Hello guys!

I've been thinking to build a straight MLTL in a 6' midbass + 1' tweeter configuration with a midbass which has the following T/S parameters:

Fs = 36Hz

Qts = 0.34

Qms = 2.81

Qes = 0.38

Vas = 31 L

Re = 6.9 Ohms

Le = 0.34 mH

Sd = 0.0131 m2

BL = 7.6 T-M

Sens = 87.98 dB

Reading sites as t-linespeakers.org, quarter-wave.com, from Planet10, Bob Brine and Troels Gravesen I've reached a frankstein cabinet sized around 970mmH x 189mmW x 205mmD and 76mmDia x 102mmLenght vent, 102mm up from the bottom (internal). Plus tweeter should be positioned roughly from 750mm to 800mm from the floor.

Actually I didn't simulate anything and I'm wondering to get your help in:

1. to correct the dimms if necessary;

2. positioning the mid and tweeter; and

3. to stuff the cabinet;

I appreciate your help in making these design come true.

Regards,

I've been thinking to build a straight MLTL in a 6' midbass + 1' tweeter configuration with a midbass which has the following T/S parameters:

Fs = 36Hz

Qts = 0.34

Qms = 2.81

Qes = 0.38

Vas = 31 L

Re = 6.9 Ohms

Le = 0.34 mH

Sd = 0.0131 m2

BL = 7.6 T-M

Sens = 87.98 dB

Reading sites as t-linespeakers.org, quarter-wave.com, from Planet10, Bob Brine and Troels Gravesen I've reached a frankstein cabinet sized around 970mmH x 189mmW x 205mmD and 76mmDia x 102mmLenght vent, 102mm up from the bottom (internal). Plus tweeter should be positioned roughly from 750mm to 800mm from the floor.

Actually I didn't simulate anything and I'm wondering to get your help in:

1. to correct the dimms if necessary;

2. positioning the mid and tweeter; and

3. to stuff the cabinet;

I appreciate your help in making these design come true.

Regards,

Greets!

Assuming I did all the conversions correctly and the dims are i.d.:

38.189" H x 7.441" W x 8.071" D (1.327 ft^3)/2.992" dia. x 4.016" long vent 4.016" i.d. from bottom - tweeter between 31.496" - 29.528" from floor.

I calculate zdriver = 14.194" for smoothest response, which coincidentally works for your desired tweeter location. It sims a somewhat underdamped 'classic' vented alignment with a ~44 Hz tuning. My sim assumes minimal stuffing, i.e. lining the top, one side and back with 1" acoustic fiberglass.

For my records, what brand/model is this and its Pe, Xmax?

GM

Assuming I did all the conversions correctly and the dims are i.d.:

38.189" H x 7.441" W x 8.071" D (1.327 ft^3)/2.992" dia. x 4.016" long vent 4.016" i.d. from bottom - tweeter between 31.496" - 29.528" from floor.

I calculate zdriver = 14.194" for smoothest response, which coincidentally works for your desired tweeter location. It sims a somewhat underdamped 'classic' vented alignment with a ~44 Hz tuning. My sim assumes minimal stuffing, i.e. lining the top, one side and back with 1" acoustic fiberglass.

For my records, what brand/model is this and its Pe, Xmax?

GM

Attachments

Hi GM,

Greetings from Brasil!

The midbass is an Akron KB6 and the tweeter is an Akron KBT25 (please see http://www.akronaudiotec.com.br/akronconcertoeng.htm; http://www.diyaudio.com.br/2007/03/mid-akron-kb6.html for KB6;

http://www.diyaudio.com.br/2007/03/brasil-tweeter-akron-kbt25.html for tweeter).

This guy is a very well reckon Brasilian audiophile and equipment/loudspeakers builder. It's worth take a time to surf through his website. You going to find very cool things.

Answering your other question the Xmax is 7mm and sorry for the dumb question: what is Pe means? But I guess you can figure out from the link above. Please note that some parameters has changed. I have updated info.

And when you said: "I calculate zdriver = 14.194" for smoothest response," this means from the top, right?

Once again, many thanks for your kindly help.

Best,

Greetings from Brasil!

The midbass is an Akron KB6 and the tweeter is an Akron KBT25 (please see http://www.akronaudiotec.com.br/akronconcertoeng.htm; http://www.diyaudio.com.br/2007/03/mid-akron-kb6.html for KB6;

http://www.diyaudio.com.br/2007/03/brasil-tweeter-akron-kbt25.html for tweeter).

This guy is a very well reckon Brasilian audiophile and equipment/loudspeakers builder. It's worth take a time to surf through his website. You going to find very cool things.

Answering your other question the Xmax is 7mm and sorry for the dumb question: what is Pe means? But I guess you can figure out from the link above. Please note that some parameters has changed. I have updated info.

And when you said: "I calculate zdriver = 14.194" for smoothest response," this means from the top, right?

Once again, many thanks for your kindly help.

Best,

Greets!

I've wanted to visit Brazil ever since reading about Brasilia during its construction, but alas, some things aren't meant to be.

Pe = electrical power rating = 60 WRMS for this driver.

Yes, MJK's worksheets are all calculated from the top down.

He does nice work, thanks for the links! If they perform as good as they look and you get the XO right, yours should be real winners.

You're welcome!

GM

I've wanted to visit Brazil ever since reading about Brasilia during its construction, but alas, some things aren't meant to be.

Pe = electrical power rating = 60 WRMS for this driver.

Yes, MJK's worksheets are all calculated from the top down.

He does nice work, thanks for the links! If they perform as good as they look and you get the XO right, yours should be real winners.

You're welcome!

GM

Hey GM!

Brasilia is really beautiful. Oscar Niemeyer, the architect is celebrating his 100th birthday and according to the news his pencil is still sharp.

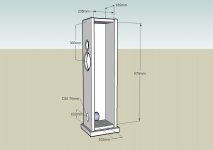

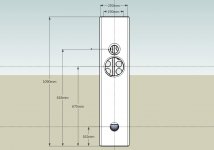

Attached you can see a sketch of the cabinet. I’m wondering to use 25mm thick MDF on front, rear, top and bottom panels and 18mm thick MDF on side and brace. What do you think? The braces is going to be based on Small Thor - swiss cheese style. (The sketch is just to see if we are at the same page).

Paulo from Akronaudio is a great person. He’s going to sell me the drives and the XO built (it’s a linkwitz-raley based design) and he will help me out with the stuffing and calibration. It’s really great for a newbie like me!

Feel free to suggest changes and corrections.

Many thanks,

Brasilia is really beautiful. Oscar Niemeyer, the architect is celebrating his 100th birthday and according to the news his pencil is still sharp.

Attached you can see a sketch of the cabinet. I’m wondering to use 25mm thick MDF on front, rear, top and bottom panels and 18mm thick MDF on side and brace. What do you think? The braces is going to be based on Small Thor - swiss cheese style. (The sketch is just to see if we are at the same page).

Paulo from Akronaudio is a great person. He’s going to sell me the drives and the XO built (it’s a linkwitz-raley based design) and he will help me out with the stuffing and calibration. It’s really great for a newbie like me!

Feel free to suggest changes and corrections.

Many thanks,

Attachments

Greets!

You're welcome!

I much prefer to use no-void 11-13 ply 19 mm plywood such as Baltic Birch or Appleply as it requires much less bracing/damping, but if you use MDF, then the sides need to be thick too since it takes ~1.125" (28.6 mm) thick MDF to match the 19 mm plywood's stiffness. Note that due to the high pressure points being at the top/bottom regardless of material used, a massive top plate made from marble, slate or similar to mass load the cab is desirable. At least double up the material thickness.

WRT bracing, assuming you mean something like this, then it's fine for 19 mm MDF, but a bit overkill if >25 mm or the suggested 19 mm plywood, though there should be a driver support/mass loading brace: http://www.greenie512.net/greenie512/assets/images/autogen/a_100_1427.jpg

I imagine you'll want to lower its tuning to around Fs with up to a ~204 mm long vent, which will require an elbow, so initially make the vent removable and use Play Doh or similar to temporarily seal it, ergo no need to flush mount it during tuning.

WRT the cab drawing, it's fine except my sim is based on the vent length being from the front of the baffle with the distance up from the bottom being an inside one.

Yeah, he sounds like a Dan Wiggins (Adire Audio) kind of guy, so you're indeed lucky. Anyway, looking to forward to a review with final vent/stuffing chosen, etc..

GM

You're welcome!

I much prefer to use no-void 11-13 ply 19 mm plywood such as Baltic Birch or Appleply as it requires much less bracing/damping, but if you use MDF, then the sides need to be thick too since it takes ~1.125" (28.6 mm) thick MDF to match the 19 mm plywood's stiffness. Note that due to the high pressure points being at the top/bottom regardless of material used, a massive top plate made from marble, slate or similar to mass load the cab is desirable. At least double up the material thickness.

WRT bracing, assuming you mean something like this, then it's fine for 19 mm MDF, but a bit overkill if >25 mm or the suggested 19 mm plywood, though there should be a driver support/mass loading brace: http://www.greenie512.net/greenie512/assets/images/autogen/a_100_1427.jpg

I imagine you'll want to lower its tuning to around Fs with up to a ~204 mm long vent, which will require an elbow, so initially make the vent removable and use Play Doh or similar to temporarily seal it, ergo no need to flush mount it during tuning.

WRT the cab drawing, it's fine except my sim is based on the vent length being from the front of the baffle with the distance up from the bottom being an inside one.

Yeah, he sounds like a Dan Wiggins (Adire Audio) kind of guy, so you're indeed lucky. Anyway, looking to forward to a review with final vent/stuffing chosen, etc..

GM

Hi GM!

I knew you would suggest plywood! Good and certificate plywood is hard to find, so I would go with MDF. Hope you don’t mind 😉

Actually I’m betting that I would get good stiffness using WRT bracing.

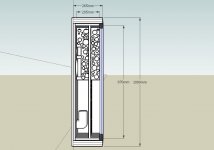

Anyway attached you can find 3 sketch with your suggestions, except for the wood.

When you’ve said Play Doh you meant that modeling stuff for kids? If you have my daughter will get a new set for Xmas 😉

Waiting for your thoughts,

Thank you!

I knew you would suggest plywood! Good and certificate plywood is hard to find, so I would go with MDF. Hope you don’t mind 😉

Actually I’m betting that I would get good stiffness using WRT bracing.

Anyway attached you can find 3 sketch with your suggestions, except for the wood.

When you’ve said Play Doh you meant that modeling stuff for kids? If you have my daughter will get a new set for Xmas 😉

Waiting for your thoughts,

Thank you!

Attachments

I'm not GM, but MDF should be OK, providing you increase the thickness to the levels he suggests. MDF is dirt-cheap, so easiest way would be to laminate 1/2in to 3/4in panels, or simply double up the 3/4in thickness. You'll need it if you want to avoid unplesent resonances -bracing will help, but you'll need both the thicker panels & the bracing if you really want to push them out of the cab. passband. Still not as good as the ply though.

Hi Scottmoose,

Definitely! I'm thinking at the same way. I mean, double the thickness using 2 15mm panels, reaching 30mm at the end.

I'm a little concern about the internal dims. It might be a little off at the end.

I'll go back to the computer and render another sketch.

Best,

Definitely! I'm thinking at the same way. I mean, double the thickness using 2 15mm panels, reaching 30mm at the end.

I'm a little concern about the internal dims. It might be a little off at the end.

I'll go back to the computer and render another sketch.

Best,

Greets!

Why should I mind? I'm not the one that's going to listen to it. 😉 Anyway, what Scott said.

I give up, what program opens your file? I unzip it, but none of my programs will display it.

Yes, or similar that's not too oily.

GM

Why should I mind? I'm not the one that's going to listen to it. 😉 Anyway, what Scott said.

I give up, what program opens your file? I unzip it, but none of my programs will display it.

Yes, or similar that's not too oily.

GM

GM said:I give up, what program opens your file? I unzip it, but none of my programs will display it.

It's a pdf. Here is a gif

dave

Attachments

Greets!

Thanks!

Hmm, I DLed it a couple of times and the zip file was an uncompressed 'ml-tl', but now it's a 17% compressed 'ML-TL by DIYAudio.pdf' file, which displays properly, so did you do something to it?

GM

Thanks!

Hmm, I DLed it a couple of times and the zip file was an uncompressed 'ml-tl', but now it's a 17% compressed 'ML-TL by DIYAudio.pdf' file, which displays properly, so did you do something to it?

GM

Port Ends

Mutuano, your design looks nice so far. I wanted to point out something about your bent port. Where it exits the cabinet (102mm) is not where it will be excited by the line. The end inside the cabinet is where the magic happens. In your case this looks more like 204mm from the bottom. This will throw off your tuning if you have simulated at 104mm. Perhaps you could keep it straight and pass it through the center brace? If it doesn't end up too close to the rear wall this would be the way to go.

Kevin

Mutuano, your design looks nice so far. I wanted to point out something about your bent port. Where it exits the cabinet (102mm) is not where it will be excited by the line. The end inside the cabinet is where the magic happens. In your case this looks more like 204mm from the bottom. This will throw off your tuning if you have simulated at 104mm. Perhaps you could keep it straight and pass it through the center brace? If it doesn't end up too close to the rear wall this would be the way to go.

Kevin

Mutuano said:

I mean, double the thickness using 2 15mm panels, reaching 30mm at the end.

Greets!

Well, if I was going to use MDF in such a pipe I'd laminate two 19 mm thickness sheets and leave out all that labor intensive bracing since this will be at least as stiff as if constructed from 1" BB or Appleply plywood, which I know from experience is ~akin to using boilerplate, though I would still mass load the woofer using either a fixed cradle to support/pre-load it or a screw block, which offers more long term flexibility: http://melhuish.org/audio/images/press-screw.gif

Note that when I mentioned maybe needing a vent elbow I meant a 45 deg one and you stick it on the end inside the cab for KM's reason. This way it can be closer to a boundary without compromising its performance.

GM

Dear friends,

Now I realize that I misunderstood some concepts...

Attached I'm posting the revision #2.

However I'm a little concern about the dim of the front baffle. I thought that for a 6'driver it should not go wider that 9' or 228mm. I have now 250mm and using 19mm (38mm final) I should have at the end 266mm. Would I have problems of baffle diffraction?

I'm going back to the computer to render another version.

Many thanks to all.

PS: It's jpeg files zipped.

Now I realize that I misunderstood some concepts...

Attached I'm posting the revision #2.

However I'm a little concern about the dim of the front baffle. I thought that for a 6'driver it should not go wider that 9' or 228mm. I have now 250mm and using 19mm (38mm final) I should have at the end 266mm. Would I have problems of baffle diffraction?

I'm going back to the computer to render another version.

Many thanks to all.

PS: It's jpeg files zipped.

Attachments

GM said:

I would still mass load the woofer using either a fixed cradle to support/pre-load it or a screw block, which offers more long term flexibility: http://melhuish.org/audio/images/press-screw.gif

GM

GM,

Now it's my turn... I'm not reaching this url. But I guess you've meant something similar to the upper brace, right?

Just to double check: are you saying: no internal braces? Just a support behind the driver?

I'm going to post my revision #3 for your confirmation.

Many thanks, once again.

Greets!

I've never seen/heard anything about baffle width being a function of driver size, but the bottom line is that until you bury your speakers flush in the ground out in a huge/smooth/flat pasture there will be baffle diffraction of some sort/magnitude, so the WIDER a baffle is the less likely you'll have audible/objectionable baffle step issues and in my experience at around 30" it's wide enough to blend into the room's gain BW and/or below our acute hearing BW enough for it not to be an issue in most HIFI/HT apps.

Right, if two 19 mm thick MDF sheets are laminated for all sides, then no internal bracing required IMO. Note that due to the baffle thickness relative to driver size, the rear of the baffle cutout needs to be chamfered at least at a 45 deg angle. Some (most?) folks though just increase the inner panel's hole diameter ~1.5" for woofers/mid-bass drivers to approximate it, so as always YMMV.

I don't have a clue what's going on with these attachments/link. I have no problem going to the link from my bookmark, but get an error 403 message clicking on the hot link. Your attachment DLs as an 'unknown/unknown' in Firefox, so no recognized zip file, etc.. Tried IE and got a security error message, so reset it to 'default' and it DLed/opened just fine, but in Firefox I can't find a setting to change/whatever. Very frustrating! 🙁

GM

I've never seen/heard anything about baffle width being a function of driver size, but the bottom line is that until you bury your speakers flush in the ground out in a huge/smooth/flat pasture there will be baffle diffraction of some sort/magnitude, so the WIDER a baffle is the less likely you'll have audible/objectionable baffle step issues and in my experience at around 30" it's wide enough to blend into the room's gain BW and/or below our acute hearing BW enough for it not to be an issue in most HIFI/HT apps.

Right, if two 19 mm thick MDF sheets are laminated for all sides, then no internal bracing required IMO. Note that due to the baffle thickness relative to driver size, the rear of the baffle cutout needs to be chamfered at least at a 45 deg angle. Some (most?) folks though just increase the inner panel's hole diameter ~1.5" for woofers/mid-bass drivers to approximate it, so as always YMMV.

I don't have a clue what's going on with these attachments/link. I have no problem going to the link from my bookmark, but get an error 403 message clicking on the hot link. Your attachment DLs as an 'unknown/unknown' in Firefox, so no recognized zip file, etc.. Tried IE and got a security error message, so reset it to 'default' and it DLed/opened just fine, but in Firefox I can't find a setting to change/whatever. Very frustrating! 🙁

GM

Attachments

GM,

Thank you for your inputs.

Unfortunately I don't know how to add 3 pictures per post...

I'll add 1 pic per post just for your appreciation.

Hope this helps.

Please remind that this is the rev#2. I'll post the revision #3 sooner.

Many thanks,

Thank you for your inputs.

Unfortunately I don't know how to add 3 pictures per post...

I'll add 1 pic per post just for your appreciation.

Hope this helps.

Please remind that this is the rev#2. I'll post the revision #3 sooner.

Many thanks,

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Need some help for designing a MLTL