0.56 ft3 = 15.85 litres.

You couldn’t get a smaller one?

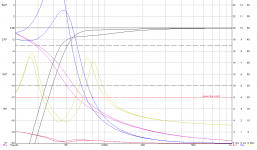

3” vent (76mm) 390mm long F6 40, F10 low mid 40s. Response is kinda droopy thou. It may seem mid/upper bass light.

If you can put a “brick” into the box and reduce the volume that would be a good thing. 9-12 litres target. The optimum for miniOnken tuning (the maximum size) is 9 litres per driver.

You could get another pair of A11ms and build a twin driver box :^)

dave

You couldn’t get a smaller one?

3” vent (76mm) 390mm long F6 40, F10 low mid 40s. Response is kinda droopy thou. It may seem mid/upper bass light.

If you can put a “brick” into the box and reduce the volume that would be a good thing. 9-12 litres target. The optimum for miniOnken tuning (the maximum size) is 9 litres per driver.

You could get another pair of A11ms and build a twin driver box :^)

dave

Attachments

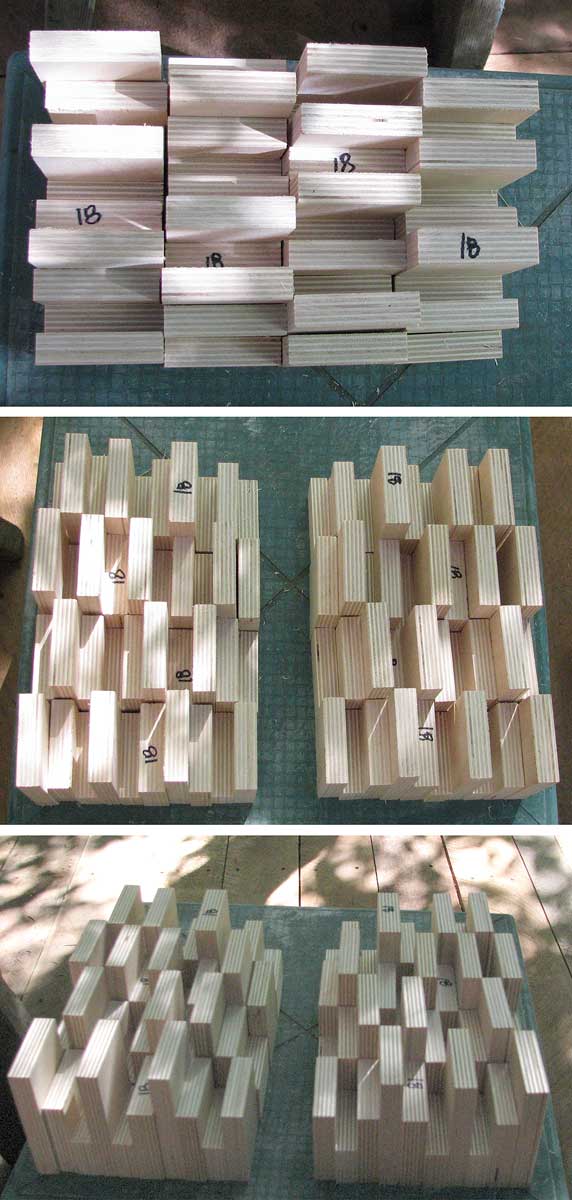

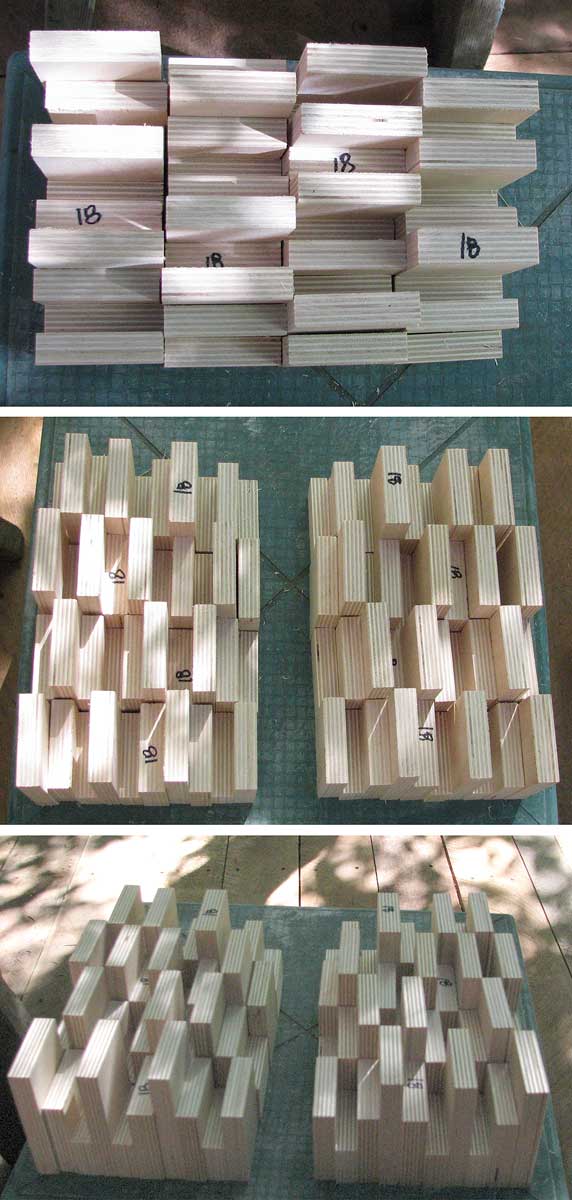

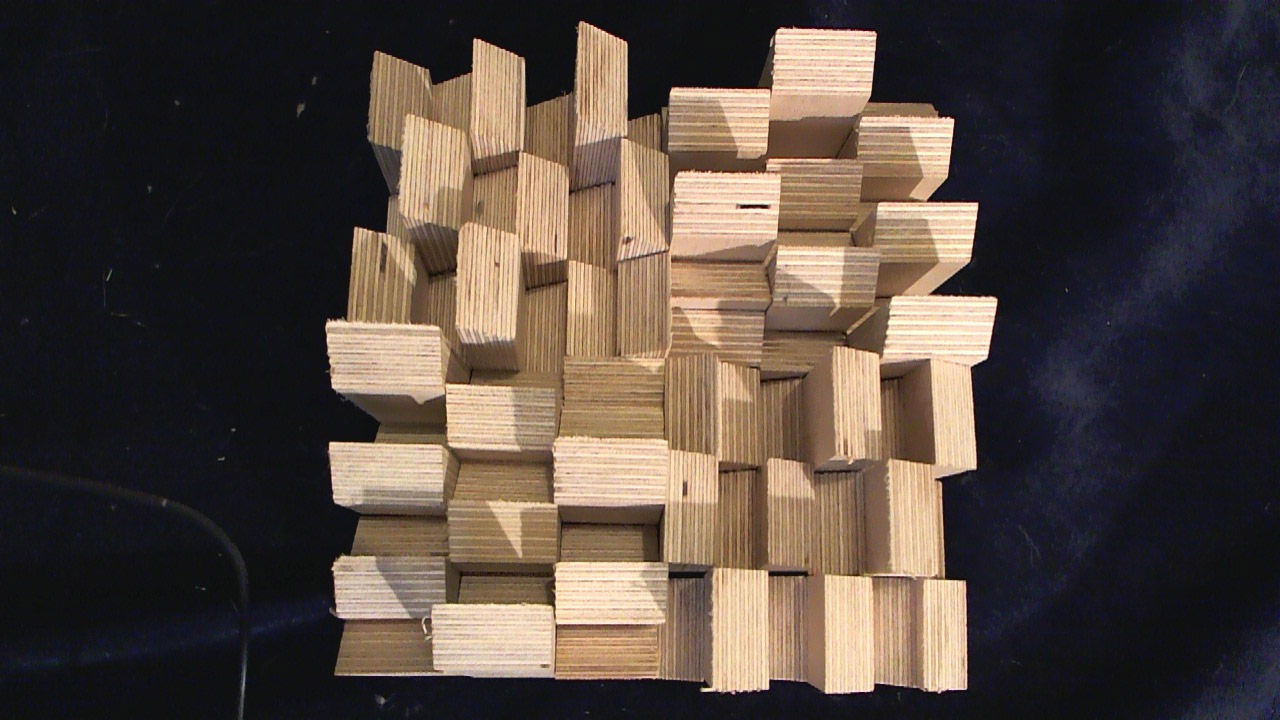

Remember the trick with staggered pieces of scrap wood inside the box in the attempt to create some chaotic reflections / break up standing waves. If the PE boxes have removable baffles, internal access to accomplish that or add extra bracing should be easy enough, I’d imagine.

Not really, I was just somewhat aggravated at being informed by somebody (not anyone here) that they know more about my own designs, their objectives, criteria etc. than I do myself.

Hello all

I am somewhat aggravated that Scottmoose feel like this. If there is anyone, including all on this forum I would listen to when it comes to speaker design, it would be Scottmoose.

I would encourage all new and "old" to speaker design, to pay attention when Scottmoose talks.

All the best

Excellent reminder Chris.

The B&W DM302 i bought new when i worked hifi had a “mass-manufactured version of that idea:

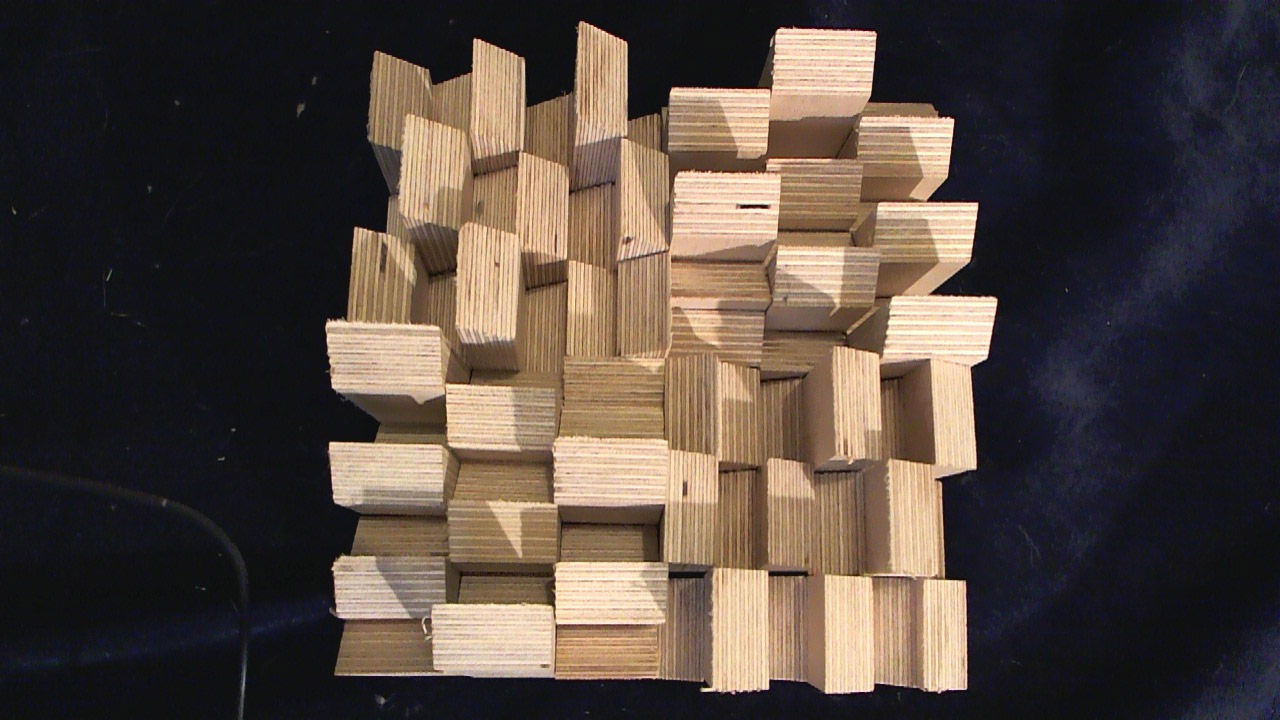

Some diy that could be repurposed: Taking the Air Cavity/pre-chamber to the next level...

dave

The B&W DM302 i bought new when i worked hifi had a “mass-manufactured version of that idea:

Some diy that could be repurposed: Taking the Air Cavity/pre-chamber to the next level...

dave

Not really, I was just somewhat aggravated at being informed by somebody (not anyone here) that they know more about my own designs, their objectives, criteria etc. than I do myself. So I felt obliged to recommend everyone at least consider alternatives. Which speaking generally is good practice anyway, even if you do eventually come back to the original choice.

I saw the original post that was not very complimentary to Scottmoose, and I thought the comments outrageous in assumption of facts not in evidence, and I understand his reaction. I for one, greatly value his insight and hope he keeps up what he has been doing for the DIYAUDIO group and speaker design for those of us who care.

-david BTW

I plan to build the Alpair 11 MS speaker in the tall MLTL listed in post no 9 of this thread.

My question :

Is there any trade off if l move the port to be front firing rather than rear as shown in the drawing?

My question :

Is there any trade off if l move the port to be front firing rather than rear as shown in the drawing?

0.56 ft3 = 15.85 litres.

You couldn’t get a smaller one?

3” vent (76mm) 390mm long F6 40, F10 low mid 40s. Response is kinda droopy thou. It may seem mid/upper bass light.

If you can put a “brick” into the box and reduce the volume that would be a good thing. 9-12 litres target. The optimum for miniOnken tuning (the maximum size) is 9 litres per driver.

You could get another pair of A11ms and build a twin driver box :^)

dave

Lol, the next size down was .23 cu ft.

The brick or additional wood such as a piece of 2x4 to reduce the volume sounds ok to me.

Remember the trick with staggered pieces of scrap wood inside the box in the attempt to create some chaotic reflections / break up standing waves. If the PE boxes have removable baffles, internal access to accomplish that or add extra bracing should be easy enough, I’d imagine.

They don't have removable baffles, but the rear panel can be made to be removable, especially since the boxes are a bit too large anyway.

Excellent reminder Chris.

The B&W DM302 i bought new when i worked hifi had a “mass-manufactured version of that idea:

Some diy that could be repurposed: Taking the Air Cavity/pre-chamber to the next level...

dave

That all looks pretty cool, but the brick sounds way easier 😀

If you installed that randomness of wooden angles, would you still add poly or any kind of batting/insulation?

Is there any trade off if l move the port to be front firing rather than rear as shown in the drawing?

SeaStack, as long as you arr aware that its functioning will change somewhat if you it to close to a boundary.

dave

If you installed that randomness of wooden angles, would you still add poly or any kind of batting/insulation?

it does not obviate the need for damping.

dave

I received the flat pack cabinets from PE. The cuts are pretty accurate and the test fit came together easily.

Attachments

Not really, I was just somewhat aggravated at being informed by somebody (not anyone here) that they know more about my own designs, their objectives, criteria etc. than I do myself. So I felt obliged to recommend everyone at least consider alternatives. Which speaking generally is good practice anyway, even if you do eventually come back to the original choice.

That's nonsense! I just finished building a pair of your Okapi for Alpair 7MS and they sound absolutely amazing. I'll soon be starting on your Water Buffalos.

Thank you for your amazing designs and please don't listen to the haters, they're probably just jealous.

About to build Alpair 11MS in medium Nostromo cabinet.

This is my first speaker build so please excuse my questions. I have the drive units and hardware on order but yet to find anyone local to cut the wood - I guess the lock-down isn't helping. I chose this build as the cabinet size fits with my domestic limitations, and the design will suit my existing amps. Questions:

1. Why don't all the inner surfaces have felt applied to them?

2. Can the port be placed in the front baffle without changing the overall performance? They will be on stands but one is close to a wall.

3. I assume the cabinet is built-up minus one of the sides, felt applied, connections made, and then the side glued on. Is this correct?

Many thanks.

This is my first speaker build so please excuse my questions. I have the drive units and hardware on order but yet to find anyone local to cut the wood - I guess the lock-down isn't helping. I chose this build as the cabinet size fits with my domestic limitations, and the design will suit my existing amps. Questions:

1. Why don't all the inner surfaces have felt applied to them?

2. Can the port be placed in the front baffle without changing the overall performance? They will be on stands but one is close to a wall.

3. I assume the cabinet is built-up minus one of the sides, felt applied, connections made, and then the side glued on. Is this correct?

Many thanks.

You could contact Stefan at KJF Audio; possibly not local, but he may be able to assist. Re the numbered questions, in order

1/ Because it's not required, lagging the non-opposing faces provides the required amount of damping for these enclosure designs.

2/ Not ideally, I intended them to be rear-positioned to prevent any chance of noise from excess air velocity through the vents at higher SPLs, and also offer superior boundary loading. The alignments are damped, so it shouldn't be an issue. However, you can if you wish.

3/ You can build it in any way you feel works best for you; there is no right or wrong answer to this, and no doubt different builders / cabinet makers will have different approaches that they feel works best for them. Chances are that's the approach I'd take, but I'm a lousy woodworker who can weild a hammer on my better days, but that's about all, so I'm not well placed to discuss such matters.

1/ Because it's not required, lagging the non-opposing faces provides the required amount of damping for these enclosure designs.

2/ Not ideally, I intended them to be rear-positioned to prevent any chance of noise from excess air velocity through the vents at higher SPLs, and also offer superior boundary loading. The alignments are damped, so it shouldn't be an issue. However, you can if you wish.

3/ You can build it in any way you feel works best for you; there is no right or wrong answer to this, and no doubt different builders / cabinet makers will have different approaches that they feel works best for them. Chances are that's the approach I'd take, but I'm a lousy woodworker who can weild a hammer on my better days, but that's about all, so I'm not well placed to discuss such matters.

Thanks Scott, I appreciate your response. Still trying locally to sort the wood but will contact Stefan if needed, after all, he is selling me the drivers!

One comment on the last question, i always recommend binding posts on a plat eor cup such that they can be accessed from the outside of the box to make wring (or rewiring easier). I also loke those to be recessed so that they are hard to accidentally break off.

I avoid any with too much metal, look for plastic nuts, not metal ones.

Vent out the bottom or top might satidy your need to place the vent other than on the back and still (mostly) satisfy Scott’s criteria.

dave

dave

I avoid any with too much metal, look for plastic nuts, not metal ones.

Vent out the bottom or top might satidy your need to place the vent other than on the back and still (mostly) satisfy Scott’s criteria.

dave

dave

With that name, likely a lot of money too. To make those accessible from the outside you have to add a removable plate somehow.

dave

dave

About £10 a pair. If I need to service them following the final glued closure, I'll go in via the driver hole (so to speak). People likely to break speaker terminals have long since flown the nest, but never say never!

- Home

- Loudspeakers

- Full Range

- New pair of Alpair 11ms