PB2 said:

I saw that the fellow selling the Shiva-X had talked about FR plots on another forum, but I didn't see them. You might ask for them and what sort of smoothing he's using.

I'd think that you could use the Shiva at least up to 200 Hz overlaping the 8" as is done in the Wilson.

A pair of these might be nice, however I would not trust the FR plot it is probably heavily smoothed:

http://www.partsexpress.com/pe/showdetl.cfm?&Partnumber=264-874

Many of the PE drivers are available in 4 ohm one in their reference line might also work for the lower mid.

I think someone already mentioned this driver, you can always pad it down, and it needs to be closer to the woofer since the bottom of its range is up on the BSC curve:

http://www.partsexpress.com/pe/showdetl.cfm?&Partnumber=294-654

People here are questioning the sensitivity numbers, Unibox calculates them from the T&S parameters which provides a sanity check for our calculations. You can even put in the midrange, or even tweeter drivers. Also put them in to determine their diplacement limited max SPL.

Pete B.

Hey, I just Uniboxed the 12" Shiva and it only performs 5Hz better (<F3) than the HF-extended Dayton unit in the same enclosure.

Now that the BSC issue is passed, I think my 250Hz/3.5kHz

W

MT

W

plan with the pair of Daytons, the Seas midrange and the Visaton ribbon is still going in the right direction............ 🙂

Though I am at this stage quite open to suggestions on alternative 90dB (2.83V/1m) tweeters for >3kHz with 100W power handling ability.

Cheers,

Glen

G.Kleinschmidt said:

Hi Pete.

For the bass-mid cross over I will likely use a 2nd order low pass witha 3rd order high pass to avoid potential nulling effects at the crossover and having to stuff around with driver phases, but for for now I have just run a series of second order LTspice sims which pretty much demonstrate in my mind that the assertion that performing the BSC entirely in the bass-mid "won't work" is a red herring (as well as the claim that the bass needs to be "blended" into the mid-range - the opposite is true).

Attached below is the start.

A pair of second order filters consisting of a bass low-pass and mid-range high-pass with f3=250Hz are drawn into LTspice and simmed.

The responses of these second order filters sum flat.

agree about the BS.

Not sure what you're showing there, they look like traditional 2nd order BUT filters, which are known to notch when wired in phase, and peak at +3dB when wired out of phase. This is a very old traditional XO. I do agree anyway no reason why this shouldn't work just fine. Did you spread the -3dB points? Didn't check carefully.

I've not read this through, can't confirm the quality but it looks fairly good at a glance:

http://www.rane.com/note160.html

Pete B.

G.Kleinschmidt said:Finally, the peaking is reduced to a neglible +1db by spreading out the filter responses about the crossover frequency (bass F3 <250Hz, mid-range F3>250Hz)

Cheers,

Glen

You've certainly got the hang of it Glen, however you've not included the acoustical response of the drivers which you must cascade in with those filters. Not a major issue, easier to do in a speaker system simulator. You certainly have the concepts covered there.

Pete B.

Eva said:

Air coils exhibit very high crosstalk between them and with anything producing or picking up magnetic fields around them. Also, ferrous stuff around them changes their value and linearity. There are no free lunches.

Thanks Eva, interesting points, I still prefer air core, very important for high powered systems. Steel laminate has shown the lowest distortion in most tests. Have you seen any recent power/distortion tests of XO inductors that we could take a look at?

These steel laminate are quite good, still not as good as air core:

http://madisound.com/catalog/index.php?manufacturers_id=139&sort=3a&filter_id=29

I'm off for the night folks. I knew you'd master this quickly Glen.

Pete B.

PB2 said:

agree about the BS.

Not sure what you're showing there, they look like traditional 2nd order BUT filters, which are known to notch when wired in phase, and peak at +3dB when wired out of phase. This is a very old traditional XO. I do agree anyway no reason why this shouldn't work just fine. Did you spread the -3dB points? Didn't check carefully.

I've not read this through, can't confirm the quality but it looks fairly good at a glance:

http://www.rane.com/note160.html

Pete B.

Doh!

You are of course right. They are Butterworth filters and I incorrectly stated that the filter responses sum flat - they don't, and that is where the peaking at the x-o is coming from.

Yes, I did reduce the peaking by spreading out the -3dB points.

Back to BSC - we are only talking about a 1st order effect over a narrow frequency range, so even with a relatively poorly implemented BSC, the results should never be that bad. Then you have to factor in diffraction anomalies and bass reinforcement for placement issues, not to mention the frequency response ripple of the driver themselves – which are much more of an issue.

Cheers,

Glen

Attachments

PB2 said:

You've certainly got the hang of it Glen, however you've not included the acoustical response of the drivers which you must cascade in with those filters. Not a major issue, easier to do in a speaker system simulator. You certainly have the concepts covered there.

Pete B.

Ok, cool. Cheers!

And I'm off to lunch...........

EDIT: the acoustical responses to the drivers I have selected extend > 2 octaves about the crossover, so even less major an issue 🙂

PB2 said:

These steel laminate are quite good, still not as good as air core:

Ferrite cores fall somewhere in between air core and metal cores. They can provide a great tradeoff between DCR, cross-modulation and of course distortion. HOWEVER that depends strongly on what type of ferrite core you adopt. Drum cores (look like bobbins) work better than the other geometries for crossovers because of the large air gap.

-Ram

G.Kleinschmidt said:What about permite?

The principle is similar - introduce lots of air gap or nonmagnetic material between highly magnetic material that can otherwise get saturated easily. Therefore Jantzen describes permite as "ferrous powder" where the binding material is nonmagnetic. Of course that binding material had better have nice nonmagnetic properties too! I have not seen hard data on permite and have not had a chance to plot a B-H curve of Jantzen's core yet.

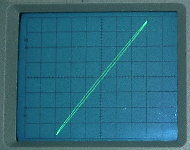

Attached is a B-H curve I obtained of a ferrite drum core. It was a 1 mH ferrite-core inductor handling 5 amps RMS @ 200Hz. Shows no signs of saturation.

-Ram

Attachments

All of the powdered iron core inductors I have ever measured have been junk. They all have an order of magnitude more distortion than a laminated steel core at low drive levels, exactly where you don't want it.

I agree that using the T/S parameters to calculate the drivers sensitivity is the best thing to do. Most software calculates the SPL at a "1W" drive level. This is because the underlying math is really calculating the drivers efficiency. If you want to know the drivers voltage sensitivity, you usually need to correct by the ratio of 8/Re. This is probably why two of the software packages listed in this thread have SPL ratings that are around 2dB different.

At NHT we usually didn't underwind the top layers of the VC to make the BL curve more linear. I think it is easier and gives better results to extend the pole piece a few mm above the top plate. When the 1259 was designed in 1992, we didn't have any magnetics FEA software. Corporate Technology at Jensen did, but the computer and software were usually tied up for the automotive customers. The tools we had for measuring BL curves were hand made and not that good.

I agree that using the T/S parameters to calculate the drivers sensitivity is the best thing to do. Most software calculates the SPL at a "1W" drive level. This is because the underlying math is really calculating the drivers efficiency. If you want to know the drivers voltage sensitivity, you usually need to correct by the ratio of 8/Re. This is probably why two of the software packages listed in this thread have SPL ratings that are around 2dB different.

At NHT we usually didn't underwind the top layers of the VC to make the BL curve more linear. I think it is easier and gives better results to extend the pole piece a few mm above the top plate. When the 1259 was designed in 1992, we didn't have any magnetics FEA software. Corporate Technology at Jensen did, but the computer and software were usually tied up for the automotive customers. The tools we had for measuring BL curves were hand made and not that good.

Jack Hidley said:All of the powdered iron core inductors I have ever measured have been junk. They all have an order of magnitude more distortion than a laminated steel core at low drive levels, exactly where you don't want it.

I agree that using the T/S parameters to calculate the drivers sensitivity is the best thing to do. Most software calculates the SPL at a "1W" drive level. This is because the underlying math is really calculating the drivers efficiency. If you want to know the drivers voltage sensitivity, you usually need to correct by the ratio of 8/Re. This is probably why two of the software packages listed in this thread have SPL ratings that are around 2dB different.

At NHT we usually didn't underwind the top layers of the VC to make the BL curve more linear. I think it is easier and gives better results to extend the pole piece a few mm above the top plate. When the 1259 was designed in 1992, we didn't have any magnetics FEA software. Corporate Technology at Jensen did, but the computer and software were usually tied up for the automotive customers. The tools we had for measuring BL curves were hand made and not that good.

Interesting Jack, the extended pole piece is a good idea but as you can see from the BL curve it is not a complete solution. Did you have rapid prototyping ability, so that you could build with say 1 - 4 turns removed, then measure the distortion vs. drive level?

I do like the 1259 and have a pair of them on each side in my best system. The system has incredible dynamics.

Probably do something with the Shiva-X next.

I also agree about powdered iron inductors.

Pete B.

Pete,

Yes, we could have done more experimentation by playing with the coil winding geometry. Most of our time was spent making the driver behave well at high excursions and getting the baseline T/S parameters where we wanted them. At some point you just have to call the product done and ship it.

Seven or eight years ago, I put the 1259 motor into an FEA program. It took all of 15 minutes to make the BL curve perfectly flat. The changes would have had zero effect on the product price. Some things just make you want to cry🙁

Yes, we could have done more experimentation by playing with the coil winding geometry. Most of our time was spent making the driver behave well at high excursions and getting the baseline T/S parameters where we wanted them. At some point you just have to call the product done and ship it.

Seven or eight years ago, I put the 1259 motor into an FEA program. It took all of 15 minutes to make the BL curve perfectly flat. The changes would have had zero effect on the product price. Some things just make you want to cry🙁

Ok guys, if I go for a cored inductor I'll try to find a steel laminate one.

A question for any of the numerous Aussies that hang out here - know of any .au distributers for Seas and Dayton drivers?

Cheers,

Glen

A question for any of the numerous Aussies that hang out here - know of any .au distributers for Seas and Dayton drivers?

Cheers,

Glen

Hmmmmmm.......

I just double checked the MHT-10 ribbon tweeter

http://www.visaton.com/en/chassis_zubehoer/ht_baendchen/mht12_8.html

specs on the manufacturers site as the 3kHz/–12dB crossover spec. stated on the distributor site looked a little low when contrasted with the FR plot – and it was.

Visaton says 4kHz/-12dB.

How about this 120W 1” dome crossed over at 3.5kHz instead:

http://www.audiomarketplace.com.au/pdfs/Morel ST728.pdf

Cheers,

Glen

I just double checked the MHT-10 ribbon tweeter

http://www.visaton.com/en/chassis_zubehoer/ht_baendchen/mht12_8.html

specs on the manufacturers site as the 3kHz/–12dB crossover spec. stated on the distributor site looked a little low when contrasted with the FR plot – and it was.

Visaton says 4kHz/-12dB.

How about this 120W 1” dome crossed over at 3.5kHz instead:

http://www.audiomarketplace.com.au/pdfs/Morel ST728.pdf

Cheers,

Glen

Back on the topic of the value of Qts and its relation to subjectively convincing bass.

I just simulated (with Unibox) the Foster 1259 12” driver as used in the NHT-3.3 – a speaker apparently renowned for its bass performance.

This speaker can deliver an impressively low F3 (30Hz easy) in relatively small sealed enclosures, but I figured that that must come at some cost elsewhere – and it does.

With a series resistance of zero ohms this driver requires a massive sealed box of 245 litres for a critically damped Qtc of 0.707.

The NHT speaker used a –12dB crossover for the 1259 with a 12mH inductor in series with a 0.43 ohm resistor.

That 12mH inductor would have to have a DCR of 0.5 ohms at least.

Simulating with a series resistance of 0.9 ohms as an optimistic ballpark figure, the required seal box volume for a Qtc of 0.707 leaps to 899 litres!

The NHT-3.3 used less that 10% this volume at 80L – which returns a whopping Qtc of 1.13, with an F3 of 28Hz.

I guess the NHT-3.3 had some pretty good fibre fill, because once the speaker lead resistance and the very significant rise in Qtc that occurs with a little voice coil heating at moderate listening levels, the figures look a lot more “boomy”.

So, a serious question: why did the NHT-3.3 designers go with such a largely under damped Qtc? - just a design compromise, or was such a low damping factor actually desired for some reason?

I can get a 32Hz F3 (only 4Hz higher than the 1259) from a Dayton RSS315HF-4 with a Qtc of 0.75 in the same size sealed enclosure with the same 0.9 ohms series resistance.

How would these compare sonically, in terms of bass below 100Hz?

Cheers,

Glen

I just simulated (with Unibox) the Foster 1259 12” driver as used in the NHT-3.3 – a speaker apparently renowned for its bass performance.

This speaker can deliver an impressively low F3 (30Hz easy) in relatively small sealed enclosures, but I figured that that must come at some cost elsewhere – and it does.

With a series resistance of zero ohms this driver requires a massive sealed box of 245 litres for a critically damped Qtc of 0.707.

The NHT speaker used a –12dB crossover for the 1259 with a 12mH inductor in series with a 0.43 ohm resistor.

That 12mH inductor would have to have a DCR of 0.5 ohms at least.

Simulating with a series resistance of 0.9 ohms as an optimistic ballpark figure, the required seal box volume for a Qtc of 0.707 leaps to 899 litres!

The NHT-3.3 used less that 10% this volume at 80L – which returns a whopping Qtc of 1.13, with an F3 of 28Hz.

I guess the NHT-3.3 had some pretty good fibre fill, because once the speaker lead resistance and the very significant rise in Qtc that occurs with a little voice coil heating at moderate listening levels, the figures look a lot more “boomy”.

So, a serious question: why did the NHT-3.3 designers go with such a largely under damped Qtc? - just a design compromise, or was such a low damping factor actually desired for some reason?

I can get a 32Hz F3 (only 4Hz higher than the 1259) from a Dayton RSS315HF-4 with a Qtc of 0.75 in the same size sealed enclosure with the same 0.9 ohms series resistance.

How would these compare sonically, in terms of bass below 100Hz?

Cheers,

Glen

use a linkwitz transform to adjust to a different Q and a different Fbox.

And accept the massive power boost required in return for these adjustments.

Most sealed box bass speakers require at least some EQ to deliver bass.

And accept the massive power boost required in return for these adjustments.

Most sealed box bass speakers require at least some EQ to deliver bass.

I was going to say, if this is a sub it's probably using a Linkwitz Transform circuit, which alters the total Q and provides a low frequency shelving boost to get a really low F3.

Simon

Simon

AndrewT said:use a linkwitz transform to adjust to a different Q and a different Fbox.

And accept the massive power boost required in return for these adjustments.

Most sealed box bass speakers require at least some EQ to deliver bass.

SimontY said:I was going to say, if this is a sub it's probably using a Linkwitz Transform circuit, which alters the total Q and provides a low frequency shelving boost to get a really low F3.

Simon

????????

The NHT-3.3 does not use a Linkwitz Transform circuit.

F3= ~30Hz is what the Foster 1259 12" sub woofer does in an 80L sealed box.

What I want to know is why the NHT-3.3 designers were happy with such under damped Qtc.

Cheers,

Glen

Glen,

The M3.3 enclosure is very thin. The outside width is 7". The inside width is just under 5". There are several shelf type braces inside the cabinet with large thru holes in them. The entire enclosure is filled with Dacron fiber.

The result of this is that the Qms of the driver in the box is lowered a lot. As the woofer moves, the air has to move through a long distance filled with fiber. This provides a lot more frictional damping. Most standard T/S simulation software assumes an enclosure Ql of 7 or so. To accurately model the 1259 in a M3.3 enclosure, you need to lower that value a lot.

A second issue are the internal dimensions of the enclosure. T/S modeling makes lots of assumptions that most people don't realize unless you have studied the original papers and the papers they were founded on. One of these assumptions is how much air load the cabinet places on the backside of drivers cone. I'm not talking about the lumped parameter compliance that the air in the box has. I'm talking about the lumped parameter mass of air that moves with the cone. In the M3.3, this value is higher due to the extremely small cabinet dimensions relative to the cone diameter. This makes the inbox Fs (Fcb) lower than the simple T/S model predicts.

The M3.3 enclosure is very thin. The outside width is 7". The inside width is just under 5". There are several shelf type braces inside the cabinet with large thru holes in them. The entire enclosure is filled with Dacron fiber.

The result of this is that the Qms of the driver in the box is lowered a lot. As the woofer moves, the air has to move through a long distance filled with fiber. This provides a lot more frictional damping. Most standard T/S simulation software assumes an enclosure Ql of 7 or so. To accurately model the 1259 in a M3.3 enclosure, you need to lower that value a lot.

A second issue are the internal dimensions of the enclosure. T/S modeling makes lots of assumptions that most people don't realize unless you have studied the original papers and the papers they were founded on. One of these assumptions is how much air load the cabinet places on the backside of drivers cone. I'm not talking about the lumped parameter compliance that the air in the box has. I'm talking about the lumped parameter mass of air that moves with the cone. In the M3.3, this value is higher due to the extremely small cabinet dimensions relative to the cone diameter. This makes the inbox Fs (Fcb) lower than the simple T/S model predicts.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Parallel driver interaction in a 4-way system.