Parasitic Fredditeck Karlflex

Hi Matthew, I tried to add a parasitic chamber in the bottom of the cabinet.

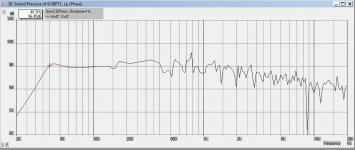

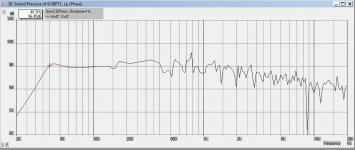

First I added a small duct "P5" attached to enclosure V1 (20L). It extended the response, but did not limit x-max Here is the sim: hope I did it right😛

Here is the sim: hope I did it right😛

FR:

The next thing I will try, is to make the parasitic chamber you did in post 1292 with a vent...........if I can🙄

Fun toying around in Akabak, when you have taken a couple of steps on the mile high learning latter🙂

Hi Matthew, I tried to add a parasitic chamber in the bottom of the cabinet.

First I added a small duct "P5" attached to enclosure V1 (20L). It extended the response, but did not limit x-max

Here is the sim: hope I did it right😛

Here is the sim: hope I did it right😛

Code:

|System FREDDITECH 5000 99LITER KARLFLEX FOR THE 15LB100-8

|With simplified front chamber and mouth system, Aperture Style "E"

|The outer dimensions are 24" H x 20" W x 18.25" D with half-inch ply material

Def_Driver '15LB100'

dD=38cm |Piston

fs=40.9Hz Vas=113L Qms=7.13

Qes=0.35 Re=5.5ohm Le=1.4mH ExpoLe=0.618

System '99L-KARLFLEX'

| vt=99L, (net)

|Rear Chamber=74L, fB=40Hz,

|Front chamber=25L-ish (roughly 17L+8-ish from the Fredditech-Cavity)

|---------------------------------------------------------

| The speaker or driver :

|---------------------------------------------------------

Driver 'Driver' Def='15LB100' Node=1=0=18=2

|--------------------------------------------

| The first section (S1, S2 , S3 in Hornresponse lingo):

|--------------------------------------------

|S1=F0 (adjusting this waveguide's length adjusts the driver offset)

|P0 (make this half of your driver's diameter)

|S2=Node2 (center of driver's cone)

|s3=F1 (length is = Node2 to the bottom of main vent aka interchamber vent)

|--------------------------------------------------

Waveguide 'F0'

Node=50=51

wth=48.3cm hth=10cm

wmo=48.3cm hmo=10.1cm

Len=50.8cm

Conical

|OFF

AcouResistance 'Stuffing1' Node=50=51 Ra=30e3Pas/m3 | Simulate moderate stuffing

Duct 'P0' Node=51=2

WD=48.3cm

HD=23.5cm

Len=19.7cm

VISC=1

|---------------------------------

| Opening to Enclosure V1

|--------------------------------

Duct 'p5' Node=51=52

WD=48.3cm

HD=2cm

Len=1,5cm

|-----------------------------

| Parasitic chamber

|-----------------------------

Enclosure 'V1' Node=52

Vb=20L Qb/fo=0.5 Lb=46cm

|----------------------------

Waveguide 'F1'

Node=2=4

wth=48.3cm hth=23.5cm

wmo=48.3cm hmo=23.6cm

Len=23.5cm

Conical

|---------------------------------------------

| The interchamber vent (connects the rear chamber to the front chamber)

| Be sure to account for some additional effective length if there are

|boundaries near the end of the vent.

|----------------------------------------------

Duct 'P2' Node=4=5

WD=48.3cm

HD=6.3cm

Len=31.1cm

Visc=1

| EXPERIMENTAL CAVITY/DUCT/STUB

| Suggested by Freddi from DIYaudio.com

| This is a very effective method of suppressing the

| upper pipe harmonics and therefore tames and smooths response

Duct 'P3' Node=5=0

WD=48.3cm

HD=6.3cm

Len=35cm

VISC=50

|-----------------------------------------------------------------------------

| APERTURE STYLE "E" SECTION

| Simple Front Chamber combined with shallow ML-Transflex style mouth

| Couples end of path with other side of cone's output (aka "Tapped") in

| regards to bass frequencies but not in the upper frequencies allowing

|6th order performance without the bandpass cutoff limitations in bandwidth.

|-----------------------------------------------------------------------------

|

| The front chamber section (above the driver), nodes reversed for tapered shape.

|

Waveguide 'F2'

Node=18=5

wth=48.3cm hth=6.3cm

wmo=48.3cm hmo=9cm

Len=23cm

Conical

|

| The dimensions and depth of the mouth/aperture(technically also part

| of the front chamber).

|

Duct 'P4' Node=18=6

WD=48.3cm

HD=40.6cm

Len=2.6cm

VISC=1

Radiator 'Radiator' DEF='P4' Node=6 |Radiator or mouth dimensions defined by P4

The next thing I will try, is to make the parasitic chamber you did in post 1292 with a vent...........if I can🙄

Fun toying around in Akabak, when you have taken a couple of steps on the mile high learning latter🙂

PARA-TROOPER

Oh yes , Akabak is really fun and useful for experiments like this 🙂

Sebastian , what you have made here is the Clements/PAS style parasitic chamber.. You can also try connecting this chamber at other places such as node=2 , or node=4 , or even node=5 ..... The original Clements/PAS concept connected at the equivalent of node=5 ...... You may find that this style of chamber shifts the box tuning down , so you will have to shorten the interchamber vent in order to maintain the same FB ...

If the mission is to control excursion you will want to make the chamber large enough (or adjust it's vent size/length) in order to allow it's resonance to move into the 1.5x to 2x fundamental range (classic DCR/ABC cabinets go with a tuning almost exactly an octave above FB, or just below) in order to achieve additional control over the driver's cone, because in theory it begins to have an suppression affect upon the bump in excursion that is normally present above tuning (although Akabak may only show the result as a dip or notch in the excursion bump, accompanied by a dip in impedance at the para-chamber resonance, as well as a wiggle in response and phase)...

You can also try adding a little bit of stuffing the chamber to change the resonance's Q , spread it out , soften it etc ...

The vented parasitic chamber (Weems/Augsperger style from which my Labyrinthine para-chamber was a spinoff) is what i ended up building so i have more real-world experience with it ..... Since it is vented there is an upward shift in FB that can be compensated for by extending the interchamber vent Duct-P2 if necessary...

The vented para-chamber that i built was composed of three ducts (all full width , 12.5" in this case) , the first which connected to the equivalent of node=2 or node=51 and was 1" tall , followed by a 3" tall duct , and then the final vent was 1" tall (and then a radiator as Akabak requires) ......... So in essence it is a pipe section which is intended to develop it's own personal resonance while also acting as an additional vent for the main system all at the same time!! Cool eh? 😎

Now here is the problem that i ran into:

Even though my labyrinthine experiment's duct ratio was only 3:1 (something that i would hope would control the sharp nature of the resonance) i still ended up with an abrupt spike shaped resonance at around 70hz which was exactly where Akabak predicted it would be located (so that part is good) , but i was really hoping for a resonance that would have more of a wide damped hump shape because that would be more effective at controlling the cone and less disruptive to the frequency response of the cabinet ...

The Labyrinth did not leave much room within it's folds to place any significant amount of damping fiber without choking the path and ruining efficiency , and the small amount of poly-fiberfill i was able to put in there wasn't nearly enough to damp the sharp resonance ... So it was obvious that my para-chamber needed to be redesigned ...

Perhaps the duct ratios could have been reduced to 2:1 and made longer to bring it's parasitic resonance back down to 70hz blah blah blah blah , BUT I SOON FIGURED OUT A BETTER SOLUTION!!

After some more dabbling around in Akabak i realized that i could add a stub section within the para-chamber , and the stub could be stuffed with fiber for damping without choking the path !!! This would soften up the resonance enough to knock down the sharp peak and spread things out (at least more effectively than my previous designs ever could have) , hopefully this method would result in the measurable improvement that i was striving for but i never got around to building it .... I only simulated it .................... If i remember correctly i think it ended up being a duct , followed by the stuffed stub, followed by a wider duct, then the smaller duct/vent , and then the radiator of course ...

This would soften up the resonance enough to knock down the sharp peak and spread things out (at least more effectively than my previous designs ever could have) , hopefully this method would result in the measurable improvement that i was striving for but i never got around to building it .... I only simulated it .................... If i remember correctly i think it ended up being a duct , followed by the stuffed stub, followed by a wider duct, then the smaller duct/vent , and then the radiator of course ...

Essentially we are already using two stuffed stubs in the Karlflex cabinet , and the above idea would add a third stuffed stub ...

Hi Matthew, I tried to add a parasitic chamber in the bottom of the cabinet.

First I added a small duct "P5" attached to enclosure V1 (20L). It extended the response, but did not limit x-maxHere is the sim: hope I did it right😛

The next thing I will try, is to make the parasitic chamber you did in post 1292 with a vent...........if I can🙄

Fun toying around in Akabak, when you have taken a couple of steps on the mile high learning latter🙂

Oh yes , Akabak is really fun and useful for experiments like this 🙂

Sebastian , what you have made here is the Clements/PAS style parasitic chamber.. You can also try connecting this chamber at other places such as node=2 , or node=4 , or even node=5 ..... The original Clements/PAS concept connected at the equivalent of node=5 ...... You may find that this style of chamber shifts the box tuning down , so you will have to shorten the interchamber vent in order to maintain the same FB ...

If the mission is to control excursion you will want to make the chamber large enough (or adjust it's vent size/length) in order to allow it's resonance to move into the 1.5x to 2x fundamental range (classic DCR/ABC cabinets go with a tuning almost exactly an octave above FB, or just below) in order to achieve additional control over the driver's cone, because in theory it begins to have an suppression affect upon the bump in excursion that is normally present above tuning (although Akabak may only show the result as a dip or notch in the excursion bump, accompanied by a dip in impedance at the para-chamber resonance, as well as a wiggle in response and phase)...

You can also try adding a little bit of stuffing the chamber to change the resonance's Q , spread it out , soften it etc ...

The vented parasitic chamber (Weems/Augsperger style from which my Labyrinthine para-chamber was a spinoff) is what i ended up building so i have more real-world experience with it ..... Since it is vented there is an upward shift in FB that can be compensated for by extending the interchamber vent Duct-P2 if necessary...

The vented para-chamber that i built was composed of three ducts (all full width , 12.5" in this case) , the first which connected to the equivalent of node=2 or node=51 and was 1" tall , followed by a 3" tall duct , and then the final vent was 1" tall (and then a radiator as Akabak requires) ......... So in essence it is a pipe section which is intended to develop it's own personal resonance while also acting as an additional vent for the main system all at the same time!! Cool eh? 😎

Now here is the problem that i ran into:

Even though my labyrinthine experiment's duct ratio was only 3:1 (something that i would hope would control the sharp nature of the resonance) i still ended up with an abrupt spike shaped resonance at around 70hz which was exactly where Akabak predicted it would be located (so that part is good) , but i was really hoping for a resonance that would have more of a wide damped hump shape because that would be more effective at controlling the cone and less disruptive to the frequency response of the cabinet ...

The Labyrinth did not leave much room within it's folds to place any significant amount of damping fiber without choking the path and ruining efficiency , and the small amount of poly-fiberfill i was able to put in there wasn't nearly enough to damp the sharp resonance ... So it was obvious that my para-chamber needed to be redesigned ...

Perhaps the duct ratios could have been reduced to 2:1 and made longer to bring it's parasitic resonance back down to 70hz blah blah blah blah , BUT I SOON FIGURED OUT A BETTER SOLUTION!!

After some more dabbling around in Akabak i realized that i could add a stub section within the para-chamber , and the stub could be stuffed with fiber for damping without choking the path !!!

This would soften up the resonance enough to knock down the sharp peak and spread things out (at least more effectively than my previous designs ever could have) , hopefully this method would result in the measurable improvement that i was striving for but i never got around to building it .... I only simulated it .................... If i remember correctly i think it ended up being a duct , followed by the stuffed stub, followed by a wider duct, then the smaller duct/vent , and then the radiator of course ...

This would soften up the resonance enough to knock down the sharp peak and spread things out (at least more effectively than my previous designs ever could have) , hopefully this method would result in the measurable improvement that i was striving for but i never got around to building it .... I only simulated it .................... If i remember correctly i think it ended up being a duct , followed by the stuffed stub, followed by a wider duct, then the smaller duct/vent , and then the radiator of course ...Essentially we are already using two stuffed stubs in the Karlflex cabinet , and the above idea would add a third stuffed stub ...

Hi Matthew,thanks for elaborate on the problem at hand 🙂

Yes, I knew it wasn't the "true" paracitic chamber I was doing, but what I want to do, is what you are refereing to here; "If i remember correctly i think it ended up being a duct , followed by the stuffed stub, followed by a wider duct, then the smaller duct/vent , and then the radiator of course ..." and that is depicted in post 1292. But as I read it, you are refering to them both at the same time 😉 the stub is a closed duct, right?

Well, if I have to raise the cabinet hight, in order to get the horn up in ear-level, I might just do some usefull with that extra height. Some cone-control and lower tuning would certainly be a win-win situation 😛

I will try look into your ideas when my brain allows me 😀

Yes, I knew it wasn't the "true" paracitic chamber I was doing, but what I want to do, is what you are refereing to here; "If i remember correctly i think it ended up being a duct , followed by the stuffed stub, followed by a wider duct, then the smaller duct/vent , and then the radiator of course ..." and that is depicted in post 1292. But as I read it, you are refering to them both at the same time 😉 the stub is a closed duct, right?

Well, if I have to raise the cabinet hight, in order to get the horn up in ear-level, I might just do some usefull with that extra height. Some cone-control and lower tuning would certainly be a win-win situation 😛

I will try look into your ideas when my brain allows me 😀

realized that i could add a stub section within the para-chamber , and the stub could be stuffed with fiber for damping without choking the path !!!

Stubs can be added almost anywhere, and post-facto too. An easy way is to take a hole saw and cut a 2in or 3in dia hole at a strategically placed spot and glue on a section of PVC pipe(s) stuffed with fiberglass. Of course, model the effect first to tell you where to point the hole saw. I have found that the most bang for the buck on stubs is to stick them right at the where the driver front chamber is, or immediately after the first turn from the drivers near the corner. You will have something that looks like a dragster engine from Mad Max with "exhaust pipes" with elbows, etc sticking out - but a good way to test the stub efficacy for next build where you incorporate the stub as standard channel and folded into the main wooden path geometry. Some of Danley's TH's have PVC pipe stubs buried inside and they connect to main driver chamber at throat area.

Stubs are wonderful

X,

Oh yes, i totally agree, especially with a prototype cabinet you could add them any number of places post-facto because you don't have to worry about what it looks like of course i know a few people who would probably love to have a gnarly Mad Max cab!

of course i know a few people who would probably love to have a gnarly Mad Max cab!  Like you say the stubs can be integrated in the final builds ...

Like you say the stubs can be integrated in the final builds ...

I think you are right about using the stubs on the front chamber as well , at least to know it to be true in my case because i had a front chamber that was undersized , and adding the Freddi-Mod stub after the fact not only tamed the resonances that needed to be tamed but also did double duty by adding some much needed volume to the front chamber! I love things that do double duty 🙂

The offset-driver designs also adopt a double duty device as the "S1" section in an "OD" system not only acts as a stub to tame harmonics (the 3rd in many cases, as with the Karlflex) but also contributes to total path length in a quarter wave (eigenmode) design, and as with any stub you can also use an effective amount of fine fibrous stuffing within the stub without causing excessive losses at the box's fundamental, in other words (as long as you keep the fiber in the stubs) you can have the smoothing and resonance softening de-Q effect benefits of stuffing without nearly as much of a downside on the bottom end!

Stubs can be added almost anywhere, and post-facto too. An easy way is to take a hole saw and cut a 2in or 3in dia hole at a strategically placed spot and glue on a section of PVC pipe(s) stuffed with fiberglass. Of course, model the effect first to tell you where to point the hole saw. I have found that the most bang for the buck on stubs is to stick them right at the where the driver front chamber is, or immediately after the first turn from the drivers near the corner. You will have something that looks like a dragster engine from Mad Max with "exhaust pipes" with elbows, etc sticking out - but a good way to test the stub efficacy for next build where you incorporate the stub as standard channel and folded into the main wooden path geometry. Some of Danley's TH's have PVC pipe stubs buried inside and they connect to main driver chamber at throat area.

X,

Oh yes, i totally agree, especially with a prototype cabinet you could add them any number of places post-facto because you don't have to worry about what it looks like

of course i know a few people who would probably love to have a gnarly Mad Max cab!

of course i know a few people who would probably love to have a gnarly Mad Max cab!  Like you say the stubs can be integrated in the final builds ...

Like you say the stubs can be integrated in the final builds ...I think you are right about using the stubs on the front chamber as well , at least to know it to be true in my case because i had a front chamber that was undersized , and adding the Freddi-Mod stub after the fact not only tamed the resonances that needed to be tamed but also did double duty by adding some much needed volume to the front chamber! I love things that do double duty 🙂

The offset-driver designs also adopt a double duty device as the "S1" section in an "OD" system not only acts as a stub to tame harmonics (the 3rd in many cases, as with the Karlflex) but also contributes to total path length in a quarter wave (eigenmode) design, and as with any stub you can also use an effective amount of fine fibrous stuffing within the stub without causing excessive losses at the box's fundamental, in other words (as long as you keep the fiber in the stubs) you can have the smoothing and resonance softening de-Q effect benefits of stuffing without nearly as much of a downside on the bottom end!

PARA-TROOPER chat

Sebastian,

No problem, i just wanted you to know about my struggles, observations and where i was going with the redesign on the next round because i think these things could help by giving you a "head start" if you decide you want to try to take on the para-challenge! 😀

The Clements/PAS style chamber is a legitimate type of parasitic chamber as well but yes, you are correct about my proposed idea (as you quoted above) of adding a stub to the middle of a labyrinth is like a combination of both methods 🙂

The stub allows us to have a place to put the fibrous material to De-Q the para-chamber's resonance without suffering excessive losses at the cabinet's fundamental tuning (because using the stub means that we aren't choking the path with stuffing in any way in regards to the very low frequencies).

I worked it out in an Akabak Simulation a while back .... I can try to find the old script ...

Right? It is just a matter of sticking the 10" to 12" 60hz to 80hz tuned para-chamber on top or on bottom of a 24" cab then readjusting the main interchamber duct P2 to dial-in your FB ... That would give you a 34" to 36" tall cabinet .... The node used to connect the para-chamber can make a big difference so you might have to try a few to see what effects on response it makes ...

What do you consider the optimal height for your situation?

I might have another idea to consider, one that is easy to implement, and fills all of the requirements while also increasing the front chamber volume significantly! 🙂 ... We should try to model the PAS/Clements concept as a chamber that is located on top of a Karlflex connecting at node=5 (the end of the interchamber vent and also where the Freddi-mod stub connects)

Hi Matthew,thanks for elaborate on the problem at hand 🙂

Sebastian,

No problem, i just wanted you to know about my struggles, observations and where i was going with the redesign on the next round because i think these things could help by giving you a "head start" if you decide you want to try to take on the para-challenge! 😀

Yes, I knew it wasn't the "true" paracitic chamber I was doing, but what I want to do, is what you are refereing to here; "If i remember correctly i think it ended up being a duct , followed by the stuffed stub, followed by a wider duct, then the smaller duct/vent , and then the radiator of course ..." and that is depicted in post 1292. But as I read it, you are refering to them both at the same time 😉 the stub is a closed duct, right?

The Clements/PAS style chamber is a legitimate type of parasitic chamber as well but yes, you are correct about my proposed idea (as you quoted above) of adding a stub to the middle of a labyrinth is like a combination of both methods 🙂

The stub allows us to have a place to put the fibrous material to De-Q the para-chamber's resonance without suffering excessive losses at the cabinet's fundamental tuning (because using the stub means that we aren't choking the path with stuffing in any way in regards to the very low frequencies).

I worked it out in an Akabak Simulation a while back .... I can try to find the old script ...

Well, if I have to raise the cabinet hight, in order to get the horn up in ear-level, I might just do some usefull with that extra height. Some cone-control and lower tuning would certainly be a win-win situation 😛

I will try look into your ideas when my brain allows me 😀

Right? It is just a matter of sticking the 10" to 12" 60hz to 80hz tuned para-chamber on top or on bottom of a 24" cab then readjusting the main interchamber duct P2 to dial-in your FB ... That would give you a 34" to 36" tall cabinet .... The node used to connect the para-chamber can make a big difference so you might have to try a few to see what effects on response it makes ...

What do you consider the optimal height for your situation?

I might have another idea to consider, one that is easy to implement, and fills all of the requirements while also increasing the front chamber volume significantly! 🙂 ... We should try to model the PAS/Clements concept as a chamber that is located on top of a Karlflex connecting at node=5 (the end of the interchamber vent and also where the Freddi-mod stub connects)

NOTE ABOUT SUBJECTIVE or MEASURED VERSUS VIRTUAL MODELS

NOTE: I really don't think that Akabak was able to properly estimate just how much the front chamber benefits this system .... Without the front chamber it sounds anemic and thin, but adding the front panel (creating the front chamber) it sounds rich and large, it is a very stark "day and night" difference, yet that drastic change cannot be seen in the Akabak simulation when removing the virtual front panel from the virtual box, (only when removing the real front panel from the real box ) .

So it leaves me wondering if the Karlson designers of the 1950s were aware of this through their trial and error experimentation and therefore used a larger front chamber (ratio) because they knew the importance of the front chamber's role in creating a bold sound, and that is something that us pixel pushers of the modern day with our fancy software are unable to see with our virtual models so awesome designs like the Karlson get largely ignored (unfairly) because the benefits of the design are not being modeled correctly but not necessarily because of user error but perhaps due to some factors that software is not taking into account............................. (and if this above ascertainment is true) Could the changes or lack of changes in cone control/excursion in such a system also be understated in our virtual simulations???? .... I suspect that it might be the case, and i say this based upon the fact that i can open Akabak and plug in a script for a classic ABC/DCR model and the difference in cone control between that cabinet compared to a standard reflex cab of the same size with same driver is underwhelming, not impressive, not enough to justify the extra complexity (in the virtual model), however people who build these ABC/DCR boxes will tell you that the DCR feature (parasitic radiator system) makes a very significant improvement in cone control and is well worth the extra complexity ....... So what do you make of that? Are we to believe that all of this is due to poor interpretation, poor execution and placebo effects? 🙄 Surely there is some of that going on but i think there is more to it than that ......... Freddi even had an experiment where he tested different K-slot widths and could hear drastic tonal changes even though there was no noticeable difference in measured response graphs ..... Fascinating

..... Fascinating

Anyway , *END OF RANT* I thought i would share some of these things that this project has me contemplating lately ..

NOTE: I really don't think that Akabak was able to properly estimate just how much the front chamber benefits this system .... Without the front chamber it sounds anemic and thin, but adding the front panel (creating the front chamber) it sounds rich and large, it is a very stark "day and night" difference, yet that drastic change cannot be seen in the Akabak simulation when removing the virtual front panel from the virtual box, (only when removing the real front panel from the real box ) .

So it leaves me wondering if the Karlson designers of the 1950s were aware of this through their trial and error experimentation and therefore used a larger front chamber (ratio) because they knew the importance of the front chamber's role in creating a bold sound, and that is something that us pixel pushers of the modern day with our fancy software are unable to see with our virtual models so awesome designs like the Karlson get largely ignored (unfairly) because the benefits of the design are not being modeled correctly but not necessarily because of user error but perhaps due to some factors that software is not taking into account............................. (and if this above ascertainment is true) Could the changes or lack of changes in cone control/excursion in such a system also be understated in our virtual simulations???? .... I suspect that it might be the case, and i say this based upon the fact that i can open Akabak and plug in a script for a classic ABC/DCR model and the difference in cone control between that cabinet compared to a standard reflex cab of the same size with same driver is underwhelming, not impressive, not enough to justify the extra complexity (in the virtual model), however people who build these ABC/DCR boxes will tell you that the DCR feature (parasitic radiator system) makes a very significant improvement in cone control and is well worth the extra complexity ....... So what do you make of that? Are we to believe that all of this is due to poor interpretation, poor execution and placebo effects? 🙄 Surely there is some of that going on but i think there is more to it than that ......... Freddi even had an experiment where he tested different K-slot widths and could hear drastic tonal changes even though there was no noticeable difference in measured response graphs

..... Fascinating

..... Fascinating

Anyway , *END OF RANT* I thought i would share some of these things that this project has me contemplating lately ..

yes - the mic thought things were the same but subjectively using a Smith "distributed source horn" on top, the sound of a small coupler loaded with an 18" was choked with a narrow gap and very good with the upper gap opened to ~1.25"

Carl Neuser checks his K's with several flares varying from a p=1, q=1.7 which opens faster in the driver area than a radial arc swing, to p=1, q=3 which is tighter. (Carl expected the tighter aperture to go lower - maybe in cases where the system tunes lower)

here's the good aperture gap for the flare I used - that's a 15" Altec 421-8 - the tone was better than any direct radiator fullrange I've played with. I later cut 3" off the top of the wings and moved them up - did not help further and looked less cool.

the same cabinet is the one which I added a 20 liter cavity - look at the left of the 2nd picture with the duct tape - - - - I also mounted a K-tube tweeter

Carl Neuser checks his K's with several flares varying from a p=1, q=1.7 which opens faster in the driver area than a radial arc swing, to p=1, q=3 which is tighter. (Carl expected the tighter aperture to go lower - maybe in cases where the system tunes lower)

here's the good aperture gap for the flare I used - that's a 15" Altec 421-8 - the tone was better than any direct radiator fullrange I've played with. I later cut 3" off the top of the wings and moved them up - did not help further and looked less cool.

the same cabinet is the one which I added a 20 liter cavity - look at the left of the 2nd picture with the duct tape - - - - I also mounted a K-tube tweeter

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

NOTE: I really don't think that Akabak was able to properly estimate just how much the front chamber benefits this system .... .

Maybe your design is pushing Akabak to the limit....😀

I did some more sims. Increased your standart 99 Freddiditech with 5 cm at F0, F1 and aperture F2 plus added a parasitic chamber. Think I got the nodes and such right this time 🙂

Got a little more sensitivity and low end, without sacrificing the x-max, nice. Could problably refine it, but wanted you to see it before moving on.

Code:

System 'S1'

|The outer dimensions are 24" H x 20" W x 18.25" D with half-inch ply material

Def_Driver '15LB100'

dD=38cm |Piston

fs=40.9Hz Vas=113L Qms=7.13

Qes=0.35 Re=5.5ohm Le=1.4mH ExpoLe=0.618

System '99L-KARLFLEX'

| vt=99L, (net)

|Rear Chamber=74L, fB=40Hz,

|Front chamber=25L-ish (roughly 17L+8-ish from the Fredditech-Cavity)

|---------------------------------------------------------

| The speaker or driver :

|---------------------------------------------------------

Driver 'Driver' Def='15LB100' Node=1=0=18=2

|--------------------------------------------

| The first section (S1, S2 , S3 in Hornresponse lingo):

|--------------------------------------------

|S1=F0 (adjusting this waveguide's length adjusts the driver offset)

|P0 (make this half of your driver's diameter)

|S2=Node2 (center of driver's cone)

|s3=F1 (length is = Node2 to the bottom of main vent aka interchamber vent)

|--------------------------------------------------

Waveguide 'F0'

Node=50=51

wth=48.3cm hth=10cm

wmo=48.3cm hmo=10.1cm

Len=55.8cm

Conical

|OFF

AcouResistance 'Stuffing1' Node=50=51 Ra=30e3Pas/m3 | Simulate moderate stuffing

Duct 'P0' Node=51=2

WD=48.3cm

HD=23.5cm

Len=19.7cm

VISC=1

Waveguide 'F1'

Node=2=4

wth=48.3cm hth=23.5cm

wmo=48.3cm hmo=23.6cm

Len=28.5cm

Conical

|-----------------------------------

| Parasitic chamber

|-----------------------------------

Duct 'P5' Node=51=52

WD=48.3cm HD=4cm Len=44cm

Duct 'P6' Node=52=0

WD=48.3cm HD=7.5cm Len=43cm Visc=50

Duct 'P7' Node=52=53

WD=48.3cm HD=2.5cm Len=43cm

Radiator 'Rad1' Def='P7' Node=53

x=0 y=0 z=0 HAngle=0 VAngle=0

|---------------------------------------------

| The interchamber vent (connects the rear chamber to the front chamber)

| Be sure to account for some additional effective length if there are

|boundaries near the end of the vent.

|----------------------------------------------

Duct 'P2' Node=4=5

WD=48.3cm

HD=6.3cm

Len=31.1cm

Visc=1

| EXPERIMENTAL CAVITY/DUCT/STUB

| Suggested by Freddi from DIYaudio.com

| This is a very effective method of suppressing the

| upper pipe harmonics and therefore tames and smooths response

Duct 'P3' Node=5=0

WD=48.3cm

HD=6.3cm

Len=35cm

VISC=50

|-----------------------------------------------------------------------------

| APERTURE STYLE "E" SECTION

| Simple Front Chamber combined with shallow ML-Transflex style mouth

| Couples end of path with other side of cone's output (aka "Tapped") in

| regards to bass frequencies but not in the upper frequencies allowing

|6th order performance without the bandpass cutoff limitations in bandwidth.

|-----------------------------------------------------------------------------

|

| The front chamber section (above the driver), nodes reversed for tapered shape.

|

Waveguide 'F2'

Node=18=5

wth=48.3cm hth=6.3cm

wmo=48.3cm hmo=9cm

Len=28cm

Conical

|

| The dimensions and depth of the mouth/aperture(technically also part

| of the front chamber).

|

Duct 'P4' Node=18=6

WD=48.3cm

HD=40.6cm

Len=2.6cm

VISC=1

Radiator 'Radiator' DEF='P4' Node=6 |Radiator or mouth dimensions defined by P4THE MAGIC OF THE KARLSON CANNOT BE QUANTIFIED!!!

I find it fascinating that the measurement equipment cannot really see the difference, yet our ears can hear it clearly .... Was there a phase response measurement taken that day as well?

What do the "p=" and "q=" terms stand for? I should have paid more attention in geometry class when i was going to school .

Even with my limited experience hearing real-world K-cabs i can already see how these can have much better tone than direct radiating boxes ....... I am convinced that it is all about the front chamber and aperture which ties everything together and makes it extra special

I see your duct taped Freddi-mod!! Slapped on top of the box like an afterthought just like mine, because it was an afterthought, a fantastic idea on your part by the way, it works well ....................................... I glued mine on with PL, messy but very permanent, don't breathe the vapors

In that picture do i see a Stand up Bass with a K-slot ?!?!!? That is so very cool 😎

yes - the mic thought things were the same but subjectively using a Smith "distributed source horn" on top, the sound of a small coupler loaded with an 18" was choked with a narrow gap and very good with the upper gap opened to ~1.25"

I find it fascinating that the measurement equipment cannot really see the difference, yet our ears can hear it clearly .... Was there a phase response measurement taken that day as well?

Carl Neuser checks his K's with several flares varying from a p=1, q=1.7 which opens faster in the driver area than a radial arc swing, to p=1, q=3 which is tighter. (Carl expected the tighter aperture to go lower - maybe in cases where the system tunes lower)

What do the "p=" and "q=" terms stand for? I should have paid more attention in geometry class when i was going to school .

here's the good aperture gap for the flare I used - that's a 15" Altec 421-8 - the tone was better than any direct radiator fullrange I've played with. I later cut 3" off the top of the wings and moved them up - did not help further and looked less cool.

the same cabinet is the one which I added a 20 liter cavity - look at the left of the 2nd picture with the duct tape - - - - I also mounted a K-tube tweeter

Even with my limited experience hearing real-world K-cabs i can already see how these can have much better tone than direct radiating boxes ....... I am convinced that it is all about the front chamber and aperture which ties everything together and makes it extra special

I see your duct taped Freddi-mod!! Slapped on top of the box like an afterthought just like mine, because it was an afterthought, a fantastic idea on your part by the way, it works well ....................................... I glued mine on with PL, messy but very permanent, don't breathe the vapors

In that picture do i see a Stand up Bass with a K-slot ?!?!!? That is so very cool 😎

Checking it over right now .

Sebastian ,

I have your script loaded into Akabak right now and hey, this looks really good ! You definitely have the right idea about this . You must be eating the fatty coldwater fish (and their eggs) and seaweed up there in Denmark and all of the other good brain foods because you learn fast!

. You must be eating the fatty coldwater fish (and their eggs) and seaweed up there in Denmark and all of the other good brain foods because you learn fast!

You can temporarily set your para-stub's VISC=1 in order to get a clear indication of exactly where the Parasitic resonance is tuned ... Shoot for an octave over FB (or just under 1 octave) , it looks like you were a little over the target but not by much , so i reduced the height of Duct p5 to 2.6cm , and I left the other para-ducts alone, so you basically have a 1" duct, a 3" para-stub, and then the final 1" duct. The change shifts the para-frequency down and gets us closer to our target of around 80hz .. Increasing the height of the para-stub can shift it even lower ....

....

How tall do you want the box to be? right now i think this ends up being about 81.6cm tall (outer dimension) if i am calculating it correctly? ....

For the sake of fun and science you can change the para duct P5 nodes from 51=52 to 5=52 (this places the para chamber on top of the box instead of the bottom with the benefit of adding a significant amount of effective volume to the front chamber which should be a good thing)

For the sake of fun and science you can change the para duct P5 nodes from 51=52 to 5=52 (this places the para chamber on top of the box instead of the bottom with the benefit of adding a significant amount of effective volume to the front chamber which should be a good thing)

I did some more sims. Increased your standart 99 Freddiditech with 5 cm at F0, F1 and aperture F2 plus added a parasitic chamber. Think I got the nodes and such right this time 🙂

Got a little more sensitivity and low end, without sacrificing the x-max, nice. Could problably refine it, but wanted you to see it before moving on.

Sebastian ,

I have your script loaded into Akabak right now and hey, this looks really good ! You definitely have the right idea about this

. You must be eating the fatty coldwater fish (and their eggs) and seaweed up there in Denmark and all of the other good brain foods because you learn fast!

. You must be eating the fatty coldwater fish (and their eggs) and seaweed up there in Denmark and all of the other good brain foods because you learn fast!

You can temporarily set your para-stub's VISC=1 in order to get a clear indication of exactly where the Parasitic resonance is tuned ... Shoot for an octave over FB (or just under 1 octave) , it looks like you were a little over the target but not by much , so i reduced the height of Duct p5 to 2.6cm , and I left the other para-ducts alone, so you basically have a 1" duct, a 3" para-stub, and then the final 1" duct. The change shifts the para-frequency down and gets us closer to our target of around 80hz .. Increasing the height of the para-stub can shift it even lower

....

.... How tall do you want the box to be? right now i think this ends up being about 81.6cm tall (outer dimension) if i am calculating it correctly? ....

For the sake of fun and science you can change the para duct P5 nodes from 51=52 to 5=52 (this places the para chamber on top of the box instead of the bottom with the benefit of adding a significant amount of effective volume to the front chamber which should be a good thing)

For the sake of fun and science you can change the para duct P5 nodes from 51=52 to 5=52 (this places the para chamber on top of the box instead of the bottom with the benefit of adding a significant amount of effective volume to the front chamber which should be a good thing)Sebastian ,

I have your script loaded into Akabak right now and hey, this looks really good ! You definitely have the right idea about this. You must be eating the fatty coldwater fish (and their eggs) and seaweed up there in Denmark and all of the other good brain foods because you learn fast!

😛 I believe that if you have an interest in something, your brain allows you to absorb new information more easily, hence learn it more quickly. Or maybe it is, that you are willing to invest more time and energy, because you think it is fun, or a mix of the above 😀

I tried some of your ideas and I'll keep the parasitic chamber in the bottom.

Fun to see the effect of removing stuffing from PARA-chamber stub.

With some more sims the latest iteration is like this:

Code:

System 'S1'

|The outer dimensions are 24" H x 20" W x 18.25" D with half-inch ply material

Def_Driver '15LB100'

dD=38cm |Piston

fs=40.9Hz Vas=113L Qms=7.13

Qes=0.35 Re=5.5ohm Le=1.4mH ExpoLe=0.618

System '99L-KARLFLEX'

| vt=99L, (net)

|Rear Chamber=74L, fB=40Hz,

|Front chamber=25L-ish (roughly 17L+8-ish from the Fredditech-Cavity)

|---------------------------------------------------------

| The speaker or driver :

|---------------------------------------------------------

Driver 'Driver' Def='15LB100' Node=1=0=18=2

|--------------------------------------------

| The first section (S1, S2 , S3 in Hornresponse lingo):

|--------------------------------------------

|S1=F0 (adjusting this waveguide's length adjusts the driver offset)

|P0 (make this half of your driver's diameter)

|S2=Node2 (center of driver's cone)

|s3=F1 (length is = Node2 to the bottom of main vent aka interchamber vent)

|--------------------------------------------------

Waveguide 'F0'

Node=50=51

wth=48.3cm hth=8cm

wmo=48.3cm hmo=8.1cm

Len=58.8cm

Conical

|OFF

AcouResistance 'Stuffing1' Node=50=51 Ra=30e3Pas/m3 | Simulate moderate stuffing

Duct 'P0' Node=51=2

WD=48.3cm

HD=25.5cm

Len=19.7cm

VISC=1

Waveguide 'F1'

Node=2=4

wth=48.3cm hth=25.5cm

wmo=48.3cm hmo=25.6cm

Len=31.5cm

Conical

|-----------------------------------

| Parasitic chamber

|-----------------------------------

Duct 'P5' Node=51=52

WD=48.3cm HD=2,5cm Len=43cm

Duct 'P6' Node=52=0

WD=48.3cm HD=7,5cm Len=43cm Visc=50

Duct 'P7' Node=52=53

WD=48.3cm HD=2,5cm Len=43cm

Radiator 'Rad1' Def='P7' Node=53

x=0 y=0 z=0 HAngle=0 VAngle=0

|---------------------------------------------

| The interchamber vent (connects the rear chamber to the front chamber)

| Be sure to account for some additional effective length if there are

|boundaries near the end of the vent.

|----------------------------------------------

Duct 'P2' Node=4=5

WD=48.3cm

HD=6.3cm

Len=31.1cm

Visc=1

| EXPERIMENTAL CAVITY/DUCT/STUB

| Suggested by Freddi from DIYaudio.com

| This is a very effective method of suppressing the

| upper pipe harmonics and therefore tames and smooths response

Duct 'P3' Node=5=0

WD=48.3cm

HD=6.3cm

Len=35cm

VISC=50

|-----------------------------------------------------------------------------

| APERTURE STYLE "E" SECTION

| Simple Front Chamber combined with shallow ML-Transflex style mouth

| Couples end of path with other side of cone's output (aka "Tapped") in

| regards to bass frequencies but not in the upper frequencies allowing

|6th order performance without the bandpass cutoff limitations in bandwidth.

|-----------------------------------------------------------------------------

|

| The front chamber section (above the driver), nodes reversed for tapered shape.

|

Waveguide 'F2'

Node=18=5

wth=48.3cm hth=6.3cm

wmo=48.3cm hmo=9cm

Len=31cm

Conical

|

| The dimensions and depth of the mouth/aperture(technically also part

| of the front chamber).

|

Duct 'P4' Node=18=6

WD=48.3cm

HD=40.6cm

Len=2.6cm

VISC=1

Radiator 'Radiator' DEF='P4' Node=6 |Radiator or mouth dimensions defined by P4Box is, with internal dividers, H:82,6 W:52,3 D:47, all outer dimentions.

I think a height between 80 and 85 is fine, to let the horn center get in ear level, when sitting down.

I am liking it =)

Sebastian ,

I loaded the script into Akabak and it looks great to me so far, I am not seeing any problems with it ...

...

You may have nailed it!

Keep in mind that even though the simulated response graph shows a minor sag around the parasitic resonance frequency but in reality you may actually end up with a bump there instead (as i measured on this end) 🙂.....

Something else just came to mind and this is about the para-chamber's vent ratios: it is generally considered good policy to keep ducts/vents/ports (in their typical role) at less than a 1:10 height-to-width ratio because the port's behavior will be more accurately predicted with our software as long as the ratio isn't too high (and there can be issues with port compression or non-linearity when the system is played at high volume) ... I barely exceeded the vent ratio in my build (1" x 12.5" ) and i got away with it, but a 1:19 ratio is pushing our luck ...... OTOH since these ducts are not the cabinet's main vent it may not be quite as critical, perhaps nothing to get concerned about (the para-chamber's vents do not have to carry as much air flow.... The velocity is verifiable with Akabak), so you could still be fine in this regard .....

I did however do an experiment with the script just to see if it was possible to increase the height of both para-vents to 3.8cm but that tuned the para-chamber too high so i increased the height of the para-stub to 10cm which helped shift the para-tuning back down to 90hz (not ideal but a compromise)... These changes make the box 5.1cm taller unless compensations are made ...

😛 I believe that if you have an interest in something, your brain allows you to absorb new information more easily, hence learn it more quickly. Or maybe it is, that you are willing to invest more time and energy, because you think it is fun, or a mix of the above 😀

I tried some of your ideas and I'll keep the parasitic chamber in the bottom.

Fun to see the effect of removing stuffing from PARA-chamber stub.

With some more sims the latest iteration is like this:

I increased F0, F1 and F2 slightly more of a total of 8 cm compared to your original 99 L. design. I slimmed F0 to 8 cm and increased P0 and F1 accordingly.Code:

Box is, with internal dividers, H:82,6 W:52,3 D:47, all outer dimentions.

I think a height between 80 and 85 is fine, to let the horn center get in ear level, when sitting down.

Sebastian ,

I loaded the script into Akabak and it looks great to me so far, I am not seeing any problems with it

...

... You may have nailed it!

Keep in mind that even though the simulated response graph shows a minor sag around the parasitic resonance frequency but in reality you may actually end up with a bump there instead (as i measured on this end) 🙂.....

Something else just came to mind and this is about the para-chamber's vent ratios: it is generally considered good policy to keep ducts/vents/ports (in their typical role) at less than a 1:10 height-to-width ratio because the port's behavior will be more accurately predicted with our software as long as the ratio isn't too high (and there can be issues with port compression or non-linearity when the system is played at high volume) ... I barely exceeded the vent ratio in my build (1" x 12.5" ) and i got away with it, but a 1:19 ratio is pushing our luck ...... OTOH since these ducts are not the cabinet's main vent it may not be quite as critical, perhaps nothing to get concerned about (the para-chamber's vents do not have to carry as much air flow.... The velocity is verifiable with Akabak), so you could still be fine in this regard .....

I did however do an experiment with the script just to see if it was possible to increase the height of both para-vents to 3.8cm but that tuned the para-chamber too high so i increased the height of the para-stub to 10cm which helped shift the para-tuning back down to 90hz (not ideal but a compromise)... These changes make the box 5.1cm taller unless compensations are made ...

Something else just came to mind and this is about the para-chamber's vent ratios: it is generally considered good policy to keep ducts/vents/ports (in their typical role) at less than a 1:10 height-to-width ratio because the port's behavior will be more accurately predicted with our software as long as the ratio isn't too high (and there can be issues with port compression or non-linearity when the system is played at high volume) ... I barely exceeded the vent ratio in my build (1" x 12.5" ) and i got away with it, but a 1:19 ratio is pushing our luck ...... OTOH since these ducts are not the cabinet's main vent it may not be quite as critical, perhaps nothing to get concerned about (the para-chamber's vents do not have to carry as much air flow.... The velocity is verifiable with Akabak), so you could still be fine in this regard .....

I did however do an experiment with the script just to see if it was possible to increase the height of both para-vents to 3.8cm but that tuned the para-chamber too high so i increased the height of the para-stub to 10cm which helped shift the para-tuning back down to 90hz (not ideal but a compromise)... These changes make the box 5.1cm taller unless compensations are made ...

Ok I'll look at it, good point 🙂

I was wondering about the ragged response from 300 hz. The more I close the front chamber section, the more smooth it gets. So the ? is when is too much. Closed in heavily like this:

Waveguide 'F2'

Node=18=5

wth=48.3cm hth=1.3cm

wmo=48.3cm hmo=4cm

Len=31cm

Conical

The FR gets smoother, but now the exit is only 1.3 cm, to small I recon... or maybe I am too worried and the ragged response will not be so prominent in "real life".

This also introduces other problems like tuning Fb too low, combined with too low sensitivity 🙄

I did this sim, it smoothes the HF by making front chamber smaller. Then I increased the PARA chamber. I also reduced lenght of P2, P3.

If this could work, it would be nice. A bit of a saddle in LF, but a little raised response at Fb only gives a bit more grunt.

Code:

System 'S1'

Small front chamber, increased PARA-chamber

|The outer dimensions are 24" H x 20" W x 18.25" D with half-inch ply material

Def_Driver '15LB100'

dD=38cm |Piston

fs=40.9Hz Vas=113L Qms=7.13

Qes=0.35 Re=5.5ohm Le=1.4mH ExpoLe=0.618

System '99L-KARLFLEX'

| vt=99L, (net)

|Rear Chamber=74L, fB=40Hz,

|Front chamber=25L-ish (roughly 17L+8-ish from the Fredditech-Cavity)

|---------------------------------------------------------

| The speaker or driver :

|---------------------------------------------------------

Driver 'Driver' Def='15LB100' Node=1=0=18=2

|--------------------------------------------

| The first section (S1, S2 , S3 in Hornresponse lingo):

|--------------------------------------------

|S1=F0 (adjusting this waveguide's length adjusts the driver offset)

|P0 (make this half of your driver's diameter)

|S2=Node2 (center of driver's cone)

|s3=F1 (length is = Node2 to the bottom of main vent aka interchamber vent)

|--------------------------------------------------

Waveguide 'F0'

Node=50=51

wth=48.3cm hth=8cm

wmo=48.3cm hmo=8.1cm

Len=55.8cm

Conical

|OFF

AcouResistance 'Stuffing1' Node=50=51 Ra=30e3Pas/m3 | Simulate moderate stuffing

Duct 'P0' Node=51=2

WD=48.3cm

HD=28.5cm

Len=19.7cm

VISC=1

Waveguide 'F1'

Node=2=4

wth=48.3cm hth=28.5cm

wmo=48.3cm hmo=28.6cm

Len=28.5cm

Conical

|-----------------------------------

| Parasitic chamber

|-----------------------------------

Duct 'P5' Node=51=52

WD=48.3cm HD=6cm Len=43cm

Duct 'P6' Node=52=0

WD=48.3cm HD=10cm Len=43cm Visc=50

Duct 'P7' Node=52=53

WD=48.3cm HD=6cm Len=43cm

Radiator 'Rad1' Def='P7' Node=53

x=0 y=0 z=0 HAngle=0 VAngle=0

|---------------------------------------------

| The interchamber vent (connects the rear chamber to the front chamber)

| Be sure to account for some additional effective length if there are

|boundaries near the end of the vent.

|----------------------------------------------

Duct 'P2' Node=4=5

WD=48.3cm

HD=6cm

Len=30.1cm

Visc=1

| EXPERIMENTAL CAVITY/DUCT/STUB

| Suggested by Freddi from DIYaudio.com

| This is a very effective method of suppressing the

| upper pipe harmonics and therefore tames and smooths response

Duct 'P3' Node=5=0

WD=48.3cm

HD=6cm

Len=33cm

VISC=50

|-----------------------------------------------------------------------------

| APERTURE STYLE "E" SECTION

| Simple Front Chamber combined with shallow ML-Transflex style mouth

| Couples end of path with other side of cone's output (aka "Tapped") in

| regards to bass frequencies but not in the upper frequencies allowing

|6th order performance without the bandpass cutoff limitations in bandwidth.

|-----------------------------------------------------------------------------

|

| The front chamber section (above the driver), nodes reversed for tapered shape.

|

Waveguide 'F2'

Node=18=5

wth=48.3cm hth=2,5cm

wmo=48.3cm hmo=5cm

Len=28cm

Conical

|

| The dimensions and depth of the mouth/aperture(technically also part

| of the front chamber).

|

Duct 'P4' Node=18=6

WD=48.3cm

HD=40.6cm

Len=2.6cm

VISC=1

Radiator 'Radiator' DEF='P4' Node=6 |Radiator or mouth dimensions defined by P4If this could work, it would be nice. A bit of a saddle in LF, but a little raised response at Fb only gives a bit more grunt.

RESONANT WONDERMENT

Sebastian ,

The front chamber's vent (F2's hth= figure) should not really be made any smaller than the interchamber duct's height (P2's HD= figure , about 6.3cm) because that (in conjunction with these cabinet width slot ducts) is already at the limit of how much we can constrict the path without running into problems with air particle velocity...

Unfortunately the dip at 300hz does show up in real life just like it does in simulations , but I think you will be happy to know that using the para-chamber somehow reduces that dip ... Take a look at this 🙂

With the Karlflex there are many different resonances supporting the output almost all across it's effective range .... They don't always exactly meet or play nicely together if they overlap , and this is the case at 300hz .. ... The hump in response that you see centered around 200hz (extending from 180hz to 250hz) is created from the upper harmonics (5th and 7th) and is a product of the main path .... The Freddi-mod cavity's job is taming that range .... Then above that the resonance of the front chamber picks up at around 400hz and extends out to almost 1khz , which leaves a gap between resonant ranges right at around 300hz ....

So the entire accompaniment of resonances for the Karlflex is as follows:

OUTLANDISH RIGHT??

If it can be made to work well then it will be an acoustic multi-resonant wondercontraption!!!

It is such a balancing act though, and during various Akabak modeling experiments i found that if the front chamber's resonance is shifted down enough to overlap with the main pipe path's upper harmonics i would encounter ragged response, i presumed that their incompatibility was phase related *shrug* , but it is possible that a happy medium can be found ....

I have an idea for a worthwhile experiment but i won't have access to my Akabak machine until later today , i was thinking that if we increased the height of the Freddi-Mod it (in theory) should knock down the hump centered around 200hz while also increasing the effective volume of the front chamber therefore shifting it's lower range of resonance from 400hz down to something in the mid to upper 300s , hopefully filling in our dip somewhat, we will see, at least it is worth a shot .....

Sebastian, the front chamber is vital to giving this design an acceptably bold and full sound, without it the cabinet sounds anemic and thin .... This was one of those things that Akabak was seemingly incapable of showing me , it is something i had to figure out by experimenting with the real-world cabinet ... I think this is also why the classic Karlson cabinets used larger front chambers ... The front chamber on the Karlflex is already undersized (the reason i had to close off the K-slot) , and making it any smaller would be heading in the wrong direction in my honest opinion ...

Your script from #1572 is an awesome script , i would revert back to that one and try more experiments on that one , but be sure to either maintain or increase front chamber volume (avoid reducing), and also be careful not to pinch the main path to less than 6.3cm (stubs and para-ducts can be less, but the main path requires good air flow ) ..

, i would revert back to that one and try more experiments on that one , but be sure to either maintain or increase front chamber volume (avoid reducing), and also be careful not to pinch the main path to less than 6.3cm (stubs and para-ducts can be less, but the main path requires good air flow ) ..

HAPPY SCIENCING!!

NOTE: The two measurements shown above are both tuned too low at around 5hz below my 40hz-ish target .... If this cabinet had a fundamental of 40hz the upper pipe harmonics would in theory also be shifted upwards alleviating the 300hz dip by filling it in to some degree ...

Sebastian ,

The front chamber's vent (F2's hth= figure) should not really be made any smaller than the interchamber duct's height (P2's HD= figure , about 6.3cm) because that (in conjunction with these cabinet width slot ducts) is already at the limit of how much we can constrict the path without running into problems with air particle velocity...

Unfortunately the dip at 300hz does show up in real life just like it does in simulations , but I think you will be happy to know that using the para-chamber somehow reduces that dip ... Take a look at this 🙂

An externally hosted image should be here but it was not working when we last tested it.

With the Karlflex there are many different resonances supporting the output almost all across it's effective range .... They don't always exactly meet or play nicely together if they overlap , and this is the case at 300hz .. ... The hump in response that you see centered around 200hz (extending from 180hz to 250hz) is created from the upper harmonics (5th and 7th) and is a product of the main path .... The Freddi-mod cavity's job is taming that range .... Then above that the resonance of the front chamber picks up at around 400hz and extends out to almost 1khz , which leaves a gap between resonant ranges right at around 300hz ....

So the entire accompaniment of resonances for the Karlflex is as follows:

- Fundamental=40hz-->

- Para-Chamber 80hz --->

- 3rd harmonic 150hz-ish (suppressed by the S1 section offset)-->

- 5th and 7th harmonics (tamed by the Freddi-Mod) -->

- Front chamber resonance (provides a a small amount of loading and gain from 400hz to almost 1k)

OUTLANDISH RIGHT??

If it can be made to work well then it will be an acoustic multi-resonant wondercontraption!!!

It is such a balancing act though, and during various Akabak modeling experiments i found that if the front chamber's resonance is shifted down enough to overlap with the main pipe path's upper harmonics i would encounter ragged response, i presumed that their incompatibility was phase related *shrug* , but it is possible that a happy medium can be found ....

I have an idea for a worthwhile experiment but i won't have access to my Akabak machine until later today , i was thinking that if we increased the height of the Freddi-Mod it (in theory) should knock down the hump centered around 200hz while also increasing the effective volume of the front chamber therefore shifting it's lower range of resonance from 400hz down to something in the mid to upper 300s , hopefully filling in our dip somewhat, we will see, at least it is worth a shot .....

Sebastian, the front chamber is vital to giving this design an acceptably bold and full sound, without it the cabinet sounds anemic and thin .... This was one of those things that Akabak was seemingly incapable of showing me , it is something i had to figure out by experimenting with the real-world cabinet ... I think this is also why the classic Karlson cabinets used larger front chambers ... The front chamber on the Karlflex is already undersized (the reason i had to close off the K-slot) , and making it any smaller would be heading in the wrong direction in my honest opinion ...

Your script from #1572 is an awesome script

, i would revert back to that one and try more experiments on that one , but be sure to either maintain or increase front chamber volume (avoid reducing), and also be careful not to pinch the main path to less than 6.3cm (stubs and para-ducts can be less, but the main path requires good air flow ) ..

, i would revert back to that one and try more experiments on that one , but be sure to either maintain or increase front chamber volume (avoid reducing), and also be careful not to pinch the main path to less than 6.3cm (stubs and para-ducts can be less, but the main path requires good air flow ) ..HAPPY SCIENCING!!

NOTE: The two measurements shown above are both tuned too low at around 5hz below my 40hz-ish target .... If this cabinet had a fundamental of 40hz the upper pipe harmonics would in theory also be shifted upwards alleviating the 300hz dip by filling it in to some degree ...

Last edited:

Random thoughts about upper mid dispersion

On a Karlson related subject and about dispersion i found an interesting post where someone named "Kenpeter" here on DIYaudio talks about covering the sides of a driver in order to get more consistent horizontal polar response higher in frequency .....

He is talking about the same thing that i also observed when experimenting with the K-slot , he says that using this technique of (obscuring the sides of the driver) requires a driver with rising response or the upper midrange output can droop and suffer, but then again he is talking about taking it to an extreme with only an 8" wide gap in order to get great dispersion to 1800hz (in theory) , yet how far axis is he talking about here? I am getting good output 45 degrees off-axis up to 2khz with my 12" driver, perhaps dispersion gets even wider at 2k or extends to 3k with the addition of some small wings at the sides of the cone? Is moderation the key with this? If i have some extra time i might experiment with removable mini-wings ..

Here is the link to the post i am referring to: http://www.diyaudio.com/forums/mult...woofer-sealed-seos-speaker-3.html#post4277665

I recall Xrk once saying that the slot created by the K-wings forms an acoustic diffraction lens ....

If my driver had a strong rising response i would definitely be more enthused about giving this idea another go ...

On a Karlson related subject and about dispersion i found an interesting post where someone named "Kenpeter" here on DIYaudio talks about covering the sides of a driver in order to get more consistent horizontal polar response higher in frequency .....

He is talking about the same thing that i also observed when experimenting with the K-slot , he says that using this technique of (obscuring the sides of the driver) requires a driver with rising response or the upper midrange output can droop and suffer, but then again he is talking about taking it to an extreme with only an 8" wide gap in order to get great dispersion to 1800hz (in theory) , yet how far axis is he talking about here? I am getting good output 45 degrees off-axis up to 2khz with my 12" driver, perhaps dispersion gets even wider at 2k or extends to 3k with the addition of some small wings at the sides of the cone? Is moderation the key with this? If i have some extra time i might experiment with removable mini-wings ..

Here is the link to the post i am referring to: http://www.diyaudio.com/forums/mult...woofer-sealed-seos-speaker-3.html#post4277665

I recall Xrk once saying that the slot created by the K-wings forms an acoustic diffraction lens ....

If my driver had a strong rising response i would definitely be more enthused about giving this idea another go ...

Yeah, JBL has been using the concept for a while. As far as I know, the famous Eminence "rising response" is a symptom of the driver having a reasonably flat power response but narrowing directivity up where the radiator is getting large relative to wavelength. Using a diffraction lens is a way to take that narrowing beamwidth and diffract it to maintain more even coverage.

The K-slot is interesting because it is both a diffraction lens and a resonator without a single path length.

MMJ - could the front chamber be made somewhat deeper and not be wasteful or chaotic in response so a regular warm and fuzzy K-aperture could be retained?

here's an 18" K in my pile - ~41.5"H x 22.5"W x 16D - does a higher aspect tend to limit cavity peaking with low q drivers ?

- it did not "go low", - - there are dips with the mic on the ground - not sure how well it does/did in the listening plane

here's an 18" K in my pile - ~41.5"H x 22.5"W x 16D - does a higher aspect tend to limit cavity peaking with low q drivers ?

- it did not "go low", - - there are dips with the mic on the ground - not sure how well it does/did in the listening plane

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

if we increased the height of the Freddi-Mod it (in theory) should knock down the hump centered around 200hz while also increasing the effective volume of the front chamber therefore shifting it's lower range of resonance from 400hz down to something in the mid to upper 300s , hopefully filling in our dip somewhat, we will see, at least it is worth a shot .....

Nice with your dissection of this Transflex Fredditeck 5000 Karlson monster cab 😎

I tried your idea;

Duct 'P3' Node=5=0

WD=48.3cm

HD=10cm

Len=25cm

VISC=50

Code:

System 'S1'

|The outer dimensions are 24" H x 20" W x 18.25" D with half-inch ply material

Def_Driver '15LB100'

dD=38cm |Piston

fs=40.9Hz Vas=113L Qms=7.13

Qes=0.35 Re=5.5ohm Le=1.4mH ExpoLe=0.618

System '99L-KARLFLEX'

| vt=99L, (net)

|Rear Chamber=74L, fB=40Hz,

|Front chamber=25L-ish (roughly 17L+8-ish from the Fredditech-Cavity)

|---------------------------------------------------------

| The speaker or driver :

|---------------------------------------------------------

Driver 'Driver' Def='15LB100' Node=1=0=18=2

|--------------------------------------------

| The first section (S1, S2 , S3 in Hornresponse lingo):

|--------------------------------------------

|S1=F0 (adjusting this waveguide's length adjusts the driver offset)

|P0 (make this half of your driver's diameter)

|S2=Node2 (center of driver's cone)

|s3=F1 (length is = Node2 to the bottom of main vent aka interchamber vent)

|--------------------------------------------------

Waveguide 'F0'

Node=50=51

wth=48.3cm hth=8cm

wmo=48.3cm hmo=8.1cm

Len=58.8cm

Conical

|OFF

AcouResistance 'Stuffing1' Node=50=51 Ra=30e3Pas/m3 | Simulate moderate stuffing

Duct 'P0' Node=51=2

WD=48.3cm

HD=25.5cm

Len=19.7cm

VISC=1

Waveguide 'F1'

Node=2=4

wth=48.3cm hth=25.5cm

wmo=48.3cm hmo=25.6cm

Len=31.5cm

Conical

|-----------------------------------

| Parasitic chamber

|-----------------------------------

Duct 'P5' Node=51=52

WD=48.3cm HD=2,5cm Len=43cm

Duct 'P6' Node=52=0

WD=48.3cm HD=7,5cm Len=43cm Visc=50

Duct 'P7' Node=52=53

WD=48.3cm HD=2,5cm Len=43cm

Radiator 'Rad1' Def='P7' Node=53

x=0 y=0 z=0 HAngle=0 VAngle=0

|---------------------------------------------

| The interchamber vent (connects the rear chamber to the front chamber)

| Be sure to account for some additional effective length if there are

|boundaries near the end of the vent.

|----------------------------------------------

Duct 'P2' Node=4=5

WD=48.3cm

HD=6.3cm

Len=31.1cm

Visc=1

| EXPERIMENTAL CAVITY/DUCT/STUB

| Suggested by Freddi from DIYaudio.com

| This is a very effective method of suppressing the

| upper pipe harmonics and therefore tames and smooths response

Duct 'P3' Node=5=0

WD=48.3cm

HD=10cm

Len=25cm

VISC=50

|-----------------------------------------------------------------------------

| APERTURE STYLE "E" SECTION

| Simple Front Chamber combined with shallow ML-Transflex style mouth

| Couples end of path with other side of cone's output (aka "Tapped") in

| regards to bass frequencies but not in the upper frequencies allowing

|6th order performance without the bandpass cutoff limitations in bandwidth.

|-----------------------------------------------------------------------------

|

| The front chamber section (above the driver), nodes reversed for tapered shape.

|

Waveguide 'F2'

Node=18=5

wth=48.3cm hth=6.3cm

wmo=48.3cm hmo=9cm

Len=31cm

Conical

|

| The dimensions and depth of the mouth/aperture(technically also part

| of the front chamber).

|

Duct 'P4' Node=18=6

WD=48.3cm

HD=40.6cm

Len=2.6cm

VISC=1

Radiator 'Radiator' DEF='P4' Node=6 |Radiator or mouth dimensions defined by P4It narrows the gab at 300 and pushes it up to 400-500 and less severe, which is nice, but at the same time makes a "rollercoaster" from 100-200hz. Like you said, it is a balancing act 🙄

- Home

- Loudspeakers

- Subwoofers

- New sub design? Constricted Transflex, simple build (series tuned 6th order)