hi pcgab,

last questions about woodwork:

how many watts has your router?

the circle guide is an accessory sold separately? how much it cost?

last questions about woodwork:

how many watts has your router?

the circle guide is an accessory sold separately? how much it cost?

I can make a pass with the router, jump a few spots down the circle guide, route, repeat, until I get to the final mark.

Why don't you use a larger router bit and do it in one pass? Do the small bits have any advantage over the large ones?

hi pcgab,

last questions about woodwork:

how many watts has your router?

the circle guide is an accessory sold separately? how much it cost?

The router is 1678 watts / 2.25 hp. It's the Bosch 1617 EVSPK I believe. Personally I have the MRC23EVSK, which is also an excellent router.

The circle jig looks like a Jasper circle jig, works very well. Not 100% sure which model pcgab has 🙂

mbrennwa, generally I have found that larger shank router bits will result in a better cut, but good results can be achieved with smaller ones as well as we can see from pcgab's excellent work here. The most important thing equipment-wise is to buy a high quality bit in my opinion, and to make sure you're using it properly (correct speed on your router, which I determine with scrap and trial and error). Personally, all my bits are Whiteside and CMT. I prefer the Whiteside ones slightly because I find I get somewhat better/cleaner cuts with them.

The router is 1678 watts / 2.25 hp. It's the Bosch 1617 EVSPK I believe. Personally I have the MRC23EVSK, which is also an excellent router.

The circle jig looks like a Jasper circle jig, works very well. Not 100% sure which model pcgab has 🙂

mbrennwa, generally I have found that larger shank router bits will result in a better cut, but good results can be achieved with smaller ones as well as we can see from pcgab's excellent work here. The most important thing equipment-wise is to buy a high quality bit in my opinion, and to make sure you're using it properly (correct speed on your router, which I determine with scrap and trial and error). Personally, all my bits are Whiteside and CMT. I prefer the Whiteside ones slightly because I find I get somewhat better/cleaner cuts with them.

The bit I used to cut those is Whiteside, they make great bits.

Pretty sure that's the model router I have, and it is a Jasper circle jig. 'Jasper 200J Model 200 Circle Cutting Jig for Plunge Router'

I used that bit, a 1/4" cutting diameter bit because it was recently sharpened and it is a spiral down cut, which tends to leave the top face a bit cleaner. When I'm cutting work material that's clamped to a sacrificial top on my bench, I prefer the spiral down cut bit. This generally allows the cuts to be executed so that both end up with clean edges.

Cheers,

Gable

Why don't you use a larger router bit and do it in one pass? Do the small bits have any advantage over the large ones?

They don't have any real advantage in this use case. It was simply what I had available that was sharpest. For a small recess like this, 16-18mm IIRC, it only takes a minute or so to make multiple passes, so it's not terribly inconvenient.

Cheers,

Gable

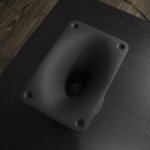

I wrapped up the insert for the TD8, got it flush like I wanted.

The mounting ring has a slight flare that makes the transition from cone to baffle even more smooth. Very well thought out driver.

Yes, my machinist square is dirty, I could sand it clean, but there's more important things in life..... single malt comes to mind. 😀

Gable, That looks awesome 🙂

Cheers.

I recieved the other HF107 over the weekend, it has been shipped in different packages but the guys at speakerdirect were very helpful.

HF107 looks very well built as you would expect from Faital, it is a big CD and has some weight to it, I dont have my DATS with me at the moment, but we will do some measurements soon.

what was more impressive was build quiality of STH100, solid aluminum piece (casted of course) looks heavy duty, I will post some pics 😉

HF107 looks very well built as you would expect from Faital, it is a big CD and has some weight to it, I dont have my DATS with me at the moment, but we will do some measurements soon.

what was more impressive was build quiality of STH100, solid aluminum piece (casted of course) looks heavy duty, I will post some pics 😉

I recieved the other HF107 over the weekend, it has been shipped in different packages but the guys at speakerdirect were very helpful.

HF107 looks very well built as you would expect from Faital, it is a big CD and has some weight to it, I dont have my DATS with me at the moment, but we will do some measurements soon.

what was more impressive was build quiality of STH100, solid aluminum piece (casted of course) looks heavy duty, I will post some pics 😉

Sorry for the delay on the 1pc. Yeah. Those horns are beauties! Oh yes, and its SpeakerAddict 😎

Check out the top end on the new hf111

FaitalPRO | HF Drivers | HF111

Also, we can work out a group buy on the drivers for the project if many people want to build some. Just brought in a couple pallets of mylar caps, air core coils and resistors as well

hey speekas, that is good news, thanks for the support🙂

I m busy with the holidays and I imagine others are as well, I haven't done much recently, Gable(pcgab) had plans for holidays as well as far as I know, we will be back on the track after holidays 🙂

I m busy with the holidays and I imagine others are as well, I haven't done much recently, Gable(pcgab) had plans for holidays as well as far as I know, we will be back on the track after holidays 🙂

HF111 looks really smooth.

Not the same low end as the HF107, but it does seem more "well behaved", resonant behaviour is reduced down low, might work well to 1800hz with a 4th order filter?

But 3rd order at 2200-2600hz might be better.

Not the same low end as the HF107, but it does seem more "well behaved", resonant behaviour is reduced down low, might work well to 1800hz with a 4th order filter?

But 3rd order at 2200-2600hz might be better.

ughh, very anxious to do so, but it is a very busy time and I better take my time on this.

I try to get the parts needed little by little, and for damping material I was think about car damping sheets to cover the walls (aside from damping wool) or

Acry-Tech Acoust-X 1 Gallon Absorption Coating Paintable Damping Material.

any experience with Acoust-X stuff ?

I try to get the parts needed little by little, and for damping material I was think about car damping sheets to cover the walls (aside from damping wool) or

Acry-Tech Acoust-X 1 Gallon Absorption Coating Paintable Damping Material.

any experience with Acoust-X stuff ?

- Home

- Loudspeakers

- Multi-Way

- Open Source "Tower XL"