I love my Argon 18 Platinum HDS.

Just heading out for a spin.

jeff

Jeff,

I used one of those on my TT and it not only had lousy sound, but it destroyed my LP. Never again!

😀

Best Regards,

TerryO

Jeff,

I used one of those on my TT and it not only had lousy sound, but it destroyed my LP. Never again!

😀

Best Regards,

TerryO

Terry - Juuuuuuust a friendly suggestion mate - don't us off road bikes for TT tone arms. 😉

Attachments

Terry - Juuuuuuust a friendly suggestion mate - don't us off road bikes for TT tone arms. 😉

You're probably right, although I didn't think it would make a difference. What would you suggest as a suitable replacement?

🙄

Best Regards,

TerryO

You're probably right, although I didn't think it would make a difference. What would you suggest as a suitable replacement?

🙄

Best Regards,

TerryO

hmmmm - back full circle

Attachments

My NAnook 219 Arrived

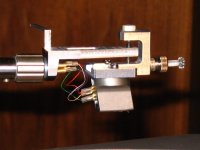

I have yet to wire it and work out all of the details, but here is what one semi put together looks like.. Can't wait to finish it and try it out. Need to make an arm rest and a few other odds and ends.

I think my little diy brass counterweight which weighs 88gms is going to work out well.

Thanks Stew for coming up with such an interesting project, and Dave for sending me one to play with.. 😀

Yeah, that is swarf on my listening room carpet, the machine shop is directly behind, and I am currently vacuum cleaner challenged.. 😱

I have yet to wire it and work out all of the details, but here is what one semi put together looks like.. Can't wait to finish it and try it out. Need to make an arm rest and a few other odds and ends.

I think my little diy brass counterweight which weighs 88gms is going to work out well.

Thanks Stew for coming up with such an interesting project, and Dave for sending me one to play with.. 😀

Yeah, that is swarf on my listening room carpet, the machine shop is directly behind, and I am currently vacuum cleaner challenged.. 😱

Attachments

Last edited:

kevin...

it looks semi put together... How do you like the idea of the pen refill? And the camo? Could call it the "Bushmaster". Nice counter-weight.

wait until you see the next arm 🙂

Think full brass construction with a similar counter-weight. I do like "suspended" counter-weights though...

The only thing I think I would try to change would be to try a DIY "RS Labs" type headshell to completely minimize tracking error.

it looks semi put together... How do you like the idea of the pen refill? And the camo? Could call it the "Bushmaster". Nice counter-weight.

wait until you see the next arm 🙂

Think full brass construction with a similar counter-weight. I do like "suspended" counter-weights though...

The only thing I think I would try to change would be to try a DIY "RS Labs" type headshell to completely minimize tracking error.

Attachments

Last edited:

A Twig.

Hi everyone

I have been considering the advantages of using wood and have some nice dried wood here in the form of:-

A Twig

If it goes wrong there's lots more outside on the trees.

Also they have a very random resonance beating form supplied by nature.

Bit of bark striping is advisable to avoid moss in the grooves.

Cheers... Simon...

I'm using aluminium, Easton shafts (7075 I think). I don't like the idea of carbon fibre anything, regardless of the high performance characteristics. I'd prefer using wood if I could devise a way to make them consistent. Bamboo comes to mind...

Hi everyone

I have been considering the advantages of using wood and have some nice dried wood here in the form of:-

A Twig

If it goes wrong there's lots more outside on the trees.

Also they have a very random resonance beating form supplied by nature.

Bit of bark striping is advisable to avoid moss in the grooves.

Cheers... Simon...

A Twig #2

Hi again

Just another thought...

Twigs come in ready made 'L' & 'S' type shapes, supplied by nature again.

Also...

Careful selection of twig could easily yield a built in counter-weight in the form of 'a branch' cut off at a suitable mass.

Not shure the 'twig' method would yield the perfect headshell shape, but a shaped wooden one could be easily glued on with non toxic wood glue.

Cheers... Simon...😀

A Twig ...

Hi again

Just another thought...

Twigs come in ready made 'L' & 'S' type shapes, supplied by nature again.

Also...

Careful selection of twig could easily yield a built in counter-weight in the form of 'a branch' cut off at a suitable mass.

Not shure the 'twig' method would yield the perfect headshell shape, but a shaped wooden one could be easily glued on with non toxic wood glue.

Cheers... Simon...😀

it looks semi put together... How do you like the idea of the pen refill? And the camo? Could call it the "Bushmaster". Nice counter-weight.

wait until you see the next arm 🙂

Think full brass construction with a similar counter-weight. I do like "suspended" counter-weights though...

The only thing I think I would try to change would be to try a DIY "RS Labs" type headshell to completely minimize tracking error.

I think the pen refill bearing is one of the best examples of adaptive reuse I have seen - I understand small knitting needles can also work pretty well. The pen refill probably has a slight edge as I imagine that the ball in the tip is hardened and the knitting needle isn't..

I think I have some tone arm wire around here, hope so anyway. Definitely have some kynar wire though, and can probably get more easily.. The tone arm wire is more flexible.

Need to figure out how I am going to bring the wires out, but I think I will probably drill a small hole just a bit forward of the pivot point, a tiny grommet should do the trick.. (just have to find one, perhaps an old SME bed plate grommet will do..)

This is going to be fun..

I like that RS headshell... a lot..

Like the camo, should shake up the audio dust around here once I show it to a couple of my friends..

Definitely interested in anything you come up with, the idea of an affordable, possibly customizable arm is appealing to me.

Last edited:

Thank you VERY much wjlamp.

Hi wjlamp.

Thank you for taking the time and trouble to reply to my post.

You have given me a GREAT source for arm cable that I could not find on the net.

I also think the arm the guy does is pretty interesting, I hadn't seen one before.

I think comments on my SME arm in another thread might well be justified !!!

Catch you later............................

Cheers... Simon...

Hi wjlamp.

Thank you for taking the time and trouble to reply to my post.

You have given me a GREAT source for arm cable that I could not find on the net.

I also think the arm the guy does is pretty interesting, I hadn't seen one before.

I think comments on my SME arm in another thread might well be justified !!!

Catch you later............................

Cheers... Simon...

hadn't seen one yet....

the "Terminator" grew from ideas posted here at DIYaudio and elsewhere. It started out as an example of Poul Ladegaard's DIY air bearing tonearm

kevinkr: one of the details I chose not to "do" for the arm parts provided to Dave and the folks on the island was to determine the exit location for the tonearm wires. Some might argue the benefits of exiting the wire on the underside of the arm, whilst others would argue for the wires to exit on the topside. It was intentionally left up to the end user to decide and do for themselves. Something as simple as a bit of heat shrink can be used for a grommet.

Again the use of a pen refill was based on junk lying around, but was quite intentional too. Even cheap pens can write well, so a decent ball bearing must be in there. The use of a set screw or pipe plug was decided upon as the female bearing "cup". the original used an acorn nut. Hogging out the arm tube to hold the acorn nut resulted in something quite gruesome to look at. It looked terrible, but sounded great, but was time consuming and ended with several ruined shafts.

the "Terminator" grew from ideas posted here at DIYaudio and elsewhere. It started out as an example of Poul Ladegaard's DIY air bearing tonearm

kevinkr: one of the details I chose not to "do" for the arm parts provided to Dave and the folks on the island was to determine the exit location for the tonearm wires. Some might argue the benefits of exiting the wire on the underside of the arm, whilst others would argue for the wires to exit on the topside. It was intentionally left up to the end user to decide and do for themselves. Something as simple as a bit of heat shrink can be used for a grommet.

Again the use of a pen refill was based on junk lying around, but was quite intentional too. Even cheap pens can write well, so a decent ball bearing must be in there. The use of a set screw or pipe plug was decided upon as the female bearing "cup". the original used an acorn nut. Hogging out the arm tube to hold the acorn nut resulted in something quite gruesome to look at. It looked terrible, but sounded great, but was time consuming and ended with several ruined shafts.

Last edited:

Hey Nanook....Thanks...Just for fun, and for absolutely Free, I made one of your arms out of a Cedar Arrow and a spare Dust Bug base. All I can say is Wow!.. It works, and sounds Great. The USB wire was too stiff though, so I used the wires from an old pair of Ear Buds. They seem to do the trick, and you can't beat the price. It really does a good job with this Idler Garrard....

Attachments

Last edited:

effective mass...

tmblack:

the arm tubes weigh in at approximately 12 grams. The fasteners are 2 grams or less, the headshell is approximately 4 grams, the cartridges I use are Grados, so the mass is about 5.5 grams and the compliance is approximately 20.

F=159/(M *C)^(1/2)

M=25 grams (approximately using the Grado cartridges with a mass of about 5.5 grams)

C= 20

resulting in a resonant frequency of 7.2 Hz, way too low. It's been suggested dynamic compliance can be up to about 1.2X's smaller than Static compliance, therefore C=16.7

and the resulting solution ends up being 7.8, better but still not great. But close to the 8Hz range. Remember that these arms are in the 12" length class.

How else to get the resonant frequency a little higher? Decrease the mass of the arm/cartridge system and use a less compliant cartridge.

tmblack:

the arm tubes weigh in at approximately 12 grams. The fasteners are 2 grams or less, the headshell is approximately 4 grams, the cartridges I use are Grados, so the mass is about 5.5 grams and the compliance is approximately 20.

F=159/(M *C)^(1/2)

M=25 grams (approximately using the Grado cartridges with a mass of about 5.5 grams)

C= 20

resulting in a resonant frequency of 7.2 Hz, way too low. It's been suggested dynamic compliance can be up to about 1.2X's smaller than Static compliance, therefore C=16.7

and the resulting solution ends up being 7.8, better but still not great. But close to the 8Hz range. Remember that these arms are in the 12" length class.

How else to get the resonant frequency a little higher? Decrease the mass of the arm/cartridge system and use a less compliant cartridge.

Hi Stew,

the 219,is here safe and sound.It is very nicely made,and you are too modest for your design.

I will get back on it, as soon as,its finished and working.(Waiting for some litz cable)

Thanks for your time and effort.

B.L.

the 219,is here safe and sound.It is very nicely made,and you are too modest for your design.

I will get back on it, as soon as,its finished and working.(Waiting for some litz cable)

Thanks for your time and effort.

B.L.

nicely made....

wj:..er, depends on your frame of reference. The bases and headshells were made by bernie. I had intended on using a hockey puck for the bases, but at the last moment asked bernie if he could do something quick and simple out of wood scraps. What you got was his idea. A good one at that.

Litz wire? cartridge tags? You must be building the "millionaire's edition 219 tonearm"! Actually I need to price out some good tonearm wire, and cartridge tags. Everything else I have a handle on regarding the costs of using new parts. Oh, and I suppose new counter-weights as well. If the bases were enlarged slightly, an arm rest could easily be made into it. Right now I'm using a small piece of dowel with a hole drilled into it. I stuffed a folded over and shaped paperclip, int the hole, and used the same sort of set screw type collar to hold it . That way the arm rest can easily be moved about. I also have a small amount of Blu-tac to "secure" (and I use that term loosely----pardon the pun, but it is intentional😉 ) the base of the tonearm to a location.

Dave or bernie: if either have the specifications on the arms (each one was weighed and marked with a reference number), can you email back to me? Dave: could you send back the slide show and I'll redo in pdf? (the dead HD killed everything off).

I cannot over-state the efforts of bernie in building the headshells (which are quite beautiful, and nicely made), of Dave for "administering" the delivery of the remaining "kits", and of course to Charles Altmann for his original design and which I implemented in a modified form.

wj:..er, depends on your frame of reference. The bases and headshells were made by bernie. I had intended on using a hockey puck for the bases, but at the last moment asked bernie if he could do something quick and simple out of wood scraps. What you got was his idea. A good one at that.

Litz wire? cartridge tags? You must be building the "millionaire's edition 219 tonearm"! Actually I need to price out some good tonearm wire, and cartridge tags. Everything else I have a handle on regarding the costs of using new parts. Oh, and I suppose new counter-weights as well. If the bases were enlarged slightly, an arm rest could easily be made into it. Right now I'm using a small piece of dowel with a hole drilled into it. I stuffed a folded over and shaped paperclip, int the hole, and used the same sort of set screw type collar to hold it . That way the arm rest can easily be moved about. I also have a small amount of Blu-tac to "secure" (and I use that term loosely----pardon the pun, but it is intentional😉 ) the base of the tonearm to a location.

Dave or bernie: if either have the specifications on the arms (each one was weighed and marked with a reference number), can you email back to me? Dave: could you send back the slide show and I'll redo in pdf? (the dead HD killed everything off).

I cannot over-state the efforts of bernie in building the headshells (which are quite beautiful, and nicely made), of Dave for "administering" the delivery of the remaining "kits", and of course to Charles Altmann for his original design and which I implemented in a modified form.

Attachments

Last edited:

wj:..er, depends on your frame of reference. The bases and headshells were made by bernie. I had intended on using a hockey puck for the bases, but at the last moment asked bernie if he could do something quick and simple out of wood scraps. What you got was his idea. A good one at that.

Litz wire? cartridge tags? You must be building the "millionaire's edition 219 tonearm"! Actually I need to price out some good tonearm wire, and cartridge tags. Everything else I have a handle on regarding the costs of using new part. Oh, and I suppose new counter-weights as well.

As they say,my compliments to the "chef ".

The wire and tags are less than $ 2,from the source in U.K..Not quite in the mil. class.I think, that by returning the favour,I have to send you a set,of the wire and tags,and make you feel like a "millionaire" too🙂

B.L.

Litz wire? cartridge tags? You must be building the "millionaire's edition 219 tonearm"! Actually I need to price out some good tonearm wire, and cartridge tags.

I used Cardas tonearm wire and gold plated Cardas cartridge clips for my recently completed oak unipivot. Relatively inexpensive and available from Michael Percy Audio in California:

Michael Percy Audio Ordering Information

Is there something wrong with using Ear Bud wire for the Tonearm wires? It's very thin and flexible.

Is there something wrong with using Ear Bud wire for the Tonearm wires? It's very thin and flexible.

Certainly not.Unless of course you feel adventurous,and you can identify, a possible better quality,by using something more exotic.

B.L

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- my latest iteration of "Nanook's 219 tonearm"..