Very unconventional, and I'm sure I'll get a lot of flames by by saying so, but it is a product that I discovered some years ago, and since then I stop solder plating my PCB. Now I call my PCB <Pure Copper> 😉

I think they sound better than the previous solder platted PCB I was doing, and it is certainly much easier to do. By solder platting I don't mean the one chemically plated, that personnaly I never liked very much, but actually platted by hand by soldering over all the PCB.

My secret is <Automotive paint clear coat spray> from Canadian Tire...

The very nice thing is that you cover the PCB entirely, and that the coating goes away when you solder 😉

The smell is even nice. I know, I know, probably chemical fume, nasty, toxic, whatever. I won't get in a flame war about it.

It works fine for me and it protect the copper from oxidation, it is easy to apply and work, etc...

That's it.

I think they sound better than the previous solder platted PCB I was doing, and it is certainly much easier to do. By solder platting I don't mean the one chemically plated, that personnaly I never liked very much, but actually platted by hand by soldering over all the PCB.

My secret is <Automotive paint clear coat spray> from Canadian Tire...

The very nice thing is that you cover the PCB entirely, and that the coating goes away when you solder 😉

The smell is even nice. I know, I know, probably chemical fume, nasty, toxic, whatever. I won't get in a flame war about it.

It works fine for me and it protect the copper from oxidation, it is easy to apply and work, etc...

That's it.

Probably not worst than 35 years of lead solder fume 😉

Here the stuff: Dupli-Color Perfect Match Auto Paint, Clear Top Coat, 8-oz | Canadian Tire

Here the stuff: Dupli-Color Perfect Match Auto Paint, Clear Top Coat, 8-oz | Canadian Tire

What I've been inhaling for the last 3 decades, before and during soldering (70 super nowadays)

www.crceurope.com/wwwcrc/tds/TKC2 Plastik70.pdf

www.crceurope.com/wwwcrc/tds/TKC2 Plastik70.pdf

Audio Research PCB-s are all with solder plating tracks and without solder resist. They think that bare PCB-s have the best sound. I tried chemical tinning , but solderability is not good. Plastic 70 is based on acrylic, I tried it, but after very prolonged period copper turned into brown . Also, acrylic dielectric is not known as the best.

Thanks Jacco for the info, seems to be the perfect product for this application. It seems to be difficult to get in North America though. I'll continue my search but the product doesn't seem to be distributed around here ;(

I have access to MG Chemical Acrylic Conformal Coating. I'll give it a try!

http://www.mgchemicals.com/products/protective-coatings/conformal/acrylic-conformal-coating-419c/

I have access to MG Chemical Acrylic Conformal Coating. I'll give it a try!

http://www.mgchemicals.com/products/protective-coatings/conformal/acrylic-conformal-coating-419c/

Last edited:

CRC also has a single-component urethane spray which is more durable and seals better than Plastik 70.

Sold under different name in different countries :

https://www.youtube.com/watch?v=exC_pr5yRQc

http://www.crcindustries.com/auto/services/get-pds/72049

CRC Clear Urethane Seal Coat, 312 Grams - 72049

Robot Check

Because it seals too well, you should make sure the PCB is totally clean and dry before spraying.

I preheat the board to 60°C in an oven to drive out any moisture completely.

And also bake it at 80°C for half an hour after spraying.

This shortens the specified 72 hours drying time.

The resulting film is thin but very durable, and seals extremely well against oxidation.

We used this until we discovered that if you bake the photo resist of the PCB at 120°C for half an hour, its chemistry changes such that it is solvent (IPA) resistant.

This applies at least to the photo-sensitive PCBs from Bungard.

So we do a second exposure after etching to expose the solder pads, then bake.

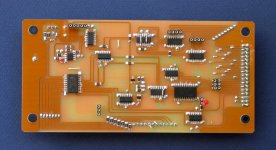

You can see the result here (in dark orange).

Patrick

Sold under different name in different countries :

https://www.youtube.com/watch?v=exC_pr5yRQc

http://www.crcindustries.com/auto/services/get-pds/72049

CRC Clear Urethane Seal Coat, 312 Grams - 72049

Robot Check

Because it seals too well, you should make sure the PCB is totally clean and dry before spraying.

I preheat the board to 60°C in an oven to drive out any moisture completely.

And also bake it at 80°C for half an hour after spraying.

This shortens the specified 72 hours drying time.

The resulting film is thin but very durable, and seals extremely well against oxidation.

We used this until we discovered that if you bake the photo resist of the PCB at 120°C for half an hour, its chemistry changes such that it is solvent (IPA) resistant.

This applies at least to the photo-sensitive PCBs from Bungard.

So we do a second exposure after etching to expose the solder pads, then bake.

You can see the result here (in dark orange).

Patrick

Attachments

Yes,

it is really great headamp!

Meldano has made very good layout and power supply, thanks! It ist totally quit, no hum, nothing. 😀

How it sounds? Only great! :lick face:

=> 2SJ313/2SK2013, 5R

it is really great headamp!

Meldano has made very good layout and power supply, thanks! It ist totally quit, no hum, nothing. 😀

An externally hosted image should be here but it was not working when we last tested it.

How it sounds? Only great! :lick face:

=> 2SJ313/2SK2013, 5R

Hi. I was still not entirely satisfied with the sound of this amp, hence today I installed the Toshiba K2013/J313 instead of the FKP3P20/FKP4N20 parts. Much better, now we're talking 😉

So this amp can work with different MOSFET without change, but the sound we get out of it, is not the same...

Now time to upgrade the coupling cap to ClarityCap, the cheap Solen I have seems to be the limiting factor.

So this amp can work with different MOSFET without change, but the sound we get out of it, is not the same...

Now time to upgrade the coupling cap to ClarityCap, the cheap Solen I have seems to be the limiting factor.

Found in my boxes a few Mundorf MCap EVO, 2.2uF and installed them instead of the Solen. WOW the amp is now sounding just great. Now it can just improve. I'll let it on and burning for a few days.

I'm still waiting for some Philips Tin Foil film cap for the 100pF cap of the feedback network. I'll try and let you know if there is any change from the polystyrene I'm currently using.

SB

I'm still waiting for some Philips Tin Foil film cap for the 100pF cap of the feedback network. I'll try and let you know if there is any change from the polystyrene I'm currently using.

SB

Hi. I was still not entirely satisfied with the sound of this amp, hence today I installed the Toshiba K2013/J313 instead of the FKP3P20/FKP4N20 parts. Much better, now we're talking 😉

So this amp can work with different MOSFET without change, but the sound we get out of it, is not the same...

Now time to upgrade the coupling cap to ClarityCap, the cheap Solen I have seems to be the limiting factor.

Yes you sure can change the MOSFET with this auto bias circuit and as you see the sound changes also.

Hi Wayne. Indeed the K2013/J313 is the real winner here.

Jacco, cap Part Number 2222-464-81001, so I guess it is the KP464 Series

Jacco, cap Part Number 2222-464-81001, so I guess it is the KP464 Series

The only 100pf value in that series, nice and blue (plus epoxy coated).

464 is the 630V range

Yeap that's the one, they are marked 630V, my mistake

- Home

- Amplifiers

- Pass Labs

- New PassDIY Headphone Amp (now available)

)

)