That looks like a very solid structure Grant! I think the wood frame would also provide effective damping without overdoing it.

Look forward to your listening impressions!

Look forward to your listening impressions!

I am taking my time with the frame redesign because there're a number of things that need to be considered and best experimented on my current frame first, where possible.

I suspected the raised frame edges on the front side might be sonically undesirable and decided to move the U shaped channels (that hold the panels) forward. These channels are fixed with strong double sided tapes, hence not difficult to relocate. After the change the panels now sit protruding a few millimeters from the frame.

Before:

After:

The whole back side is now covered with a 3mm thick sheet of wool felt (before the fabric cover is put on):

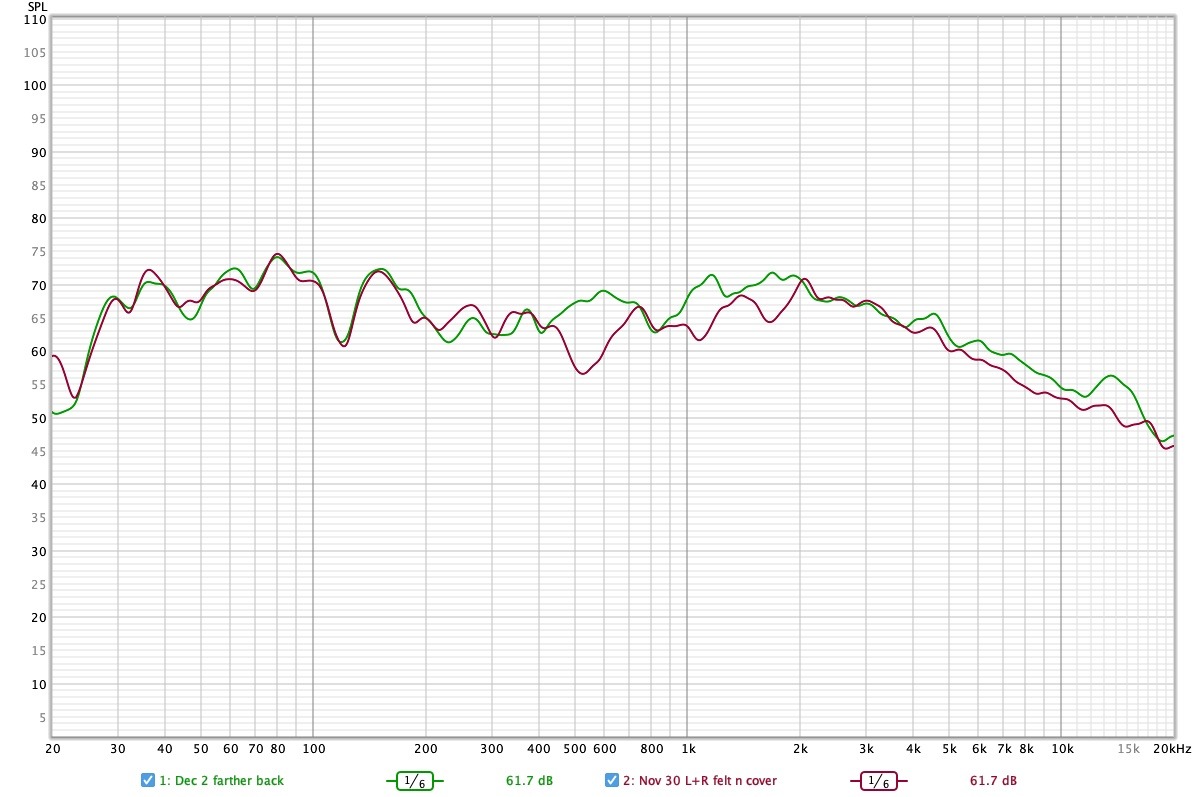

The REW room/speakers measurements before and after these changes; the green curve being the "after" one.

The sound has gained more warmth, perhaps because the low bass is now better controlled. Somehow the midrange brightness is improved a little too, but getting rid of the midrange anomaly is still my top priority for the frame redesign. The Acorn seems to be very sensitive to cancellation/reinforcement from diffraction/reflection--Perhaps a super slim frame is the way to go. Carbon fiber rails?

I've ordered 5mm thick wool felt sheets and will experiment with more back damping.

I suspected the raised frame edges on the front side might be sonically undesirable and decided to move the U shaped channels (that hold the panels) forward. These channels are fixed with strong double sided tapes, hence not difficult to relocate. After the change the panels now sit protruding a few millimeters from the frame.

Before:

After:

The whole back side is now covered with a 3mm thick sheet of wool felt (before the fabric cover is put on):

The REW room/speakers measurements before and after these changes; the green curve being the "after" one.

The sound has gained more warmth, perhaps because the low bass is now better controlled. Somehow the midrange brightness is improved a little too, but getting rid of the midrange anomaly is still my top priority for the frame redesign. The Acorn seems to be very sensitive to cancellation/reinforcement from diffraction/reflection--Perhaps a super slim frame is the way to go. Carbon fiber rails?

I've ordered 5mm thick wool felt sheets and will experiment with more back damping.

Meanwhile I tried to alleviate the midrange surges by re-positioning the Acorns in my room. When none of the away-from-the-side-walls positions worked, I decided to take the opposite approach just to see what would happen. I noticed a big improvement immediately and finally settled on 34cm between the outer edge of the panel and the side wall. This is counterintuitive but very nice as far as aesthetics and WAF are concerned, because the speakers sort of "disappear" visually. Sonically, other than a smoother and warmer sound, the soundstage becomes even wider and extends beyond the speakers with many recordings.

I then called up REW to take a measurement, which appeared to agree with what I heard, as shown in the graph below (the green curve). Note that the gradually falling highs are the result of off-axis measurement because the Acorns are not toed-in.

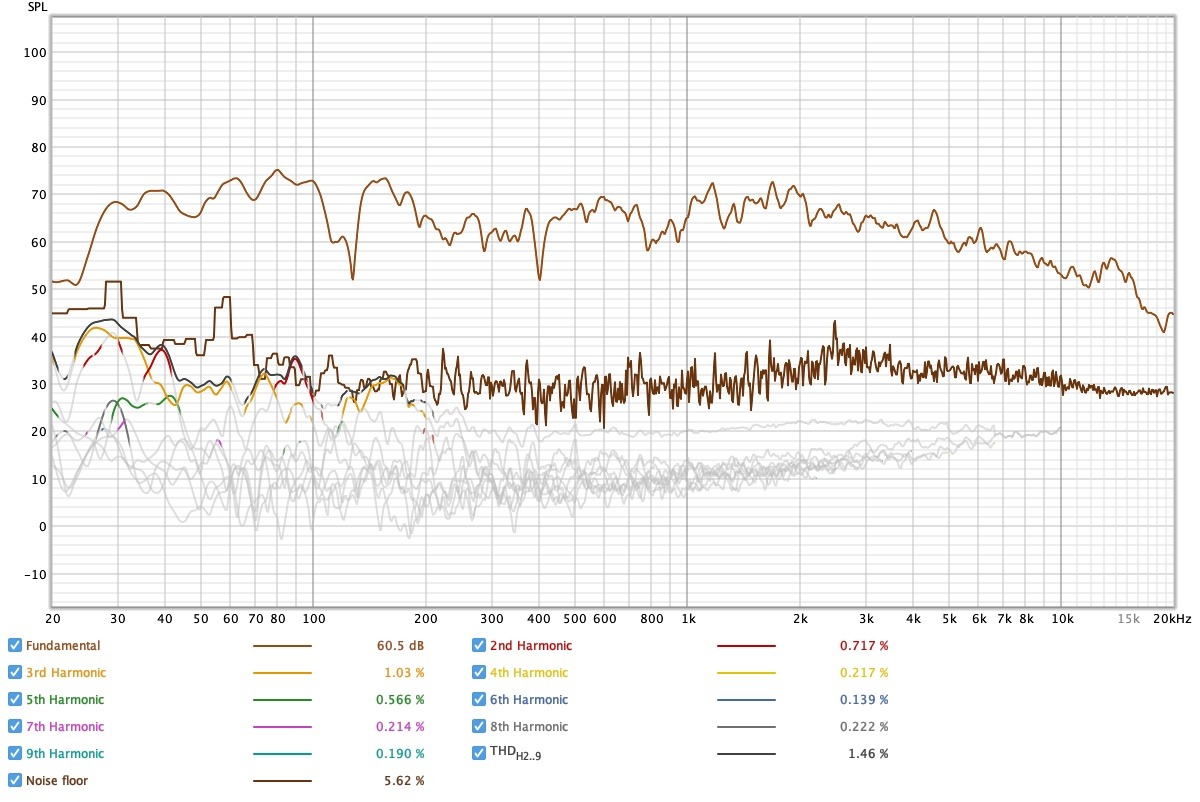

Here's the distortion graph view of the same measurement, just for reference.

I then called up REW to take a measurement, which appeared to agree with what I heard, as shown in the graph below (the green curve). Note that the gradually falling highs are the result of off-axis measurement because the Acorns are not toed-in.

Here's the distortion graph view of the same measurement, just for reference.

Many thanks Sheldon for the suggestion! I am trying to find a local source for silkscreen mesh and will give it a try.

The fine mesh should also help preventing dust from entering inside the panels. For now I am wrapping the wool felt sheet with the thicker grille fabric, which has a sandwiched layer of filter foam, as shown in the picture below. Clips are used as temporary solution so I could switch between different types and/or thickness of damping materials more easily, until the ideal damping is reached.

I tried wool felt of 2mm and 5mm in thickness for back damping and found the thicker felt to suppress the bass (below 100Hz) a little too much, otherwise no noticeable differences in mid and treble. For me the 2mm felt seems to work just fine. I will try the less dense "mover's felt," especially for the mid/treble, to see how it works.

In an effort to identify the cause of the midrange aberration, I moved one channel of the Acorn to the middle of my listening space (hence farther away from both side walls) and measured the bass, midrange, treble separately, as well as all combined, with the microphone placed at 2 meters. The combined measurement now showed a peak at 3kHz and a dip at 400Hz. The treble only measurement also shows the same 3kHz peak, which is reminiscent of the 2nd order high pass filter with a higher Q of a DIY speaker project from years ago. Out of curiosity I removed the inductor in the treble high pass filter (a 2nd order one) just to see if the peak would go away. It did so I proceeded to try different values for the remaining capacitor, and settled on 0.47uF based on measurements. I will continue tweaking the crossover with Rob's help and share my findings here.

Taking and interpreting speaker/room measurements does require involved learning, but I feel that even before one has the time to really study it, it's still an effective/efficient tool for tweaking speakers, and could potentially save one tons of time.

The fine mesh should also help preventing dust from entering inside the panels. For now I am wrapping the wool felt sheet with the thicker grille fabric, which has a sandwiched layer of filter foam, as shown in the picture below. Clips are used as temporary solution so I could switch between different types and/or thickness of damping materials more easily, until the ideal damping is reached.

I tried wool felt of 2mm and 5mm in thickness for back damping and found the thicker felt to suppress the bass (below 100Hz) a little too much, otherwise no noticeable differences in mid and treble. For me the 2mm felt seems to work just fine. I will try the less dense "mover's felt," especially for the mid/treble, to see how it works.

In an effort to identify the cause of the midrange aberration, I moved one channel of the Acorn to the middle of my listening space (hence farther away from both side walls) and measured the bass, midrange, treble separately, as well as all combined, with the microphone placed at 2 meters. The combined measurement now showed a peak at 3kHz and a dip at 400Hz. The treble only measurement also shows the same 3kHz peak, which is reminiscent of the 2nd order high pass filter with a higher Q of a DIY speaker project from years ago. Out of curiosity I removed the inductor in the treble high pass filter (a 2nd order one) just to see if the peak would go away. It did so I proceeded to try different values for the remaining capacitor, and settled on 0.47uF based on measurements. I will continue tweaking the crossover with Rob's help and share my findings here.

Taking and interpreting speaker/room measurements does require involved learning, but I feel that even before one has the time to really study it, it's still an effective/efficient tool for tweaking speakers, and could potentially save one tons of time.

Hi Fred?

I would be keen to see those individual driver responses and I assume this is driving each of the cross over sections with your OTL/OCL amps?

I have in the past driven Acoustat 1+1 with Atmasphere M60's, although I cheated using the Zero autoformer. They were surprisingly good in areas I did not expect.

Do you think it is possible that the output impedance of your amps could play a part in the frequency response? I have not seen an impedance curve for the Acorns, and not sure if they are difficult to drive as some esl at frequency extremes.

Cheers

Grant

I would be keen to see those individual driver responses and I assume this is driving each of the cross over sections with your OTL/OCL amps?

I have in the past driven Acoustat 1+1 with Atmasphere M60's, although I cheated using the Zero autoformer. They were surprisingly good in areas I did not expect.

Do you think it is possible that the output impedance of your amps could play a part in the frequency response? I have not seen an impedance curve for the Acorns, and not sure if they are difficult to drive as some esl at frequency extremes.

Cheers

Grant

Last edited:

I have been thinking of the same thing Grant, and plan to take measurements both with the Merz OTLs and with a Quad 306. I will post the new and hopefully more thorough/better controlled measuring results once I have them.

I have wanted to try the Zero autoformer for a long time because they make so much sense, but the "purist" in me has always prevented me from doing it. Luckily the Acorn is quite efficient and the Merz OTL can drive them beautifully to a loudness level way beyond what's healthy for my ears. How did you find the Zero sound quality wise? And the M60? Is the M60 a circlotron design?

I have wanted to try the Zero autoformer for a long time because they make so much sense, but the "purist" in me has always prevented me from doing it. Luckily the Acorn is quite efficient and the Merz OTL can drive them beautifully to a loudness level way beyond what's healthy for my ears. How did you find the Zero sound quality wise? And the M60? Is the M60 a circlotron design?

Grant--I took some more measurements and am still working on the annotations (lots of combinations), but can share a comparison of the treble-only curves first. The green curve was taken a few days ago with the standard 2nd order high-pass filter. The orange one was taken yesterday, with the inductor removed and the 0R5 resistor (before the capacitor) bypassed, so only the original 2.2uF capacitor remained. Please excuse and ignore the slight level difference.

BTW, I tried both the Merz OTLs and the Quad 306 this time. No discernible difference in the measurements as far as I can tell.

BTW, I tried both the Merz OTLs and the Quad 306 this time. No discernible difference in the measurements as far as I can tell.

Hey interesting.

Now crossovers on ESL's are complex and do not conform to convention due to the naturally rising response of the panels.

I am a little confused however, as I remember reading somewhere that the Acorns "tweeter section" was handing over to the midrange section at 6K, not 3K!

The midrange was then theoretically handing off to the bass panels at roughly 250Hz.

The plot without inductor looks almost like mid and treble panels.

However, I will be running mine "as supplied" (plus Gary Damping😉) for a good deal of time, just because I have taken way too long to get these functional.

Big weekend planned.

Cheers

Grant

PS: I will PM you regarding Acoustats and Atmasphere (yes Circlotron) as it may not be related to this thread, yet. 😅

Now crossovers on ESL's are complex and do not conform to convention due to the naturally rising response of the panels.

I am a little confused however, as I remember reading somewhere that the Acorns "tweeter section" was handing over to the midrange section at 6K, not 3K!

The midrange was then theoretically handing off to the bass panels at roughly 250Hz.

The plot without inductor looks almost like mid and treble panels.

However, I will be running mine "as supplied" (plus Gary Damping😉) for a good deal of time, just because I have taken way too long to get these functional.

Big weekend planned.

Cheers

Grant

PS: I will PM you regarding Acoustats and Atmasphere (yes Circlotron) as it may not be related to this thread, yet. 😅

I am sure the Acorn's crossover as supplied works well. In my case, the midrange peak present in my implementation needed to be taken care of. Not capable of doing simulation or calculating on paper first (the capacitance of the panels and the transformers make things a lot more complicated), I simply relied on measurements and Rob's suggestions to arrive at what is to me a closer-to-ideal result. It's my experience that good-sounding speakers almost always measured relatively flat--in my listening room at least.

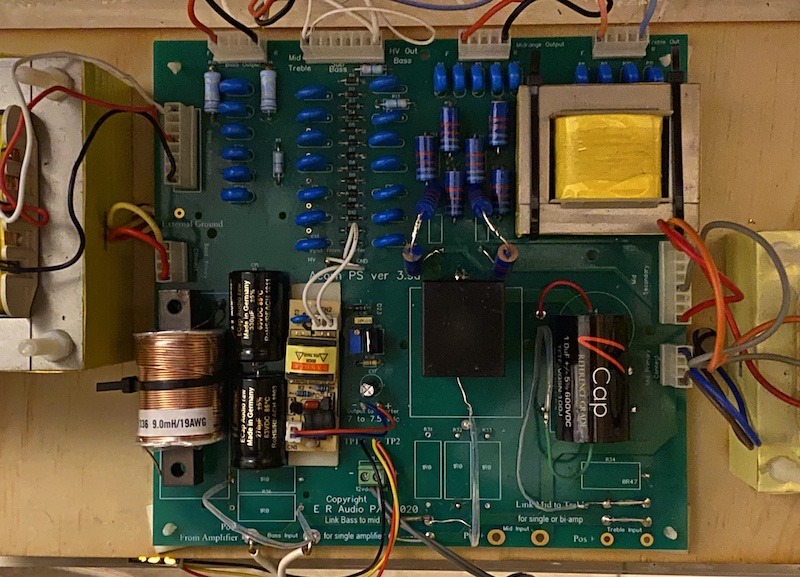

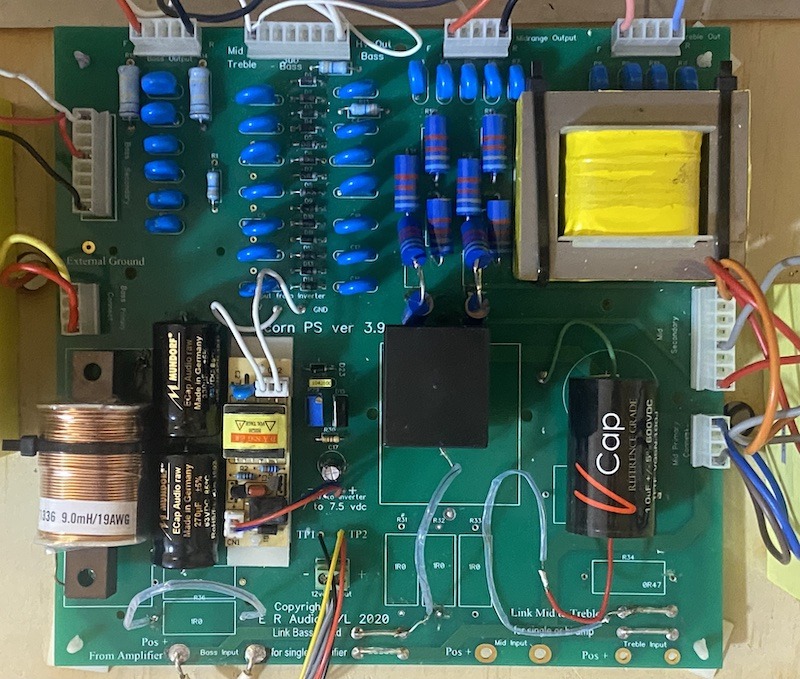

The Acorn has its crossover placed before the step-up transformers, unlike the Quad ESL (the '57), so the crossover components aren't exposed to high voltages. This makes experimenting with different RC parts/values much easier. I also appreciate that its PCB can be taken off rather quickly by simply unplugging all the connectors to the panels and transformers. I have probably done it a hundred times over these past couple weeks! 😀

The Acorn has its crossover placed before the step-up transformers, unlike the Quad ESL (the '57), so the crossover components aren't exposed to high voltages. This makes experimenting with different RC parts/values much easier. I also appreciate that its PCB can be taken off rather quickly by simply unplugging all the connectors to the panels and transformers. I have probably done it a hundred times over these past couple weeks! 😀

Realized that the lead orientation of the treble capacitor wasn't following the manufacturer's recommendation (that the outermost foil be connected to the lower impedance path to ground) and corrected it:

The Acorns are sounding terrific after these changes. However in order to narrow the spectrum the treble panel covers so as not to "overwork" it long term, I have ordered two inductors (which I would feel more comfortable unwinding to adjust their inductance) to experiment with reverting to a 2nd order high pass filter for the treble section, albeit with a different Q factor.

The Acorns are sounding terrific after these changes. However in order to narrow the spectrum the treble panel covers so as not to "overwork" it long term, I have ordered two inductors (which I would feel more comfortable unwinding to adjust their inductance) to experiment with reverting to a 2nd order high pass filter for the treble section, albeit with a different Q factor.

I found that the compacted wool felt I used really doesn't shed any fiber, hence no need for the protective fabric cover. Clipping the felt directly to the side rails allows it to fit the frame more snugly.

Occasionally vibrations would occur at an edge spot on one of the midrange panels (where it's clamped together with the bass panel). Following Rob's suggestion, I cut and put a narrow piece of EPE between the panel and the white spacing strip behind it (I used a credit card to gently push it in the gap). Worked like a charm. This is an easy and effective fix before I can make the time to design and construct new frames. Looking at the photo closely, one can see that the innermost openings are partially blocked by the clamps--something to consider when designing the new frames.

EPE sheets are usually multi-layered, and can be easily cut down to the desired thickness.

Occasionally vibrations would occur at an edge spot on one of the midrange panels (where it's clamped together with the bass panel). Following Rob's suggestion, I cut and put a narrow piece of EPE between the panel and the white spacing strip behind it (I used a credit card to gently push it in the gap). Worked like a charm. This is an easy and effective fix before I can make the time to design and construct new frames. Looking at the photo closely, one can see that the innermost openings are partially blocked by the clamps--something to consider when designing the new frames.

EPE sheets are usually multi-layered, and can be easily cut down to the desired thickness.

Having now kept the mid-high peak more at bay, I am starting to think about the next steps. My ultimate goal for the Acorns is to achieve a relatively flat in-room response trending slightly downward to roughly -4dB at 20kHz. A series (series-connected LCR in parallel with the midrange) or parallel (parallel-connected LCR in series with the midrange) notch filter would be the logical solution. I would actually like to go with a 1st order crossover with comprehensive correcting networks (per Vandersteen) if I could manage to come up with such a design. As a DIY person our advantage is that we can empirically measure and perfect the crossover in our own room.

Beyond that, I would also like to experiment with the fascinating Broskie series-shunt crossover, though that will be a completely different direction.

But those are for the near and far future, and I still want to make the most out of what I have now:

New dress on

The new single layer fabric is basically see-through transparent

I also replaced the white spacer behind the mid/treble panel with EPE strips on both sides of the panel. This would also position the mid/treble diaphragm on the same plane as the bass diaphragm.

Close-up of the white spacer. The bass panel is thicker than the mid/treble panel, but both are clamped by the same set of clips, hence a spacer is needed behind the mid/treble panel. In practice however, the spacer would often come loose.

EPE strips in place of the spacer on both front and back sides of the mid/treble panels.

Beyond that, I would also like to experiment with the fascinating Broskie series-shunt crossover, though that will be a completely different direction.

But those are for the near and far future, and I still want to make the most out of what I have now:

New dress on

The new single layer fabric is basically see-through transparent

I also replaced the white spacer behind the mid/treble panel with EPE strips on both sides of the panel. This would also position the mid/treble diaphragm on the same plane as the bass diaphragm.

Close-up of the white spacer. The bass panel is thicker than the mid/treble panel, but both are clamped by the same set of clips, hence a spacer is needed behind the mid/treble panel. In practice however, the spacer would often come loose.

EPE strips in place of the spacer on both front and back sides of the mid/treble panels.

Thanks cab for the suggestion! Yes, DSP crossover is definitely a great option.DSP crosseovers would make things a lot easier.

Only two things are keeping me from investigating into it immediately:

The first is that I still listen to vinyl from time to time. Although DSP phono RIAA such as the Puffin is gaining ground, I am really hoping to see a more "purist" solution, such as a novel cartridge design that outputs digital signals directly.

The second (which probably has more to do with my self-awareness) is that, given my (particularly deep) understanding of the masochist nature of us DIY audiophiles, I don't have the confidence that my DSP crossover, even if it starts as a straight forward DCX2496 (or MiniDSP, or DBX) unit, won't become frankensteined and spawn a bunch of huge external power supplies and unexplainable enhancing devices, as is the case with my JPlay/PC based digital source system... 😀

I just tried and couldn't access the ER Audio site either.

like you use of computer components etc !! i looked at this image and is there something wrong with the mylar in the left side of the upper panel ?

Hi WrineX--The panel surface in the photo seems to have some discoloring. I can't really tell if there's something wrong with the mylar (looks normal to me). Grant has been working on getting his Acorns ready so maybe we will hear from him about it soon.

The computer components I use for my JPlay based digital source system are mostly based on the recommendations from the thread on the Taiwanese forum I mentioned in post #3.

Interesting, I was a bit disturbed when I zoomed in too.i looked at this image and is there something wrong with the mylar in the left side of the upper panel ?

However ...

This is a photo at the rear of the same panel.

As you can now see the "speckled" surface is actually the paint finish of the outer surface of the stators, not the diaphragm.

The appearance is alot worse looking in the original photo because of, wierd lighting, weird depth of field effects and my poor photographic skills. 🤣

And I almost embarrassed myself further, by say "Aw shucks, my SOtM SMS200 is hardly bleeding edge computer technology. 🤓"

Cheers

Grant

aaah ok yeah might just be a reflection or something ! looks like a nice system !!Hi WrineX--The panel surface in the photo seems to have some discoloring. I can't really tell if there's something wrong with the mylar (looks normal to me). Grant has been working on getting his Acorns ready so maybe we will hear from him about it soon.

The computer components I use for my JPlay based digital source system are mostly based on the recommendations from the thread on the Taiwanese forum I mentioned in post #3.

- Home

- Loudspeakers

- Planars & Exotics

- My ER Audio Acorn Mk II build