Thanks guys!

I built the rail with acrylic tube simply because... it is very easy to drill. With my poor toolbox I can't work with hard metals. I looked alluminium tubes in my DIY store but the inner wall does not look so smooth.

At this moment I want try to understand strengths and weaknesses of this first prototype.

I won't use grease or oil; but I can easily build others rails.. so I would try something like this one Dry PTFE | ROCOL - Industrial Lubricants, Metalworking Fluids & Traffic Management.

Cheers,

Nando

I built the rail with acrylic tube simply because... it is very easy to drill. With my poor toolbox I can't work with hard metals. I looked alluminium tubes in my DIY store but the inner wall does not look so smooth.

At this moment I want try to understand strengths and weaknesses of this first prototype.

I won't use grease or oil; but I can easily build others rails.. so I would try something like this one Dry PTFE | ROCOL - Industrial Lubricants, Metalworking Fluids & Traffic Management.

Cheers,

Nando

If you want to..

You can try any lubricant you want to try and let us know what you think. As far as the guy* who designed this arm and who has been building them for about 25 years now, zero lubricant is the recommendation.

You could check around to see if you can find someone to hone the id of an aluminum tube for you or just buy one and do it yourself. Glass tube is available uses a standard glass cutter to make the slot. Or you could take a length of aluminum angle (or cut a wooden piece) and line it with window glass for the same difference. Best regards Moray James.

* Bo at Rauna of Sweden

You can try any lubricant you want to try and let us know what you think. As far as the guy* who designed this arm and who has been building them for about 25 years now, zero lubricant is the recommendation.

You could check around to see if you can find someone to hone the id of an aluminum tube for you or just buy one and do it yourself. Glass tube is available uses a standard glass cutter to make the slot. Or you could take a length of aluminum angle (or cut a wooden piece) and line it with window glass for the same difference. Best regards Moray James.

* Bo at Rauna of Sweden

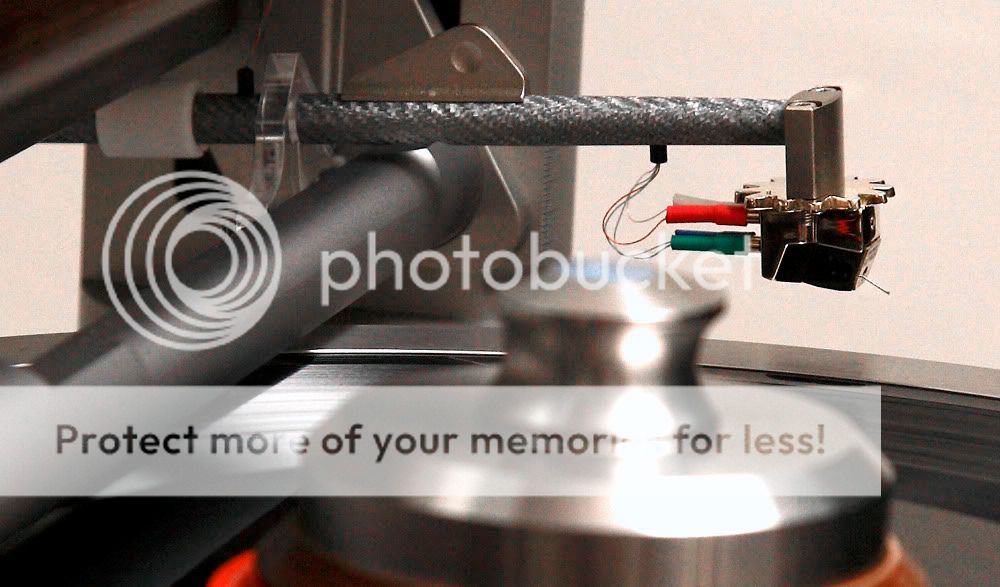

I've been working on a couple of inter-related challenges that LTs present. One is to get the vertical pivot point low and the second is that a low beam makes record changing difficult so I thought maybe a lift mechanism of some sort might be the answer. The LT with a hinged tower I posted back a couple of pages dealt with both considerations pretty well, but I thought it could be improved.

The articulated tower is my second attempt. It works pretty well, but it's complicated and the lift motion, especially with the arm at the end of the beam, is clumsy and unsatisfactory. The counter weight helped smooth the lift motion, but not enough. So on to another design which I'll post in a follow up to this one.

The third photo is of a kit I built for three friends of mine. I made the kits so they can be either bearings in a tube or wheels on a V beam. One of the friends has become LT obsessed and I haven't heard much from him since. I have a lot more respect for kit manufacturers, now. I figured out roughly how much I'd have to charge for these kits and was startled by the amount.

The articulated tower is my second attempt. It works pretty well, but it's complicated and the lift motion, especially with the arm at the end of the beam, is clumsy and unsatisfactory. The counter weight helped smooth the lift motion, but not enough. So on to another design which I'll post in a follow up to this one.

The third photo is of a kit I built for three friends of mine. I made the kits so they can be either bearings in a tube or wheels on a V beam. One of the friends has become LT obsessed and I haven't heard much from him since. I have a lot more respect for kit manufacturers, now. I figured out roughly how much I'd have to charge for these kits and was startled by the amount.

Attachments

OK, second adventure. After my experience with the articulated lift, I decided simple was the way to go. Instead of lifting the entire tower, the cam lifts the arm and the tower slides back so the beam winds up at the rear edge of the record. This arrangement is very stable - no wild, scary motions - and the beam remains level at all times. The beam and lift cam are adjustable for level and parallel.

The tolerances had to be fairly tight so I built jigs and worked as precisely as I could. The extra steps paid off.

The tolerances had to be fairly tight so I built jigs and worked as precisely as I could. The extra steps paid off.

Attachments

Bo Hansson father of Opus 3 Cantus parallel tracking arm has left us after a period of illnes on the evening of 2011-05-20.

Rauna :: Läser ämne - Bo Hansson avliden

R.I.P Bosse

Anders

Rauna :: Läser ämne - Bo Hansson avliden

R.I.P Bosse

Anders

I'm terribly sorry to hear that. His LT is brilliant and is a wonderful legacy. It was the one that got me started building LT s. The design is beautifully simple and elegant, entirely sufficient and only what's necessary - a splendid example of form following function.

R.I.P Bosse, indeed.

Damn, I'm almost in tears.

R.I.P Bosse, indeed.

Damn, I'm almost in tears.

Very sad.... Condolence to his family and friends. He certainly left a lot for others to enjoy between the arm and the music.

This is lined up for my next build....

This is lined up for my next build....

Last edited:

I cannot even begin to describe how sad it made me wen i got the call friday from a mutual friend, we all thought that he would pull through. My big mentor and inspiration in the audio world is no longer among us. Not only was he a great audio designer, thinker and friend, he was also the best acoustic recording engineer i know of!

My thoughts go to his loved ones!

R.I.P Bosse

//Anders

My thoughts go to his loved ones!

R.I.P Bosse

//Anders

Condolences to his family.Bo Hansson father of Opus 3 Cantus parallel tracking arm has left us after a period of illnes on the evening of 2011-05-20.

Rauna :: Läser ämne - Bo Hansson avliden

R.I.P Bosse

Anders

Hey I am not a German! I am Dutch.Vielen dank, Helmuth.

Then you shout say "hartelijk dank" I live close to the german border and understand write and speak German to, not very good though.

Last edited:

Helmuth,

Oh man, I've gotten in trouble for that before - a serious chewing out in Amsterdam. Serves me right for making assumptions and being a smart*ss. Thanks for setting me straight more gently than the previous person did.

Oh man, I've gotten in trouble for that before - a serious chewing out in Amsterdam. Serves me right for making assumptions and being a smart*ss. Thanks for setting me straight more gently than the previous person did.

Very sad to read this news about Bo. Best wishes and thoughts to Bo's family and friends. Best regards Moray James.

Or you can just build this. Same principles and a whole lot cheaper.

I agree. That's the point. 🙂

Great pictures!

Happy Holiday, DIYers!

- Home

- Source & Line

- Analogue Source

- Opus 3 Cantus parallel tracking arm