So i still insist that something isn't adding up, either our software is simulating high on velocity, or maybe we are just keeping our definition of what we consider "DANGERZONE" threshold too low (as i believe XRK may have been suggesting earlier)

I was wondering why you say turbulence equals distortion.

You already posted the answer to this question in your next few sentences. Here's the highlights, I've bolded the most important parts.

Turbulence is ... eddies and vortices... Turbulence in the constrictor duct just adds more resistance and losses... You will hear a sound not unlike the sound a vacuum cleaner makes when you listen to the air flow going into the attachment hose...

If you are ok with this behavior then I guess there's not much more to discuss, as long as everyone is aware that this is happening.

I am familiar with reynolds number and I am aware that most of the audible chuffing is going to be masked by distance, content and the fact that the constriction is inside the enclosure. This does not mean there won't be significant port compression.

Having said all this, I do agree that we should strive to aim for velocities below 20m/s for regular program levels. I think velocity excursion into 30's of m/s are OK for peak levels which are not continuous for the reasons shown above.

This is where I disagree. As a personal aside, port issues are my pet peeve and the reason I started to study audio. I built a sub from a plan and it chuffed. I didn't know why so I started my education.

There is an extremely popular sub (not the one described above) called the Cerberus. It uses the Tang Band w6-1139 with a 1.5 inch port. I've used the same driver with a 3 inch port (4x larger in width and many times larger in length than 1.5 inch port) with approximately the same tuning and it chuffed horribly. My name is just a guy and I am against chuffing and port losses. That is the basis of my campaign.

Since the majority of audible port effects are masked in this design it's not really a chuffing issue, but more of a port compression issue. Resistance and losses. If you are happy with resistance and losses this design is fine but I'm not sure how anyone can comment on how acceptable the losses are until the design is measured at high power. The only thing we have until then is what the software tells us is happening.

XRK,

I see, so we really need a measurement at HR's Apt/Lpt section (Maybe we can put in a request with David) , But STILL with that said this doesn't add up since a pipe with an area of 356sq cm shouldn't have a velocity of 10m/s (halfway to the DANGERZONE😉) at only 38 volts ... If that were the case then all reflex cabinets made for car subs, home subs and whatever else would need MUCH larger ports or they would be blatantly chuffing far too much to be acceptable as they use 2" , 2.5" and 3" diameter ports or high aspect ratio slot vents with equivalent areas and we know about the power levels and xmax ratings involved in some of those apps ...... Yet , no noticeable chuffing takes place in those boxes, even when the ends of the ports are not concealed behind a bandpass cutoff 🙂

You are not using the right software and you are not looking at the right thing. You can't simulate a completely different design and say that this design is ok. Akabak is not wrong. Flare It is not wrong (although it's used in a different way and for different port shapes than intended here). My analysis could be wrong but without measurements I'm going to assume it's not.

You can have turbulence and port compression long before chuffing becomes an audible problem, especially when the chuffing is heavily masked. Chuffing is a symptom of a problem, but the problem starts well before chuffing is audible, especially when chuffing is well masked.

So i still insist that something isn't adding up, either our software is simulating high on velocity, or maybe we are just keeping our definition of what we consider "DANGERZONE" threshold too low (as i believe XRK may have been suggesting earlier)

Flare It is more conservative than any of the velocity numbers that are usually considered acceptable (especially for smaller ports), and that guy did actual research to find chuffing and core limit velocity info. Our threshold is usually too high, not too low.

If you sim a tapped horn and a ported box at xmax and they have the same low knee and the same spl at the low knee, and you build and measure those two designs the tapped horn will generally always outperform the ported box. This is because of compression. It's almost impossible to build a port big enough to completely escape port compression unless you morph the ported box into some type of transmission line or horn. Small ducts that are required to pass a lot of air quickly are always a problem.

Last edited:

Having said all this, I do agree that we should strive to aim for velocities below 20m/s for regular program levels. I think velocity excursion into 30's of m/s are OK for peak levels which are not continuous for the reasons shown above.

I think just looking at the velocity alone might not be enough. I'd be interested in the changes in velocity expected across the length of the horn or duct, and of course at the exit of the duct on the speaker's cabinet.

JAG,Several people are arguing that since this is inside the box it doesn't matter but when you have 26 - 30 m/s rushing by a sharp corner you are going to have massive turbulence, there's no way around that. Turbulence equals distortion, that's a fact.

And there's not a whole lot else to say, except that measurements are required.

Yes, measurements are required, though I have no accurate way of measuring vent velocity, other than if the vent chuffs, it is too small.

Funny, on the basis of my WSLab 2x12" Bassbox Pro sim (done by an on line friend) showing a vent velocity of 15 meters /sec, and there being no audible chuffing, I have frequently recommended that velocity as a reasonable "ballpark" to stay under, but just realized that velocity figure was at only 9mm, rather than the 13mm Xmax that I frequently ran the cabinet to (the surround hits the grill cloth at a bit over Xmax), with no audible chuffing.

Since I don't own Bass Box pro, I just compared the difference between 9 and 13mm in Hornresp, and found the particle velocity to be 20m/s at 9mm (30v) and 27.55m/s at 13mm (41v), about 25% higher, right in the middle of the 26- 30m/s "danger zone" you seem all excited about.

In this post, I compared the distortion of the cabinet in push pull and normal configuration:

http://www.diyaudio.com/forums/subwoofers/191833-push-pull-vs-normal-distortion-compared.html

At 35 volt drive level, which is close to Xmax, at and above Fb distortion averaged around 4% for the normal cab, and about 2% for the PP. For those of you unfamiliar with sub distortion levels, those are both quite good, few people can actually detect less than 10% LF distortion even with pure tones.

The same test with the cabinet sealed resulted in considerably higher distortion, your contention that high vent velocity results in distortion is unfounded.

In addition, having tested the cabinet at moderate excursion and at and beyond Xmax, port compression seems quite low, certainly no more than 2 dB- one of these 2x12" cabinets can produce more output at 40 Hz than two dual 18" Meyers 650P.

Of further interest, though no chuffing was audible even within a meter distance of the cabinet, the vent noise of the reversed Lab 12 was audible enough at several meters that the listeners found that noise much more objectionable than the even order harmonics at both the 35v and 49v levels. Of note, at Fb, the cabinet is only about 2.2 ohms, 49 volts is actually closer to 1100 watts than 800 as indicated on the test results, 35v around 550 watts.

If the Lab 15 is like the Lab 12 in regard to vent noise, I would not run it magnet out.

Art

Attachments

Last edited:

I think just looking at the velocity alone might not be enough. I'd be interested in the changes in velocity expected across the length of the horn or duct, and of course at the exit of the duct on the speaker's cabinet.

Hi Brian !!

I was wondering if you were going to chime in here sooner or later since you are the guy who pioneered this mid-path constriction idea with your DFD modified POC tapped horn cab 🙂 ..

I was wondering if you were going to chime in here sooner or later since you are the guy who pioneered this mid-path constriction idea with your DFD modified POC tapped horn cab 🙂 ..Your POC was also 1/3rd area restricted with good results..

I think you may be right though , there is probably much going on here worth consideration .....

One thing that comes to mind is that since the pressure end of a classic quarter wave resonator is located at the closed end, and the max velocity end of the pipe is the mouth/terminus i would imagine that moving the constriction up the path (away from the mouth) could cut down on velocity since it is no longer the end anymore (the smaller segment does contribute to path length) which sets this design apart from any standard ML-TL , but even some DIY ML-TLs have surprisingly small ports and somehow get away with it (to be fair it could be that many of those are made for low wattage use).

I also think something is terribly awry with how software calculates velocity since numerous different softwares can show you numerous different velocity results when simulating the same cab & driver at the same power level...

Last edited:

Art, any change in the signal from input signal to output spl is distortion. A good way to look at port compression is to measure at 1 watt, then measure at xmax and compare the shape of the response curve. If you lose some dbs at the low knee it's likely caused by port compression.

I've already mentioned several times that the problem starts long before chuffing becomes audible.

There are a bunch of resources available that study port compression. You even seem to admit that you measured 2 db of port compression between moderate to high excursion - and there was probably already a modest amount of port compression happening in the moderate excursion measurement. So 2 db of port compression is probably a low estimation IN YOUR OWN MEASUREMENT, and 2 db of lost output at the low knee is a HUGE issue, isn't it?

Again, if you guys are happy with 2, 3, maybe 4 or more db of losses due to port compression in various designs and examples there isn't much to discuss. Personally losses don't make me happy.

I've already mentioned several times that the problem starts long before chuffing becomes audible.

There are a bunch of resources available that study port compression. You even seem to admit that you measured 2 db of port compression between moderate to high excursion - and there was probably already a modest amount of port compression happening in the moderate excursion measurement. So 2 db of port compression is probably a low estimation IN YOUR OWN MEASUREMENT, and 2 db of lost output at the low knee is a HUGE issue, isn't it?

Again, if you guys are happy with 2, 3, maybe 4 or more db of losses due to port compression in various designs and examples there isn't much to discuss. Personally losses don't make me happy.

I also think something is terribly awry with how software calculates velocity since numerous different softwares can show you numerous different velocity results when simulating the same cab & driver at the same power level...

Depends which software you use. Garbage in (programs), garbage out (results). Hornresp and Akabak are not wrong. There are things they do not take into consideration and therefore they are not perfectly accurate but they are not wrong. Akabak is the only program that is useful in this situation. At this point, arguing that the Akabak sims are wrong would be foolish. If the script is correct the results are correct. This program has been out for 20 years now and subject to plenty of scrutiny, it is arguably still the most complete and accurate program available still, it isn't wrong (again with the caveat that there are things it doesn't account for like all software, but it does account for more than most programs).

Anyway, most programs will have differences but should be fairly similar in results. If you see dramatic differences the program is junk or there is user error at fault.

Last edited:

My name is just a guy and I am against chuffing and port losses. That is the basis of my campaign.

JustAGuy ,

Your mission is an honorable one! I would vote for you .... Your campaign slogan made me laugh.... I apologize if the above quote is reposted out of context here, but i think we need regular infusion of humor when discussing such technically tedious subjects... Even some Canadian dry humor helps 😉 hehe

Since there has been all of this discussion about velocity , port compression and chuffing I came up with an idea for the Eminence ML-Transflex cab that i think you really might appreciate .... I wanted to work on the Eminence Lab 15 version of this design because the velocity is more likely to be an issue in the Lab based cab as opposed the Alpine boxes , so im trying this in an order of priority..... I know you said that proper flares can really help the situation so i think i might have figured out a simple and clean way to work those flares in without wasting any space or reducing path length .....I might even be able to open the constriction a bit (would be nice to get it to around 1/3 of the path area , like the Alpine designs)..... If i can get this to work i will be posting some inputs and sketches soon ...

Someone's Akabak skills may also be required to verify the updated design ..🙂

JustAGuy ,

Your mission is an honorable one! I would vote for you .... Your campaign slogan made me laugh.... I apologize if the above quote is reposted out of context here, but i think we need regular infusion of humor when discussing such technically tedious subjects... Even some Canadian dry humor helps 😉 hehe

Since there has been all of this discussion about velocity , port compression and chuffing I came up with an idea for the Eminence ML-Transflex cab that i think you really might appreciate .... I wanted to work on the Eminence Lab 15 version of this design because the velocity is more likely to be an issue in the Lab based cab as opposed the Alpine boxes , so im trying this in an order of priority..... I know you said that proper flares can really help the situation so i think i might have figured out a simple and clean way to work those flares in without wasting any space or reducing path length .....I might even be able to open the constriction a bit (would be nice to get it to around 1/3 of the path area , like the Alpine designs)..... If i can get this to work i will be posting some inputs and sketches soon ...

Someone's Akabak skills may also be required to verify the updated design ..🙂

Do tell, do tell .....

There was no visible change in response from 2 volts to somewhere in the 25volt range, then progressively at high levels 49 volts, <2 dB deviation in the low end. 2 dB is not at all a big deal to me at 127 dB, I'd never be able to notice it by ear, as the losses are progressive. The larger power compression losses of the Lab 12s are more an issue to me than the port compression losses, as they affect the entire level, I do notice when the overall sub level stops increasing with increased drive level, or decreases with time as heating occurs.You even seem to admit that you measured 2 db of port compression between moderate to high excursion - and there was probably already a modest amount of port compression happening in the moderate excursion measurement. So 2 db of port compression is probably a low estimation IN YOUR OWN MEASUREMENT, and 2 db of lost output at the low knee is a HUGE issue, isn't it?

You may also be concerned that the measured losses in the upper sub range at large signal compared to small in TH was similar to the LF loss in BR.

Though I found that to be of interest, is also is not big concern to me.

Art

JAG,

Yes, measurements are required, though I have no accurate way of measuring vent velocity, other than if the vent chuffs, it is too small.

Funny, on the basis of my WSLab 2x12" Bassbox Pro sim (done by an on line friend) showing a vent velocity of 15 meters /sec, and there being no audible chuffing, I have frequently recommended that velocity as a reasonable "ballpark" to stay under, but just realized that velocity figure was at only 9mm, rather than the 13mm Xmax that I frequently ran the cabinet to (the surround hits the grill cloth at a bit over Xmax), with no audible chuffing.

Since I don't own Bass Box pro, I just compared the difference between 9 and 13mm in Hornresp, and found the particle velocity to be 20m/s at 9mm (30v) and 27.55m/s at 13mm (41v), about 25% higher, right in the middle of the 26- 30m/s "danger zone" you seem all excited about.

In this post, I compared the distortion of the cabinet in push pull and normal configuration:

http://www.diyaudio.com/forums/subwoofers/191833-push-pull-vs-normal-distortion-compared.html

At 35 volt drive level, which is close to Xmax, at and above Fb distortion averaged around 4% for the normal cab, and about 2% for the PP. For those of you unfamiliar with sub distortion levels, those are both quite good, few people can actually detect less than 10% LF distortion even with pure tones.

The same test with the cabinet sealed resulted in considerably higher distortion, your contention that high vent velocity results in distortion is unfounded.

In addition, having tested the cabinet at moderate excursion and at and beyond Xmax, port compression seems quite low, certainly no more than 2 dB- one of these 2x12" cabinets can produce more output at 40 Hz than two dual 18" Meyers 650P.

Of further interest, though no chuffing was audible even within a meter distance of the cabinet, the vent noise of the reversed Lab 12 was audible enough at several meters that the listeners found that noise much more objectionable than the even order harmonics at both the 35v and 49v levels. Of note, at Fb, the cabinet is only about 2.2 ohms, 49 volts is actually closer to 1100 watts than 800 as indicated on the test results, 35v around 550 watts.

If the Lab 15 is like the Lab 12 in regard to vent noise, I would not run it magnet out.

Art

Magnet out as in magnet in the mouth? Just making sure I'm getting what you're saying. You're saying to flip the driver so the cone faces the outside world and the magnet is in the beginning of the path correct?

There was no visible change in response from 2 volts to somewhere in the 25volt range, then progressively at high levels 49 volts, <2 dB deviation in the low end. 2 dB is not at all a big deal to me at 127 dB, I'd never be able to notice it by ear, as the losses are progressive. The larger power compression losses of the Lab 12s are more an issue to me than the port compression losses, as they affect the entire level, I do notice when the overall sub level stops increasing with increased drive level, or decreases with time as heating occurs.

The most important thing I'd like to repeat here is that losses started around 25 volts even though chuffing was not an audible problem even at 49 volts. Compression losses are a big problem LONG before chuffing is an audible problem.

Yes, the losses are progressive and hard (impossible?) to quantify by ear, making measurements necessary. And power compression is an issue too which is why your driver tests that you post are so important to those of us that can't afford all these nice things. But power compression and port compression work together to rob us of our bass and this is what I'm trying to point out. The port compresses so you turn up the volume, you get into (more) power compression, so you turn it up more and round and round you go until the speaker blows.

A 2 db loss of bass at the low knee is a problem for me. You could get by with (almost) half the amount of drivers or (almost) half the amount of power if the loss could be avoided or at least minimized.

And the low knee is the heart of the music I listen to. You don't like the same kind of music I do so you probably wouldn't understand how disappointing it is when the low notes are weak or missing completely. The low notes are the only real reason to listen to that type of music in the first place (sometimes).

You may also be concerned that the measured losses in the upper sub range at large signal compared to small in TH was similar to the LF loss in BR.

Though I found that to be of interest, is also is not big concern to me.

Art

Yes this is interesting but I wouldn't call it a concern. Higher frequency bass is easy to come by, up in the range of low(er) excursion, it's the low frequency bass down at the low knee which is hard to do, and that's why it hurts so much to lose it there. The hpf eats up spl at the low knee, port compression affects the same frequencies, air leaks affect this range, etc., and then power compression compounds the problems further.

The whole reason resonant cabs have to be large is to make those low frequencies a reality with a reasonable amount of sensitivity. To lose that sensitivity to port compression and other things is just a waste of ... everything - drivers, amps, cab size. Minimizing losses allows you to get by with much less resources. The higher frequencies are not a problem so much as the lower ones, those lower frequencies (around the low knee) are the ones that are expensive and require size to achieve.

Last edited:

P.S. I'm beginning my second cab build today and in ~ 3 days I'll be putting in ports so if you come accross something, like a way to make an extra cut and do a slight flare or some other idea let me know. I'll likely just put it aside for the next "batch" as I want these two to be as identical as possible.

The most important thing I'd like to repeat here is that losses started around 25 volts even though chuffing was not an audible problem even at 49 volts. Compression losses are a big problem LONG before chuffing is an audible problem.

Yes, the losses are progressive and hard (impossible?) to quantify by ear, making measurements necessary. And power compression is an issue too which is why your driver tests that you post are so important to those of us that can't afford all these nice things. But power compression and port compression work together to rob us of our bass and this is what I'm trying to point out. The port compresses so you turn up the volume, you get into (more) power compression, so you turn it up more and round and round you go until the speaker blows.

A 2 db loss of bass at the low knee is a problem for me. You could get by with (almost) half the amount of drivers or (almost) half the amount of power if the loss could be avoided or at least minimized.

Yes this is interesting but I wouldn't call it a concern. Higher frequency bass is easy to come by, up in the range of low(er) excursion, it's the low frequency bass down at the low knee which is hard to do, and that's why it hurts so much to lose it there. The hpf eats up spl at the low knee, port compression affects the same frequencies, air leaks affect this range, etc., and then power compression compounds the problems further.

The whole reason resonant cabs have to be large is to make those low frequencies a reality with a reasonable amount of sensitivity. To lose that sensitivity to port compression and other things is just a waste of ... everything - drivers, amps, cab size. Minimizing losses allows you to get by with much less resources. The higher frequencies are not a problem so much as the lower ones, those lower frequencies (around the low knee) are the ones that are expensive and require size to achieve.

Major issue here is flaring the port could screw up the tune a fair amount, I'll try flaring one once we decide that it can maintain the path length/FR.

That is true, but when given a cabinet volume resource restriction, a larger port volume reduces it, commensurately reducing LF efficiency. Less port compression, less output- zero sum game.Minimizing losses allows you to get by with much less resources. The higher frequencies are not a problem so much as the lower ones, those lower frequencies (around the low knee) are the ones that are expensive and require size to achieve.

If cabinet volume is not a concern, then going with TH and gaining around 6 dB sensitivity with no port compression is the way to go, but with low tuned BR there is a catch 22- you won't get an acceptable (to you) vent velocity and maintain the sensitivity in the same size BR box as the OP has posted.

I just remembered another test using the same cabinet as my prior post, re-used with 15":

http://www.diyaudio.com/forums/subwoofers/255010-compact-2x15-ppsl-using-dayton-pa385-8-drivers.html

The vent velocity in this test was higher than with the Lab 12s, as much higher drive levels were used.

Near Fb, at 40 Hz, going from 63 volts to 89.3 volts, a 3 dB power increase resulted in a 1.8 dB SPL increase, a 1.2 db loss.

At 100 Hz, going from 63 volts to 89.3 volts resulted in a 2.1 dB increase, so "port compression" amounts to only a .3 dB difference.

Last edited:

What Welter says is basically the predicament I'm in. In order to get vent velocity in check I need to flare the port which essentially means adding another turn to the port and more complexity/parts (albeit not thaaat bad), which means bigger externally by about 3 inches tall (keeping everything else the same). While it may be a decent option that I'll entertain for my future builds it doesn't make sense to make external size adjustments for this particular build seeing as one is already fully built. Definitely for the Lab 15 build I do I'll look into incorporating a flare as Matthew has mentioned he is looking into from a design standpoint. Thanks again for raising your concerns Just A Guy, you've got your point across and we're not ignoring you, I will be focusing on this build I'm currently in and checking back to see what else is discussed, otherwise you probably won't hear back from me for a while. I don't have my SPL meter (can't find it) so high power testing is useless until I find it - I've looked everywhere.

I just remembered another test using the same cabinet as my prior post, re-used with 15":

http://www.diyaudio.com/forums/subwoofers/255010-compact-2x15-ppsl-using-dayton-pa385-8-drivers.html

The vent velocity in this test was higher than with the Lab 12s, as much higher drive levels were used.

Near Fb, at 40 Hz, going from 63 volts to 89.3 volts, a 3 dB power increase resulted in a 1.8 dB SPL increase, a 1.2 db loss.

At 100 Hz, going from 63 volts to 89.3 volts resulted in a 2.1 dB increase, so "port compression" amounts to only a .3 dB difference.

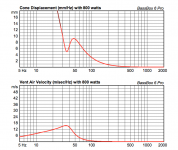

I'm going to make a couple of comments about this but first here's an image that shows what port compression is all about, and this is pretty common. The chart is labelled power compression but when you look at the output at 120 hz you can see there's almost no power compression but there's a boatload of port compression going on here. Shown here is the worse of the two graphs which is accompanied by this text.

The compression in both instances appears to be largely related to overloading of the ports at the level that the sweeps were stopped. The LFM-1 EX exhibits much less overall compression in two ports mode than in one port mode. Likely due to the larger vent area, but the last two sweep levels still exhibit notable vent compression with both ports open. This is normal to see in most ported subwoofers. The LFM-1 EX did exhibit some distress noises and vent chuffing especially in one port mode...

From here - Outlaw Audio LFM-1 EX Review Measurements and Analysis | Audioholics

An externally hosted image should be here but it was not working when we last tested it.

I'm going to make a couple of comments about this but first here's an image that shows what port compression is all about, and this is pretty common.

Outlaw Audio LFM-1 EX Powered Subwoofer

Given that is an active subwoofer, I'll bet that "compression" has a lot more to do with the amp/DSP than the vents. It might be using some sort of dynamic EQ to keep the driver within its linear limits, or some sort of limiting to reduce distortion at high levels (peak current draw will be at Fb). It would explain why the "compression" seems to start way above Fb.

To illustrate the real effects of port compression, we really need to start with a passive subwoofer driven by an amp with no DSP involved to massage the output signal.

A NEW TWIST (WHICH LOOKS A LOT LIKE THE ORIGINAL TWIST) =P

Ok guys,

TAKE A LOOK AT THIS!!😀

This design borrows the constriction in the corner method just like the original concept that started this whole discussion, i think they call this "coming full circle" right?

This update was inspired by JustaGuy's concerns (especially about the ML-Transflex for the Lab 15 special).

We now have some flare on BOTH sides of the port! and more area at the constriction!

Path length should be around 6 feet-ish total including constriction (can increase height of box a little to meet that if needed but not much or magnet will begin to stick out) .....

It sims at about 130 liters actually but im sure that can also be fine-tuned if needed..

This box has almost as much oomph-to-the-liter (Wasn't that an old Roger Troutman/ Zapp song?) as the 40hz Alpine boxes but not quite, of course these 35hz cabs have more extension which makes them better is some apps...

Hornresponse cannot absolutely simulate this as drawn but it can come close enough that i think the results will be very similar .... Someone should create this in Akabak to confirm..

Thoughts? questions? Some feedback would be greatly appreciated !

By the way , you guys are AWESOME! Thanks for participating

Ok guys,

TAKE A LOOK AT THIS!!😀

This design borrows the constriction in the corner method just like the original concept that started this whole discussion, i think they call this "coming full circle" right?

This update was inspired by JustaGuy's concerns (especially about the ML-Transflex for the Lab 15 special).

We now have some flare on BOTH sides of the port! and more area at the constriction!

- Lower velocity at the constriction

- great output

- Low group delay

- does not exceed xmax even at 58v

- flared constriction

- Simple build , so simple it is OBSCENE! (keeping with the theme)

- maintains the net size of 135 liters or less

- Did i mention simple?

- Eliminated APT/LPT

- Constriction is now at S3

Path length should be around 6 feet-ish total including constriction (can increase height of box a little to meet that if needed but not much or magnet will begin to stick out) .....

It sims at about 130 liters actually but im sure that can also be fine-tuned if needed..

This box has almost as much oomph-to-the-liter (Wasn't that an old Roger Troutman/ Zapp song?) as the 40hz Alpine boxes but not quite, of course these 35hz cabs have more extension which makes them better is some apps...

Hornresponse cannot absolutely simulate this as drawn but it can come close enough that i think the results will be very similar .... Someone should create this in Akabak to confirm..

Thoughts? questions? Some feedback would be greatly appreciated !

By the way , you guys are AWESOME! Thanks for participating

Attachments

Last edited:

- Home

- Loudspeakers

- Subwoofers

- New sub design? Constricted Transflex, simple build (series tuned 6th order)