They are starting to look very organic, like trumpet flowers. +1

Have you ever rolled over the mouth edge like a Le Cléac'h horn. ?

Have you ever rolled over the mouth edge like a Le Cléac'h horn. ?

I try to stabilize my building process, but it is very hard to resist to the appeal of creativity.

I've made this one with my inkjet paper sheets (no scotch at all 😀)... for nothing a all 🙄

Not totally useless indeed, we can clearly see the deformation problem of the water based PVA glue with the lack of support during the curing process 🙁

Edit : "rolled over the mouth" is the next part on my DIY list.

I've made this one with my inkjet paper sheets (no scotch at all 😀)... for nothing a all 🙄

Not totally useless indeed, we can clearly see the deformation problem of the water based PVA glue with the lack of support during the curing process 🙁

Edit : "rolled over the mouth" is the next part on my DIY list.

Last edited:

There is another thread using paper mache horns Building John's Paper Mache Horns and the technique at inlowsound.com . It's a lot more work for a qty=2 but allows more flexibility and maybe repeatability in wall curvatures.

Yes, i'm aware of the long and complex technique used here.

They seems to be a kind of forerunners and they've experimented a lot, but it is very easy to reduce drastically the costs and the building time.

They seems to be a kind of forerunners and they've experimented a lot, but it is very easy to reduce drastically the costs and the building time.

I agree, creating a plaster mold is time and labour intensive using a screed. I can make a polystyrene mold relatively quickly but it is a messy creation OmniDirectional - work in progress . One of those shapes matches the inside of a Dayton 10" circular waveguide.

Well, the polyurethane was my first choice but i don't know how you can have a precise profile with your artisanal lathe

The surface of the polyurethane is very vulnerable to the impacts, it is probably sufficient to your needs but not really compatible with medium sized precise horns IMO.

The surface of the polyurethane is very vulnerable to the impacts, it is probably sufficient to your needs but not really compatible with medium sized precise horns IMO.

The curve profile is calculated, graphed and printed 1:1 using excel. The curve profile is transferred to a plywood template, where a "slot" is cut to make a curve template (removable piece) that is the same as the printed curve profile. The grinder is mounted to a X-Y travel platform that has a "pin" fitted to follow the curve template. It works like a key copying machine. The cutting disc follows the curve slot reproducing the profile on the polystyrene. This polystyrene is dense, .... 🙂 at least as good as inkjet paper and bee's wax 😀

I've watched your topic yesterday, your diffusers don't need to be dimentionally accurate, the small horns is another story.

My mold parts are laser cutted, the mold is measured adjusted and rejected if necessary until the level of dimentional quality is sufficient.

The plaster cost 1.75€ for each part, i'm ready for tons of rejected parts at the beginnig of the molding process, when it is well done the mold last forever.

Edit : the bee wax is a kind of "bee *** juice", the paraffin made of petroleum.

Edit : *** = fesses, postérieur, rectum, séant, arrière train.

My mold parts are laser cutted, the mold is measured adjusted and rejected if necessary until the level of dimentional quality is sufficient.

The plaster cost 1.75€ for each part, i'm ready for tons of rejected parts at the beginnig of the molding process, when it is well done the mold last forever.

Edit : the bee wax is a kind of "bee *** juice", the paraffin made of petroleum.

Edit : *** = fesses, postérieur, rectum, séant, arrière train.

Last edited:

Edit : "rolled over the mouth" is the next part on my DIY list.

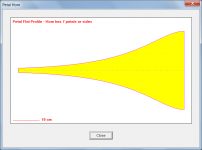

Hornresp can calculate the petal dimensions for a Le Cléac'h horn having from 3 to 20 petals, with a "rolled-over mouth" if so desired.

The attached example has 7 petals, for a horn with a mouth flare tangent angle of 180 degrees.

Attachments

Thanks 🙂

I'm not using your software because i must integrate the baffle shape in the horn flare design 😉

The expertise that i'm accumulating with my handwork and customized excel sheets is the manufacturing AND the intergration of a EJMLC paper made horn (complex challenge) with a very high profile accuracy... specific tools are uneludable.

I'm not using your software because i must integrate the baffle shape in the horn flare design 😉

The expertise that i'm accumulating with my handwork and customized excel sheets is the manufacturing AND the intergration of a EJMLC paper made horn (complex challenge) with a very high profile accuracy... specific tools are uneludable.

Hornresp can calculate the petal dimensions for a Le Cléac'h horn having from 3 to 20 petals, with a "rolled-over mouth" if so desired.

The attached example has 7 petals, for a horn with a mouth flare tangent angle of 180 degrees.

That's very interesting and useful.

How is that txt profile created in Hornresp ? I need a few hints. 🙂

How is that txt profile created in Hornresp ?

Hi DonVK,

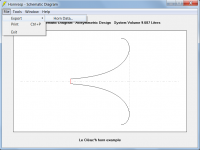

1. Select File > Export > Horn Data from the main Schematic Diagram window (see Attachment 1).

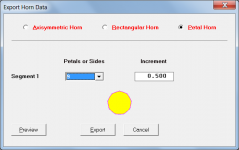

2. Select the Petal Horn option and specify the number of petals and length increment size (see Attachment 2).

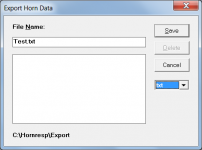

3. Click the Export button to export the horn data as a .txt or .csv file (see Attachment 3).

Hornresp has nine horn flare profiles to choose from:

* Conical

* Exponential

* Hyperbolic-exponential

* Le Cléac'h

* Oblate spheroidal

* Parabolic

* Radius

* Spherical wave

* Tractrix

Kind regards,

David

Attachments

* Conical

* Exponential

* Hyperbolic-exponential

* Le Cléac'h

* Oblate spheroidal

* Parabolic

* Radius

* Spherical wave

* Tractrix

I can't find the EJMLC 😕

Hi DonVK,

1. Select File > Export > Horn Data from the main Schematic Diagram window (see Attachment 1).

David

Thanks David, for the export instructions and making this s/w available.

I can't find the EJMLC 😕

That's because it's not there.

Good luck in trying to make an elliptical Le Cléac’h horn out of paper 🙂.

Sorry, i falls back into childhood :That's because it's not there.

Good luck in trying to make an elliptical Le Cléac’h horn out of paper 🙂.

Mike's flying scale model pages

I'm always lazy with the maths... would you add a function in your super calc sheet in order to fold a horn like this, please :

Angled and helicoidal.

Hi DonVK,

1. Select File > Export > Horn Data from the main Schematic Diagram window (see Attachment 1).

The 7 petal Le Cléac'h from cardstock. It's also posted with results at Dayton PC83-8 (3") test results. It can be compared to other designs attempted with the PC83-8.

Attachments

Man, I have some really fancy card paper here at work I'll need to print that out on. Might try it on some tweeters and piezo drivers for augmenting my mini Karlsonators.

I used dollar store foam board and cardstock, I printed the pedal 1:1 on regular paper then traced it out on the cardstock and repeat. The horn is less than $2 in materials.

Last edited:

By any chance can you export a PDF or some sort of file? I have access to a printer here at work, but not at home...

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- Paper Horn constuction