictured are 4 sets for the diaphragm side ready. With FAT subwoofer type butyl rubber roll surrounds and total 70g moving mass for the surround and alloy disc. As well, the 30mm XPS foam sheet that the plugs will be CNC'd from and maybe stacked and scarfed together with foil

I will either print or CNC a custom sealed sides basket that attaches to the port tube (PVC) at either end

Things to try

Whether back to back sandwiching the foam plug or spooning

Plug lengths and diameters

Re the second point. How about replacing the air mass in the original poor aspect long resonant port with the non-resonant (audio frequencies) foam plug and tube. Sandwiching the plug in that tube with a pair of diaphragms at either end. The slight amount of air left inside this structure will act as air bearings.

Another way to think about this is a test to see if small and compliant but high excursion PR diaphragms can be connected together with a sandwich foam pushrod to cap and replace the air and the associated chuffing and resonance issues

The objective here is to bring down the price of PR systems by reducing diameter. Can such a PR based port piston replace a long and poor aspect BR air based port?

Thoughts?

I will either print or CNC a custom sealed sides basket that attaches to the port tube (PVC) at either end

Things to try

Whether back to back sandwiching the foam plug or spooning

Plug lengths and diameters

Re the second point. How about replacing the air mass in the original poor aspect long resonant port with the non-resonant (audio frequencies) foam plug and tube. Sandwiching the plug in that tube with a pair of diaphragms at either end. The slight amount of air left inside this structure will act as air bearings.

Another way to think about this is a test to see if small and compliant but high excursion PR diaphragms can be connected together with a sandwich foam pushrod to cap and replace the air and the associated chuffing and resonance issues

The objective here is to bring down the price of PR systems by reducing diameter. Can such a PR based port piston replace a long and poor aspect BR air based port?

Thoughts?

Randy,Re the second point. How about replacing the air mass in the original poor aspect long resonant port with the non-resonant (audio frequencies) foam plug and tube. Sandwiching the plug in that tube with a pair of diaphragms at either end. The slight amount of air left inside this structure will act as air bearings.

A 6" diameter port tube ~117" (three meters) long contains ~70 grams of air, a 70gram PR can replace it, without the air volume and pipe resonance of such a long tube.

That said, the Sd (equivalent piston area of the diaphragm) of a 6" diameter PR would be considerably less than a 6" diameter piston, as ~2/3 of the surround does not contribute to Sd.

The Sd of the PR exposed to the outside of the cabinet is the only part making low frequency output (SPL) around the Fb (tuning frequency).

Sounds like you are suggesting four diaphragms, surrounds and a plug of foam between them to do the work of one PR.

Any compression and rarefaction of the air between the diaphragms and surrounds will waste power and reduce their phase coherency.

Large displacement is required for low frequency output, and since the PR does most of the displacement at Fb, it needs to be around double that of the driven diaphragm since four times the displacement is required for each halving of frequency to maintain the same SPL level.The objective here is to bring down the price of PR systems by reducing diameter. Can such a PR based port piston replace a long and poor aspect BR air based port?

Sd ) times (linear) excursion = displacement.

To displace the same volume, a smaller diameter PR needs more excursion than a larger diameter PR.

A surround with more excursion costs more, and reduces Sd.

So far, seems your approach will increase the cost per displacement ratio by a large amount, the opposite of your intention.

Last edited:

But also consider that a 6" air tube will produce usable output up to 3" displacement and probably more.A 6" diameter port tube ~117" (three meters) long contains ~70 grams of air, a 70gram PR can replace it, without the air volume and pipe resonance of such a long tube.

Not sure how to get the corresponding Xmax from a PR...

Guys, not really trying to make a traditional PR here. The four flapperers are to make two sets and these four total AUD $26 not counting the foam which divides into cents per disc layer

The aim is to retain the poor aspect port, not replace it with a traditional PR. I propose to use these to cap a 2-4" dia port and connect them with a foam pushrod through the port. The SD would be greater than the port dia and represent the dia at a port flare rather than straight tube

The aim is to retain the poor aspect port, not replace it with a traditional PR. I propose to use these to cap a 2-4" dia port and connect them with a foam pushrod through the port. The SD would be greater than the port dia and represent the dia at a port flare rather than straight tube

Why waste cabinet space with a non-functional 2-4" dia port ?I propose to use these to cap a 2-4" dia port and connect them with a foam pushrod through the port.

- Home

- Loudspeakers

- Subwoofers

- Passive Radiator things