How about this? Or we could easily drill the WV series heatsink.

Sink Ex | Ohmite Mfg Co

The 38E is for TO-247.

Jac

Sink Ex | Ohmite Mfg Co

The 38E is for TO-247.

Jac

Jac, we who are industrious would just drill a hole and tap it (as you suggest) but I guess the BOM should just have a “ready to use” order number, no?

I see we supplied the same item#. I wasn’t fast enough

I see we supplied the same item#. I wasn’t fast enough

I was thinking to something like this:

Home - Fischerelektronik, Product: FK 245 MI 247 V

Copper, solder tabs to attach to ground and increase so heat dissipation...

Home - Fischerelektronik, Product: FK 245 MI 247 V

Copper, solder tabs to attach to ground and increase so heat dissipation...

I think we are guilty of overkill in heatsink selection for R3. Doubt a heatsink is even needed for TO-220 or TO-247 package resistors.

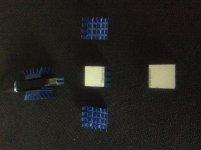

But I am an overkill builder too. These are what I attach to R3 now. Have also stuck them to the top of LM3886. In this position they do get warm during use.

Also found other uses for them. The tape (film) is thermal conductive and seems set with use. Never have experienced one falling off.

Read an interesting theory recently on heatsink selection. Based on thermal memory. Thought was low mass aluminum with fins heats up and cools down faster. Quicker settling time.

This was in a commercial application, cost saving may play here also. In purchase price and shipping expense.

But I am an overkill builder too. These are what I attach to R3 now. Have also stuck them to the top of LM3886. In this position they do get warm during use.

Also found other uses for them. The tape (film) is thermal conductive and seems set with use. Never have experienced one falling off.

Read an interesting theory recently on heatsink selection. Based on thermal memory. Thought was low mass aluminum with fins heats up and cools down faster. Quicker settling time.

This was in a commercial application, cost saving may play here also. In purchase price and shipping expense.

I was thinking to something like this:

Home - Fischerelektronik, Product: FK 245 MI 247 V

Copper, solder tabs to attach to ground and increase so heat dissipation...

Dario, those look efficient inexpensive and easy to use as well. I Googled the item number and Newark Electronics has them here to purchase in the USA, although they have to be shipped from their UK warehouse it seems.

Pete

I think we are guilty of overkill in heatsink selection for R3. Doubt a heatsink is even needed for TO-220 or TO-247 package resistors.

Panelhead, I’d have to be in agreement with you. I’ve touched my resistor at R3 after hours of playing and it’s just warm but I don’t really crank up my speakers either. Have I run it w/o a heatsink ever..nope....

Pete

Well almost - do use Oyaide USB

Do not use USB to connect computer to dac (professional interface). Went from FireWire to Thunderbolt dacs.

The heatsinked cable is a Corning optical TB. These draw 150 ma at 12 volts. The plastic ends get quite warm. May explain the high early failure rate of the Corning optical USB and TB cables.

I use Oyaide USB to connect external drives and an Oyaide power cord. Here is a picture I took earlier today other business end of the Mac Mini.Neo Oyaide USB?

Do not use USB to connect computer to dac (professional interface). Went from FireWire to Thunderbolt dacs.

The heatsinked cable is a Corning optical TB. These draw 150 ma at 12 volts. The plastic ends get quite warm. May explain the high early failure rate of the Corning optical USB and TB cables.

Attachments

I built this amp a few years back , never installed heatsinks on the bd139/140 or lm317/337 or on the thick Film Resistors. With Antek as 3222 these components were barely warm to the touch. I had a suggestion, to move C1, C2 ( 16mm capacitors) 2-3 mm away from the LM3886 heatsink .I think we are guilty of overkill in heatsink selection for R3. Doubt a heatsink is even needed for TO-220 or TO-247 package resistors.

This is a great amp , probably the best lm3886 implementation .

Gabe

Attachments

Not so easy...

Well, things are going in an unexpected direction...

The Mundorf manganins seem to have a weird sound signature, colder and less rich than they should (like Russian polystirenes) but this could be due to wrong orientation or more burn-in needed.

But according bass sound the right orientation seems the straight one which is also colder and simplifed, though.... more listening and time needed.

On the contrary Dale RS-5 have spot-on timbre and richness, a nice improvement from the Caddocks that suffer from their peculiar, greyish, coloration.

And this with steel end caps...

Maybe boards could be modified for axial R3 instead of TO247...who knows? We'll see. 😉

Well, things are going in an unexpected direction...

The Mundorf manganins seem to have a weird sound signature, colder and less rich than they should (like Russian polystirenes) but this could be due to wrong orientation or more burn-in needed.

But according bass sound the right orientation seems the straight one which is also colder and simplifed, though.... more listening and time needed.

On the contrary Dale RS-5 have spot-on timbre and richness, a nice improvement from the Caddocks that suffer from their peculiar, greyish, coloration.

And this with steel end caps...

Maybe boards could be modified for axial R3 instead of TO247...who knows? We'll see. 😉

Used the Dale LVR-5 Current Sense axial in the beginning for R3. Right up to a Evo compensation. Never found in 0.33 ohm.

Seemed great. Non magnetic and non-inductive.

Seemed great. Non magnetic and non-inductive.

Dale rs-5 looks like new candidate for R3 in “standard industrial BOM”.

Compact, cheap, no need for heatsink.

Compact, cheap, no need for heatsink.

Maybe boards could be modified for axial R3 instead of TO247...who knows? We'll see. 😉

Hi Dario, I think that if you modify the board to mount an R3 of the TO247 type (space between the external pins about 11 mm) it is also possible to mount an axial resistance (space between the leads about 22-25 mm), the opposite is practically impossible. I say this even if for my taste, given your descriptions of the sound of these two types of resistances, I might prefer an axial resistance.

Thanks again for the new developments and new possibilities to tune this amplifier.

I continue to find it incredible that an amplifier as good as sound characteristics and measurements can be tuned for practically every taste. So said, with only the limit of impossible loads and the need for very high powers, we are facing a universal amp ...

Ciao

Giacinto

I was thinking to something like this:

Home - Fischerelektronik, Product: FK 245 MI 247 V

Copper, solder tabs to attach to ground and increase so heat dissipation...

The copper is nice and extremely fast to respond to temperature change. Even faster than aluminum.

It would be interesting to get thermal compound on the part and then slide it under the clip.

Dario,

Since you are looking at a range of R3 resistors, would you like a pair of my quad boards? They are professionally made, have a gold surface to avoid corrosion, are their own heatsink, and can be used with many choices of SMD resistors. I have only tried them with 1W SMD and MELF, but they stay so cool that lower power SMD would likely work. If you are interested, I would be happy to send them to you.

Jac

- Home

- Amplifiers

- Chip Amps

- My_Ref Fremen Edition - Build thread and tutorial