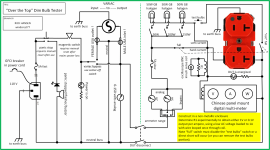

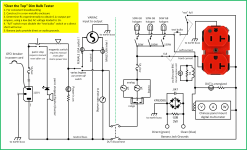

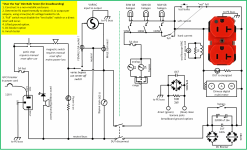

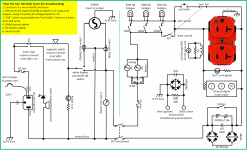

I will keep the latest schema in post #1, ignore any others in threads I have made mistakes...

I do a lot of breadboarding for fun. Currently I've just been running my Variac into a chosen step up transformer, then into a LCLCLC (secondary fused) 200ma chokes, pi filter to get 0-n DC volts choke regulated but pretty damn clean and stiff. I'm very cautious about handling, one hand in pocket, shoes on, standing at bench not sitting, and I wear tight disposible nitrile gloves as a last defense, and I set my personal limit at 500 VDC (for now) etc. But I thought I can make things even safer by improving the mains supply chain... I'm thinking of more fuses, current limiting (dim bulb), an always-present analog AC ammeter and AC voltmeter, more indicator lights of charged connection points, adding a twist-reset "panic" shut down switch, maybe a red beacon light bolted near bench indicating mains is on, etc. On the DC side I want to make a cap discharging probe with led and resistor that I can quickly use to reset things.

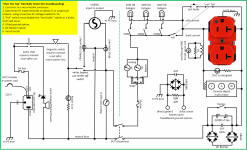

Design with the help of posters in the thread:

I do a lot of breadboarding for fun. Currently I've just been running my Variac into a chosen step up transformer, then into a LCLCLC (secondary fused) 200ma chokes, pi filter to get 0-n DC volts choke regulated but pretty damn clean and stiff. I'm very cautious about handling, one hand in pocket, shoes on, standing at bench not sitting, and I wear tight disposible nitrile gloves as a last defense, and I set my personal limit at 500 VDC (for now) etc. But I thought I can make things even safer by improving the mains supply chain... I'm thinking of more fuses, current limiting (dim bulb), an always-present analog AC ammeter and AC voltmeter, more indicator lights of charged connection points, adding a twist-reset "panic" shut down switch, maybe a red beacon light bolted near bench indicating mains is on, etc. On the DC side I want to make a cap discharging probe with led and resistor that I can quickly use to reset things.

Design with the help of posters in the thread:

Attachments

Last edited:

Fuse and switch both sides of the AC line after the IEC.

Stock several different wattage light bulbs, and multiples of each. They are becoming hard to get.

Stock several different wattage light bulbs, and multiples of each. They are becoming hard to get.

It is quite fine as is. IMO it is a nonsense a 2A fuse and a 5A ammeter. The fuse must be somewhat higher, 6A slow blow. Another nonsense is the shorting swich across ammeter. Ammeters have very low resistance, so its voltage drop is well under a volt. If a moving iron type, they support large overloasd without damage.

I have 3 of them of various power in parallel and a switch on each to use 0, 1, 2 or 3 of them at a time.Fuse and switch both sides of the AC line after the IEC.

Stock several different wattage light bulbs, and multiples of each. They are becoming hard to get.

Fuse and switch both sides of the AC line after the IEC.

Stock several different wattage light bulbs, and multiples of each. They are becoming hard to get.

Check that! I'll do a DPST household wall switch, double fuses, also I have a twist-reset (slam-down) cutoff panic button, I'll add that in series too.

Last edited:

It is quite fine as is. IMO it is a nonsense a 2A fuse and a 5A ammeter. The fuse must be somewhat higher, 6A slow blow. Another nonsense is the shorting swich across ammeter. Ammeters have very low resistance, so its voltage drop is well under a volt. If a moving iron type, they support large overloasd without damage.

I have all the NOS Simpson AC meters already 5A and 3A scales and AC volts. Yeah the meter bypass makes no sense, but I can just leave the switch open. You think I need as much as 6A surge allowance?

I have 3 of them of various power in parallel and a switch on each to use 0, 1, 2 or 3 of them at a time.

Having plug in bulbs like that is convenient, I suppose I can just keep separate 40, 100 and 150 watt bulbs around (as shown) or install 3 sockets with switching like you did. I'll have to consider the size of the enclosure.

There's no need for two fuses. I'd just use a fused IEC inlet. I wonder if the original designer wanted to rely on the 2 A fuse to protect the connected circuit. Fuses might save your house from burning down but they usually burn up after the circuit has blown up, so their use in that application is pretty minimal.

You could fuse both the live and the neutral if you want. I see that in some IEC inlets, but if you have polarized plugs I don't think that'd be of much use.

I don't like that this circuit uses a duplex outlet for the light bulb and the output. You can add all the labels you want, but at some point you'll plug it in wrong. I also generally don't like Edison-to-anything adapters. Just get a chassis mounted Edison socket for the bulb.

If you're going through the trouble of building this, I'd add an isolation transformer. 120:120 VAC at, say, 500 VA.

Tom

You could fuse both the live and the neutral if you want. I see that in some IEC inlets, but if you have polarized plugs I don't think that'd be of much use.

I don't like that this circuit uses a duplex outlet for the light bulb and the output. You can add all the labels you want, but at some point you'll plug it in wrong. I also generally don't like Edison-to-anything adapters. Just get a chassis mounted Edison socket for the bulb.

If you're going through the trouble of building this, I'd add an isolation transformer. 120:120 VAC at, say, 500 VA.

Tom

Mount that panic button well clear of any other controls (or the light bulb) so you can wack it fast, without thinking much.Check that! I'll do a DPDT household wall switch, double fuses, also I have a twist-reset (slam-down) cutoff panic button, I'll add that in series too.

Might also want a guard over the light bulb.

There's no need for two fuses. I'd just use a fused IEC inlet. I wonder if the original designer wanted to rely on the 2 A fuse to protect the connected circuit. Fuses might save your house from burning down but they usually burn up after the circuit has blown up, so their use in that application is pretty minimal.

You could fuse both the live and the neutral if you want. I see that in some IEC inlets, but if you have polarized plugs I don't think that'd be of much use.

I don't like that this circuit uses a duplex outlet for the light bulb and the output. You can add all the labels you want, but at some point you'll plug it in wrong. I also generally don't like Edison-to-anything adapters. Just get a chassis mounted Edison socket for the bulb.

If you're going through the trouble of building this, I'd add an isolation transformer. 120:120 VAC at, say, 500 VA.

Tom

Good point on the bulb adapter I'll just mount a bulb socket. I could do the isolation transformer, but usually my motus operandi is to breadboard using the power transformer I'd likely use if building the circuit for keeps, so that winds up being my isolation. The weight and size is an issue. Right now I keep all my power transformers on a lazy Suzan left of the bench so its easy to just rotate to the one I want without having to lift 8 other ones out of the way! But I'll consider a 500va toroid or triplite vs adding all that weight and size.

Mount that panic button well clear of any other controls (or the light bulb) so you can wack it fast, without thinking much.

Might also want a guard over the light bulb.

I may fabricate the enclosure to well and window the bulb somehow, so its all a flush box.

Another option is to have a separate junction box with just the light bulb and a power cord running through. Use it when you need it. I know many swear by the light bulb testers, but I never saw a need when I designed tube amps. I'd just dial up the voltage slowly on the variac. I think it only happened once that I blew the 500 mA, fast-blow fuse in it. Once the circuit is working and you're just tweaking component values or trying different topologies, there's no need for the bulb tester (IMO).

Tom

Tom

Another question, considering the size of the variac. Currently I have a 2000W 15A @ 120v Variac, the kind wood-burning hobbyists use, I think thats overkill, shouldn't have even bought it. Its huge, heavy and just too much, I'm embarrassed that I bought now.

Variacs typically come 300W, 500W, 1000W or 2000W. I'm thinking I'd enclose the variac in the case too. Would a 500W unit be good enough for most projects 3.8A max. Or would the 1000W 7.7A max be "better". The 300W sustains 2.5A @ 120v. too small? IOW I'd like to go with a "right-sized" not over-sized variac for the task of general breadboarding, as compact as I can get away with.

Also on the schematic do you think I should install a switch to bypass the variac? I think it would be handy, you'd use the variac to smoke test, then be able to quickly try out things at your house voltage without losing the setting on your variac dial. Any reasons to not do a variac/direct switch?

Variacs typically come 300W, 500W, 1000W or 2000W. I'm thinking I'd enclose the variac in the case too. Would a 500W unit be good enough for most projects 3.8A max. Or would the 1000W 7.7A max be "better". The 300W sustains 2.5A @ 120v. too small? IOW I'd like to go with a "right-sized" not over-sized variac for the task of general breadboarding, as compact as I can get away with.

Also on the schematic do you think I should install a switch to bypass the variac? I think it would be handy, you'd use the variac to smoke test, then be able to quickly try out things at your house voltage without losing the setting on your variac dial. Any reasons to not do a variac/direct switch?

Those are pic of mine. No variac in my case, and as it is fixed to the wall, no need for inlet. All 3 old fashioned at left switch connect or no one of the lamps on top. There is fourth unpluged. The outlets are under the workbench. One lamp is 300W, other is 150W and 100W. The one unplugued is 60W. The white pushbutton and the rightest switch is a latching relay for instantaneous power faults.

Attachments

I see, do you use the 300W bulb very much? If I made mine with two bulb sockets then with 40W and 60W installed it could be switched for 40, 60 or 100 watts. Install a 100W and a 60W and it could switch between 100, 60 or 160 watts. The latter to me seems like a good coverage range for what I do.

On a variac though, do people think a 500W Variac is a good compromise of size vs power? It can sustain 4.23A at my house voltage of 118v. I've never seen an Amp with a 4A fuse! Also on the addition of a variac/direct switch, good idea or bad idea?

On a variac though, do people think a 500W Variac is a good compromise of size vs power? It can sustain 4.23A at my house voltage of 118v. I've never seen an Amp with a 4A fuse! Also on the addition of a variac/direct switch, good idea or bad idea?

May be, but you will need a dual changeover shitch, else you will be shorting the variac.

Or a 3 position rotary leaving the center as off. Then the switch would exist ahead of the variac input one leg to the variac input and the other leg going around the whole variac. It would always switch to off before the changeover. A 3 position changeover switch would look cool too!

You said you already have a variac. Use it. There's no harm in using a 2 kVA model. Many 500 VA ones - especially the cheap ones on ePay - have very high wiper resistance. It's pretty frustrating to have to adjust the variac depending on the load current to get the desired mains voltage out. A 2 kVA model would have much lower wiper resistance.

Tom

Tom

If you have it, and like it, do it.I have a twist-reset (slam-down) cutoff panic button

If not: I really like these specific switches:

Woodstock D4151 110/220-Volt Paddle Switch

https://www.amazon.com/gp/product/B005W17FRS/

I have them on my heating furnace.

You may want to look for the top picture "review" for wiring and mounting hints. It won't fit a standard 1-gang box well.

This one is pure mechanical. The voltage rating is not real important.

I want the furnace to come-on after a power drop; I don't stick my hand in it casually (I do have a cheater so I can, but I keep it out of sight).

There is also Woodstock D4160 110-Volt Paddle Switch

https://www.amazon.com/gp/product/B005W17HYY/

Looks the same BUT!! has a drop-out feature!! Like if your helper kicks-out the power-saw plug, and you unknowingly put your finger in to figure the problem, and assistant plugs-in again without warning.

"Invaluable switch if you like your fingers"

This one, it loses power, it stays off until you turn it on again.

In this the hold-in coil is the rated voltage. They also come in a 220V flavor which probably won't hold on US small-circuit power.

Last edited:

Thanks PRR,

That drop out feature is nice, my table saw does that feature, requires a reset if power is lost before you can turn on the saw again. I have a couple small paddle switches around because they fit my drill press and grinder replacement. For this project I have a twist-to-reset round aluminum plunger switch like you might find on an industrial wired mobile control box.

That drop out feature is nice, my table saw does that feature, requires a reset if power is lost before you can turn on the saw again. I have a couple small paddle switches around because they fit my drill press and grinder replacement. For this project I have a twist-to-reset round aluminum plunger switch like you might find on an industrial wired mobile control box.

- Home

- Amplifiers

- Tubes / Valves

- Over the top dim bulb tester, improvements