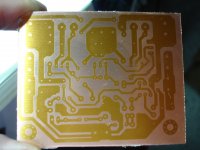

Hi Sakis .looking good so far ...

I want to try it.

I don't know if this is a functional PCB.

Has anybody test this?

It's by Alex mm of cource!

Last edited:

looks ok go ahead ...If you run in to any trouble give us a call there is many willing people here to run for help

Kind regards

sakis

PS if you have a blue print or a link of the pcb you may email it and i ca run a quick check for you

Kind regards

sakis

PS if you have a blue print or a link of the pcb you may email it and i ca run a quick check for you

Oooops on start up you might need to be careful since the original VBE transistors was BC 546 and you are using a BD 139 in this case may the VBE scheme might need a small tweak ( never tried anything like that before )

Kind regards

Sakis

Kind regards

Sakis

p3a

You have p.mOooops on start up you might need to be careful since the original VBE transistors was BC 546 and you are using a BD 139 in this case may the VBE scheme might need a small tweak ( never tried anything like that before )

Kind regards

Sakis

after a quick look seems to be Ok work with caution Miller caps are supposed to be 100pf is that the value you used ?

can you also state type and brand of capacitor ?

Kind regards

Sakis

can you also state type and brand of capacitor ?

Kind regards

Sakis

these are 100pf wima +-2.5%.after a quick look seems to be Ok work with caution Miller caps are supposed to be 100pf is that the value you used ?

can you also state type and brand of capacitor ?

Kind regards

Sakis

Just that i have

Last edited:

P3A

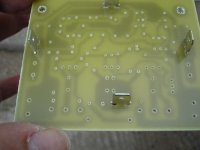

Because i dont know the type exactly look at this board ,it's same capacitor.

Wima is a brand, but what type? Is it marked MKP, MKT, MKS etc. film types?

Because i dont know the type exactly look at this board ,it's same capacitor.

Attachments

I assume you mean the green film caps which don't follow WIMA's current grade code (since 2005). WIMA

As you suggest, these will be old parts and markings. They are not all the same, but I take the "S" to mean Polyester as it has been a standard WIMA code for many years. U refers to voltage, I believe.

No doubt these work OK, like many film caps do but at 100 pF, genuine NPO/COG ceramic will be economical and likely better choices. The awful Y5 and similar ceramic grades used by a lot of DIYs though, are a complete disaster as Miller compensation caps and I can't understand why they are still used, when their data sheets show their unsuitability.

As Sakis points out, mica will be best, even if just because you can be fairly certain of the type by its physical form. Uncertainty is the enemy here.

As you suggest, these will be old parts and markings. They are not all the same, but I take the "S" to mean Polyester as it has been a standard WIMA code for many years. U refers to voltage, I believe.

No doubt these work OK, like many film caps do but at 100 pF, genuine NPO/COG ceramic will be economical and likely better choices. The awful Y5 and similar ceramic grades used by a lot of DIYs though, are a complete disaster as Miller compensation caps and I can't understand why they are still used, when their data sheets show their unsuitability.

As Sakis points out, mica will be best, even if just because you can be fairly certain of the type by its physical form. Uncertainty is the enemy here.

I don't like those green WIMA. And I don't know why, I have never been impressed by siver mica. And I don't know why, I have been impressed many times by styroflex (may be I like to hear distortion? 😀)

Jay, as someone who trys a lot of parts comparisons, what do you understand those green WIMA parts are? Looking at the size for only 100 pF, perhaps they are film/foil?

In a way that is correct for me also Styroflex was very fine from sonic/ stability /value combinations but to your surprise i will have to add that in the repair business i have seen some of them fail especially if used as miller compensations and one of them used as compensation but in bias scheme .

Have seen them fail in some Rotel and also in the Alchemist Forsetti which is a company that moved the application to polyester type and a higher grade of voltage .

Styroflex though in input filter application never presented any issues .

After that i settled with mica to stay on the safe side .

Kind regards

Sakis

Have seen them fail in some Rotel and also in the Alchemist Forsetti which is a company that moved the application to polyester type and a higher grade of voltage .

Styroflex though in input filter application never presented any issues .

After that i settled with mica to stay on the safe side .

Kind regards

Sakis

Jay, as someone who trys a lot of parts comparisons, what do you understand those green WIMA parts are? Looking at the size for only 100 pF, perhaps they are film/foil?

Internet specifies them as FKP2 (foil). This is logical as the size is a bit bigger than MKP. FKP2 I think is the smallest of their FKP series.

I have used foil caps (many brands but not those teflon class) many times with unsatisfactory result, I think because they work better for power supply bypass instead of signal coupling/decoupling.

but to your surprise i will have to add that in the repair business i have seen some of them fail

Ah, that explains why such a cheap and good sounding part is not used more often. But usually price is the major concern in business. Some companies who knows how to make good sound from cheap part will often use them. Look at Rotel, some of their mid-fi amps use WIMA MKP10 at critical position (no other amp at that class level uses such an expensive cap).

Ah, that explains why such a cheap and good sounding part is not used more often. But usually price is the major concern in business. Some companies who knows how to make good sound from cheap part will often use them. Look at Rotel, some of their mid-fi amps use WIMA MKP10 at critical position (no other amp at that class level uses such an expensive cap).

very correct also the mica i use 2% grade are way too expensive if massive production is the target ...

Kind regards

Sakis

In a way that is correct for me also Styroflex was very fine from sonic/ stability /value combinations but to your surprise i will have to add that in the repair business i have seen some of them fail especially if used as miller compensations and one of them used as compensation but in bias scheme

Styroflex is very delicate part, it is possible to damage it during soldering.

Could I use multilayer ceramics as miller caps?Because i dont know the type exactly look at this board ,it's same capacitor.

Could I use multilayer ceramics as miller caps?

Of course, if multilayer ceramic is NP0/CGO, it can be used for compensation. That's what I used for my P3A (100pF) and the sound is excellent.

- Home

- Amplifiers

- Solid State

- P3A Comparison table ( long .... )