I think best to disregard the note, as this current PCB will require custom drillings.

OR

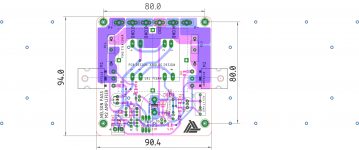

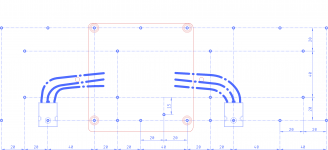

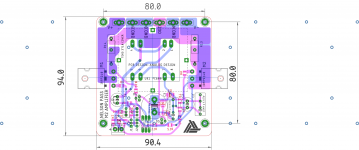

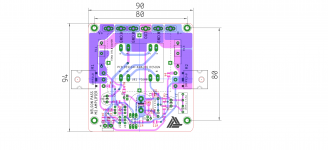

(attached) One possibility is to use 80 x 80 mm grid for PCB mounting and fets can be mounted via wires to nearest convenient holes. The modified drawing is attached. If really wanting to use UMS , I will post the gerbers for this version also.

OR

(attached) One possibility is to use 80 x 80 mm grid for PCB mounting and fets can be mounted via wires to nearest convenient holes. The modified drawing is attached. If really wanting to use UMS , I will post the gerbers for this version also.

Attachments

Last edited:

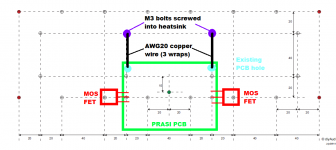

The existing board looks workable to me. Just support it by the MOSFET legs-and-bodies (with hole to hole distance of 120mm to match UMS) and by stiff copper wires between the existing mounting holes in the PCB, and the nearest UMS tapped bolt-hole.

If you're paranoid, use 1/8" thick aluminum plate (link to example sales page) instead of copper wire. Cut to size and drill 3.5mm holes to accommodate M3 bolts. Black lines in image below, become aluminum rectangles.

_

If you're paranoid, use 1/8" thick aluminum plate (link to example sales page) instead of copper wire. Cut to size and drill 3.5mm holes to accommodate M3 bolts. Black lines in image below, become aluminum rectangles.

_

Attachments

Last edited:

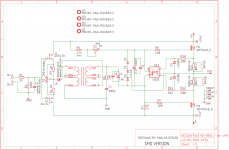

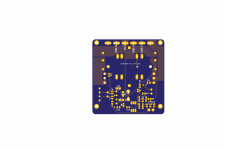

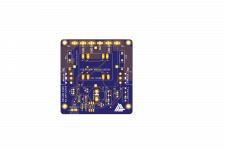

One of the advantages of Prasi’s work is how compact it is and how short the signal paths are. I wouldn’t want that compromised for a UMS fitting. Longer PCB traces along with SMD parts would be unfortunate. Just an opinion.

For those of us willing to drill holes, does anybody know the heat dissipation of the 240/9240 Mosfets in this design? I forgot what the bias settings were assuming the usual +/- 24 to 26 VDC supply. I’m wondering if a Modushop 3U/300 would work (0.40 deg C/watt). Edit: It’s 1.3A in the output stage.

Best,

Anand.

For those of us willing to drill holes, does anybody know the heat dissipation of the 240/9240 Mosfets in this design? I forgot what the bias settings were assuming the usual +/- 24 to 26 VDC supply. I’m wondering if a Modushop 3U/300 would work (0.40 deg C/watt). Edit: It’s 1.3A in the output stage.

Best,

Anand.

Last edited:

The original M2 PCB had long, loooooooong signal paths. Practically the entire length of the heatsink. Designed by Nelson Pass himself. Customers seemed to like its sound a whole lot.

I figure that if shorter signal paths would have improved the sonic performance, Nelson would have laid out his board that way. But he didn't.

The semi-clone "M2x" was/is UMS compatible and has much longer signal paths than this drawing by Prasi. DIY builders seem to like its sound a whole lot.

Maybe M2 tolerates long signal paths really well.

I figure that if shorter signal paths would have improved the sonic performance, Nelson would have laid out his board that way. But he didn't.

The semi-clone "M2x" was/is UMS compatible and has much longer signal paths than this drawing by Prasi. DIY builders seem to like its sound a whole lot.

Maybe M2 tolerates long signal paths really well.

Here is a compromise path like proposed earlier. The nothing in design as such changed, only hole locations and PCB size by 2-4 mm at the edges.

1. Making the mounting hole grid to 80 mm x 80 mm.

2. Fets bolted to heatsink via short wires to nearest holes.

1. Making the mounting hole grid to 80 mm x 80 mm.

2. Fets bolted to heatsink via short wires to nearest holes.

Attachments

One of the advantages of Prasi’s work is how compact it is and how short the signal paths are. I wouldn’t want that compromised for a UMS fitting. Longer PCB traces along with SMD parts would be unfortunate. Just an opinion.

For those of us willing to drill holes, does anybody know the heat dissipation of the 240/9240 Mosfets in this design? I forgot what the bias settings were assuming the usual +/- 24 to 26 VDC supply. I’m wondering if a Modushop 3U/300 would work (0.40 deg C/watt). Edit: It’s 1.3A in the output stage.

Best,

Anand.

my estimate... 1.3A x 48V=63W per channel.

temperature rise - 63W*0.4 deg.C/W=25 deg.C. assuming Ambient 25Deg. C , so it will be 50-51 Deg. C.

https://www.diyaudio.com/media/build-guides/diyaudio-f5-build-guide.pdf page 17.

So ventilation and open spaces would be required.

Files for 80mmx80mm mounting version.

Attachments

Thanks for this, prasi, it looks really cool.

It's also the perfect solution to what to do with two really nice heatsinks I have that are too narrow to fit the UMS boards. I have a few old (genuine) 2SK170 and 2SJ74, so I think this is next up on my list.

I have never sent gerbers to get them fabricated. I colleagues recommended oshpark.com, but when I tried to send the files you posted to get a couple boards made (I hope that was OK) the site complained that there was no "board outline file". Is this something we do ourselves, in kicad or somewhere, from the files you posted? Or have I misunderstood something?

Best

Nigel

It's also the perfect solution to what to do with two really nice heatsinks I have that are too narrow to fit the UMS boards. I have a few old (genuine) 2SK170 and 2SJ74, so I think this is next up on my list.

I have never sent gerbers to get them fabricated. I colleagues recommended oshpark.com, but when I tried to send the files you posted to get a couple boards made (I hope that was OK) the site complained that there was no "board outline file". Is this something we do ourselves, in kicad or somewhere, from the files you posted? Or have I misunderstood something?

Best

Nigel

- Home

- Amplifiers

- Pass Labs

- Nelson Pass M2