Paul W said:Yes, 2 sealed 15" should be enough. Here is something to consider if you think you might ever use 15" higher in frequency...even the RCF drivers with shorting ring (LFX) have fairly high Le compared to models from BMS and 18 Sound.

Maybe you remember, you were the one who originally pointed me to BMS 🙂. I have been working with the 18N850 on and off for the past few months and like it...my only issue with the 18N is the high MMS which needs a heavy baffle for vibration control.

Yep. The mms issue crossed my mind as well. More output from more linear excursion but I'm not so sure do I need it. 15" model of 18N850 is darn expensive here.

Many of the pro woofers will work in small boxes, so you have several options if that is the direction you go. If you eventually want to try dipole, you could stack multiples vertically in about the same floor space as the high WAF baffles.

Yep. I think I'll have to settle to the brands I can invest from here. No point to use some other and pay all the shipping costs. Plenty of options in local market.

There are some good features in a big dipole stack. For example my panels are about 130-135cm (51-53") tall. With compact setup it's possible to use four 12" SLS woofers in vertical line. For example S-baffle which is basically half of W. Or double that and use eight 12" SLS on each side in regular W-baffle or "crankshaft". But such configurations run pretty large. The advantage would be vertical directivity. But the cavity resonances cause some problems and limit usable range. And personally I don't like the looks of a box that is wider than its deep unless it's very flat like a panel.

One option is to use forward firing woofers in vertical line using flat panel. It doesn't allow push-pull or force cancellation operations but doesn't suffer from resonances and therefore allow at least 100Hz 2nd order cross. I guess it has to be crossed pretty low since it starts to behave like a linesource at some point and that's pretty different than the radiation pattern to other ranges. But that totally fixes that floor bounce problem. Large overlap area with separated woofers in tall panel. 130-135cm would allow four woofers on each side. Place them along the sidewall and point towards listener. Wall acts as a mirror source adding 6dB more output without messing up anything. This "double-D" doesn't allow very wide baffle before it runs out of dipole operation. For example 350mm wide baffle acts as 700mm wide baffle along the wall which changes its behavior at higher frequences. But that's also an advantage. I don't have that much space between mains and the wall and the mains definitely need some space to breath. Visual appearance could be very similar to my mains. Flat plain baffle, black cloth, nice contrast and heavier spine since rear radiation isn't messed with those wavelenghts.

Allthought it makes pretty large system visually. Even if both panels are very flat. 350mm wide woofer panel along the wall, a small gap and a another 340mm wide main panel in the inside. Basically a 700mm wide wall along both sidewalls. Looks massive even if it isn't ...

Darn. Have I thought my main panels all the way through?

Using two long throw 12" woofers or even 15" woofers on each side would allow mains to act on their own without sub or dipolesub assistance. But both solutions make overall main panel appearance much heavier since structures have to be optimized to heavier drivers, more mms and more vibrations. In this size room it gets pretty dominating... And using larger woofers in larger panel doesn't allow to run them as high as I can use these 10" woofers which messes up some of my thoughts about vertical directivity. I think I have a solid packadge down to 80Hz or so. Below that, well, still solid but less usable output. What do use below 80Hz?

Jussi

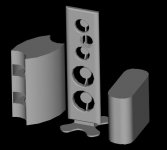

Here is a 3D model from both main panels "production" scetch and mensioned crankshaft woofer system side by side. Crank is turned 30 degrees outside as it would be along the sidewall while main is toed towards the listener.

It's pretty much as compact as it can be and holds four 12" SLS woofers with plenty of output for my needs. But it also looks pretty bulky and big. Unfortunately. And it doesnt help things that they have to be placed pretty much like this.

There is also a Minos style monopole. Just for comparison. Big enough to hold for example RCF LF15G401 in closed environment.

Jussi

It's pretty much as compact as it can be and holds four 12" SLS woofers with plenty of output for my needs. But it also looks pretty bulky and big. Unfortunately. And it doesnt help things that they have to be placed pretty much like this.

There is also a Minos style monopole. Just for comparison. Big enough to hold for example RCF LF15G401 in closed environment.

Jussi

Attachments

Some progress. I got the main panel frame and floorplate cleaned, welded and painted today. Looks good so far. I didn't measure them but they sure weight pretty darn much. And adding the floorplate decreased ringing. I guess that narrow spine should improve things even more. Setup is also stable at the floor. With the drivers, woodpanels and all it should be very stable. Mission accomplished so far. Unfortunately no new pics.

Jussi

Jussi

To me the best floor space saving OB bass would be to go with vertical manifolds using 8 KEF B139's per side (or on a budget the right car audio 6x9's). Then you can pack a lot of Sd into very compact forms and take advantage of vibration cancellation and push/pull. Plus the resulting shallow cavity depths would allow use at least an octave higher than manifolds using larger drivers.

Jussi,

what sort of roundover are you using on the edges? Nothing as Hi-tech as your steel panels here, just old fashioned MDF sheet & MDF rounds for my main panel test baffles. Oh yeah, and masking tape LOL.

Should serve the purpose 😉 .

Cheers,

AJ

what sort of roundover are you using on the edges? Nothing as Hi-tech as your steel panels here, just old fashioned MDF sheet & MDF rounds for my main panel test baffles. Oh yeah, and masking tape LOL.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Should serve the purpose 😉 .

Cheers,

AJ

johninCR said:To me the best floor space saving OB bass would be to go with vertical manifolds using 8 KEF B139's per side (or on a budget the right car audio 6x9's). Then you can pack a lot of Sd into very compact forms and take advantage of vibration cancellation and push/pull. Plus the resulting shallow cavity depths would allow use at least an octave higher than manifolds using larger drivers.

I'm not familiar with KEF B139. Is it 8" woofer? Peerless SLS 8" might work nicely. Need more but can be placed more freely. Flatter structure also allows narrow W-baffles.

AJinFLA said:

what sort of roundover are you using on the edges? Nothing as Hi-tech as your steel panels here, just old fashioned MDF sheet & MDF rounds for my main panel test baffles. Oh yeah, and masking tape LOL.

Metal frames are just sharp edged frames. No curves on them. But the woodpanels on top are rounded. Sides have 25x50mm elliptic roundover while top and bottom have 20mm radius curves.

So the system looks symmetric from the top. No gentle "U" or similar like your prototypes have.

Jussi

Too long thread to read it at once 😎

Jussi, just a question - how do you mount drivers into the dipole cabinet? The openings seems too small. 😉

Jussi, just a question - how do you mount drivers into the dipole cabinet? The openings seems too small. 😉

I do not think so. Standing waves can occur between two surfaces with arbitrary shape and mutual position. With nonparallel surfaces standing waves are spread in frequency, but still exist.Standing waves are pretty simple thing to optimize. ...... As you know standing waves can occur only between two surfaces in the same direction. ......

It is really too simplistic model and could be true sufficiently below the panel's resonant frequency which will be low. For all this panel resonances can add nonlinear distortion, but IMO not in the way you wrote.Other related problem is panels modulation problems. Panel shouldn't shake at all to keep drivers operation linear. There isn't that much use to have low distorsion driver motors and pistonic cones if whole system shakes and modulate signal. I once calculated one very pessimistic model of this problem. Lets consider panel is 100% stiff and 100% of drivers motion is transfered to move the whole panel. My panel is about 130 x 34cm. That's 4420cm2. Install couple 10" woofers on it. That's 660cm2 leaving 3760cm2 bare panel surface. So 660cm2 should be creating sound and 3760cm2 should be totally quiet. Calculating relation to there it means that moving 660cm2 cones 1mm forward panel has to move just 0,17mm back to cancel whole sound.

Like said. This is very pessimistic model. Panel isn't 100% stiff, it doesnt create 100% modulations and so on. But the problem is there. Just think how small 1" domes movements are. And how messed up it's sound is if the panel rocks even small amounts. Modulation distorsion.

x-over frequency?

AJ,

What crossover frequency are you using between the MTM and your (sub)woofer(s)? Are those 7" or 8" drivers?

Reason I ask is that I'm currently working on a 8" MTM using the Dayton RS225 drivers, and I hope to get it as low as 70 Hz, LR4, but I'm not too sure the drivers will handle it very gracefully. I don't listen very loudly, and I'm thinking that with 70 Hz I can have most of the dipole benefits (in the midbass) and then cross to stereo monopole sealed subwoofers for the rest... so I need to determine the optimum depth of the wings so that I don't have resonance issues but so that the 8"ers can also get low enough.

I'm crossing at 190 Hz (also LR4) to a Manger driver, and so U-frame resonance is going to be precariously near, so I'll be splaying the U-frame to the point where it'll be a 9" baffle with the wings at a significant angle (maybe 20 degrees), approximating a V shape with the front flattened out for the drivers.... I also hope this doesn't inadvertently horn-load the rear wave.

My apologies for the hijack.

thanks,

-tal

ps: feel free to email me... would love to discuss offline

AJinFLA said:Jussi,

what sort of roundover are you using on the edges? Nothing as Hi-tech as your steel panels here, just old fashioned MDF sheet & MDF rounds for my main panel test baffles. Oh yeah, and masking tape LOL.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Should serve the purpose 😉 .

Cheers,

AJ

AJ,

What crossover frequency are you using between the MTM and your (sub)woofer(s)? Are those 7" or 8" drivers?

Reason I ask is that I'm currently working on a 8" MTM using the Dayton RS225 drivers, and I hope to get it as low as 70 Hz, LR4, but I'm not too sure the drivers will handle it very gracefully. I don't listen very loudly, and I'm thinking that with 70 Hz I can have most of the dipole benefits (in the midbass) and then cross to stereo monopole sealed subwoofers for the rest... so I need to determine the optimum depth of the wings so that I don't have resonance issues but so that the 8"ers can also get low enough.

I'm crossing at 190 Hz (also LR4) to a Manger driver, and so U-frame resonance is going to be precariously near, so I'll be splaying the U-frame to the point where it'll be a 9" baffle with the wings at a significant angle (maybe 20 degrees), approximating a V shape with the front flattened out for the drivers.... I also hope this doesn't inadvertently horn-load the rear wave.

My apologies for the hijack.

thanks,

-tal

ps: feel free to email me... would love to discuss offline

Those are 10" Daytons & a JBL 5" aluminum mid/1" titanium compression driver coax. I don't do MTM. The MCXM 😉 panel will run above 100hz.

I will start a seperate thread when I have more to show as not to hijack this one anymore.

I would not advise running 8" with limited diplacement drivers to 70hz dipole. You don't want you driver anywhere near xmax at normal operation output.

John K has a setup you may want to look at http://www.musicanddesign.com/NaOMini.html

Read his technical studies also, especially the one about crossing between dipole/monopole.

Start a seperate thread for your manger 😉

I'm not quite understanding the setup.

cheers,

AJ

I will start a seperate thread when I have more to show as not to hijack this one anymore.

I would not advise running 8" with limited diplacement drivers to 70hz dipole. You don't want you driver anywhere near xmax at normal operation output.

John K has a setup you may want to look at http://www.musicanddesign.com/NaOMini.html

Read his technical studies also, especially the one about crossing between dipole/monopole.

Start a seperate thread for your manger 😉

I'm not quite understanding the setup.

cheers,

AJ

MethMan said:Jussi, just a question - how do you mount drivers into the dipole cabinet? The openings seems too small. 😉

They would have to be mounted while piling the whole thing together. Leave construction open which makes it weaker or build solid and loose possibilities to change drivers.

I do not think so. Standing waves can occur between two surfaces with arbitrary shape and mutual position. With nonparallel surfaces standing waves are spread in frequency, but still exist.

Yep but I remember conversation about bass cabinets. And if slots in the cabinet are small enough compared to played frequency there are no such problems. Naturally slots run way too small at some point so it doesn't apply to midrange.

In midrange application it's possible to use angled plates to get the bounce around the cabinet long enough before reaching cone or other exit. With fully stuffed cabinet most midrange frequences are damped before running out of the box.

But naturally this is just one problem. Cabinet vibrations, radiation pattern...

It is really too simplistic model and could be true sufficiently below the panel's resonant frequency which will be low.

Like mensioned:

"This is very pessimistic model. Panel isn't 100% stiff, it doesnt create 100% modulations and so on."

But the problem is there. Some time ago I build a small 2-way using 5" midwoofer and 20mm tweeter. Crossed around 3500Hz 2nd order, tuned to 60Hz or so. Used 22mm MDF for it with internal brace between midwoofer and tweeter. And there still is considerable amount of vibrations in the cabinet. Easy to feel around the midwoofer while playing "loud" (compared to systems reasonable output). And while I can feel it with my hand there is way too much vibrations to mush the sound. Quickly estimated twice the conearea of sidewalls and front panel was shaking. Not like the cone of cource but considerable amount.

I don't think any cabinet, box or panel, can be made overdamped. Naturally this runs into new problems. Installing 5" driver into a cubic meter block of concrete doesn't vibrate that much but makes 2-ways pretty bulky and ruines some other ideas like acoustic resistance cabinet and such. Same with panels. My present construction is 50mm thick and I know I can't reach similar stiffness with same thickness without using more than MDF. And while good acoustic-mechanical operation is desirable combined to elegant and high WAF outlook there isn't that many ways to do it ...

Shame well build (I don't consider mine well build, not yet anyway since I don't have any proof how it really behaves) constructions are so rare. Personally I consider cabinet structure pretty important and most problems are measurable data. Distorsion, CSD and in worst cases responses.

Jussi

Packadges arrived. Seems like I'll have a very busy chrismas holiday. 🙂

Woodpanels fit like a glove. Simply perfect. All curves are like they should be and the whole thing weights like hell. 😀

Merry Chrismas to me. And to you as well. 😉

Jussi

Woodpanels fit like a glove. Simply perfect. All curves are like they should be and the whole thing weights like hell. 😀

Merry Chrismas to me. And to you as well. 😉

Jussi

Attachments

Wow, lucky guy

Those look great! I don't anticipate much by way of baffle resonance there, the only weak point I'd see would be the coupling from the foot to the panel, but being thick steel, should be pretty strong 🙂

Those look great! I don't anticipate much by way of baffle resonance there, the only weak point I'd see would be the coupling from the foot to the panel, but being thick steel, should be pretty strong 🙂

Re: Wow, lucky guy

Construction actually lacks that spine I added to my scetches some time ago. I can add them later if the overall configuration and mainly midrange polar behavior satisfies me. That should make the whole thing much more rigid.

Jussi

badman said:Those look great! I don't anticipate much by way of baffle resonance there, the only weak point I'd see would be the coupling from the foot to the panel, but being thick steel, should be pretty strong 🙂

Construction actually lacks that spine I added to my scetches some time ago. I can add them later if the overall configuration and mainly midrange polar behavior satisfies me. That should make the whole thing much more rigid.

Jussi

Kensai said:Coming together, eh? They're looking nice.

Bit by bit. Measurements look promissing, some complications with the tweeter.

Jussi

Attachments

Looks like tweeter complications force my Esotars to retire from this project. Shame. I assume the dome profile is incompatible with the waveguide causing stored energy and twinkled response problems.

Ribbons? Seas aluminiums? Vifa XT? Accutons?

Jussi

Ribbons? Seas aluminiums? Vifa XT? Accutons?

Jussi

What about the Eton air motion tweeter? You might have to make a specialized mount for it to fit in the waveguide area, but otherwise should do really nicely.

Member

Joined 2003

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Open baffle 4-ways under construction