Why am I responsible for submitted a better design?. . . . . I have no idea why this has become a "design something better" challenge.

You obviously know your horn theory and you put a lot of time and thought into this subject. So my retort is "why not try to design something better?"

To me, that is what this is all about - trying your best and seeing what happens. If Mr. Danley and his friends hadn't stuck their necks out and designed the LabHorn, we might still be stuck with those Cerwin-Vega FLH's as being the epitome of high performance speaker design. This is your golden opportunity to take your knowledge to the next level. You might lose a couple of teeth in the process, but once the dust settles I think you will be glad you made the attempt.

And beware, I am suddenly getting the desire to try designing a FLH myself, and I am sure you don't want me doing that. So please, save me some embarrassment and you go first.

Because you seem to think your changes in Hornresp inputs constitute a "design", while having demonstrated no certain way to improve the actual cabinet design, then defend your simulation as if it actually demonstrated an improvement.

I did not present a design at all. I simply showed the Hornresp results of the original design (before folding) and then an approximation of the folded design with and without a properly sized rear chamber (50 liters as called for by the original design vs 40 liters in the plans) and an end loaded vs offset driver. The only improvement I suggested was to actually build the original design as designed or change the sim to reflect an offset design.

I did not present any original design work here and I don't have any design to defend.

Reducing output at the impedance and excursion minima, while increasing output at the upper excursion maxima does not translate to less heat in a Lab 12 when power is turned up and the coil heats up.

An externally hosted image should be here but it was not working when we last tested it.

The ONLY difference in these two responses is 2 ohms added Rg in the lower response curve. The dip absolutely does get worse with power compression. Not terribly worse but it was bad enough to start with. I didn't say anything about less heat, just that power compression will make the saddle deeper.

Even if a re-designed cabinet conforming to your simulation did happen to do what you think it would (which based on observations of measured cabinets of this horn geometry, probably won't), it may not be a net improvement.

I'm not sure what you are saying. You think you can cut your rear chamber size by 20 percent and offset an end loaded horn with no consequences? Or you don't trust simulations? Or are you talking about the power compression issue? Either way, I don't think it matters. If you accurately build what you simulated, the measurements should be very close to the simulated response.

Last edited:

And beware, I am suddenly getting the desire to try designing a FLH myself, and I am sure you don't want me doing that. So please, save me some embarrassment and you go first.

Thinking it over, I get the impression that FLHs, like sealed alignments, are contra-indicated for modern low-frequency output at PA levels. The availability of very good drivers and high-power, high-efficiency amplifiers at reasonable costs means that you no longer have to accept having to build and use a very big complicated box to produce low frequencies at high SPL levels. So designing a FLH for that purpose, while that may be nice to see what the theory can come up with, may not actually serve any practical purpose.

I did not present a design at all. I simply showed the Hornresp results of the original design (before folding) and then an approximation of the folded design with and without a properly sized rear chamber (50 liters as called for by the original design vs 40 liters in the plans) and an end loaded vs offset driver.

Does that dip get filled in if the chamber is sized correctly?

If so, this should be a fairly easy mod to make to an existing LAB12 to confirm the result - replace the access panels for the drivers with bolt-on chambers that provide the additional volume that's required. Surely it shouldn't take long for one of the existing LAB12 owners here (if there are any left) to fabricate and test something like that.

You obviously know your horn theory and you put a lot of time and thought into this subject. So my retort is "why not try to design something better?"

1. The problem here is not the design, it's the fold. If I were to attempt something better the design process would be pretty much the same as the Labhorn's design process except the folding part. In an attempt to do better I would simply raise the flare T and hope the drivers could handle it, and then accurately fold what I simulated.

2. Nobody is interested in having me actually do an original design, and even if they were no one is going to build and measure my design so what's the point? This "design challenge" is an attempt by others to make me prove to myself that the Labhorn can't easily be beat. I already agreed that with the exception of the saddle it's a great design and can't easily be beat without raising the compression ratio or using more modern drivers. I've already done the work.

The LAB12 was good in it's day but it has serious thermal issues compared to modern drivers. It's not worth building a design around anymore if you can afford something like B&C. The LAB12 is ok for low tuned designs but not for something tuned as high as the Labhorn where the limitations are thermal and not excursion related.

And beware, I am suddenly getting the desire to try designing a FLH myself, and I am sure you don't want me doing that. So please, save me some embarrassment and you go first.

I DO want you to do that. I will help you do that. Everyone should do that. It's good clean fun.

Does that dip get filled in if the chamber is sized correctly?

Only partially. I showed the effect of the undersized chamber in post 27, as well as the effect of simulating as end loaded but folding as offset, and then the cumulative effect of both.

http://www.diyaudio.com/forums/subw...-horn-vs-modern-vented-box-3.html#post3795195

This end loaded vs offset issue was a big problem 15 years ago, everyone was doing it. Parham did the same thing in his Hornresp study of the Labhorn too, which is probably why his own 12Pi didn't fix the issue, and I think the Labhorn 2 and 3 (by different designers) also did the same thing. Akabak was required back then to simulate offset driver horns and not many people used it.

Last edited:

Thinking it over, I get the impression that FLHs, like sealed alignments, are contra-indicated for modern low-frequency output at PA levels. The availability of very good drivers and high-power, high-efficiency amplifiers at reasonable costs means that you no longer have to accept having to build and use a very big complicated box to produce low frequencies at high SPL levels. So designing a FLH for that purpose, while that may be nice to see what the theory can come up with, may not actually serve any practical purpose.

Regardless of frequency the pros and cons are the same. Horns use more space but less drivers and amp power to accomplish the same thing as other alignments. The tradeoffs are up to the designer and end user to choose.

I dont know many people (on this forum or otherwise) who can afford to build 8 "pk sound" subs here (16x800 dollar drivers plus 4 x 1200 amps). I do suppose some people at least can afford half that number of drivers (and amps) and bang out 8 tapped horns, or 8 FLHs to cover the same frequency response (flat to 35 with a 30hz filter) ESPECIALLY considering at the most, a Front loaded horn will be 33 percent larger than the PK box (and offer more output) and there are 2 well documented tapped horn designs here that have similar freq resp and output that are actually smaller than the PK sound vented alignment.

Only partially. I showed the effect of the undersized chamber in post 27, as well as the effect of simulating as end loaded but folding as offset, and then the cumulative effect of both.

You mentioned that your sim has the offset placed to far in comparison to the built system, due to HornResp limitations. Perhaps the impact of the actual offset on the dip is not as great as the sim suggests.

The suggestion that the LAB12 lost 100 liters when folded is interesting. That's a lot to lose. That's almost the net volume of my POC #2 TH 🙂.

You mentioned that your sim has the offset placed to far in comparison to the built system, due to HornResp limitations. Perhaps the impact of the actual offset on the dip is not as great as the sim suggests.

True, but my sim is still pretty close to the measurement at PSW, especially when simulated as a single cab in 2 pi space (to compare apples to apples).

That sim was done several years ago and in retrospect I probably should have ignored the flare in the throat area in favor of simulating the offset more accurately. Regardless, as it stands, that sim is very useful for evaluating these issues.

The suggestion that the LAB12 lost 100 liters when folded is interesting. That's a lot to lose. That's almost the net volume of my POC #2 TH .

I've never studied the flare in depth so I'm not sure where that volume went but if you run the numbers on the original (unfolded) design it's about 750 liters vs the plans at about 620 liters, but as I mentioned my sim of the plans isn't perfectly accurate. The original design actually wouldn't fit in a 45x45x22.5 package once wood and dead space in the corners was accounted for, so I guess something had to give.

The CV FLH in the OP are not close to the epitome of Gene's L-48-SE, which ushered in the modern era of plaster cracking LF potential.To me, that is what this is all about - trying your best and seeing what happens. If Mr. Danley and his friends hadn't stuck their necks out and designed the LabHorn, we might still be stuck with those Cerwin-Vega FLH's as being the epitome of high performance speaker design.

Gramps, you are old enough to remember 1974's Earthquake movie, but perhaps unaware that Tom's first SDL horns a decade later use Gene's fold pattern,(and are roughly the same physical size) though the SDL 7 (and the later Labhorn) pay homage to spiral designs from decades before that, dating back to Western Electric in the 1920s.

Horn design has changed little in 100 years, but modern drivers can handle more heat and have longer excursion, so given more power, can get louder.

The trend will continue, though may change towards the magnet moving in a fixed coil as amperage and excursion demands increase.

http://soundforums.net/varsity/7842-powersoft-30-inch-sub-seen-wild.html

Remains to be seen whether Powersoft's entry will end up going forward or still be surpassed by conventional drivers as the Servodrive was when manufacturers realized there was a large market for LF.

Art

Attachments

Last edited:

Gramps, you are old enough to remember 1974's Earthquake movie, but perhaps unaware that Tom's first SDL horns a decade later use Gene's fold pattern . . .

Well, Old Man Welter, the farther back in time I am required to go, the hazier the details are. And there are definitely huge gaps in my speaker knowledge where family responsibilities took precedence for years at a time.

But, thinking about the good old days again made me remember ProSoundNews magazine. You youngsters don't realize what you are missing. This was a HUGE magazine (I seem to remember it being about 24" x 18" with about 100 pages, with high quality color printing on thick, glossy paper). Man, this thing was better than a porno mag. And the best part was that it was FREE if you were an industry professional. It has great articles and interviews, and all the new gear!

Well, in the later 1980's I went down a different career path and my subscription lapsed. When I got back into ProSound stuff a year ago I just assumed that ProSoundNews had disappeared like many printed publications. But this morning I decided to check to make sure.

Heck, it is still there as an e-zine. So I subscribed (just say you are a professional and spend lots of money on prosound gear, and you are in).

Subscribe to Pro Sound News

Well, the good old days are definitely over. The e-zine is an anorexic, emasculated version of what it used to be, but it's better than nothing. It seems to be more biased towards recording/post production than live sound now. But why don't all you guys sign up and check it out. Maybe if the get enough people subscribing to it, they can build it up to it's glory days again.

But back to the subject of horn vs. vented box though, are you tapping out on this discussion? If so, I have a related topic that might stir up some interesting comments.

You are right, the details can get hazy 😱.Well, Old Man Welter, the farther back in time I am required to go, the hazier the details are.

But, thinking about the good old days again made me remember ProSoundNews magazine. You youngsters don't realize what you are missing. This was a HUGE magazine (I seem to remember it being about 24" x 18" with about 100 pages, with high quality color printing on thick, glossy paper). Man, this thing was better than a porno mag. And the best part was that it was FREE if you were an industry professional. It has great articles and interviews, and all the new gear!

But back to the subject of horn vs. vented box though, are you tapping out on this discussion? If so, I have a related topic that might stir up some interesting comments.

In post #51, reported that we had cut down our 4x15" 45" deep FLH boxes to "V" load BR in the mid 1980s.

Then I look in the Pro Sound News magazine from December of 1990 (picture was taken August of 1990) and see 3 blocks of L4 bass speakers (24 out of the 72 15" in the shot) had not yet hit the chopping block.

Things have come a ways in 24 years of speaker design, the EVX150 (and EVX180) were rated 500 watt sine wave, 600EIA RS-426A, had 6.35mm Xmax, long for the time, but half (-6dB) the excursion of current speakers costing a fraction of the cost not even factoring in inflation.

Looking at the faded fax printouts Bob Oswood sent me (he was an Altec dealer and had a bass reflex calculator program) it is interesting to see the comment the EVX could put out 12 dB more at 50 Hz than the EV15B that they replaced, it was a real step up.

I wanted to go for a 35-40Hz Fb, but decided on 45 Hz for efficiency in the undersized box (45 x32 x30 inch exterior, with several cubic feet in the "V")

45 Hz was lower than most of the PA rock bins of the time, but around 10 Hz too high for today.

Hornresp simulation of the quad EVX150 loaded L4 indicate the tuning may have actually been lower than we thought, at 36 volt input (245 watts per driver) and a 38 Fb one L4 could hit 130 dB at 40 Hz at Xmax.

With a side of a Crest 8000 in at 2 ohms, that is about the power level we had, though those amps could put out at least another 3 dB peak when the clip light flashed, which it did 😉.

With 10 blocks (20 L4s), you could feel it at 250 feet 🙂.

What's your related topic?

Art

Attachments

Last edited:

Within the boundaries of the OPs "vented box example" we are looking at about 131 db continous output out of the single PK box, with an f3 around 34hz. Power compression is likely not *very* high considering there is still a considerable amount of xmax left in the tank with the manufacturer specified 30hz hipass (12 mm of excursion in passband at 48ish hz, 10mm at 28hz) and power available from their chosen amp (although tracks like "hunter" and other lower than 3 crest factor tracks centered around 35 hz will likely cause power compression). The center port is not *too huge* at approximately 700 square cm, but it appears to keep vent velocity under 18 m/s even when pushed to 2000 watts per box, providing a bit of evidence for minimal port compression at max power.

the danley TH118, which has the same nominal impedance (4 ohms), is actually a bit smaller (42x28x22.5 vs 45x30.5x22.5), has similar sensitivity (actually a bit higher), and will take the same 90 volts at 4ohms that the pk sound sub is given via its onboard amp, with a slightly lower hipass (which is offset by the tapped horns faster decline below tuning). all of Excursion is higher (as per the sims) so one may argue there may be slightly more distortion, but it may be negligble. In the end this adds up to very similar continuous spl and extension, with the Danley box using half the number of drivers but pumping twice the watts to it (being as its a 4 ohm driver, each box still only uses 2000 watts).

Id expect similar performance (with a bit more oomph above 45) from the keystone as well (which is still smaller than the pk sound sub).

Here's the track referenced in the post above:

Kaiju ft. Flowdan - Hunter [OSMUK029] - YouTube

Here are a lot of real-world measurements done ground-plane in a wide open space (Tulsa Speedway) using power levels from 100 watts to wide open, hit the breaker, full-tilt:

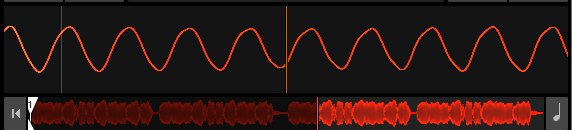

Heres the "dynamic range" (really just crest factor) of the lowpassed (100hz) bassline for hunter, a shot of the waveform (lopassed), and the average spectrum (Lopassed at about 150 to show upper harmonics).

Attachments

What's your related topic?

Art, nice picture there my man! That's a hellacious wall of speakers. I am glad to see I am not the only one to remembers ProSoundNews.

My related topic is a comparison of the variety of different Lab12 enclosures. The first two contestants are both your designs. I started a new forum thread so as to not distract from this topic.

http://www.diyaudio.com/forums/subw...oofer-smack-down-death-match.html#post3797809

Wayne,Here are a lot of real-world measurements done ground-plane in a wide open space (Tulsa Speedway) using power levels from 100 watts to wide open, hit the breaker, full-tilt:

Did you ever measure the 12Pi V2 to see if it conformed to the simulation, filling in the 2 dB dip around 45 Hz ?

If so, an overlay of the two measured responses would be interesting to see.

Art

I'd like to point out that only one of the amps in the cx800 could likely power a stack of at least 6 to 8 series wired labhorns to xmax.... (90 volts into series wired boxes), providing the same output and extension as about 6 pk sound cabs (granted they take up 33 percent more space).

We know that PK sound used to deploy lab subs. We also know they claimed to start producing a subwoofer based on the design characteristics of the labsub , the cs212s (using "custom designed" drivers, and different chamber topology/horn charactaristics in a 45x45x22.5 space).

Eventually they moved on to their current dual18 vented enclosure. be it because of size/design conflict/driver failure rate/ ease of construction/performance , etc, we likely will never know.

One odd thing about the PK boxes is that they seem to feature a series of mistakes:

1) The box size is way too big. Like twice as big as it needs to be. It's possible that there's a lot of braces in the box, but considering it weighs 196lbs, that's not likely. (Once you factor in the weight of the amps and the subs, that means there's less than two sheets of plywood in the box.)

2) The vent appears to be a basic slot port, with no flaring, and it would be nice if it was twice the size.

Basically the boxes remind me a lot of what I see the car audio SPL guys build. Basically very very expensive woofers and outrageous amps, but thrown into a vented box that has room for improvement.

Luckily, we live in an era where making a vented sub box isn't magic, and you can get good results with that formula.

eh.

they dont *really* have ridiculous amps. they drive the speakers to their rms rating and no further (which probably means they suffer very few driver failures). If the power soft amp is anything like the SP4000 then it only weighs 7 lbs

then there is the 2 nlw 9600s (27 lbs a piece for 54 lbs total). Considering they dont get driven to xmax, the box could be even larger for the power they apply (for more sensitivity).

at 30 x 45 on the large faces, they use at least a sheet of ply between the top and bottom (with a 15x 60 inch piece of scrap remain for bracing). they cant quite squeeze 2x 30x22.5 and 2x 45x22.5 out of that second sheet, so its safe to say they are using about 2.5 sheets of ply (baltic birch ply at 3/4 comes in about 64 lbs, so 2.3 sheets is a good bet).

while its true that something like the nexo RS18 may display a bit more ingenuity when it comes to the "old vented box" design, (http://nexo-sa.com/attachments/products/49/nexo_rs18_datasheet.pdf), what the nexo DOESNT have going for it is Truck Pack dimensions. For a company that makes most of its money touring with 40 plus speakers, thats a deal breaker. With only 45 inches of width to play with, there isnt really any room for anything OTHER than a center slot port.

they dont *really* have ridiculous amps. they drive the speakers to their rms rating and no further (which probably means they suffer very few driver failures). If the power soft amp is anything like the SP4000 then it only weighs 7 lbs

then there is the 2 nlw 9600s (27 lbs a piece for 54 lbs total). Considering they dont get driven to xmax, the box could be even larger for the power they apply (for more sensitivity).

at 30 x 45 on the large faces, they use at least a sheet of ply between the top and bottom (with a 15x 60 inch piece of scrap remain for bracing). they cant quite squeeze 2x 30x22.5 and 2x 45x22.5 out of that second sheet, so its safe to say they are using about 2.5 sheets of ply (baltic birch ply at 3/4 comes in about 64 lbs, so 2.3 sheets is a good bet).

while its true that something like the nexo RS18 may display a bit more ingenuity when it comes to the "old vented box" design, (http://nexo-sa.com/attachments/products/49/nexo_rs18_datasheet.pdf), what the nexo DOESNT have going for it is Truck Pack dimensions. For a company that makes most of its money touring with 40 plus speakers, thats a deal breaker. With only 45 inches of width to play with, there isnt really any room for anything OTHER than a center slot port.

- Home

- Loudspeakers

- Subwoofers

- Old School Horn vs Modern Vented Box