Hi Icsaszar,If it is just a proof of concept then sorry, but how do you remove the thing in the middle, to make the platter flat?

it is a mock-up to test the bearing principle. I am not going to play records with it. The point is that, the disk brake rotor has the weight and diameter that I want for my turntable. The mock-up cost me nothing, other than time.

I am sorry that I did not make that more clear in my first post.

Sincerely,

Ralf

Last edited:

Hi billshurv,I remember seeing a DIY turntable in the 80s using a brake disk in a Meitner style platterless setup

The name Meitner rings a bell from the past. I'll have to google it.

Sincerely,

Ralf

Hi Conrad,Sure, you need a good bearing, but I think people get overly fixated on it. A bearing with proper clearance for the speed and oil viscosity won't have any slop or play in use. The larger problem is how to generate the necessary perfect geometry. Lathe isn't good enough. You need a grinder and/or hone. It can be done by hand if you have more time than money.

There are things I wish I had mentioned in my first post such as:

I want to design and build a "high-end" turntable that I couldn't afford to buy if it were available on the market.

I want this turntable to employ a precise "zero-clearance" main bearing costing not more than 10$!.

I don't want this bearing to require any lubrication.

I want to be able to make this bearing with an ordinary Bridgeport vertical milling machine and a plain lathe.

Sincerely,

Ralf

Last edited:

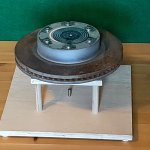

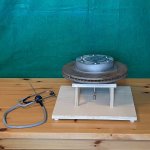

Hi everyone,

Here are some photographs of the turntable mock-up, using a disk brake rotor.

As I said, I am not going to play LPs on it. Its purpose is to test my main bearing concept which has not been built yet.

Tomorrow, I'll post some more CAD drawings showing my proposed turntable design.

There will be an overall view of the turntable and an exploded view of all the parts.

Sincerely,

Ralf

Here are some photographs of the turntable mock-up, using a disk brake rotor.

As I said, I am not going to play LPs on it. Its purpose is to test my main bearing concept which has not been built yet.

Tomorrow, I'll post some more CAD drawings showing my proposed turntable design.

There will be an overall view of the turntable and an exploded view of all the parts.

Sincerely,

Ralf

Attachments

If liquids are incompressible and even the air can behave like an incompressible liquid then there's no clearance.It all depends on how steady the motor spins so that the fluids circulation create constant pressure .You can consider a small wobble being prezent, but honestly it doesn't matter as it is usually below the audibility threshold in the presence of signals comming from vinyl.You can give Yamaha GT2000 a credit for its absolute > 80 db SNR over some 60 db SNR found in old Dual's but the wobble you can usually really hear is done by vinyl's displaced hole not platter's .Hi dreamth,

Who says I haven't studied fluids physics?

Sincerely,

Ralf

If air and inertia can do it, mineral oils can do it even better and there's no reason why avoiding using lubricants.Everybody does it everywhere including Kingsley when using air.

I'm sorry if i'm shattering anyone's dream of rediscovering the potter's wheel with this wobbly movie:

Last edited:

Some more food for thought along same lines as to why cheap turntables can perform as well as 100 k bucks turntable with just a little bit of oil...If it wasn't so, the vinyl industry would have never taken off the ground.

Hi everyone,

This time I am going to post two CAD drawings of my proposed turntable design.

As you can see, it was obviously inspired by the Micro-Seiki DDX 1000 turntable.

I am going to make the three legs from Brazilian rosewood to make it appear a little "warmer".

But rather than combining the legs with the tone arm mounts, I designed a separate three-legged tone arm mounting platform.

This platform is freely rotatable with some friction added to make it stable. That way one can always rotate the tone arm currently in use to the most convenient location wit respect to the center of the turntable.

I was going to set the turntable on a nicely finished slab of granite but it turned out to be ridiculously expensive.

I will probably use a slab of hardwood instead.

So far I haven't found a source of 12" diameter black Delrin either.

Sincerely,

Ralf

This time I am going to post two CAD drawings of my proposed turntable design.

As you can see, it was obviously inspired by the Micro-Seiki DDX 1000 turntable.

I am going to make the three legs from Brazilian rosewood to make it appear a little "warmer".

But rather than combining the legs with the tone arm mounts, I designed a separate three-legged tone arm mounting platform.

This platform is freely rotatable with some friction added to make it stable. That way one can always rotate the tone arm currently in use to the most convenient location wit respect to the center of the turntable.

I was going to set the turntable on a nicely finished slab of granite but it turned out to be ridiculously expensive.

I will probably use a slab of hardwood instead.

So far I haven't found a source of 12" diameter black Delrin either.

Sincerely,

Ralf

Attachments

Some machinist's surface plates are quite inexpensive, other than shipping. https://wttool.com/catalog/index.php?cPath=1404 or https://www.travers.com/category/granite-plates

The three leg support design is how Sol was built and various methods were examined, including a 8020 (or Minitec) frame, before a casting was decided on.

The three leg support design is how Sol was built and various methods were examined, including a 8020 (or Minitec) frame, before a casting was decided on.

Hi, The problem you may have is assuming the the brake assembly is machined to close enough tolerances to make it suitable for a T/T platter. Have you slung a DTI on the top & perimeter to see what the run out is. I worked as a design eng in the motors industry for over 30 years & can assure you the tolerances are not that tight.

Cheers

Cheers

Almost all newer 1970s turntables have so.e sort or fluid bearing. The noise and vibration from ball bearings would be greatly amplified by the RIAA EQ. I have a Realistic LAB 500 DD table , I lowered the motor supply from 22 to 18v to lower torque bursts from the motor controller. Rumble and noise below 80db.

Then if you need to lower low frequency feedback (speakers played Loud) place turntable on a marble slab.

Then if you need to lower low frequency feedback (speakers played Loud) place turntable on a marble slab.

Use layers of material with different properties, stone, silicon gel sheet, steel, to form the base.

That should give isolation.

Surface plate is not needed, except for the base support.

You can see the design as a guide.

Hydraulic type engine mounts can also be used to isolate the unit from the rest of the world.

That should give isolation.

Surface plate is not needed, except for the base support.

You can see the design as a guide.

Hydraulic type engine mounts can also be used to isolate the unit from the rest of the world.

It will be good to see your design come to fruition.

When done will there be an opportunity to compare the TT to a much more expensive design, to see if the concept has come close to meeting the brief. A Identical Tonearm > Cartridge and the same method for supporting the TT > Tonearm mounting will be the best practice parameters to make a fair assessment.

I have looked at your use of wood, and Conventional Plywood or Wood as a support can be affected by ambient conditions across seasons. If wood is the required material to be used, a Densified Wood might be worth considering for it properties, especially for Stability, Damping and Dissipation. It is going to add to the materials cost, "but it is not possible to make an omelette without breaking a few eggs".

When done will there be an opportunity to compare the TT to a much more expensive design, to see if the concept has come close to meeting the brief. A Identical Tonearm > Cartridge and the same method for supporting the TT > Tonearm mounting will be the best practice parameters to make a fair assessment.

I have looked at your use of wood, and Conventional Plywood or Wood as a support can be affected by ambient conditions across seasons. If wood is the required material to be used, a Densified Wood might be worth considering for it properties, especially for Stability, Damping and Dissipation. It is going to add to the materials cost, "but it is not possible to make an omelette without breaking a few eggs".

A few years ago TNTaudio did a set of tests on which plinth type gave the best isolation & sound. He used a kit-set T/T that was available at the time, sadly no longer available.

https://www.google.com/url?sa=t&rct..._kit2_e.html&usg=AOvVaw13Mi8nIeHQPY4QWoQMYfUR

It makes for interesting reading.

Cheers

https://www.google.com/url?sa=t&rct..._kit2_e.html&usg=AOvVaw13Mi8nIeHQPY4QWoQMYfUR

It makes for interesting reading.

Cheers

Hi DNic,Hi, The problem you may have is assuming the the brake assembly is machined to close enough tolerances to make it suitable for a T/T platter. Have you slung a DTI on the top & perimeter to see what the run out is. I worked as a design eng in the motors industry for over 30 years & can assure you the tolerances are not that tight.

Cheers

Once again, the disk brake rotor mock-up is not going to be used to play records!

I am using it to test my bearing design.

Somehow I should have made that more clear in my first post.

Sincerely,

Ralf

Hi stocktrader200,Almost all newer 1970s turntables have so.e sort or fluid bearing. The noise and vibration from ball bearings would be greatly amplified by the RIAA EQ. I have a Realistic LAB 500 DD table , I lowered the motor supply from 22 to 18v to lower torque bursts from the motor controller. Rumble and noise below 80db.

Then if you need to lower low frequency feedback (speakers played Loud) place turntable on a marble slab.

I am trying to design a bearing that runs dry. There will be no ball bearings in my bearing design.

I am also rethinking the use of a stone slab. It has too many inconveniences attached.

Sincerely,

Ralf

The outcome of the assessments using different materials is interesting.

Multi-Lamination Bamboo Board that is Compressed using applied Pressure to the Top and Side of the board is a board material that measures closest in comparison to other board materials when being compared to a Densified Wood Board material.

The other non board material used for a Plinth that measures very close to a Densified Wood Board is Polybentonite Resin.

Today I am a user of Lightweight Plinth Materials that have shown through testing their suitability for selection for use as a Plinth Material.

The supporting measurements that can be found for the materials are no guarantee that a user will be attracted to the influences to the SQ as a result of the use of the selected material.

To date, as a result of communications with users of the material, I know that users of Densified Wood as a Plinth are feeling quite sure other options will not supersede the material, and they are quite satisfied with the choice made.

I had many years ago produced a '9 Stone in weight Granite Plinth' for a Garrard 401, I agree with the findings of the plinth trial in the link, from my recollections, the material lessens the emphasis of the Bass, that an Idler Drive can be wed to, and allows for an improved balance across the frequencies to be perceived, as well as creating a quieter background. Using Granite as the plinth structure, especially in the weight that I produced, requires an extra thought process on the mounting of the TT, and the use of the material is best recognised as being a young mans sport, well honed muscles are a must when handling.

Very recently I was demonstrated a 401 with a Compressed Bamboo Plinth, which I subsequently mounted onto a Sub Plinth using a Densified Wood and Suspension Footers.

The replay using the 401 in the latter set up, was possibly the best memory I have of any Idler Drive replay I have experienced, there was a freedom of expression from the presentation I was not familiar with, much more so than an Idler Drive I own that is mounted in a Corian Plinth.

In a structure that has both mechanical and passive parts, the selection of the passive parts and how the selected material is able to manage energies transferred from the mechanical operation is a very important consideration.

Multi-Lamination Bamboo Board that is Compressed using applied Pressure to the Top and Side of the board is a board material that measures closest in comparison to other board materials when being compared to a Densified Wood Board material.

The other non board material used for a Plinth that measures very close to a Densified Wood Board is Polybentonite Resin.

Today I am a user of Lightweight Plinth Materials that have shown through testing their suitability for selection for use as a Plinth Material.

The supporting measurements that can be found for the materials are no guarantee that a user will be attracted to the influences to the SQ as a result of the use of the selected material.

To date, as a result of communications with users of the material, I know that users of Densified Wood as a Plinth are feeling quite sure other options will not supersede the material, and they are quite satisfied with the choice made.

I had many years ago produced a '9 Stone in weight Granite Plinth' for a Garrard 401, I agree with the findings of the plinth trial in the link, from my recollections, the material lessens the emphasis of the Bass, that an Idler Drive can be wed to, and allows for an improved balance across the frequencies to be perceived, as well as creating a quieter background. Using Granite as the plinth structure, especially in the weight that I produced, requires an extra thought process on the mounting of the TT, and the use of the material is best recognised as being a young mans sport, well honed muscles are a must when handling.

Very recently I was demonstrated a 401 with a Compressed Bamboo Plinth, which I subsequently mounted onto a Sub Plinth using a Densified Wood and Suspension Footers.

The replay using the 401 in the latter set up, was possibly the best memory I have of any Idler Drive replay I have experienced, there was a freedom of expression from the presentation I was not familiar with, much more so than an Idler Drive I own that is mounted in a Corian Plinth.

In a structure that has both mechanical and passive parts, the selection of the passive parts and how the selected material is able to manage energies transferred from the mechanical operation is a very important consideration.

Hi JohnnoG,It will be good to see your design come to fruition.

When done will there be an opportunity to compare the TT to a much more expensive design, to see if the concept has come close to meeting the brief. A Identical Tonearm > Cartridge and the same method for supporting the TT > Tonearm mounting will be the best practice parameters to make a fair assessment.

I have looked at your use of wood, and Conventional Plywood or Wood as a support can be affected by ambient conditions across seasons. If wood is the required material to be used, a Densified Wood might be worth considering for it properties, especially for Stability, Damping and Dissipation. It is going to add to the materials cost, "but it is not possible to make an omelette without breaking a few eggs".

I will certainly be wide open to the possibility of comparing my turntable to a more expensive design.

However, that may be difficult to implement, seeing that you are located in England while I am located in Prescott Arizona.

My main effort will be to develop a very low-cost bearing and a conventional turntable with some nice features.

As far as the use of plywood is concerned, I am only using that in my bearing test mock-up.

Sincerely,

Ralf

Hi everyone,

I will now post the last two CAD drawing of a group of six that I had prepared for this thread.

After that I will be busy creating a bill of materials for my turntable and I probably won't post for a while.

However, I will respond to questions.

One of the drawings shows a pivoting, tangentially tracking tone arm that I developed in 2019, mounted on my proposed turntable and the other drawing shows a conventional pivoting tone arm of Bearwald geometry with a floating head shell.

Sincerely,

Ralf

I will now post the last two CAD drawing of a group of six that I had prepared for this thread.

After that I will be busy creating a bill of materials for my turntable and I probably won't post for a while.

However, I will respond to questions.

One of the drawings shows a pivoting, tangentially tracking tone arm that I developed in 2019, mounted on my proposed turntable and the other drawing shows a conventional pivoting tone arm of Bearwald geometry with a floating head shell.

Sincerely,

Ralf

Attachments

So far I haven't found a source of 12" diameter black Delrin either.

Sincerely,

Ralf

Looks like a great project,

I have made a few Sp10 platters from POMC (Acetal). I used flat sheet between 20 to 50mm as 300mm round bar was very expensive at about $1000AU /meter.

Ralf, Yes I understand that you are going to test your bearing design. But any radial run out of the mock platter will effect the results you get from you bearing design.

Both bearing & platter have to be machined to the highest tolerance spec to do many meaningful testing, been there done that. If fact the heavier the platter the more the radial runout will effect the bearing.

Cheers

Both bearing & platter have to be machined to the highest tolerance spec to do many meaningful testing, been there done that. If fact the heavier the platter the more the radial runout will effect the bearing.

Cheers

- Home

- Source & Line

- Analogue Source

- My "maybe" revolutionary turntable design