What can a Karlflex do with a 18XL1600? What about 4 of them?

FaitalPRO 18XL1600 18" Neodymium Professional Subwoofer 8 Ohm

Yikes!

We must be dealing with different budgets.

Simplified code

Sebastian ,

Here is the Akabak Script based on the Karlflex sketch featured in post #1476 (but scaled up to 20" wide) and it accepts 10", 12" or 15" drivers depending on cab width, but this code is different from the one i previously posted because this one has been greatly simplified! (in regards to the aperture and front chamber section)..

(in regards to the aperture and front chamber section)..

Using aperture style "E" allows me to reduce and tidy things up quite a bit😀

This code is subject to change, I just made this update earlier today so it is new to me, i may improve it further...

This script is for the 24" cab height, so for your taller tower build you will have to adjust and adapt parts of it as mentioned in recent posts ....

Sebastian ,

Here is the Akabak Script based on the Karlflex sketch featured in post #1476 (but scaled up to 20" wide) and it accepts 10", 12" or 15" drivers depending on cab width, but this code is different from the one i previously posted because this one has been greatly simplified!

(in regards to the aperture and front chamber section)..

(in regards to the aperture and front chamber section)..Using aperture style "E" allows me to reduce and tidy things up quite a bit😀

This code is subject to change, I just made this update earlier today so it is new to me, i may improve it further...

This script is for the 24" cab height, so for your taller tower build you will have to adjust and adapt parts of it as mentioned in recent posts ....

Code:

|System FREDDITECH 5000 99LITER KARLFLEX FOR THE 15LB100-8

|With simplified front chamber and mouth system, Aperture Style "E"

|The outer dimensions are 24" H x 20" W x 18.25" D with half-inch ply material

Def_Driver '15LB100'

dD=38cm |Piston

fs=40.9Hz Vas=113L Qms=7.13

Qes=0.35 Re=5.5ohm Le=1.4mH ExpoLe=0.618

System '99L-KARLFLEX'

| vt=99L, (net)

|Rear Chamber=74L, fB=40Hz,

|Front chamber=25L-ish (roughly 17L+8-ish from the Fredditech-Cavity)

|---------------------------------------------------------

| The speaker or driver :

|---------------------------------------------------------

Driver 'Driver' Def='15LB100' Node=1=0=18=2

|--------------------------------------------

| The first section (S1, S2 , S3 in Hornresponse lingo):

|--------------------------------------------

|S1=F0 (adjusting this waveguide's length adjusts the driver offset)

|P0 (make this half of your driver's diameter)

|S2=Node2 (center of driver's cone)

|s3=F1 (length is = Node2 to the bottom of main vent aka interchamber vent)

|--------------------------------------------------

Waveguide 'F0'

Node=50=51

wth=48.3cm hth=10cm

wmo=48.3cm hmo=10.1cm

Len=50.8cm

Conical

|OFF

AcouResistance 'Stuffing1' Node=50=51 Ra=30e3Pas/m3 | Simulate moderate stuffing

Duct 'P0' Node=51=2

WD=48.3cm

HD=23.5cm

Len=19.7cm

VISC=1

Waveguide 'F1'

Node=2=4

wth=48.3cm hth=23.5cm

wmo=48.3cm hmo=23.6cm

Len=23.5cm

Conical

|---------------------------------------------

| The interchamber vent (connects the rear chamber to the front chamber)

| Be sure to account for some additional effective length if there are

|boundaries near the end of the vent.

|----------------------------------------------

Duct 'P2' Node=4=5

WD=48.3cm

HD=6.3cm

Len=31.1cm

Visc=1

| EXPERIMENTAL CAVITY/DUCT/STUB

| Suggested by Freddi from DIYaudio.com

| This is a very effective method of suppressing the

| upper pipe harmonics and therefore tames and smooths response

Duct 'P3' Node=5=0

WD=48.3cm

HD=6.3cm

Len=35cm

VISC=50

|-----------------------------------------------------------------------------

| APERTURE STYLE "E" SECTION

| Simple Front Chamber combined with shallow ML-Transflex style mouth

| Couples end of path with other side of cone's output (aka "Tapped") in

| regards to bass frequencies but not in the upper frequencies allowing

|6th order performance without the bandpass cutoff limitations in bandwidth.

|-----------------------------------------------------------------------------

|

| The front chamber section (above the driver), nodes reversed for tapered shape.

|

Waveguide 'F2'

Node=18=5

wth=48.3cm hth=6.3cm

wmo=48.3cm hmo=9cm

Len=23cm

Conical

|

| The dimensions and depth of the mouth/aperture(technically also part

| of the front chamber).

|

Duct 'P4' Node=18=6

WD=48.3cm

HD=40.6cm

Len=2.6cm

VISC=1

Radiator 'Radiator' DEF='P4' Node=6 |Radiator or mouth dimensions defined by P4

Last edited:

Sebastian ,

Here is the Akabak Script based on the Karlflex sketch featured in post #1476 (but scaled up to 20" wide) and it accepts 10", 12" or 15" drivers depending on cab width, but this code is different from the one i previously posted because this one has been greatly simplified!(in regards to the aperture and front chamber section)..

Using aperture style "E" allows me to reduce and tidy things up quite a bit😀

This code is subject to change, I just made this update earlier today so it is new to me, i may improve it further...

This script is for the 24" cab height, so for your taller tower build you will have to adjust and adapt parts of it as mentioned in recent posts ....

Thanx, you are a jem🙂 I'll also try to model in akabak using your tips, it is a good learning process, albeit steep.

Good to hear that it can be made simpler. KISS is nice...😀

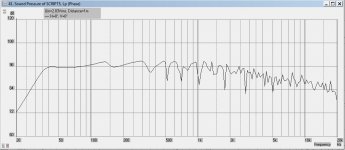

Hi Matthew, I came up with this in Acabak. It is basically your script, I just adjusted some values, so my internal box will be 72cm tall. I also slimmed F0 to 6 cm and increased P0 and F1 accordingly.

The FR looks nice without any severe nulls (steep holes). Maybe you could take a quick look, and see if it is flawed, thanx 😎

The FR looks nice without any severe nulls (steep holes). Maybe you could take a quick look, and see if it is flawed, thanx 😎

Code:

|System FREDDITECH 5000 99LITER KARLFLEX FOR THE 15LB100-8

|With simplified front chamber and mouth system, Aperture Style "E"

|The outer dimensions are 24" H x 20" W x 18.25" D with half-inch ply material

Def_Driver '15LB100'

dD=38cm |Piston

fs=40.9Hz Vas=113L Qms=7.13

Qes=0.35 Re=5.5ohm Le=1.4mH ExpoLe=0.618

System '99L-KARLFLEX'

| vt=99L, (net)

|Rear Chamber=74L, fB=40Hz,

|Front chamber=25L-ish (roughly 17L+8-ish from the Fredditech-Cavity)

|---------------------------------------------------------

| The speaker or driver :

|---------------------------------------------------------

Driver 'Driver' Def='15LB100' Node=1=0=18=2

|--------------------------------------------

| The first section (S1, S2 , S3 in Hornresponse lingo):

|--------------------------------------------

|S1=F0 (adjusting this waveguide's length adjusts the driver offset)

|P0 (make this half of your driver's diameter)

|S2=Node2 (center of driver's cone)

|s3=F1 (length is = Node2 to the bottom of main vent aka interchamber vent)

|--------------------------------------------------

Waveguide 'F0'

Node=50=51

wth=48cm hth=6cm

wmo=48cm hmo=6.1cm

Len=55cm

Conical

|OFF

AcouResistance 'Stuffing1' Node=50=51 Ra=30e3Pas/m3 | Simulate moderate stuffing

Duct 'P0' Node=51=2

WD=48cm

HD=28.5cm

Len=19.7cm

VISC=1

Waveguide 'F1'

Node=2=4

wth=48cm hth=28.5cm

wmo=48cm hmo=28.6cm

Len=29.5cm

Conical

|---------------------------------------------

| The interchamber vent (connects the rear chamber to the front chamber)

| Be sure to account for some additional effective length if there are

|boundaries near the end of the vent.

|----------------------------------------------

Duct 'P2' Node=4=5

WD=48cm

HD=8cm

Len=31cm

Visc=1

| EXPERIMENTAL CAVITY/DUCT/STUB

| Suggested by Freddi from DIYaudio.com

| This is a very effective method of suppressing the

| upper pipe harmonics and therefore tames and smooths response

Duct 'P3' Node=5=0

WD=48cm

HD=8cm

Len=35cm

VISC=50

|-----------------------------------------------------------------------------

| APERTURE STYLE "E" SECTION

| Simple Front Chamber combined with shallow ML-Transflex style mouth

| Couples end of path with other side of cone's output (aka "Tapped") in

| regards to bass frequencies but not in the upper frequencies allowing

|6th order performance without the bandpass cutoff limitations in bandwidth.

|-----------------------------------------------------------------------------

|

| The front chamber section (above the driver), nodes reversed for tapered shape.

|

Waveguide 'F2'

Node=18=5

wth=48cm hth=6.3cm

wmo=48cm hmo=9cm

Len=37cm

Conical

|

| The dimensions and depth of the mouth/aperture(technically also part

| of the front chamber).

|

Duct 'P4' Node=18=6

WD=48cm

HD=40.6cm

Len=2.6cm

VISC=1

Radiator 'Radiator' DEF='P4' Node=6 |Radiator or mouth dimensions defined by P4Call me simple minded

You are welcome Sir! 🙂

I really prefer the simplicity even though it doesn't take small details into account such as the radius/flare shape of the aperture just above the driver (i could try to emulate that but is it really worth the extra lines of code and extra potential for error for a miniscule difference in simulated performance? Maybe i will include it if i can figure out a very simple way of working it in) ...........

There is also a more complicated way of calculating the path length at the turns and switchbacks in a folded pipe/horn cabinet, but i chose the simplest method....

Thanx, you are a jem🙂 I'll also try to model in akabak using your tips, it is a good learning process, albeit steep.

Good to hear that it can be made simpler. KISS is nice...😀

You are welcome Sir! 🙂

I really prefer the simplicity even though it doesn't take small details into account such as the radius/flare shape of the aperture just above the driver (i could try to emulate that but is it really worth the extra lines of code and extra potential for error for a miniscule difference in simulated performance? Maybe i will include it if i can figure out a very simple way of working it in) ...........

There is also a more complicated way of calculating the path length at the turns and switchbacks in a folded pipe/horn cabinet, but i chose the simplest method....

XRK and Beau

Beau and XRK ,

I have found that (after lots of comparisons with this style of cabinet) when it comes to drivers there is a point of diminishing returns in terms of money spent on a single uber driver and decibels you can expect to get versus using multiples of less expensive drivers which often makes more sense if you are seeking a potent dollar per decibel value...

For example: you can get more output from two LAB15-4 drivers loaded into 100 liter Karlflex cabinets as opposed to a single 18XL1600 loaded into a 170 liter cabinet, and you save money ....

Lets look at small herds of cabinets..

Both examples tuned to 35hz (using quick and dirty HR OD-TP test, 2pi)

(the prices above are from the Parts Express website)

So in essence it is the same performance for half the price .... The Lab15-4 deal was even more sweet when we could buy them off of ebay for around $130 a piece, but that window of opportunity has passed, gee thanks PE 😛

Yikes!

We must be dealing with different budgets.

Beau and XRK ,

I have found that (after lots of comparisons with this style of cabinet) when it comes to drivers there is a point of diminishing returns in terms of money spent on a single uber driver and decibels you can expect to get versus using multiples of less expensive drivers which often makes more sense if you are seeking a potent dollar per decibel value...

For example: you can get more output from two LAB15-4 drivers loaded into 100 liter Karlflex cabinets as opposed to a single 18XL1600 loaded into a 170 liter cabinet, and you save money ....

Lets look at small herds of cabinets..

Both examples tuned to 35hz (using quick and dirty HR OD-TP test, 2pi)

- 4 x 18XL1600 in 170 liter cabinets= 136db , $1980, 680L total

- 6 x LAB15-4 in 100 liter cabinets = 137db , $1071, 600L total

(the prices above are from the Parts Express website)

So in essence it is the same performance for half the price .... The Lab15-4 deal was even more sweet when we could buy them off of ebay for around $130 a piece, but that window of opportunity has passed, gee thanks PE 😛

Last edited:

Beau and XRK ,

I have found that (after lots of comparisons with this style of cabinet) when it comes to drivers there is a point of diminishing returns in terms of money spent on a single uber driver and decibels you can expect to get versus using multiples of less expensive drivers which often makes more sense if you are seeking a potent dollar per decibel value...

For example: you can get more output from two LAB15-4 drivers loaded into 100 liter Karlflex cabinets as opposed to a single 18XL1600 loaded into a 170 liter cabinet, and you save money ....

Lets look at small herds of cabinets..

Both examples tuned to 35hz (using quick and dirty HR OD-TP test, 2pi)

- 4 x 18XL1600 in 170 liter cabinets= 136db , $1980, 680L total

- 6 x LAB15-4 in 100 liter cabinets = 137db , $1071, 600L total

(the prices above are from the Parts Express website)

So in essence it is the same performance for half the price .... The Lab15-4 deal was even more sweet when we could buy them off of ebay for around $130 a piece, but that window of opportunity has passed, gee thanks PE 😛

Well, it just so happens I have two Lab 15s waiting to go into 100 liter Karlflex cabinets (that I have yet to build). My budget thanks me.

Looking good!...followed by Parasitic chamber rants complete with run-on sentences =P

Mr Sebastian ,

It seems to me like you have the right idea, You learn fast! 🙂

The graph is great, smooth, and as you can see you have 96db @ 1w/1m efficiency on the bottom end which matches the midrange on that driver almost perfectly 😀 It should have a well balanced sound.

I went over the script and it works as far as i can tell , i haven't noticed any major problems with it yet .... Your S1 is more slender but that is fine , and the bottom of your S1 looks like it will extend down to about 7cm above the top face of your bottom panel, which is also totally fine...

Your F1 (S3) length is 29.5cm but i calculated that it should be more like 32cm, nevertheless it is close enough , i think it is awesome that you figured out how this script works (not to mention the Akabak software) practically overnight! GOOD WORK!

, i think it is awesome that you figured out how this script works (not to mention the Akabak software) practically overnight! GOOD WORK!

Ok , here are a few more ideas to think about:

Another thing to consider is the fact that K-cabs already have the reputation of controlling cone movement effectively, so adding additional cone control will only be beneficial up to a point, and beyond that it could become destructive, after all voicecoils cool themselves through their movement and the resulting movements of air across the coil and through the vents and motor (which requires some amount of excursion to happen). So an extreme lack of movement could create a heat buildup problem... We also need to consider that controlling a cone's movement too tightly could risk doing physical damage to the cone itself due to physical pressure and stress........ So some cone control is definitely a good thing, but an overly strict amount of cone control could potentially be a bad thing ....

Ever push a driver hard using sine tones tuned precisely to a reflex cabinet's fundamental frequency? You shouldn't, it is bad news , there is very little excursion to speak of but you can burn up a voicecoil quickly or cause physical damage

or cause physical damage ...

...

It would be interesting to see someone test A K-cab with parasitic chamber feature (tuned A little less than an octave over the fundamental like a DCR) compared to a similar K-cab without parasitic chamber feature at high volumes to measure excursion and see which fails first (loaded with drivers that have high thermal capability and low physical excursion capability like the Pa310) .... If the para-chambered K-cab could produce significantly more SPL (enough to justify the up to 50% increase in cabinet size) without burning itself up, tearing or blowing itself apart then it will have proven itself as a practical design innovation, but who knows if such a test will ever happen, this is all so very obscure to begin with 🙄

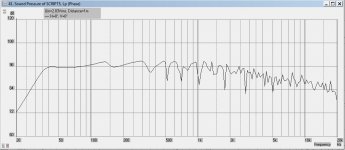

If anyone is curious: here (below) is a graph showing how the vented Para-chamber affected my response measurements ... This para-chamber was actually undersized but i was still able to make it work, notice the peak at the para-frequency instead of a dip (not typical for a DCR/ABC) ...

I called this box the "Tri-Chamber" Karlflex ... The extra complication of the build was inconvenient, but it worked 😀

Hi Matthew, I came up with this in Acabak. It is basically your script, I just adjusted some values, so my internal box will be 72cm tall. I also slimmed F0 to 6 cm and increased P0 and F1 accordingly.

The FR looks nice without any severe nulls (steep holes). Maybe you could take a quick look, and see if it is flawed, thanx 😎

Mr Sebastian ,

It seems to me like you have the right idea, You learn fast! 🙂

The graph is great, smooth, and as you can see you have 96db @ 1w/1m efficiency on the bottom end which matches the midrange on that driver almost perfectly 😀 It should have a well balanced sound.

I went over the script and it works as far as i can tell , i haven't noticed any major problems with it yet .... Your S1 is more slender but that is fine , and the bottom of your S1 looks like it will extend down to about 7cm above the top face of your bottom panel, which is also totally fine...

Your F1 (S3) length is 29.5cm but i calculated that it should be more like 32cm, nevertheless it is close enough

, i think it is awesome that you figured out how this script works (not to mention the Akabak software) practically overnight! GOOD WORK!

, i think it is awesome that you figured out how this script works (not to mention the Akabak software) practically overnight! GOOD WORK!

Ok , here are a few more ideas to think about:

- Using 3/4" ply material would help eat up some of that extra height and extra internal airspace .... Not really necessary now since you have a working script at the right height, but still an option if you prefer your box to be as stiff as concrete, survive bombings or to weigh enough to double as a boat anchor (because you never know when you might lose your main boat anchor, always good to have a backup

) ....

) ....

- Employing a fancy labyrinthine vented parasitic chamber, which would add at least 10" or 12" to the bottom of a 24" Karlflex cab and is a complex pain to build (but is certainly a good exercise in the use of Akabak) ..... Now here is something interesting about this option: The extra resonance is supposed to help control excursion and normally creates a dip in response near or just above the parasitic chamber's resonant frequency due to the phase relationships of all vents (and the cone's direct radiation) not lining up perfectly in a typical Weems/Augsperger DCR (also called ABC) cabinet ..... But with the addition of aperture type "E" i noticed that the bass range REALLY seemed to come into focus (this was just before i closed the para-chamber off) ... My theory is that aperture "E" created enough of a phase shift (through the front chamber's additional chamber/vent set) in order to get all sources of radiation to line up reasonably well so that they were no longer fighting each other.. Previously with other apertures it sounded like there was some cancellation at some frequencies, and particular bass sounds often sounded somewhat "stifled" or held back somehow but Aperture "E" fixed that and seemed to be a great solution to use in conjunction with the Karlflex+parasitic chamber , this was something that i figured out experimenting with the real box itself (not the simulation) and is actually quite a breakthrough for anyone who is considering an ABC/DCR box design, the use of a front chamber can improve performance 😀

Another thing to consider is the fact that K-cabs already have the reputation of controlling cone movement effectively, so adding additional cone control will only be beneficial up to a point, and beyond that it could become destructive, after all voicecoils cool themselves through their movement and the resulting movements of air across the coil and through the vents and motor (which requires some amount of excursion to happen). So an extreme lack of movement could create a heat buildup problem... We also need to consider that controlling a cone's movement too tightly could risk doing physical damage to the cone itself due to physical pressure and stress........ So some cone control is definitely a good thing, but an overly strict amount of cone control could potentially be a bad thing ....

Ever push a driver hard using sine tones tuned precisely to a reflex cabinet's fundamental frequency? You shouldn't, it is bad news , there is very little excursion to speak of but you can burn up a voicecoil quickly

or cause physical damage

or cause physical damage ...

... It would be interesting to see someone test A K-cab with parasitic chamber feature (tuned A little less than an octave over the fundamental like a DCR) compared to a similar K-cab without parasitic chamber feature at high volumes to measure excursion and see which fails first (loaded with drivers that have high thermal capability and low physical excursion capability like the Pa310) .... If the para-chambered K-cab could produce significantly more SPL (enough to justify the up to 50% increase in cabinet size) without burning itself up, tearing or blowing itself apart then it will have proven itself as a practical design innovation, but who knows if such a test will ever happen, this is all so very obscure to begin with 🙄

If anyone is curious: here (below) is a graph showing how the vented Para-chamber affected my response measurements ... This para-chamber was actually undersized but i was still able to make it work, notice the peak at the para-frequency instead of a dip (not typical for a DCR/ABC) ...

I called this box the "Tri-Chamber" Karlflex ... The extra complication of the build was inconvenient, but it worked 😀

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Beau and XRK ,

I have found that (after lots of comparisons with this style of cabinet) when it comes to drivers there is a point of diminishing returns in terms of money spent on a single uber driver and decibels you can expect to get versus using multiples of less expensive drivers which often makes more sense if you are seeking a potent dollar per decibel value...

For example: you can get more output from two LAB15-4 drivers loaded into 100 liter Karlflex cabinets as opposed to a single 18XL1600 loaded into a 170 liter cabinet, and you save money ....

Lets look at small herds of cabinets..

Both examples tuned to 35hz (using quick and dirty HR OD-TP test, 2pi)

- 4 x 18XL1600 in 170 liter cabinets= 136db , $1980, 680L total

- 6 x LAB15-4 in 100 liter cabinets = 137db , $1071, 600L total

(the prices above are from the Parts Express website)

So in essence it is the same performance for half the price .... The Lab15-4 deal was even more sweet when we could buy them off of ebay for around $130 a piece, but that window of opportunity has passed, gee thanks PE 😛

MMj,

Thanks for the comparisons. I know, those are expensive drivers - they just happen to be made for pro sound stadium setups designed to be bullet proof at high SPL's. I normally use pretty low price drivers too - just looking at a potential cost not a limit pro application where reliability is critical. I think you may find the Nd motors and cast frames of these more expensive drivers to have lower HD. Did you actually run the Faital in your Karflex sim?

An HR fudge

XRK,

I was using the fudged HR method (a very rough equivalent) for that comparison ....

As soon as i finish up the current Karlflex project (for 10s , 12s , and 15s) i am going to begin work on the version for 18" drivers... I will start off with getting the Akabak model ironed out, then i will make sketches ... It will require a different fold (in order to make it work in a 24" cube) but i already have ideas about how i can make that work, keeping air particle velocity low enough and also maintaining a large enough (effective) front chamber will be the tricky parts.....

Your Faital driver will work in it, and another great driver for use in this 24" cube will be the B&C 18TBW100 .... The 24" cube designs are still weeks down the road but i am contemplating them as they are in queue ...🙂

MMj,

Thanks for the comparisons. I know, those are expensive drivers - they just happen to be made for pro sound stadium setups designed to be bullet proof at high SPL's. I normally use pretty low price drivers too - just looking at a potential cost not a limit pro application where reliability is critical. I think you may find the Nd motors and cast frames of these more expensive drivers to have lower HD. Did you actually run the Faital in your Karflex sim?

XRK,

I was using the fudged HR method (a very rough equivalent) for that comparison ....

As soon as i finish up the current Karlflex project (for 10s , 12s , and 15s) i am going to begin work on the version for 18" drivers... I will start off with getting the Akabak model ironed out, then i will make sketches ... It will require a different fold (in order to make it work in a 24" cube) but i already have ideas about how i can make that work, keeping air particle velocity low enough and also maintaining a large enough (effective) front chamber will be the tricky parts.....

Your Faital driver will work in it, and another great driver for use in this 24" cube will be the B&C 18TBW100 .... The 24" cube designs are still weeks down the road but i am contemplating them as they are in queue ...🙂

Last edited:

Here we go

Beau ,

Are you ready to get started? I am going to send something to you here in a few minutes 😀

Well, it just so happens I have two Lab 15s waiting to go into 100 liter Karlflex cabinets (that I have yet to build). My budget thanks me.

Beau ,

Are you ready to get started? I am going to send something to you here in a few minutes 😀

Beau ,

Are you ready to get started? I am going to send something to you here in a few minutes 😀

Thank you my friend.

Moon events, go out and have a look !

You are welcome Beau 🙂

I hope everyone is enjoying the lunacy, it is the near Equinox Harvest blood moon supermoon eclipse tonight!

Ok , back on topic now ,

I finally added an old scrap ply panel to cover up the K-slot (instead of the cardboard duct tape, loose ply and clamps i was using before) , this is much more solid and looks a heck of a lot better for certain (not that i care what it looks like really, this is just a prototype) ....

Here is a picture of it now complete with Frankenpiezo sitting on top:

The driver really needed to be mounted about 1.5" lower on the baffle ...... In the new sketch the driver will be depicted as being mounted as low on the baffle as possible which is ideal .... Speaking of that, The new sketch is nearly done ...

...

Thank you my friend.

You are welcome Beau 🙂

I hope everyone is enjoying the lunacy, it is the near Equinox Harvest blood moon supermoon eclipse tonight!

Ok , back on topic now ,

I finally added an old scrap ply panel to cover up the K-slot (instead of the cardboard duct tape, loose ply and clamps i was using before) , this is much more solid and looks a heck of a lot better for certain (not that i care what it looks like really, this is just a prototype) ....

Here is a picture of it now complete with Frankenpiezo sitting on top:

An externally hosted image should be here but it was not working when we last tested it.

The driver really needed to be mounted about 1.5" lower on the baffle ...... In the new sketch the driver will be depicted as being mounted as low on the baffle as possible which is ideal .... Speaking of that, The new sketch is nearly done

...

...

Last edited:

what happens if the vent is extended, tuning a half octave lower and an underdamped (Q~2) highpass filter applied at fb like a 6th order reflex? - can you get a decent 30Hz from a 100 l Karlflex and still have a flat passband with ok midbass power handling? (could a system be made convertible assuming access to a removable vent extension)

Mr Sebastian ,

It seems to me like you have the right idea, You learn fast! 🙂

The apprentice has a good Master 😀

Employing a fancy labyrinthine vented parasitic chamber, which would add at least 10" or 12" to the bottom of a 24" Karlflex cab and is a complex pain to build (but is certainly a good exercise in the use of Akabak)

Must admit that I am still struggling with the node part. Making new nodes and such. Have to reread the "Toturial for Dummies"🙂

There are things to consider when taking on such a challenge... Combining something like a Karlflex with a parasitic chamber is incredibly experimental and a person would have to be comfortable with the thought of losing some time and materials in an endeavor which may or may not produce acceptable results ...

Well, if one want to walk the path unknown, there will be falldowns and the like. The joy of succes is at least equal to the endeavor, not a bad trade in the experimental world😀

Another thing to consider is the fact that K-cabs already have the reputation of controlling cone movement effectively, so adding additional cone control will only be beneficial up to a point, and beyond that it could become destructive, after all voicecoils cool themselves through their movement and the resulting movements of air across the coil and through the vents and motor (which requires some amount of excursion to happen). So an extreme lack of movement could create a heat buildup problem... We also need to consider that controlling a cone's movement too tightly could risk doing physical damage to the cone itself due to physical pressure and stress........ So some cone control is definitely a good thing, but an overly strict amount of cone control could potentially be a bad thing ....

I'm hitting x-max before thermal limit, so a bit more cone control would be welcome. I even have some crazy idea about plugging a non-magnetic metal rod in the bass magnet vent hole, to dissipate heat more effectively. I have seen it done before and the guy, who did it, claimed that he could feed the bass with something like 30% more voltage🙄

Maybe?

I don't know , perhaps something like that could be done with a vented parasitic chamber/resonator system ..... I thought it was interesting that I was getting some output (and some cone control) below FB, (at least more than i had expected) when the para-chamber was still part of the Karlflex system, and maybe that action could be somehow optimized......... I had witnessed a similar but much more pronounced effect over a year ago when i made a set of special TL towers for a friend with vented para-chamber using very high QTS drivers with very high FS figures, we observed fully useful output right down to about 60hz, which was well below the verified fundamental tuning of 75hz , i thought that was exciting!

what happens if the vent is extended, tuning a half octave lower and an underdamped (Q~2) highpass filter applied at fb like a 6th order reflex? - can you get a decent 30Hz from a 100 l Karlflex and still have a flat passband with ok midbass power handling? (could a system be made convertible assuming access to a removable vent extension)

I don't know , perhaps something like that could be done with a vented parasitic chamber/resonator system ..... I thought it was interesting that I was getting some output (and some cone control) below FB, (at least more than i had expected) when the para-chamber was still part of the Karlflex system, and maybe that action could be somehow optimized......... I had witnessed a similar but much more pronounced effect over a year ago when i made a set of special TL towers for a friend with vented para-chamber using very high QTS drivers with very high FS figures, we observed fully useful output right down to about 60hz, which was well below the verified fundamental tuning of 75hz , i thought that was exciting!

Brilliant nodes

Oh gosh no, don't say that I just recently learned how to use Akabak myself (just before i built the prototype box) so i am by no means any kind of expert, i just learned enough to get the job done, and i should probably have no business teaching it to others anytime soon..

I just recently learned how to use Akabak myself (just before i built the prototype box) so i am by no means any kind of expert, i just learned enough to get the job done, and i should probably have no business teaching it to others anytime soon..

The online tutorials are fantastic and i referenced them constantly when learning, i was also lucky to have some guidance from folks like XRK971 , and JAG ....

The nodes are a brilliant way of connecting components together, you will love them once you get accustomed to their usage .

Using a metal rod (hollow i assume?) to dissipate extra heat is interesting, I had not heard about that before, but yes, under normal circumstances (meaning in a typical cabinet) as far as your 15LB100 driver and especially my PA310 driver are concerned we are both going to reach physical excursion limitations (and or the voicecoil moving too far out of the magnetic gap which i think is still considered "physical") long before we reach any thermal/electrical limitations .......... So we would be considered physically limited as opposed to thermally limited ....

The apprentice has a good Master 😀

Oh gosh no, don't say that

I just recently learned how to use Akabak myself (just before i built the prototype box) so i am by no means any kind of expert, i just learned enough to get the job done, and i should probably have no business teaching it to others anytime soon..

I just recently learned how to use Akabak myself (just before i built the prototype box) so i am by no means any kind of expert, i just learned enough to get the job done, and i should probably have no business teaching it to others anytime soon..

Must admit that I am still struggling with the node part. Making new nodes and such. Have to reread the "Toturial for Dummies"🙂

The online tutorials are fantastic and i referenced them constantly when learning, i was also lucky to have some guidance from folks like XRK971 , and JAG ....

The nodes are a brilliant way of connecting components together, you will love them once you get accustomed to their usage .

Well, if one want to walk the path unknown, there will be falldowns and the like. The joy of succes is at least equal to the endeavor, not a bad trade in the experimental world😀

I'm hitting x-max before thermal limit, so a bit more cone control would be welcome. I even have some crazy idea about plugging a non-magnetic metal rod in the bass magnet vent hole, to dissipate heat more effectively. I have seen it done before and the guy, who did it, claimed that he could feed the bass with something like 30% more voltage🙄

Using a metal rod (hollow i assume?) to dissipate extra heat is interesting, I had not heard about that before, but yes, under normal circumstances (meaning in a typical cabinet) as far as your 15LB100 driver and especially my PA310 driver are concerned we are both going to reach physical excursion limitations (and or the voicecoil moving too far out of the magnetic gap which i think is still considered "physical") long before we reach any thermal/electrical limitations .......... So we would be considered physically limited as opposed to thermally limited ....

Thumpy dance party in our dining room experiment

IN THE NAME OF SCIENCE An experiment was performed here yesterday , some very important research! 😉 ....

After the PL adhesive cured enough (on the new front panel) to make me feel confident in pushing the Karlflex i asked my wife to pick out a few of her most thumpy dance music tracks in order to get the cone moving on our test box .... I turned the drive up enough to barely begin to tickle the -10db LED on the XLS 1500 and it was really loud at this point, house party levels.. In order to conversate you had to scream at the person next to you in the dining room to be heard, and there was no problem filling the house full of very clean sound...During this test the cone was moving but not a lot and it could now be seen easily if you look at it from the side close-up..... I get the impression that there was still much more headroom .....Abundant headroom..... Fun test!

at the person next to you in the dining room to be heard, and there was no problem filling the house full of very clean sound...During this test the cone was moving but not a lot and it could now be seen easily if you look at it from the side close-up..... I get the impression that there was still much more headroom .....Abundant headroom..... Fun test!

I know it is dangerous to assume anything but i am going to assume that this will be enough cone movement to keep the PA310s voicecoil cool with music at a high level, however, what about with a para-chamber? who knows .......... I never pushed it this hard before blocking off the vented para-chamber on both sides...

IN THE NAME OF SCIENCE An experiment was performed here yesterday , some very important research! 😉 ....

After the PL adhesive cured enough (on the new front panel) to make me feel confident in pushing the Karlflex i asked my wife to pick out a few of her most thumpy dance music tracks in order to get the cone moving on our test box .... I turned the drive up enough to barely begin to tickle the -10db LED on the XLS 1500 and it was really loud at this point, house party levels.. In order to conversate you had to scream

at the person next to you in the dining room to be heard, and there was no problem filling the house full of very clean sound...During this test the cone was moving but not a lot and it could now be seen easily if you look at it from the side close-up..... I get the impression that there was still much more headroom .....Abundant headroom..... Fun test!

at the person next to you in the dining room to be heard, and there was no problem filling the house full of very clean sound...During this test the cone was moving but not a lot and it could now be seen easily if you look at it from the side close-up..... I get the impression that there was still much more headroom .....Abundant headroom..... Fun test!

I know it is dangerous to assume anything but i am going to assume that this will be enough cone movement to keep the PA310s voicecoil cool with music at a high level, however, what about with a para-chamber? who knows .......... I never pushed it this hard before blocking off the vented para-chamber on both sides...

Last edited:

Using a metal rod (hollow i assume?) to dissipate extra heat is interesting

Yes, hollow rod of course. If you inserted the rod and then sliced it into 3 or 4 parts (the part of the rod outside the bass) and pulled them apart i little bit, there would be even more airflow around the rod, generating more heat dissipation.

Sounds good with your little bass test😛 For an easier way to see cone movement, you could put a small piece of paper on the cone with stick tape, choose any colour you like (not black) 😀

Would be nice if you did the same test with the para-chamber open, to see and hear the difference. Then the rod trick could come in handy😎

- Home

- Loudspeakers

- Subwoofers

- New sub design? Constricted Transflex, simple build (series tuned 6th order)