Ever since getting my old (old as in manufactured in the 70's) Quad ESLs (the '57) to work properly, which involved augmenting them with a pair of really good super tweeters, a pair of very fast subwoofers, and a pair of OTL (OCL actually) power amps, I realized that electrostatics are what I really enjoy. I also listened to big Sound Labs on several occasions and reckoned that true full range electrostatics would and should be the next step. However new big Sound Labs are outside of my budget and used ones are next to impossible to find where I live. Even if I luck on a used pair, chances are they would need a full restoration, which is a really tough task.

In late 2020 I found ER Audio whilst looking for Quad ESL restoration materials. After some email exchanges with Rob (Rob Mackinlay, owner of ER Audio) and ordering a repair kit for the Quads, I noticed that the Acorn, ER Audio's ESL speaker kit, was now in its Mk II incarnation. Reading through the technical descriptions of the Acorn, I found many design elements that I liked. The Acorn is a three-way (4-way actually, because it has a super tweeter on the tweeter diaphragm, crossed over with surface mount components on the panel) design with separate bass and mid/treble panels, much like the '57, whereas the ESL IV, another ESL kit of ER Audio's, is similar to the ESL63 in that the whole speaker plays full range, with the signal going through some low-pass filters towards the upper and lower ends. Personally I've always preferred what I heard from the '57 than the '63.

So ordering a repair kit for the '57 ended up leading to my purchase of an Acorn Mk II kit with pre-built panels. On one hand I felt really happy because a pair of true full range electrostatics is something I've dreamt about for years; On the other hand I was secretly doubting if it was too good to be true, especially considering the price even as a kit.

My '57s were sounding nicer and nicer as I modified the OTL amps driving them (a pair of Merz Type T with 6336 output tubes) and I got really busy at work, as a result the Acorn project was put off for two years. In the beginning of this year I happened on a thread on an Aussie forum about the Acorn Mk II, and the author is none other than Gary Jacobson, owner/creator of quadesl.org! It so happened that at the same time my '57s started to develop issues again--Time to start working on the Acorn!

The Acorn is a kit sans the frames and bases, which the user will have to build themselves. So what I plan to share in this thread is mainly the design and build plan of my frame/base for the Acorn and also updates as I implement changes (will take a few posts, perhaps over a couple months, due to lack of spare time on my part--my apology first), in the hope that it would be of some help to anyone interested in building the Acorn. If you're interested in reliable assessment of the Acorn's sonic performance, Mr. Jacobson described its sonic traits very clearly in the aforementioned thread, which I highly recommend checking out.

First some pictures.

Acorn Mk II in my listening/living room (back damping is still being experimented and not in place yet):

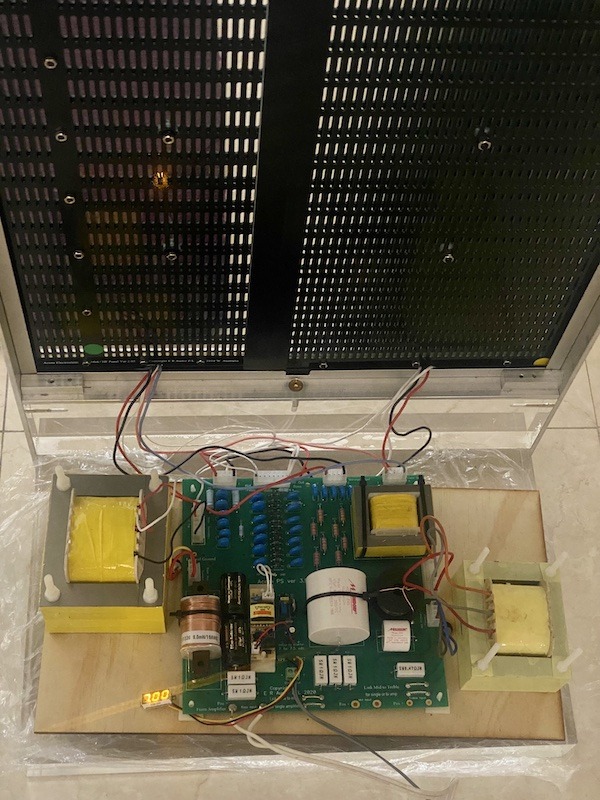

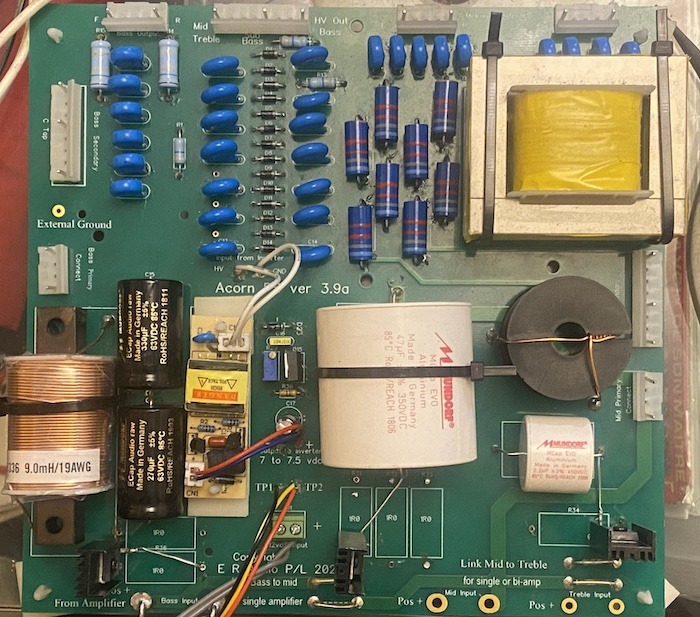

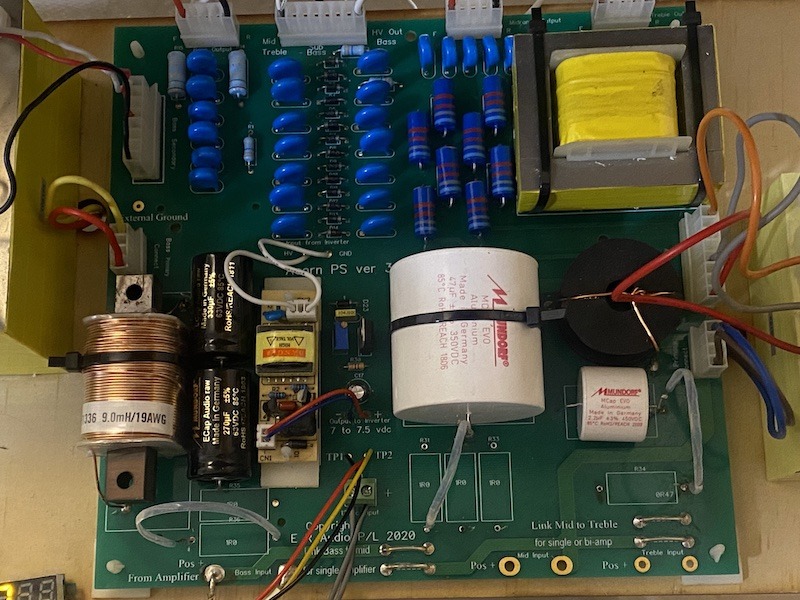

The transformers and PCB sitting on the acrylic base behind the panels:

Front of the (upper) panels. This is the left channel and the bass panel is on the left side.

In late 2020 I found ER Audio whilst looking for Quad ESL restoration materials. After some email exchanges with Rob (Rob Mackinlay, owner of ER Audio) and ordering a repair kit for the Quads, I noticed that the Acorn, ER Audio's ESL speaker kit, was now in its Mk II incarnation. Reading through the technical descriptions of the Acorn, I found many design elements that I liked. The Acorn is a three-way (4-way actually, because it has a super tweeter on the tweeter diaphragm, crossed over with surface mount components on the panel) design with separate bass and mid/treble panels, much like the '57, whereas the ESL IV, another ESL kit of ER Audio's, is similar to the ESL63 in that the whole speaker plays full range, with the signal going through some low-pass filters towards the upper and lower ends. Personally I've always preferred what I heard from the '57 than the '63.

So ordering a repair kit for the '57 ended up leading to my purchase of an Acorn Mk II kit with pre-built panels. On one hand I felt really happy because a pair of true full range electrostatics is something I've dreamt about for years; On the other hand I was secretly doubting if it was too good to be true, especially considering the price even as a kit.

My '57s were sounding nicer and nicer as I modified the OTL amps driving them (a pair of Merz Type T with 6336 output tubes) and I got really busy at work, as a result the Acorn project was put off for two years. In the beginning of this year I happened on a thread on an Aussie forum about the Acorn Mk II, and the author is none other than Gary Jacobson, owner/creator of quadesl.org! It so happened that at the same time my '57s started to develop issues again--Time to start working on the Acorn!

The Acorn is a kit sans the frames and bases, which the user will have to build themselves. So what I plan to share in this thread is mainly the design and build plan of my frame/base for the Acorn and also updates as I implement changes (will take a few posts, perhaps over a couple months, due to lack of spare time on my part--my apology first), in the hope that it would be of some help to anyone interested in building the Acorn. If you're interested in reliable assessment of the Acorn's sonic performance, Mr. Jacobson described its sonic traits very clearly in the aforementioned thread, which I highly recommend checking out.

First some pictures.

Acorn Mk II in my listening/living room (back damping is still being experimented and not in place yet):

The transformers and PCB sitting on the acrylic base behind the panels:

Front of the (upper) panels. This is the left channel and the bass panel is on the left side.

Last edited:

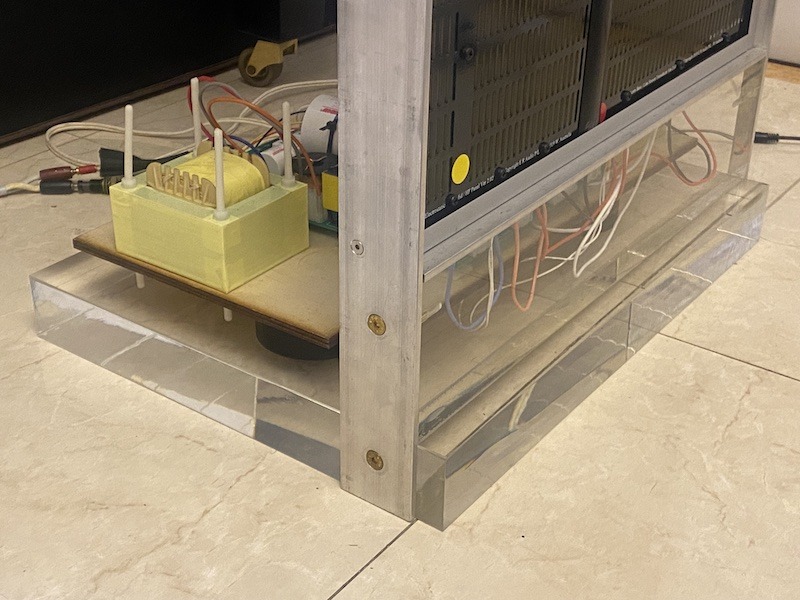

I was going to build the timbre enclosure based on the plan provided in the Acorn instructions, then realized that I didn't have all the tools to do it properly. Personally I am not a fan of MDF boards, also to make life easier I decided to have an acrylic base made by a local acrylic shop. The thickest acrylic sheet they have in stock is 50mm, and that's what I specified. To keep the cost down and everyone's life easier I simplified the design of the base as much as I could. The result looks like this:

The plan:

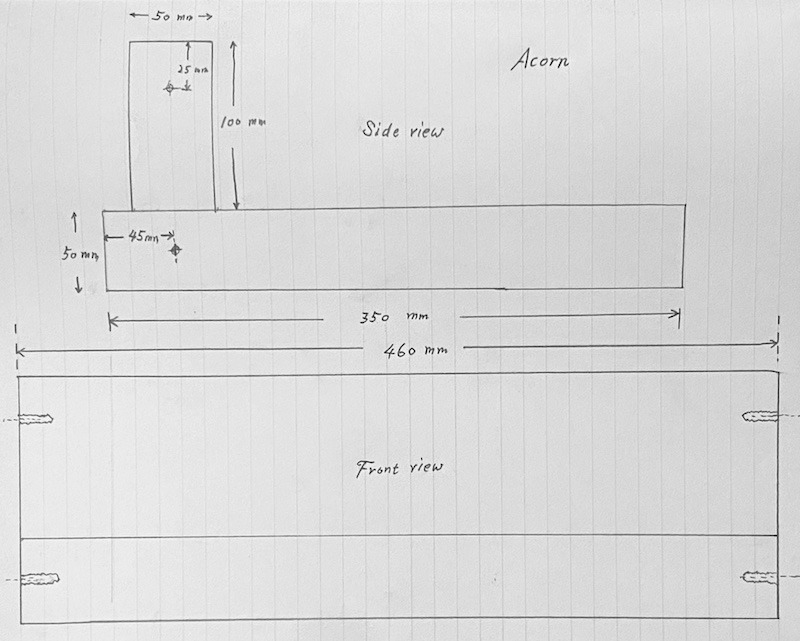

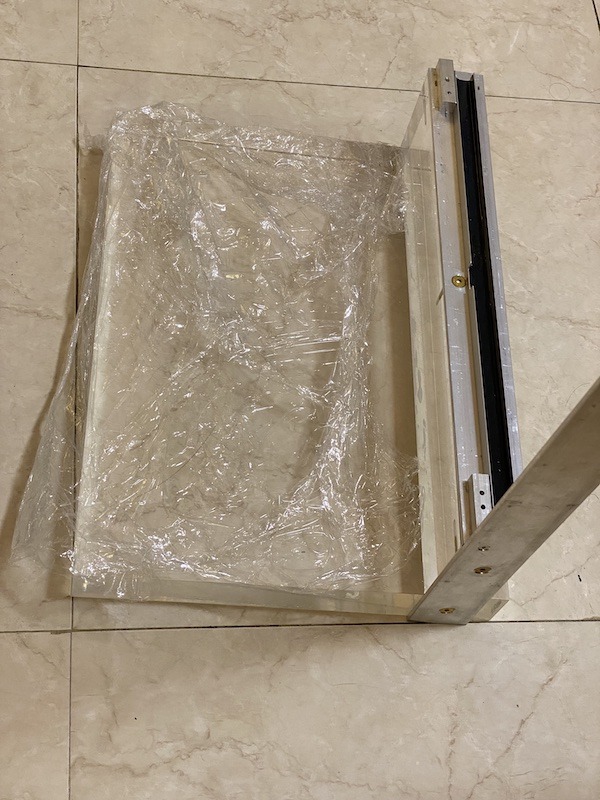

In the middle of assembly:

One advantage of the Acorn is that it's actually quite "portable," if any planar speakers can be so described. These are all the frame and base parts:

The plan:

In the middle of assembly:

One advantage of the Acorn is that it's actually quite "portable," if any planar speakers can be so described. These are all the frame and base parts:

The aluminum frame design was sort of improvised and finalized as I test assembled the Acorn. I will have to find time to draw the plan and share here. Meanwhile, a few things about setting up and tuning the Acorn:

1) The Acorns do need time to settle. Over the first ten days the sound changed drastically, to the degree that at one point I thought the grill clothes I used was killing too much mid/high and unusable. I am still patiently waiting for them to really settle, to finalize the back damping implementation. Gary in his thread mentioned that it took him 18 months (on and off I think) to reach his desired back damping configuration. In my case, I feel my Acorns began to stabilize sonically after around ten days of being kept powered on, and getting a couple hours playing time daily.

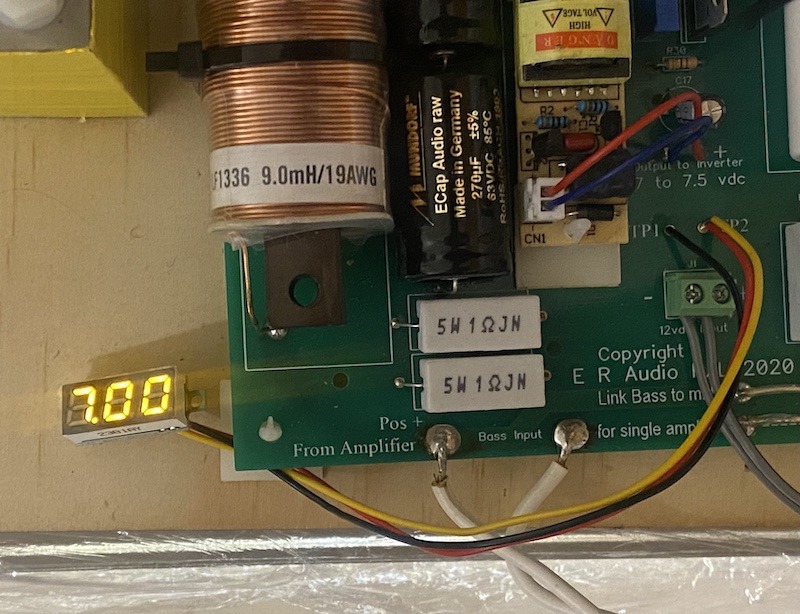

2) The Acorn's high voltage circuit is smartly designed and can be adjusted continuously over a wide range. The voltage can be set lower to reduce and/or eliminate the panel sizzling, if any, throughout the very early break-in period, and can also be adjusted within the recommended 7V to 7.5V range (the voltage measured at the test points) for fine tuning the sound. I soldered a small voltage meter with LED display to the test points. It's very convenient/intuitive and also serves as a power-on indicator:

Now some audiophile stuff:

The Acorns are the highest performance speakers that I have had the pleasure to enjoy in my own place. So in fine-tuning their performance I have tried using sources and amps as neutral and high resolving as possible. I use mostly digital (PC) source for its repeatability and speed, and occasionally analog (vinyl) for double checking.

My digital source setup is centered around JPlay running on Windows Server 2022. It's in single PC configuration currently for convenience, but will revert back to the dual-PC set up I normally use once the work on Acorn is completed.

Gigabyte Z690 Master/Intel i5-12600KF with only two P-Cores activated, on an open frame chassis:

The PC's USB output goes through a pair of U3TT and a USB 3.0 hub, before going into the DDC. All externally powered.

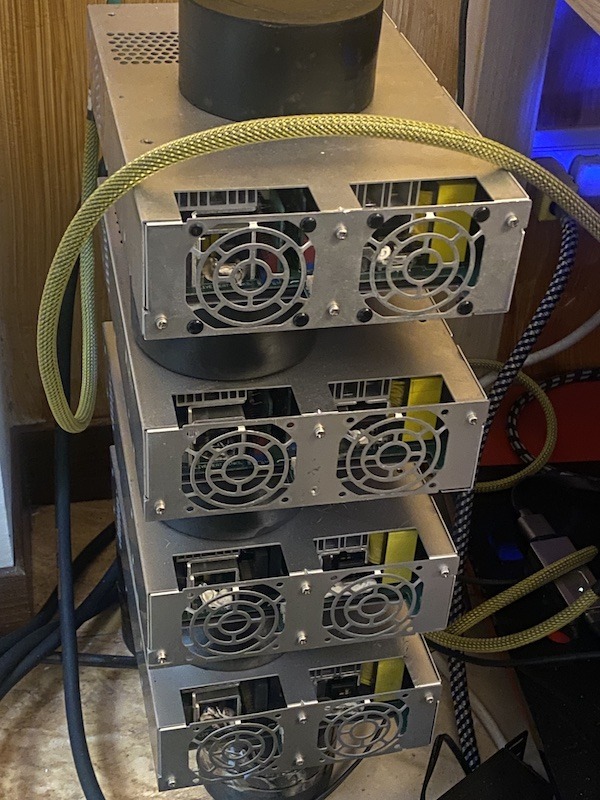

Four 1200W Cosel SMPSs feed the hubs, U3TTs and the 3.5" hard disk where the music files reside:

This audio PC setup will look familiar to many audiophiles in Taiwan, because it's based on the recipe that has been painstakingly tested and developed over more than 10 years in a thread on a Taiwanese forum. This JPlay PC transport system in a way urged me to pursue something even better than the Quad '57 setup I had been using for many years.

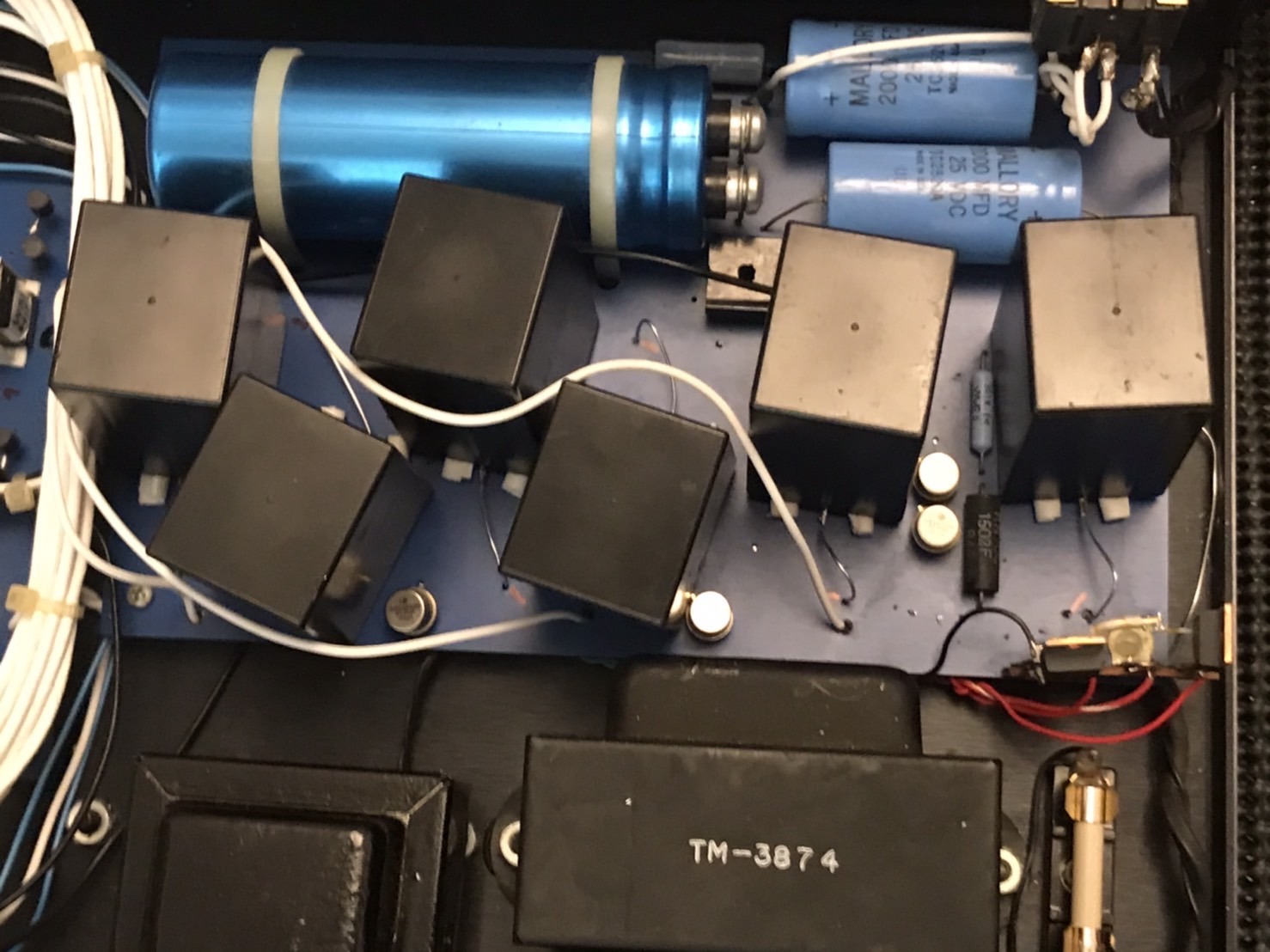

But of course everyone still needs a nice vinyl playback system . This is my vintage Theta preamp converted to a phono-only preamp. The PCC88s are transistor biased and inductor loaded; RIAA equalization is still passive CR type per the original Theta:

. This is my vintage Theta preamp converted to a phono-only preamp. The PCC88s are transistor biased and inductor loaded; RIAA equalization is still passive CR type per the original Theta:

The power supply circuit is largely unchanged, but the electrolytic caps are replaced with Mundorf TubeCaps. Amazing results:

The modified Theta might soon face a stiff competition--my Vacuum State RTP3D waiting to be revived:

And my beloved Decca Mk 4 cartridge, here mounted on the Sony Biotracer PS-X700:

1) The Acorns do need time to settle. Over the first ten days the sound changed drastically, to the degree that at one point I thought the grill clothes I used was killing too much mid/high and unusable. I am still patiently waiting for them to really settle, to finalize the back damping implementation. Gary in his thread mentioned that it took him 18 months (on and off I think) to reach his desired back damping configuration. In my case, I feel my Acorns began to stabilize sonically after around ten days of being kept powered on, and getting a couple hours playing time daily.

2) The Acorn's high voltage circuit is smartly designed and can be adjusted continuously over a wide range. The voltage can be set lower to reduce and/or eliminate the panel sizzling, if any, throughout the very early break-in period, and can also be adjusted within the recommended 7V to 7.5V range (the voltage measured at the test points) for fine tuning the sound. I soldered a small voltage meter with LED display to the test points. It's very convenient/intuitive and also serves as a power-on indicator:

Now some audiophile stuff:

The Acorns are the highest performance speakers that I have had the pleasure to enjoy in my own place. So in fine-tuning their performance I have tried using sources and amps as neutral and high resolving as possible. I use mostly digital (PC) source for its repeatability and speed, and occasionally analog (vinyl) for double checking.

My digital source setup is centered around JPlay running on Windows Server 2022. It's in single PC configuration currently for convenience, but will revert back to the dual-PC set up I normally use once the work on Acorn is completed.

Gigabyte Z690 Master/Intel i5-12600KF with only two P-Cores activated, on an open frame chassis:

The PC's USB output goes through a pair of U3TT and a USB 3.0 hub, before going into the DDC. All externally powered.

Four 1200W Cosel SMPSs feed the hubs, U3TTs and the 3.5" hard disk where the music files reside:

This audio PC setup will look familiar to many audiophiles in Taiwan, because it's based on the recipe that has been painstakingly tested and developed over more than 10 years in a thread on a Taiwanese forum. This JPlay PC transport system in a way urged me to pursue something even better than the Quad '57 setup I had been using for many years.

But of course everyone still needs a nice vinyl playback system

The power supply circuit is largely unchanged, but the electrolytic caps are replaced with Mundorf TubeCaps. Amazing results:

The modified Theta might soon face a stiff competition--my Vacuum State RTP3D waiting to be revived:

And my beloved Decca Mk 4 cartridge, here mounted on the Sony Biotracer PS-X700:

My first impression of the Acorn, from what can be seen visually, was that the Acorn appeared to have a logical layout, mechanically and electronically. Later on, from actually building the kit and my email exchanges with Rob, I realized that there is more to the design than meets the eye. For example, I thought the coating on the diaphragm must be based on the PEDOT-PSS that has recently been raved about among many Quad users, only to find that Rob had experimented with it before and was not satisfied with the long term performance/reliability. Another example--for bass freaks, provision for adding extra sub-woofer panels is already built in the Acorn (HV supply, etc.), so to further extend the Acorn's LF, to below 35Hz, requires much less work than one would have imagined. I am actually tempted to give it a try some time in the future.

Speaking of bass, it's quite an experience to listen to orchestral works on the Acorn. The coherence of bass is something I have never heard on a hybrid system, no matter how fast the subwoofers are.

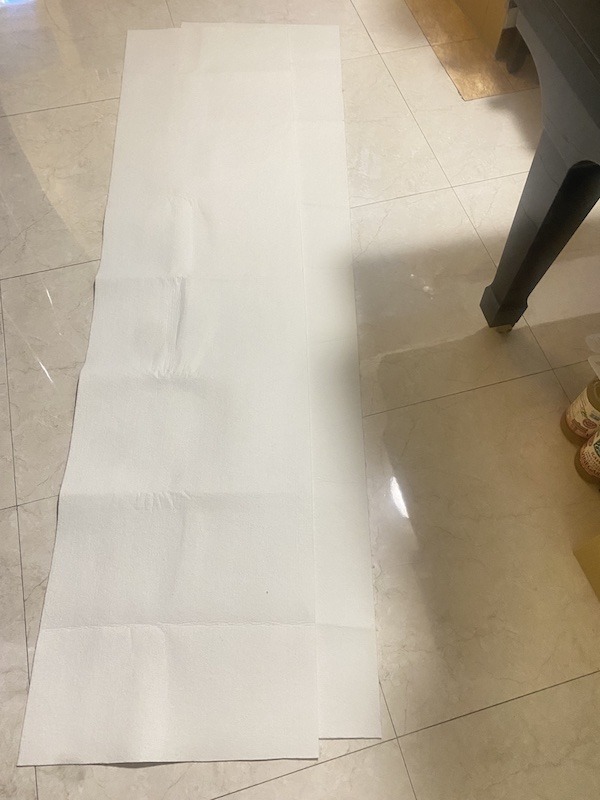

The 3mm wool felt I ordered for back damping just arrived.

Speaking of bass, it's quite an experience to listen to orchestral works on the Acorn. The coherence of bass is something I have never heard on a hybrid system, no matter how fast the subwoofers are.

The 3mm wool felt I ordered for back damping just arrived.

In regards to acoustic damping for the Acorn, this is what the ER Audio Acorn Mk II page says:

Acoustic Damping

Whilst testing my Acorns with no grilles on I observed occasions where the bass panel would "bottom out"--that is, the diaphragm touching the stator (made of 1.6mm PCBs), so Rob's advice above should be followed to avoid potential diaphragm damage.

My first try with the grille design was a failure and the grille turned out quite a bit too short, as can be seen in the picture below (I overestimated the elasticity of the grille cloth in the vertical direction). Had to use a left-over piece grille cloth to cover the exposed bottom part as a temporary fix. I am still waiting for a new batch of grille cloth--of a new color too, which I am sure has a much higher WAF--to make the grilles in a new design, where there will be a "pocket" on the back side for the wool felt. I will share the design here if it works as planed.

Meanwhile I put the wool felt, 3mm in thickness, on the Acorns just to get an idea, and the result has been quite positive. Together with the ageing from accumulating more playing time, the Acorn now sounds very similar to the '57 in tonality and transparency, only in true full range. The Acorns also project a bigger and more coherent soundstage.

Acoustic Damping

The Acorn MkII is designed to operate with a grille cloth in place. The cloth serves two functions, it prevents dust and insects getting into the works and it provides diaphragm damping at resonance. Operation of the speaker without cloth is not recommended but some clients prefer to have nothing in front of the soundwave for critical listening. It is permissible to have the front grille cloth easily removed for serious listening but the rear cloth should be left in place to provide damping. Operation with the cloth removed from both sides will likely result in uneven bass response."

Whilst testing my Acorns with no grilles on I observed occasions where the bass panel would "bottom out"--that is, the diaphragm touching the stator (made of 1.6mm PCBs), so Rob's advice above should be followed to avoid potential diaphragm damage.

My first try with the grille design was a failure and the grille turned out quite a bit too short, as can be seen in the picture below (I overestimated the elasticity of the grille cloth in the vertical direction). Had to use a left-over piece grille cloth to cover the exposed bottom part as a temporary fix. I am still waiting for a new batch of grille cloth--of a new color too, which I am sure has a much higher WAF--to make the grilles in a new design, where there will be a "pocket" on the back side for the wool felt. I will share the design here if it works as planed.

Meanwhile I put the wool felt, 3mm in thickness, on the Acorns just to get an idea, and the result has been quite positive. Together with the ageing from accumulating more playing time, the Acorn now sounds very similar to the '57 in tonality and transparency, only in true full range. The Acorns also project a bigger and more coherent soundstage.

Many thanks alexberg!

Building a pair of electrostatics might sound like a daunting task, but with the Acorn--and I presume it's the same with Rob's other creation, the ESL IV--it really is quite straight forward. The frame/base design is in many ways simpler than that for dynamic speakers.

All the parts on the Acorn's PCB appear to be of very high quality: Mundorfs, Vishay VR68 high voltage resistors, etc. The cement resistors in the crossover network are probably the only parts that look more "ordinary," though cement resistors are non-inductive and work just fine there. However from my past experiences I always prefer not to connect resistors or caps in parallel, so I decided to replace the two 1R resistors in parallel (bass) and another three 1R resistors in parallel (mid) with a 0R5 and a 0R33. Thick film resistors have always worked well for me, so here I use Caddock MP930 0R5s and Vishay RTO 20W 0R33s. I also replaced the single 0R47 cement resistor on the treble, and after consulting with Rob, the eight carbon film resistors with Riken RMAs (these resistors need to cope with very high voltage). Very happy with the result.

Building a pair of electrostatics might sound like a daunting task, but with the Acorn--and I presume it's the same with Rob's other creation, the ESL IV--it really is quite straight forward. The frame/base design is in many ways simpler than that for dynamic speakers.

All the parts on the Acorn's PCB appear to be of very high quality: Mundorfs, Vishay VR68 high voltage resistors, etc. The cement resistors in the crossover network are probably the only parts that look more "ordinary," though cement resistors are non-inductive and work just fine there. However from my past experiences I always prefer not to connect resistors or caps in parallel, so I decided to replace the two 1R resistors in parallel (bass) and another three 1R resistors in parallel (mid) with a 0R5 and a 0R33. Thick film resistors have always worked well for me, so here I use Caddock MP930 0R5s and Vishay RTO 20W 0R33s. I also replaced the single 0R47 cement resistor on the treble, and after consulting with Rob, the eight carbon film resistors with Riken RMAs (these resistors need to cope with very high voltage). Very happy with the result.

Last edited:

Just a follow-up on the resistor changes:

In order to better identify and isolate the changes brought about by replacing the resistors, I did the eight HV resistors first. Assured that it was all positive with the Riken RMAs I then proceeded with replacing the cement resistors.

With the Caddock MP930s and Vishay RTO 20s in place, there was a further improvement in clarity. However I now noticed a trace of hard edge in the sound. Once I started to notice it I was immediately reminded that the same thing happened when I "upgraded" the crossovers in a pair of dynamic speakers with Caddocks many years ago. The Acorn, though, has a much higher resolving power, so it became more noticeable this time.

While waiting to see if that trace of hard edge will go away with more breaking-in, it occurred to me that since the Acorns are likely my end-game speakers or at least my speakers for the next ten, maybe twenty years, why not give manganin resistors a try? I first learned about manganin resistors when I was seeking to upgrade my Altec VOTTs with the "ultimate" resistors. Isabellenhütte was the only brand I could find who offered manganin resistors in the value range suitable for crossovers--if one doesn't mind series-connecting a few pieces of them to get the desired value, that is. I ended up using inductors and autoformer attenuators only on my VOTTs. Isabellenhütte manganins can now be ordered from reichelt.de, in very limited values.

Then I recalled having read somewhere about making your own resistors with manganin wire. So I searched and ordered a couple meters of 0.4mm manganin wire (for a trifling sum), which is spec'ed at 3.6624 ohm/meter. That translates to 13.65 cm for 0R5 and 9 cm for 0R33. I would need to investigate into how best to wind the wire (straight, wavy, or Ayrton–Perry winding) for such short lengths/low resistance values. Will experiment and report back once I receive the wire.

Picture from the vendor:

In order to better identify and isolate the changes brought about by replacing the resistors, I did the eight HV resistors first. Assured that it was all positive with the Riken RMAs I then proceeded with replacing the cement resistors.

With the Caddock MP930s and Vishay RTO 20s in place, there was a further improvement in clarity. However I now noticed a trace of hard edge in the sound. Once I started to notice it I was immediately reminded that the same thing happened when I "upgraded" the crossovers in a pair of dynamic speakers with Caddocks many years ago. The Acorn, though, has a much higher resolving power, so it became more noticeable this time.

While waiting to see if that trace of hard edge will go away with more breaking-in, it occurred to me that since the Acorns are likely my end-game speakers or at least my speakers for the next ten, maybe twenty years, why not give manganin resistors a try? I first learned about manganin resistors when I was seeking to upgrade my Altec VOTTs with the "ultimate" resistors. Isabellenhütte was the only brand I could find who offered manganin resistors in the value range suitable for crossovers--if one doesn't mind series-connecting a few pieces of them to get the desired value, that is. I ended up using inductors and autoformer attenuators only on my VOTTs. Isabellenhütte manganins can now be ordered from reichelt.de, in very limited values.

Then I recalled having read somewhere about making your own resistors with manganin wire. So I searched and ordered a couple meters of 0.4mm manganin wire (for a trifling sum), which is spec'ed at 3.6624 ohm/meter. That translates to 13.65 cm for 0R5 and 9 cm for 0R33. I would need to investigate into how best to wind the wire (straight, wavy, or Ayrton–Perry winding) for such short lengths/low resistance values. Will experiment and report back once I receive the wire.

Picture from the vendor:

Received the manganin wire today. The whole wire, 290 cm in length, measured 11.62 ohm with my multimeter--that's 4.0069 ohm per meter. Considering the resistance of the two probes, it appeared to be inline with the spec'ed 3.6624 ohm/meter.

I then proceeded to make a 9 cm (0.33 ohm) pair and two 0.5/0.49 ohm pairs, all with solid silver wire leads.

The 0.33 ohm pair:

Meanwhile, after a few more days' breaking-in and listening, I feel that the grille cloth currently used, having a very thin sandwich'ed dust filter layer, might indeed be a bit too absorbent. I searched, found and ordered yet another batch of cloth with only one single layer and no dust filter.

I then proceeded to make a 9 cm (0.33 ohm) pair and two 0.5/0.49 ohm pairs, all with solid silver wire leads.

The 0.33 ohm pair:

Meanwhile, after a few more days' breaking-in and listening, I feel that the grille cloth currently used, having a very thin sandwich'ed dust filter layer, might indeed be a bit too absorbent. I searched, found and ordered yet another batch of cloth with only one single layer and no dust filter.

The home-made manganin wire resistors were installed on the Acorn crossover, replacing the Caddock/Vishay thick films. A smooth and highly transparent sound--definitely an improvement for me. Three hours of labour to fabricate three pairs but otherwise very friendly in material costs. I would still recommend that the resistance be checked/adjusted with a precision RLC meter if at all possible (which I plan to do soon with a friend's help).

I received several messages asking about how the Acorn compares with the VOTT system I had previously and also with planar magnetics, especially the double-sided magnet type (Infinity IRS, Genesis, Eminent Technology, etc.).

Apparently I am biased towards good, full range electrostatics, so I will just refrain from saying the obvious. But here are a couple pictures of my A5 (288C/515B) with the MR94A Mantaray horn. I also had tar-filled 805 horns that rotated with the Mantarays and worked great with the 288C.

The A5 and the ESL together: a rare occasion. Talk about sweet memories!

I love the Altec sound. If I have the time and space for a second system some time in the future I will build it around a pair of 9862, 6041 or 19.

Apparently I am biased towards good, full range electrostatics, so I will just refrain from saying the obvious. But here are a couple pictures of my A5 (288C/515B) with the MR94A Mantaray horn. I also had tar-filled 805 horns that rotated with the Mantarays and worked great with the 288C.

The A5 and the ESL together: a rare occasion. Talk about sweet memories!

I love the Altec sound. If I have the time and space for a second system some time in the future I will build it around a pair of 9862, 6041 or 19.

Last edited:

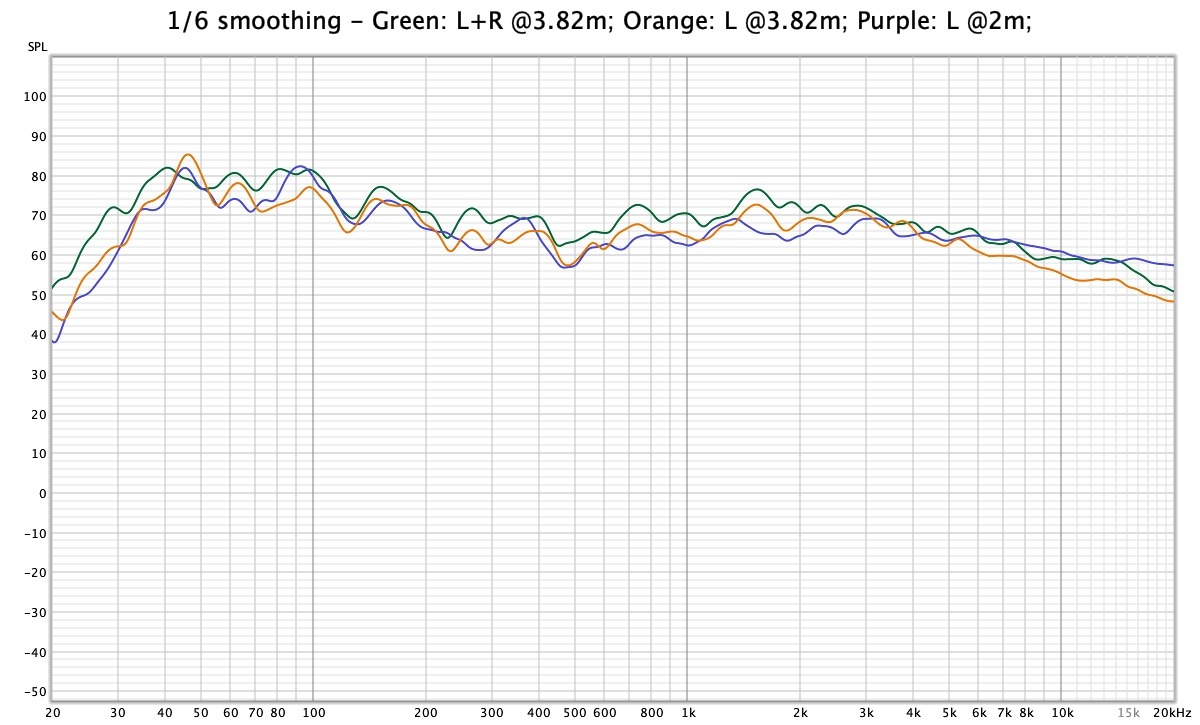

Whilst continuing to tweak my Acorns I decided to take some measurements with REW, using my simple miniDSP UMIK-1/MacBook Pro setup. I am an absolute novice when it comes to speaker/room measurement and didn't have time for research this time, so please excuse any mistakes I might have made. I welcome suggestions/corrections so I can do it more meaningfully next time. My Acorns currently have their temporary fabric grilles on without any back damping. I am hoping adding damping will boost the mids (more or less tenor voice range) a little.

For the measurement at 2 meters the microphone was placed right in front of the speaker; The @3.82 m measurements were taken from my listening position, hence off-axis because the Acorns were positioned with barely any toe-in. This gives a narrower range of ideal listening position for soundstage and imaging, but I feel the soundstage and overall presentation are more natural this way (with other types of speakers too). That said, with the Acorn I can sit on my sofa very casually because the ideal listening position is at least some 50 cm wide even with no toe-in at all.

This is how my Acorns are positioned currently. My living room is 4.24 m/13.9 ft (width) by 3.16 m/10.37 ft (height). Depth is more than 10 meters/35 feet including the dining and kitchen space. Listening to the Acorns from the dining table (that is, from behind) is no problem at all--all our guests seemed to also enjoy it!

For the measurement at 2 meters the microphone was placed right in front of the speaker; The @3.82 m measurements were taken from my listening position, hence off-axis because the Acorns were positioned with barely any toe-in. This gives a narrower range of ideal listening position for soundstage and imaging, but I feel the soundstage and overall presentation are more natural this way (with other types of speakers too). That said, with the Acorn I can sit on my sofa very casually because the ideal listening position is at least some 50 cm wide even with no toe-in at all.

This is how my Acorns are positioned currently. My living room is 4.24 m/13.9 ft (width) by 3.16 m/10.37 ft (height). Depth is more than 10 meters/35 feet including the dining and kitchen space. Listening to the Acorns from the dining table (that is, from behind) is no problem at all--all our guests seemed to also enjoy it!

Meant to say 90 or 100 cm. Wide enough to seat two listeners that is.That said, with the Acorn I can sit on my sofa very casually because the ideal listening position is at least some 50 cm wide even with no toe-in at all.

The Acorn does draw quite some current from the power amp. I know because the speaker output fuse on one of my Merz Type T amps (all-valve OTL/OCL, with a 2A speaker fuse for protection) blew the other day. I have been planning on building a mono pair of the AMB Labs β24 to pair with the RTP preamp--it's about time!

Listening to well recorded Jazz such as Interstellar Space and Turnaround (Rare Miles From The Complete On The Corner Sessions) on the Acorn is a mesmerizing experience. Like going to a live performance, it's so satisfying that afterwards I would prefer to just turn the system off and relive the moment in my mind.

Lets talk about the issues so far:

- The Acorns are quite powerful and can comfortably energize my listening space to unbearable degrees of loudness for my ears (before the fuse on my Merz blows, that is

). Perhaps because of the Acorn's potency, I feel that my current implementation still allows some unwanted vibrations to happen. This is obvious when playing "Je crois entendre encore" (The Pearl FIsher) or "una furtiva lagrima" (L'elisir d'amore) sung by any tenor. I suspect that the resonances happen at around 1k to 2kHz. Interestingly, when I played these arias sung by Jerry Hadley, my favorite tenor, which are only available as Youtube videos, there were no (or to a much less degree) such peaking to be heard, likely due to the lack of overtones in these videos which unfortunately are not of the highest quality. Anyway I am in the process of re-designing the frame structure and how the panels are secured to the frame/subframe. I am therefore going to share the detailed frame design plan only when the new frame design is done and proven effective in suppressing the unwanted vibrations. Should these resonances persist after the new frame implementation, further investigations will be needed.

- As can be seen from the measurements, there's some bloating around 40 to 100Hz, which makes the overall sound a bit bass heavy (somehow it feels a bit strange to say this about a pure electrostatic speaker system

) and the even lower LF, which is superb even by dynamic speaker standards, less easy to be heard. This is often encountered with dynamic speakers, usually caused by the room/speaker interaction. I don't think it has much to do with the frame implementation, so will experiment with different ways of positioning the Acorns in my listening space.

I look forward to seeing your plans for improving panel support. I was surprised by what appears in your photos to be reliance on just the clip together plastic strips for support between panels.

I have adopted support of these plastic strips with a vertical and horizontal "t" shaped internal frame.

I am still finishing wiring up panels and interface assembly, but hoping to have these running soon.

Kindest Regards

Grant

I have adopted support of these plastic strips with a vertical and horizontal "t" shaped internal frame.

I am still finishing wiring up panels and interface assembly, but hoping to have these running soon.

Kindest Regards

Grant

Glad to meet a fellow Acorn builder here Grant! Do share your build with us.

Other than replacing the MDF base with an acrylic one and adding a horizontal aluminium brace in the middle, my current build is more or less following the plan shown in the "Aluminium Framed Enclosure with MDF Base" section of the construction manual. All the clips/strips are tightly held by four u-shaped aluminium channels (top, bottom and two sides) but otherwise with no additional support.

Other than replacing the MDF base with an acrylic one and adding a horizontal aluminium brace in the middle, my current build is more or less following the plan shown in the "Aluminium Framed Enclosure with MDF Base" section of the construction manual. All the clips/strips are tightly held by four u-shaped aluminium channels (top, bottom and two sides) but otherwise with no additional support.

- Home

- Loudspeakers

- Planars & Exotics

- My ER Audio Acorn Mk II build