TBH its the first thing i do.I always replace the fuses anyway regardless and check the switchVery true.

And as they are an unknown it is worth checking them from a safety aspect as well. Make sure the fuses are correct values and that nothing has been bodged around the mains switch such as shorting one side out to overcome a failed switch. That is a very common tactic and very dangerous.

some are wired to switch the neutral,not all but some are.

so i change them so the live is switched, i never could work out why you would want a permanant live to the transformer.Pretty dangerous considering there is no earth.

most of these amps have no mains earth, and are fitted with 13A fuses, so i convert them with a new lead and 3A fuse, but safty is always the first consideration initialy for myself first but for others later.

Transformers can draw very high inrush current when first switched on. It depends a lot on where in the mains cycle (where on the sine) the amp was last switched off and whether the core has been left magnetised. When you switch on it also depends where on the 360 degrees of the 240 volt sine the switch contacts close.

You might think that switching on at the zero crossing point (when the mains voltage is zero) would be best but that is actually the worst case and results in the highest possible inrush current while switching on at the peak of the voltage gives the lowest inrush. Answers on a postcard as to why 😉

Toroidal transformers are the worst for inrush.

3 Amp is maybe a bit low for a plug top fuse for the NAD. It might be fine for a thousand on/off cycles and then randomly just part and go open circuit.

You might think that switching on at the zero crossing point (when the mains voltage is zero) would be best but that is actually the worst case and results in the highest possible inrush current while switching on at the peak of the voltage gives the lowest inrush. Answers on a postcard as to why 😉

Toroidal transformers are the worst for inrush.

3 Amp is maybe a bit low for a plug top fuse for the NAD. It might be fine for a thousand on/off cycles and then randomly just part and go open circuit.

i wasnt to up with what you were saying so i read this.i dont fully understand, but i kind of get the jist

https://www.te.com/commerce/Documen...v&DocNm=13C3206_AppNote&DocType=CS&DocLang=EN

and 'Toroidal transformers are the worst for inrush' what is toroidal?

https://www.te.com/commerce/Documen...v&DocNm=13C3206_AppNote&DocType=CS&DocLang=EN

and 'Toroidal transformers are the worst for inrush' what is toroidal?

Last edited:

fair enough i get your point but i wonder how many times people actualy turn thier amps on and offTransformers can draw very high inrush current when first switched on. It depends a lot on where in the mains cycle (where on the sine) the amp was last switched off and whether the core has been left magnetised. When you switch on it also depends where on the 360 degrees of the 240 volt sine the switch contacts close.

You might think that switching on at the zero crossing point (when the mains voltage is zero) would be best but that is actually the worst case and results in the highest possible inrush current while switching on at the peak of the voltage gives the lowest inrush. Answers on a postcard as to why 😉

Toroidal transformers are the worst for inrush.

3 Amp is maybe a bit low for a plug top fuse for the NAD. It might be fine for a thousand on/off cycles and then randomly just part and go open circuit.

so if you had the amp say 10 years, used it twice a day, more than most i would guess on average thats still only just over a 1000 times, but i get your point

Toroidal transformers are the round ones that have become popular. The older E I (the frame type) have lower inrush currents as a general rule.

This will get you thinking. Take one of your amps and pull the mains plug out. Now switch it on and measure the DC resistance between live and neutral. Pretty low isn't it. So if I =V/R and the voltage is 230 volts rms then why doesn't a 3 amp fuse blow?

You need to understand that in a resistor the applied voltage across the resistor and the current flowing through the resistor are 'in phase'. As the voltage rises the current rises in proportion.

For an inductor (like a transformer winding) the current lags behind the voltage by 90 degrees. For a capacitor the current leads the voltage by 90 degrees.

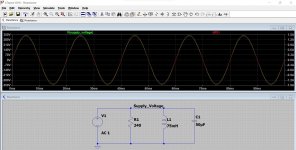

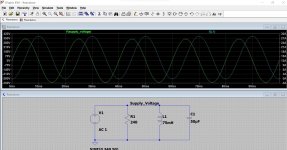

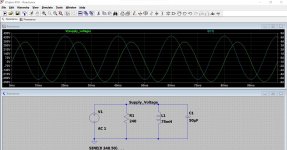

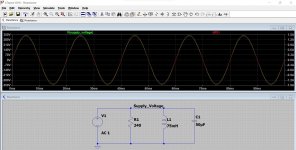

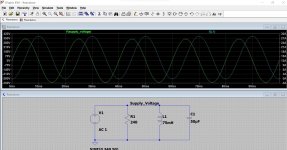

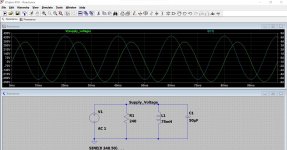

This shows mains voltage across a resistor, an inductor and a cap. Look at the timescale. 50Hz takes 20 milliseconds for one cycle. Look how the current lags the voltage by 5 milliseconds (so 90 degrees) for the inductor and how it leads by 90 degrees for the capacitor. For the resistor they are in phase.

I switch my amp on and off perhaps 4 times a day. It was built around 2005 so that's 17 years... so around 25000 on off cycles.

This will get you thinking. Take one of your amps and pull the mains plug out. Now switch it on and measure the DC resistance between live and neutral. Pretty low isn't it. So if I =V/R and the voltage is 230 volts rms then why doesn't a 3 amp fuse blow?

You need to understand that in a resistor the applied voltage across the resistor and the current flowing through the resistor are 'in phase'. As the voltage rises the current rises in proportion.

For an inductor (like a transformer winding) the current lags behind the voltage by 90 degrees. For a capacitor the current leads the voltage by 90 degrees.

This shows mains voltage across a resistor, an inductor and a cap. Look at the timescale. 50Hz takes 20 milliseconds for one cycle. Look how the current lags the voltage by 5 milliseconds (so 90 degrees) for the inductor and how it leads by 90 degrees for the capacitor. For the resistor they are in phase.

I switch my amp on and off perhaps 4 times a day. It was built around 2005 so that's 17 years... so around 25000 on off cycles.

That IS the case for the current drawn in the magnetizing inductance of the transformer. But switching on at the peak of voltage results in the highest current through the hungry capacitors hanging off the secondary side. So you're going to get a surge regardless of when it’s switched on. Just a question of how bad and how long it lasts. Enough of that one you’ll pop a quick blow fuse.You might think that switching on at the zero crossing point (when the mains voltage is zero) would be best but that is actually the worst case and results in the highest possible inrush current while switching on at the peak of the voltage gives the lowest inrush. Answers on a postcard as to why 😉

I agree things move away from the purely theoretical when dealing with real world applications, for example the transformer isn't a pure inductance. The idea was really to give an idea of some of the background theory and that things are not always what they seem.

A NAD with an EI transformer is a miles away from a 600VA toroid feeding 100k uF of capacitance but it is good to have a grasp of the basic theory as that will lead to a better understanding generally of all circuitry.

A NAD with an EI transformer is a miles away from a 600VA toroid feeding 100k uF of capacitance but it is good to have a grasp of the basic theory as that will lead to a better understanding generally of all circuitry.

'You need to understand that in a resistor the applied voltage across the resistor and the current flowing through the resistor are 'in phase'. As the voltage rises the current rises in proportion.'.

Yes I have learned this aspect and understand it.

' For an inductor (like a transformer winding) the current lags behind the voltage by 90 degrees. For a capacitor the current leads the voltage by 90 degrees.'

I have learned this as well, although not used the knowledge yet.

this could be measured with a tong tester? or the scope?

Yes I have learned this aspect and understand it.

' For an inductor (like a transformer winding) the current lags behind the voltage by 90 degrees. For a capacitor the current leads the voltage by 90 degrees.'

I have learned this as well, although not used the knowledge yet.

this could be measured with a tong tester? or the scope?

You would need a way of looking at the current as well as voltage. Depending on the value of the components you could add a low value resistor in series with the part and look with a scope at the voltage across the resistor and the voltage supplied to the cap or coil but that is easier said than done in anything other than a test set up to show the effect.

The scope for example needs a common ground point for both measurements which is no problem in the test setup but a huge problem for a part embedded in a real circuit. You would need more sophisticated test gear to do that but the principle of the measurement remains the same, its just the practicalities of doing it.

Its not something you will need to do for repair work but its good to understand the theory as it gives an insight into faults you might encounter.

For example if the NAD blew its mains fuse as soon as power was applied and if you measured the resistance between Live and Neutral and measured 10 ohms then you might think the transformer was almost short circuit but in fact that might be a typical value for a medium size transformer.

It will all start to piece together the more you look into it 🙂

The scope for example needs a common ground point for both measurements which is no problem in the test setup but a huge problem for a part embedded in a real circuit. You would need more sophisticated test gear to do that but the principle of the measurement remains the same, its just the practicalities of doing it.

Its not something you will need to do for repair work but its good to understand the theory as it gives an insight into faults you might encounter.

For example if the NAD blew its mains fuse as soon as power was applied and if you measured the resistance between Live and Neutral and measured 10 ohms then you might think the transformer was almost short circuit but in fact that might be a typical value for a medium size transformer.

It will all start to piece together the more you look into it 🙂

re:#17

It looks like someone had been trying to replace the volume control with perhaps a plain, no loudness tap version but run into difficulties and probably lost interest in the project. That's a polite way of putting it, at least. Never mind that the resale value just plummeted when things no longer worked properly. Their loss - your gain, I guess. Nice, easy repair if the pot is still good for some time to come.

It looks like someone had been trying to replace the volume control with perhaps a plain, no loudness tap version but run into difficulties and probably lost interest in the project. That's a polite way of putting it, at least. Never mind that the resale value just plummeted when things no longer worked properly. Their loss - your gain, I guess. Nice, easy repair if the pot is still good for some time to come.

yes it was fine, just a bit crackly, just needed a bit of a clean. There isn't very much you cant stirp down on amps of this age, all the pots and switches come apart ok if you are patient and clean up ok, but spraying with something like servisol though normally does the trick ok.re:#17

It looks like someone had been trying to replace the volume control with perhaps a plain, no loudness tap version but run into difficulties and probably lost interest in the project. That's a polite way of putting it, at least. Never mind that the resale value just plummeted when things no longer worked properly. Their loss - your gain, I guess. Nice, easy repair if the pot is still good for some time to come.

could you not put a low value resistor in line with the phase (live) measure the current across it and you could use a tong tester for the voltage?You would need a way of looking at the current as well as voltage. Depending on the value of the components you could add a low value resistor in series with the part and look with a scope at the voltage across the resistor and the voltage supplied to the cap or coil but that is easier said than done in anything other than a test set up to show the effect.

The scope for example needs a common ground point for both measurements which is no problem in the test setup but a huge problem for a part embedded in a real circuit. You would need more sophisticated test gear to do that but the principle of the measurement remains the same, its just the practicalities of doing it.

Its not something you will need to do for repair work but its good to understand the theory as it gives an insight into faults you might encounter.

For example if the NAD blew its mains fuse as soon as power was applied and if you measured the resistance between Live and Neutral and measured 10 ohms then you might think the transformer was almost short circuit but in fact that might be a typical value for a medium size transformer.

It will all start to piece together the more you look into it 🙂

Measuring line current and voltage at the same time is problematic without a hall effect current probe. If you use a sense resistor, you need to put it in the neutral side and invert the phase of the current. Then you get to tie the scope grounds to a common point which it requires to keep common mode voltage down to something reasonable. And when doing this you MUST USE AN ISOLATION TRAFO for the amp under test since the ground is elevated by the voltage across the sense resistor.

The proper way to do this is with a $1000 current probe. Nice to have, and indispensable if you are messing with switch mode supplies.

The proper way to do this is with a $1000 current probe. Nice to have, and indispensable if you are messing with switch mode supplies.

could you not put a low value resistor in line with the phase (live) measure the current across it and you could use a tong tester for the voltage?

It is as wg_ski say's really... measuring anything on the live incoming side needs very great care. You can measure voltage across a low value resistor using a DVM (resistor is safer in the neutral side) but the meter will float to whatever the voltage on the resistor. If it was in the live side the meter and probes would be at 230 volts. Using the scope is out of the question.

It's good to say what the issues are because then you won't be tempted to try anything like that 🙂 and a basic understanding of how caps and inductors behave with AC will help you a lot in all the circuits you come across.

ok thats fair enough, you guys are the experts.I wouldnt try anything like this without asking first 👍It is as wg_ski say's really... measuring anything on the live incoming side needs very great care. You can measure voltage across a low value resistor using a DVM (resistor is safer in the neutral side) but the meter will float to whatever the voltage on the resistor. If it was in the live side the meter and probes would be at 230 volts. Using the scope is out of the question.

It's good to say what the issues are because then you won't be tempted to try anything like that 🙂 and a basic understanding of how caps and inductors behave with AC will help you a lot in all the circuits you come across.

so another good fix, turning out to be a good weekend this one

that buzzing transfomer has now been dealt with

the casing of the transformer was being stressed in a downward curve where it had proberbly been dropped at some point as the casing a was a bit bent if you looked carefully.so i took the whole thing out and straightened it all up, put it back with slightly enlarged mounting holes to give a bit of adjustment, and hey presto, no buzzing, all good 🙂

that buzzing transfomer has now been dealt with

the casing of the transformer was being stressed in a downward curve where it had proberbly been dropped at some point as the casing a was a bit bent if you looked carefully.so i took the whole thing out and straightened it all up, put it back with slightly enlarged mounting holes to give a bit of adjustment, and hey presto, no buzzing, all good 🙂

That sounds a good fix. There is so much inertia in a transformer that it can easily do damage if the thing has been dropped. That is even worse with PCB mounted transformers where they can literally crack the board in two.

I think lucky with this one.

its a bit like old contactors, years ago you used to be able to play with them, to stop them buzzing, but not always!!

its a bit like old contactors, years ago you used to be able to play with them, to stop them buzzing, but not always!!

last week I note, that there are two different service manuals and schematics. One of the schematics have various drawing errors - go to post #67 underso this ended up being a mirror image failure, not sure why but i suddenly had this idea it could be the same the other side as i had +voltage on the neg rail.

so i tested those resistors and they were fine so i went backwards and R468 had failed along with Q422.

so the repair equated to

R466 and R468 failed and replaced

Q422 and Q420 failed and replaced

Q430 failed and replaced

Ignore post #1 stating R456 failure it was a dislexic moment and it was the other channel i was looking at(and should have been R465 anyway) still it wouldn't be me if i didn't put something down wrong at some point 😉

my guess is it was over driven perhaps

ill check back once ive completed the checks and set the bias etc

https://www.diyaudio.com/community/...repair-nad-3240pe-advice-needed.256520/page-3

Both schematic versions I have upload there.

Currently I have two different devices of this model with damaged output transistors and various burned resistors - one made in TAIWAN and one made in Singapore.

I will report after repair, what steps I have perform at both versions - under

https://www.diyaudio.com/community/...ad3240pe-power-envelope-pros-and-cons.382722/

I have upload the circuit of the soft clipping section (own drawing) between the input and the actually input of complementary differential input stage. But I don't understand in detail, how this circuit works.

- Home

- Amplifiers

- Solid State

- NAD 3240pe-high terminal voltage