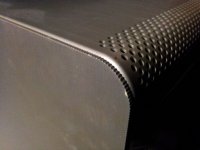

It has the same clean and dynamic presentation as all the FEs. This is actually the third shot at this configuration and all have been hum free and stable. Hope to get it off to Denver after the holidays and then on to Uriah in Texas.

Thanks D. Going through my stash now to see what needs to be ordered to populate the final boards - finally. Any new thoughts on parts other than the input cap choices?

Any new thoughts on parts other than the input cap choices?

Any new thoughts on parts other than the input cap choices?

Any new thoughts on parts other than the input cap choices?Very impressive work Bob! that's the best diy enclosure I've seen yet.

Looks like it could even deal with UK parcel force who take pride in breaking almost every item of hifi kit they handle.

Looks like it could even deal with UK parcel force who take pride in breaking almost every item of hifi kit they handle.

Thanks Davy. Learned the validity of Cal's Law again - "Never post when a DIY project will be finished" 😱 Told you I'd post pictures by the end of the day Monday, but little did I know.....

Will probably do one more to accommodate the big 300 VA transformers and include metal side panels with edge detail similar to Lian-Li computer cases.

Will probably do one more to accommodate the big 300 VA transformers and include metal side panels with edge detail similar to Lian-Li computer cases.

Attachments

Well worth the wait though Bob. You cant rush perfection eh 😀

Makes me wish I still had access to an engineering workshop but I'm very happy with my Chinese enclosures so I'm not grumbling 🙂

Makes me wish I still had access to an engineering workshop but I'm very happy with my Chinese enclosures so I'm not grumbling 🙂

VERY COOL!

Bombproof, even. Very nice recovery from a problem that most of us have never thought of. Or ever need to (I mean how often do we actually submit our DIY projects to the gorillas of UPS?). I even like the fact that you kept some wood in the build in a non-structural way.

Only one thought. The True Coppers are not light and look to be located by their leads. You might want to consider hot glue, zip tie, or some other support.

Please tell us more about your aluminum polishing technique. May I assume that power tools are involved?

I hope 6 enjoys it and I look forward to feedback from that crew. I'm sure the small size of the heat sink will be a subject of amazement.

Jac

Bombproof, even. Very nice recovery from a problem that most of us have never thought of. Or ever need to (I mean how often do we actually submit our DIY projects to the gorillas of UPS?). I even like the fact that you kept some wood in the build in a non-structural way.

Only one thought. The True Coppers are not light and look to be located by their leads. You might want to consider hot glue, zip tie, or some other support.

Please tell us more about your aluminum polishing technique. May I assume that power tools are involved?

I hope 6 enjoys it and I look forward to feedback from that crew. I'm sure the small size of the heat sink will be a subject of amazement.

Jac

Last edited:

I built some "Coppers" PE DIY TL speakers a while back and wanted a high gloss piano black surface. They are all beat up now but I got pretty close. I did some research and found Steinway used a base coat and many layers of clear lacquer - and lots of polishing. So I went to a local auto paint 'hot shot' who sold me some super sanding pads that he swore by. They are fantastic.

Anyway, the best sander I have owned is the Bosch 3725DEVS. It comes with both a flat base with vacuum port disks for sticky sanding disks and a fine-Velcro base option . I started with 150 and 220 grit dry pads then switched to the foam backed wet disks. Had it been summer and my compressor hadn't died, I would have used a pneumatic outside but was able to use minimal water and not electrocute myself - or kill the tool.

or kill the tool.

I only had 1000, 2000 and 4000 grit so I lost a little mirror depth and clarity. I can always add the other steps later this spring. The last step is Swirl Remover applied with a fine foam rubber pad at slow rotation. If I do go for perfection, the paint guru sells a two part acrylic that's mixed in a spray can at application time - SprayMax - that can beat Steinway's best on wood or metal. It's not cheap and you can't store it so I'll collect a few projects before I do any final gloss work.

Sorry Dario, OT - but Jac made me do it🙄

Anyway, the best sander I have owned is the Bosch 3725DEVS. It comes with both a flat base with vacuum port disks for sticky sanding disks and a fine-Velcro base option . I started with 150 and 220 grit dry pads then switched to the foam backed wet disks. Had it been summer and my compressor hadn't died, I would have used a pneumatic outside but was able to use minimal water and not electrocute myself -

or kill the tool.

or kill the tool.I only had 1000, 2000 and 4000 grit so I lost a little mirror depth and clarity. I can always add the other steps later this spring. The last step is Swirl Remover applied with a fine foam rubber pad at slow rotation. If I do go for perfection, the paint guru sells a two part acrylic that's mixed in a spray can at application time - SprayMax - that can beat Steinway's best on wood or metal. It's not cheap and you can't store it so I'll collect a few projects before I do any final gloss work.

Sorry Dario, OT - but Jac made me do it🙄

Attachments

Last edited:

OFf TOpic - Aluminum enclosure finishing

Yep. I totally held a gun to his head.

I've had some luck on paint with a big electric polisher, a foam pad, and increasingly fine grit polishing compounds. I've never tried to go that far on aluminum, but your project makes me want to try it.

Too bad my current project is steel sheet and paint.

Sorry Dario, OT - but Jac made me do it🙄

Yep. I totally held a gun to his head.

I've had some luck on paint with a big electric polisher, a foam pad, and increasingly fine grit polishing compounds. I've never tried to go that far on aluminum, but your project makes me want to try it.

Too bad my current project is steel sheet and paint.

The guy who bent my top was working on a piece made with polished stainless when I took delivery. That was absolutely gorgeous. Not necessary for audio but it does get one thinking.

Yay! Cant wait to hear it Bob!

Glad to see uriah up on this thread. I look forward to his impressions of the FE and to his redesign of the Lighter Note.

Do 6 MyRef FE mono channels fit in a 400mm 4U case?

Yes they do!

I was using this winters vacation to finally complete the build.

Because of some reports in this thread of hum problems I have connected all 6 channels PWR grounds precautionary together and used a ground loop breaker circuit to join PWR grounds to chassis / earth connection.

No hum or hiss problems, but with open cabinet the MyRef is sensitive to cell phone introduced noise. Have to check if this noise is picked up by speaker cable or dissapear by closed / screened cabinet.

The FE gain is little bit higher than that of my Rotel multichannel amp. Because I am using a DAC (ESS9018) as preamp, volume control is digitally and I am concerned about of possible loss in resolution because of high attenuation in digital domain. When listening to music in the evening volume attenuation is often > 40 db.

Therfore I have already ordered In Line attenuators to attenuate signal by 20 db. When receiving them I will do carefull listening if In Line Attenuators help to improve resolution.

So far the FE is a very nice sounding amplifier, bass is incredible for a single chip. But have to say that I am using the amps for a active speaker so each FE has to drive just one speaker chassis.

Thanks to Mauro, Dario and all which were involved to design and improve this amplifier!!!

BR,

1543

Yes they do!

I was using this winters vacation to finally complete the build.

Because of some reports in this thread of hum problems I have connected all 6 channels PWR grounds precautionary together and used a ground loop breaker circuit to join PWR grounds to chassis / earth connection.

No hum or hiss problems, but with open cabinet the MyRef is sensitive to cell phone introduced noise. Have to check if this noise is picked up by speaker cable or dissapear by closed / screened cabinet.

The FE gain is little bit higher than that of my Rotel multichannel amp. Because I am using a DAC (ESS9018) as preamp, volume control is digitally and I am concerned about of possible loss in resolution because of high attenuation in digital domain. When listening to music in the evening volume attenuation is often > 40 db.

Therfore I have already ordered In Line attenuators to attenuate signal by 20 db. When receiving them I will do carefull listening if In Line Attenuators help to improve resolution.

So far the FE is a very nice sounding amplifier, bass is incredible for a single chip. But have to say that I am using the amps for a active speaker so each FE has to drive just one speaker chassis.

Thanks to Mauro, Dario and all which were involved to design and improve this amplifier!!!

BR,

1543

Attachments

Yes they do!

I was using this winters vacation to finally complete the build.

And what a build!

Really an incredible job! 🙂

Only one caveat... the Nichicon ES on C9, really romantic but they hide a lot of detail and air.

The Audyns in C13 what caps are?

And what a build!

Really an incredible job! 🙂

Only one caveat... the Nichicon ES on C9, really romantic but they hide a lot of detail and air.

The Audyns in C13 what caps are?

Thanks!

The Audyns are KPSN. I am using these for 2 channels and 4 x Mundorf Supremes. I will do carefull listening to decide which of them to use for woofers and mid/highrange speakers.

I have 2 additonal spare PCBs, if will use other caps for C9 (as listed in BOM).

BGs would be first choice but I was not able to get some from a trusted supplier.

BR,

1543

The Audyns are KPSN. I am using these for 2 channels and 4 x Mundorf Supremes. I will do carefull listening to decide which of them to use for woofers and mid/highrange speakers.

Keep us informed... but I bet you'll use the KpSn for woofers and Supremes for the rest 😉

BGs would be first choice but I was not able to get some from a trusted supplier.

Parts Connexion still have the PKs 220uF/4V, they will work fine and sound incredible.

Just buy some spares, just in case they break in case of fault (4V is enough for normal operation but not enough in case of fault).

Parts Connexion still have the PKs 220uF/4V, they will work fine and sound incredible.

Just buy some spares, just in case they break in case of fault (4V is enough for normal operation but not enough in case of fault).

Parts Connexion lists also 220 uF FK types with higher voltage ratings. Do you have expierience with BG FK also?

Wow 1543 amazing build! Great attention to detail! You have created a beautiful finished product.

Parts Connexion lists also 220 uF FK types with higher voltage ratings. Do you have expierience with BG FK also?

Sure, FKs are a bit better (fuller) than PKs.

But what you're watching is probably a dead page you found via google or similar.

Actually PCX has in stock only 220uF/4V PKs and 10uf/250V STDs

- Home

- Amplifiers

- Chip Amps

- My_Ref Fremen Edition - Build thread and tutorial