Shouldn't there be a CL60 from the power supply to ground, or am I misremembering? (or not seeing it here)

I will have to pull the top off of mine.

Russellc

That is also my understanding Russell

But I will change it to the way Zen Mod suggested and report back on the results after testing

However I can see in my mechanical engineering minds eye - that Zen Mods suggestion wil give the safety earth an unrestricted direct path and the chassis and the audio ground is still protected by the CL60

But as a mechanically minded person - I could be wrong

Thats why I'm asking for knowledge based input from more savvy people on the forum

plenty of pictures here : Papa’s Koan (M)2 , an amp for living room | Zen Mod Blog

Dead as Dodo without signal , alive as ZM with signal

Dead as Dodo without signal , alive as ZM with signal

Even Pa did it..... Look here

http://www.6moons.com/audioreviews/firstwatt11/open1_big.jpg

And mine also needed some steel around the transformer.

ZM build solution is very clever giving some shielding for free!

http://www.6moons.com/audioreviews/firstwatt11/open1_big.jpg

And mine also needed some steel around the transformer.

ZM build solution is very clever giving some shielding for free!

Thank you gentlemen

Before I proceed - I have a couple of questions for Zen Mod

My M2 has 2 CL60s

One is at the safety earth ( as per drawing ) And the other is on the live wire at the On / Off switch at the front of the amp

So in light of the extra info regarding the CL60

Q - Do I still remove the CL 60 completely from the safety earth position or leave it as is

Q - I see your square PCB transformer covers in your build photos

Can I use double sided adhesive copper shielding tape ? As I have some on hand

I can also make a square can cover out of alloy plate - is alloy suitable to use for this purpose

And is that yellow wire soldered from the square transformer shield cover to an earth point

Here is an earlier photo I took of the CL60 connected on the live power side

Before I proceed - I have a couple of questions for Zen Mod

My M2 has 2 CL60s

One is at the safety earth ( as per drawing ) And the other is on the live wire at the On / Off switch at the front of the amp

So in light of the extra info regarding the CL60

Q - Do I still remove the CL 60 completely from the safety earth position or leave it as is

Q - I see your square PCB transformer covers in your build photos

Can I use double sided adhesive copper shielding tape ? As I have some on hand

I can also make a square can cover out of alloy plate - is alloy suitable to use for this purpose

And is that yellow wire soldered from the square transformer shield cover to an earth point

Here is an earlier photo I took of the CL60 connected on the live power side

Attachments

I already wrote clearly what goes in what hierarchy ....... and you can clearly see in my blog how I made it

and , again , (mains) NTC is going to be hot - supported only with wires ( no pcb or other proper mechanical way ) - that's recipe for disaster

so - put it either on terminal block or on dedicated pcb , with proper spacers form case itself

regarding input xformer shielding - that's more cosmetic than anything else - you need proper steel cage for them ......... to prevent /decrease magnetic garbage around them

copper is good as RF shield , not magnetic one

and , again , (mains) NTC is going to be hot - supported only with wires ( no pcb or other proper mechanical way ) - that's recipe for disaster

so - put it either on terminal block or on dedicated pcb , with proper spacers form case itself

regarding input xformer shielding - that's more cosmetic than anything else - you need proper steel cage for them ......... to prevent /decrease magnetic garbage around them

copper is good as RF shield , not magnetic one

Last edited:

Just for the record, the 6moons photo shows the thermistor which is in

series with the AC line. There is another one hidden which connects signal

ground to chassis/earth.

Credit for that invention goes to one of the technicians at Adcom years

ago - I am sorry that I have forgotten his name.

In that photo you can also see the Mu-metal shields I made for the Edcor

transformers. I found I didn't need them for the Jensen transformers, but it

is also important to keep them as far from the power transformer as

possible and rotate the toroid for least noise on both channels with the

RCA input connections attached to a source.

series with the AC line. There is another one hidden which connects signal

ground to chassis/earth.

Credit for that invention goes to one of the technicians at Adcom years

ago - I am sorry that I have forgotten his name.

In that photo you can also see the Mu-metal shields I made for the Edcor

transformers. I found I didn't need them for the Jensen transformers, but it

is also important to keep them as far from the power transformer as

possible and rotate the toroid for least noise on both channels with the

RCA input connections attached to a source.

Copper worked OK in mine - see post #1279. I don't have any hum. I did enclose the power transformer with a stainless steel pot, though.I already wrote clearly what goes in what hierarchy ....... and you can clearly see in my blog how I made it

and , again , (mains) NTC is going to be hot - supported only with wires ( no pcb or other proper mechanical way ) - that's recipe for disaster

so - put it either on terminal block or on dedicated pcb , with proper spacers form case itself

regarding input xformer shielding - that's more cosmetic than anything else - you need proper steel cage for them ......... to prevent /decrease magnetic garbage around them

copper is good as RF shield , not magnetic one

Just for the record, the 6moons photo shows the thermistor which is in

series with the AC line. There is another one hidden which connects signal

ground to chassis/earth.

Credit for that invention goes to one of the technicians at Adcom years

ago - I am sorry that I have forgotten his name.

In that photo you can also see the Mu-metal shields I made for the Edcor

transformers. I found I didn't need them for the Jensen transformers, but it

is also important to keep them as far from the power transformer as

possible and rotate the toroid for least noise on both channels with the

RCA input connections attached to a source.

Thanks for the input Mr Pass

I'm sure that my mate and fellow builder in my M2 would have spotted that and used the same idea

Copper worked OK in mine - see post #1279. I don't have any hum. I did enclose the power transformer with a stainless steel pot, though.

It seems that the consensus is -- shield the torodial and the Edcor's and use a shielded power supply cable

I now have the shielded power supply cable ready to go

The filtered IEC is arriving on Monday so these 2 items will be fitted first

As a mechanical engineer I can fassion a full box enclosure for the Edcore's so I purchased a sheet of Mumetal and is in transit as I post

Then I will either make or purchase a Torodial cover if required after the other items are fitted

Will keep you in the loop with photos as components are installed

Again thank you for the input gentlemen - it's much appreciated

Last edited:

ham can is good for toroidal , if you have it around

take care to avoid shortie between xfornmer bolt , cover and case

take care to avoid shortie between xfornmer bolt , cover and case

I bought 2 pcs of this item, 15cm diameter should be enough for FW donut. For me it's not too expensive instead of DIY version canned steel which might not look good 😀

Audio DIY needed Metal Shield plate cover for toroid transformer with many size

Once I had also planned to 'steal' my wife cooking pan but would need extra hard work

Audio DIY needed Metal Shield plate cover for toroid transformer with many size

Once I had also planned to 'steal' my wife cooking pan but would need extra hard work

I have searched for a suitable Torodial transformer cover to purchase, however they are all to small

The requirement for my M2 build is 155mm Dia approx 6" X 60mm H

So I searched the house with my wife, then we remembered on festive occasions we often purchase biscuits / cookies - sometimes sweets that are packaged in a lovely round tins

We found these 2 in the back of the cupboard

The one on the right is a better height but both are a perfect diameter

The good thing about this type of tin is that it's lid clicks on / off, and because the wire loom is on top of the Torodial I can cut away and bend a small section of the lid to accomodate the wiring without to much trouble

It's also possible to line the inside of the tin with copper tape for extra shielding

A spray paint of your preferred colour and it's perfect for those larger 6" torodial's

I'm not sure if festive packaging of sweets and biscuits come in smaller sized tins but it's worth a look

Anyway I thought to post up my find as a tip for other members to try out 😎😎😎

The requirement for my M2 build is 155mm Dia approx 6" X 60mm H

So I searched the house with my wife, then we remembered on festive occasions we often purchase biscuits / cookies - sometimes sweets that are packaged in a lovely round tins

We found these 2 in the back of the cupboard

The one on the right is a better height but both are a perfect diameter

The good thing about this type of tin is that it's lid clicks on / off, and because the wire loom is on top of the Torodial I can cut away and bend a small section of the lid to accomodate the wiring without to much trouble

It's also possible to line the inside of the tin with copper tape for extra shielding

A spray paint of your preferred colour and it's perfect for those larger 6" torodial's

I'm not sure if festive packaging of sweets and biscuits come in smaller sized tins but it's worth a look

Anyway I thought to post up my find as a tip for other members to try out 😎😎😎

Attachments

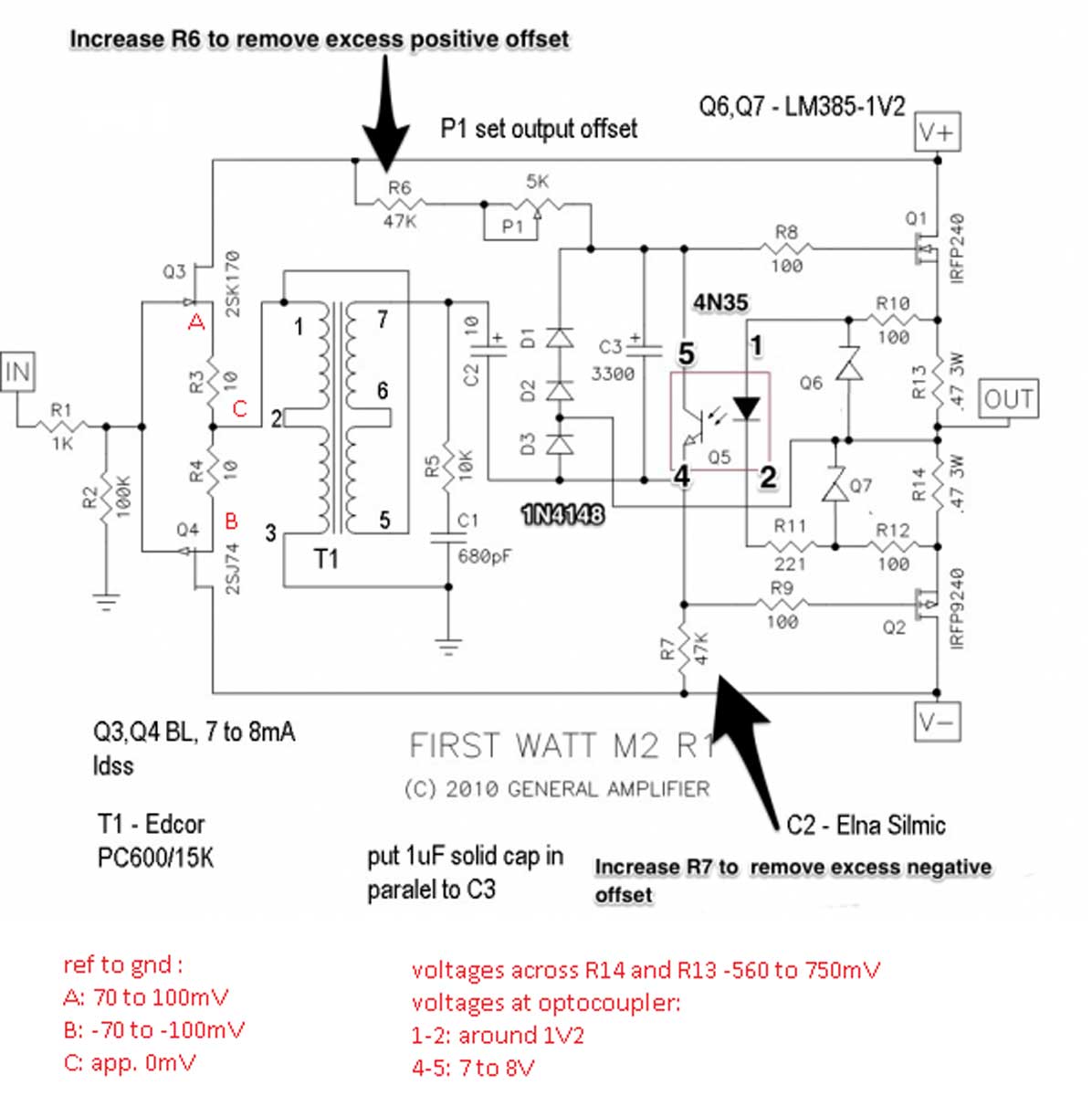

A, B and C read ok on the newly built board. Across R13 and R14 ok, pins 1-2 ok and pin 4-5 a little high at 9.4v.

I get low volume music behind a heavy hum in that channel, the hum stays even when the input wiring is removed, volume has no impact on hum level with input wire connected. Any ideas?

Last edited:

pins 4-5 at 9 volts is ok. depends on the Fets. The important figure is

the voltage across the .47 ohm resistors, which is the bias current.

the voltage across the .47 ohm resistors, which is the bias current.

- Home

- Amplifiers

- Pass Labs

- Official M2 schematic