Guys, any help with this one?For a pair of rectangular PR of 270mm x 150mm, how much xmax would be required to match with a 6.5" active with 15mm xmax?

Four times the displacement is required for each halving of frequency to maintain the same SPL level.

The passive radiator should have over double the displacement of the active driver to "keep up".

Displacement equals Sd times excursion.

Xmax (linear excursion) figures are often grossly overstated.

You need to know the Sd to determine displacement.

Most decent drivers list Sd in their specifications.

Outside dimensions or nominal size (6", 8", 10" etc.) of a driver can't give an accurate Sd figure, regardless of shape.

For high excursion drivers, only about 1/3 of the surround contributes to Sd.

The smaller the driver, and the greater it's excursion, the more driver frontal area % is "wasted" on the surround.

The passive radiator should have over double the displacement of the active driver to "keep up".

Displacement equals Sd times excursion.

Xmax (linear excursion) figures are often grossly overstated.

You need to know the Sd to determine displacement.

Most decent drivers list Sd in their specifications.

Outside dimensions or nominal size (6", 8", 10" etc.) of a driver can't give an accurate Sd figure, regardless of shape.

For high excursion drivers, only about 1/3 of the surround contributes to Sd.

The smaller the driver, and the greater it's excursion, the more driver frontal area % is "wasted" on the surround.

Art, please take a look at my cub sandwich project. What do you think about turning those side panels into PR units using a custom-made roll surround? They would have a lot more Sd compared to the current 6.5" PR that is getting fitted to each

Increasing the PR Sd is not the best way to increase it's displacement in a tiny cabinet.

The larger the Sd, the more weight required to tune low.

As I wrote in #20, difficult to make a PR's Vas large (lower stiffness, loose suspension), linear at different drive levels, support the required weight and still move pistonically at high excursion.

I doubt you can accomplish the above at a lower cost than what is commercially available, but best of luck!

The larger the Sd, the more weight required to tune low.

As I wrote in #20, difficult to make a PR's Vas large (lower stiffness, loose suspension), linear at different drive levels, support the required weight and still move pistonically at high excursion.

I doubt you can accomplish the above at a lower cost than what is commercially available, but best of luck!

Might this be due to building PRs in the manner of active drivers? A custom surround for that side panel will cost me about AUD $30 but as you can see, I am trying to explore all options hereAs I wrote in #20, difficult to make a PR's Vas large (lower stiffness, loose suspension), linear at different drive levels, support the required weight and still move pistonically at high excursion

AUD $30 for a single surround is still pretty high, but "custom" has a price.

If you want cost effective, look for standard or salvaged surrounds.

Most passive radiators are built like active drivers so "off the shelf " parts can be used.

https://patentimages.storage.googleapis.com/fb/9e/c0/b3802418bf3e25/US6044925.pdf

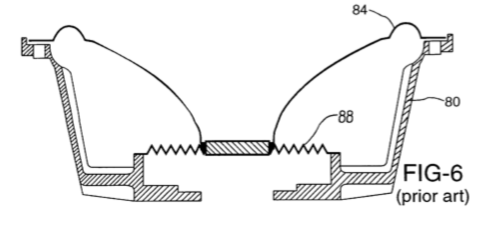

The spider and surround make a parallelogram suspension, which reduces wobbling.

A single surround won't work well with the weight of a PR under the high pressure required for large excursions.

It seems Joseph Yaacoub Sahyoun's patent for the Symmetrically Loaded Passive System (SLAPS) patent has effectively kept manufacturer's from duplicating their approach:

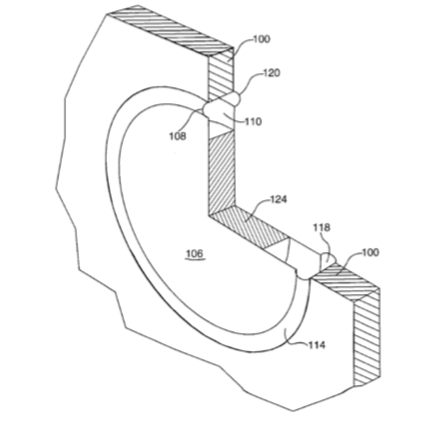

Using two surrounds, the symmetrically loaded approach could be done DIY, the diaphragm could be made of inexpensive materials.

It saves considerable internal space compared to the standard cone approach, yet still provides a parallelogram link.

That said, two identical surrounds are still not optimum, as evident by Earthquake Sound's use of various cutouts on the rear surround:

I'm sure they went though many iterations before each version was "just right".

Certainly worth comparing the removed area of the surround compared to the Sd on their various models to determine the general trend.

Some 3D printers can use Neoprene, nitrile, or polyurethane material, so DIY printed surrounds are possible, though round is still the best shape.

Cheers,

Art

If you want cost effective, look for standard or salvaged surrounds.

Most passive radiators are built like active drivers so "off the shelf " parts can be used.

https://patentimages.storage.googleapis.com/fb/9e/c0/b3802418bf3e25/US6044925.pdf

The spider and surround make a parallelogram suspension, which reduces wobbling.

A single surround won't work well with the weight of a PR under the high pressure required for large excursions.

It seems Joseph Yaacoub Sahyoun's patent for the Symmetrically Loaded Passive System (SLAPS) patent has effectively kept manufacturer's from duplicating their approach:

Using two surrounds, the symmetrically loaded approach could be done DIY, the diaphragm could be made of inexpensive materials.

It saves considerable internal space compared to the standard cone approach, yet still provides a parallelogram link.

That said, two identical surrounds are still not optimum, as evident by Earthquake Sound's use of various cutouts on the rear surround:

I'm sure they went though many iterations before each version was "just right".

Certainly worth comparing the removed area of the surround compared to the Sd on their various models to determine the general trend.

Some 3D printers can use Neoprene, nitrile, or polyurethane material, so DIY printed surrounds are possible, though round is still the best shape.

Cheers,

Art

The Slaps are my inspiration too with the dual surround suspension. Art, would you be able to make a call on a leaky PR implementation? Would that be like an aperiodic/PR hybrid? Can this be a good thing?

Leaks are not a good thing for efficiency.

An aperiodic vent reduces the impedance and response peak of an undersized sealed cabinet, or throws away some port response.

An aperiodic port has almost no acoustical mass, essentially reducing or eliminating the Helmholtz resonance.

You'd be paying for a PR and getting the response of a slightly larger sealed box.

An aperiodic vent reduces the impedance and response peak of an undersized sealed cabinet, or throws away some port response.

An aperiodic port has almost no acoustical mass, essentially reducing or eliminating the Helmholtz resonance.

You'd be paying for a PR and getting the response of a slightly larger sealed box.

Thanks for explaining that. Any other avenues of exploration to bring down the PR costs while retaining the PR system? How about another means of achieving pistonic movement? Staying with leaky for a moment, let's say a dual elastic loaded plug with air lubrication and 200mm peak to peak? The lubrication to be inserted through tunnels in the wall surface elbowing to the cab internal volume. The frame can be printed and plug machined. So as you say, losing a little bit of port response there....can this leak be exploited to functions as air bearings?

I would suggest a sensible plug or diaphragm material ... maybe air?dual elastic loaded plug with air lubrication and 200mm peak to peak?

Drawing a daybed at the moment. The resonating plug, can be drawn but wont be easy and would be a pointless excercise if the idea is without meritCould you draw that Randy?

Not until you have tamed the pipe resonance and chuffing issues....until then, a foam type might be more sensible. What say?I would suggest a sensible plug or diaphragm material ... maybe air?

Even better, a magnetic ring over two points along the plug. Ferrofluid attached to the rings for suspension/lube. This should allow massive xmax to reduce diameter and cost. If the ends of the plug are capped with a PU foam ring in the inside, they would form the stops or xlimity thingy. There might be a possibility with proportioning to have the plug naturally return to rest position when idle by exploiting effects of air compression. XPS foam can be machined and laminated with metal foil to form the plug. A true piston

So, what am I missing? Let's say the objective is to keep the plug Sd max 6" and the active driver is the 12" with 17mm xmax

So, what am I missing? Let's say the objective is to keep the plug Sd max 6" and the active driver is the 12" with 17mm xmax

Randy,So, what am I missing?

Your "piston in a magnetic pipe dream" is missing the "price performance things" that led you to make the original post 😉

Art

I haven't measured the shaft for the plug but should be around 3-5mm stainless with similar sized magnets so a few dollars on Ali, fluid is around 60c a ml with the smallest bottle size being 30ml and only a ml or two needed per magnet. Total per PR unit should work out under $30 each if a stormwater pipe section is used as housing and the mechs mounted in printed end caps. The plug to ride the shaft on a suspension of ferrofluid. I regard you guys as the educated types of folks........educated me on why this sounds like a "pipe dream"

Thats a good name for it, at least that part is sorted 😉

Thats a good name for it, at least that part is sorted 😉

Just a thought, speaking of ferrofluid:

You could try using liquid as "plug" or "oscillating weight", using water (or oil?) and an inverted siphone.

The only problem with water - the tuning will change with evaporating water ...

I might even try this myself 😊

You could try using liquid as "plug" or "oscillating weight", using water (or oil?) and an inverted siphone.

The only problem with water - the tuning will change with evaporating water ...

I might even try this myself 😊

Many, if not most musical low frequency transients are not symmetrical.educated me on why this sounds like a "pipe dream"

What keeps your "pipe dream" plug centered in the pipe?

The difference will just be fluid density. Resonances might still happen as well as splashing issues due to inertia and vortex effectsJust a thought, speaking of ferrofluid:

You could try using liquid as "plug" or "oscillating weight", using water (or oil?) and an inverted siphone.

The only problem with water - the tuning will change with evaporating water ...

I might even try this myself 😊

Sewing machine oil

Centred on which plane? Length or width? I fear we are not on the same plane hereMany, if not most musical low frequency transients are not symmetrical.

What keeps your "pipe dream" plug centered in the pipe?

Price performance, but too small for project:

Just found this amazing item on AliExpress. Check it out!

DKK2.87 15%OFF | YUXI 50*65mm Woofer Radiator Bass Passive Speaker Low Frequency Loudspeaker Diaphragm Vibration Plate DIY

https://a.aliexpress.com/_Exyw8vR

Just found this amazing item on AliExpress. Check it out!

DKK2.87 15%OFF | YUXI 50*65mm Woofer Radiator Bass Passive Speaker Low Frequency Loudspeaker Diaphragm Vibration Plate DIY

https://a.aliexpress.com/_Exyw8vR

- Home

- Loudspeakers

- Subwoofers

- Passive Radiator things