I am a bit confused what you want?Nothing wrong with the vituixcad or edge or Jeff bagby tools, for the purpose intended. But with more complex shapes of baffle and box a 3D fem like tool would help. I also realise the learning curve of such a tool may be blocking.

There is only so much a 2D tool can provide, so 3D problems are never possible?

Or are you referring to just the 2D shape?

I know that with Edge you can draw any shape you want, I forgot if that's also possible with VituixCAD

Ok, @b_force , understood. I use the diffraction tool from Vituixcad for an indication of the diffraction. But i am looking for a better simulation tool, so ihoped you would point me to one.

I've been using ATH+ABEC to model 3D diffraction. Very happy with the results so far.

Here are some threads that could probably help you modeling 3D diffraction: https://www.diyaudio.com/community/threads/2-way-waveguide-speaker-build-abec-modelling.357792/ and https://www.diyaudio.com/community/threads/the-abec-thread-translated.404937/

VituixCAD diffraction tool has used a simplified calculation like we used to do on paper, so it's worth using in the same context. Kimmo has discussed using a fudge factor for edges to give a reasonable approximation. Most diffraction spreadsheets over the years have done similar.What's wrong with the one in VituixCAD?

In addition and generally speaking, such a method doesn't simulate breakup. It may also narrow large drivers at higher frequencies without simulating the specific lobing variations with frequency. When we interpret broad multiple source calculations it should probably involve less focus on specific peaks and dips at some frequencies and more attention to generalised variations.

8" fans rejoice! SB29SDAC, TW29TX, and my first try with the TW29BN (6" incoming). Updated my website with these designs.

Thanks @augerpro

Happy New Year- Donation coming!

I've been tracing your graphs to look to beamwidth... Do you offer FRD files for quick prototyping?

Hi Auger,

You think your will work on a TW29RN waveguide ?

Thanks

I did work with that early on, but the response was kind of wacky in the top octave:

Would this waveguides work for a compression driver?

Just got a bambulab a1 and i want to test it.

Just got a bambulab a1 and i want to test it.

I doubt it but you never know. I think a CD would match better to one of the horns people are developing in Mabat's ATH thread. Unless for some reason you wanted a very shallow waveguide like mine.

I am no expert, but shallower waveguides are better for closer listening and not bigger areas like a concert or theater?

Also, what model do you use to generate de STL files? I tried Fusion 360 to edit them and add a 1 3/8 screw mount, but it seems not possible.

Also, are you planning a 3 or 4 inch waveguide for the Peerless/Vifa OT19NC00-04?? I would like to pair it with a 4 inch mid.

Thanks again for these waveguides!

Here are some pictures of the WG I printed in my Bambulab A1 with a generic PLA and without any optimization in the printer. It looks quite good. I am new to 3d printing, but I assume a better filament and with some optimization on the speed and temperature you could have a very nice finish.

Also, what model do you use to generate de STL files? I tried Fusion 360 to edit them and add a 1 3/8 screw mount, but it seems not possible.

Also, are you planning a 3 or 4 inch waveguide for the Peerless/Vifa OT19NC00-04?? I would like to pair it with a 4 inch mid.

Thanks again for these waveguides!

Here are some pictures of the WG I printed in my Bambulab A1 with a generic PLA and without any optimization in the printer. It looks quite good. I am new to 3d printing, but I assume a better filament and with some optimization on the speed and temperature you could have a very nice finish.

Attachments

Last edited:

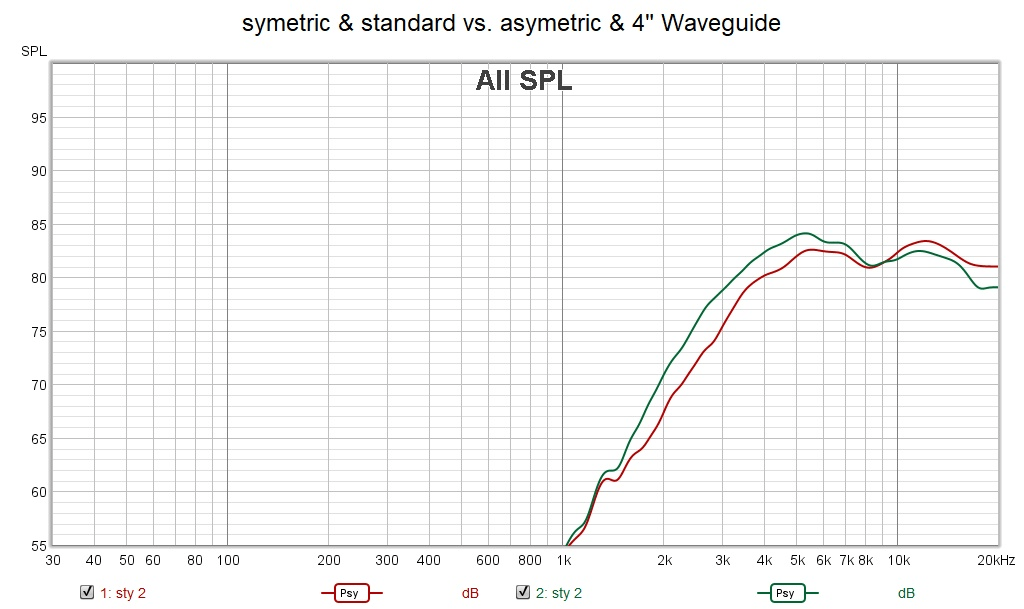

I printed 4"x.65 waveguide for my SB Textreme but results I am getting on top octave are warring me

Measurements from ca. 1m. One is without waveguide and one line with the waveguide. There is visible and clearly audible drop in energy on high frequencies.

Any idea why I am losing so much SPL? The driver suspension doesn't looks like is touched by waveguide.

Measurements from ca. 1m. One is without waveguide and one line with the waveguide. There is visible and clearly audible drop in energy on high frequencies.

Any idea why I am losing so much SPL? The driver suspension doesn't looks like is touched by waveguide.

mga2009> Looks like the important part printed nicely, but you should be able to get cleaner holes. I would like to make smaller waveguides for the little Vifa, but I just don't have time at the moment. Maybe next fall I will. I use Fusion 360. You might have better luck using the .step file and modify that. What you are trying to do should possible I think, but I don't modify .stl ever so I'm not sure how you go about it.

rafabro> yes that is problem when designing waveguides for domes that were not designed with waveguides in mind. Given the sensitivity, this should not be a problem. I hope you are going to flush mount it? That dip in both measurements is likely due to the surface mounting.

rafabro> yes that is problem when designing waveguides for domes that were not designed with waveguides in mind. Given the sensitivity, this should not be a problem. I hope you are going to flush mount it? That dip in both measurements is likely due to the surface mounting.

Absolutely in the final baffle it will be flushedrafabro> yes that is problem when designing waveguides for domes that were not designed with waveguides in mind. Given the sensitivity, this should not be a problem. I hope you are going to flush mount it? That dip in both measurements is likely due to the surface mounting.

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!