Woooow!!! 😱

Very very very nice.

Can you explain me a little bit the platter bearing.What is this in the middle (hole)?

How it rotates without tolerances?

Very very very nice.

Can you explain me a little bit the platter bearing.What is this in the middle (hole)?

How it rotates without tolerances?

Thank you !Woooow!!!

Very very very nice.

"housing" for the ball !What is this in the middle (hole)?

I carried out a polishing of bronze housing with Polishing Cream !How it rotates without tolerances?

the antiskating is very sensitive, it is necessary to test various weights according to the arm and the cartridge !Hi Roger, can you help me about the antiskating weight? Thanks

I love your turntable! I want it!!!

Please help me to build one...

I'm planning to use SHURE V15 type III cartridge (!), now before crashes, I'd like know what you think about antiskating weight... what't the weight of your antiskating piece?

I'm unable to find in italy your bearing... can you buy it for me in France and send me it? I will send you payment before all!!!

Here's my tonearm (without shell) with your great "pivot" system, but is more long than yours... I prefer 32-35 centimeters from pivot to needle 🙂

Thanks for your help!!!

Please help me to build one...

I'm planning to use SHURE V15 type III cartridge (!), now before crashes, I'd like know what you think about antiskating weight... what't the weight of your antiskating piece?

I'm unable to find in italy your bearing... can you buy it for me in France and send me it? I will send you payment before all!!!

Here's my tonearm (without shell) with your great "pivot" system, but is more long than yours... I prefer 32-35 centimeters from pivot to needle 🙂

Thanks for your help!!!

An externally hosted image should be here but it was not working when we last tested it.

hello JokerWeb !

It's my arm !!!, good work !

(it is curious to see its realization manufactured by another person!)

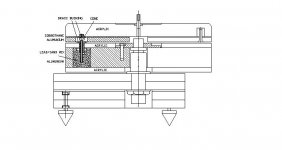

Here the manufacturing drawing, I hope that that will help you !

verin = "stem of hydraulic actuating cylinder"

Platine soudée = piece of stainless welded onto the axis and machined

Bille = ball (of ball bearing of course)

Bain d'huile = this vacuum is filled with oil "oil bath"

for a better result, it is necessary to rectify the axis and its housing !

Excuse me for the slowness of my answers but my english is very poor !

An externally hosted image should be here but it was not working when we last tested it.

It's my arm !!!, good work !

(it is curious to see its realization manufactured by another person!)

on my arm it weighs 4 gramswhat't the weight of your antiskating piece?

I would like to help you, but the "milling machine operator" has much work, I awaits parts of him since months, I despair !I'm unable to find in italy your bearing... can you buy it for me in France and send me it? I will send you payment before all!!!

Here the manufacturing drawing, I hope that that will help you !

An externally hosted image should be here but it was not working when we last tested it.

verin = "stem of hydraulic actuating cylinder"

Platine soudée = piece of stainless welded onto the axis and machined

Bille = ball (of ball bearing of course)

Bain d'huile = this vacuum is filled with oil "oil bath"

for a better result, it is necessary to rectify the axis and its housing !

Excuse me for the slowness of my answers but my english is very poor !

Don't worry for your english, I'm from italy, I'm trying to write english 🙂

I'm unable to find in italy an operator that like to build the bearing... how much is the cost of your bearing?

I've cabled the tonearm with CARDAS Tonearm Wire... for vibrations dampen I've filled up all the arm with very small pieces of felt. Also have used therm-shrinking girdle to cover the aluminium of arm. The result is very good, no little bit of noise 🙂 I'm planning to use carbonium headshell but is too expensive...

Already have build the platter same as yours, now need only the bearing...and my Roger Waters'es turntable will be on the road!!!

I'm unable to find in italy an operator that like to build the bearing... how much is the cost of your bearing?

I've cabled the tonearm with CARDAS Tonearm Wire... for vibrations dampen I've filled up all the arm with very small pieces of felt. Also have used therm-shrinking girdle to cover the aluminium of arm. The result is very good, no little bit of noise 🙂 I'm planning to use carbonium headshell but is too expensive...

Already have build the platter same as yours, now need only the bearing...and my Roger Waters'es turntable will be on the road!!!

50€ (in cash) without rectified and polishing.I'm unable to find in italy an operator that like to build the bearing... how much is the cost of your bearing?

great !!! (I did not do it yet, but I thought of filling the arm with an expansive foam)for vibrations dampen I've filled up all the arm with very small pieces of felt

what is carbonium ?

you have pictures ? 🙂Already have build the platter same as yours

on the road again ! 😉and my Roger Waters'es turntable will be on the road!!!

Sorry, not carbonium but graphite... I'm contacting some companies that can help me to build the bearing... I will send on this forum more pics only when the turntable is finished... 🙂

See you soon!!!

See you soon!!!

Hi again,

I need to know what is the method to setup antiskating. I got a free protractor from www.enjoythemusic.com but I don't know how to set the antiskating...can you help me in few words? Thanks!

I need to know what is the method to setup antiskating. I got a free protractor from www.enjoythemusic.com but I don't know how to set the antiskating...can you help me in few words? Thanks!

you need a disc with a smoothe face (certain discs for DJ have a smooth face, you find that not expensive occasion, or a disc of adjustment)

You start the turntable with the smooth disc, you places the arm on the medium:

A) the arm goes towards outside, you must reduce the force

B) the arm goes towards the interior, you must increase the force C) the arm remains motionless, it is ok, the adjustment is perfect

(before making this adjustment you must regulate your cell and the force of support)

;o)

You start the turntable with the smooth disc, you places the arm on the medium:

A) the arm goes towards outside, you must reduce the force

B) the arm goes towards the interior, you must increase the force C) the arm remains motionless, it is ok, the adjustment is perfect

(before making this adjustment you must regulate your cell and the force of support)

;o)

Mmmm, is it a LP with face without recording?

Do you know the exact name of that LP type or where can I buy it?

Thanks again!

Do you know the exact name of that LP type or where can I buy it?

Thanks again!

Diy Turntables

A good friend of mine made a clone of an LP 12 many years ago..and it's still going strong today. Funny how the clock makers can help with such a project..he knew of a local dentist that repaired repaired clocks in his spare time. He made him a few parts..sorry to go on .. Fine engineering work by the way.

A good friend of mine made a clone of an LP 12 many years ago..and it's still going strong today. Funny how the clock makers can help with such a project..he knew of a local dentist that repaired repaired clocks in his spare time. He made him a few parts..sorry to go on .. Fine engineering work by the way.

Yessss !Mmmm, is it a LP with face without recording?

used in the record dealers or the Depot Sale for few euros !Do you know the exact name of that LP type or where can I buy it?

Congrats! Great work! I also like your arm, it seems to me that your choice of materials is errr... well, unconventional and down-to-earth non-exotic. But that doesn't matter of course, as long as the sound is good.

I'm planning to build a turntable myself, right now I'm wondering what materials to use for the plinth, acrylic and steel/aluminum are the current ones. Thought of MDF too, but a lot of people think it's too 'dead' for that purpose. Dampens the liveliness of the music. What are your findings? Did you compare to other turntables?

And indeed: how are the cavities and lead arranged???

Enjoy!!

Miniwatt

I'm planning to build a turntable myself, right now I'm wondering what materials to use for the plinth, acrylic and steel/aluminum are the current ones. Thought of MDF too, but a lot of people think it's too 'dead' for that purpose. Dampens the liveliness of the music. What are your findings? Did you compare to other turntables?

And indeed: how are the cavities and lead arranged???

Enjoy!!

Miniwatt

Motor and bearing

Hi Roger,

congratulation for your work!!!

I'm interesting in building my own TT

can you give some more details on the motor unit?

Where is it coming from?

What kind of control did you choose to reach the correct speed?

I don't see any strobo unit, it means you are runnig with a AC motor?

Concerning the bearing, how can you manage to place the ball in the right position in the middle of the "verin"??

I suppose first you put oil, than the ball and at the end the "verin", if so how do you manage to keep the ball into the center during the assembly?

Thanks for your clarification.

regards

Sailorman

Hi Roger,

congratulation for your work!!!

I'm interesting in building my own TT

can you give some more details on the motor unit?

Where is it coming from?

What kind of control did you choose to reach the correct speed?

I don't see any strobo unit, it means you are runnig with a AC motor?

Concerning the bearing, how can you manage to place the ball in the right position in the middle of the "verin"??

I suppose first you put oil, than the ball and at the end the "verin", if so how do you manage to keep the ball into the center during the assembly?

Thanks for your clarification.

regards

Sailorman

for the moment I made the comparative one with an old dual, I chose the medium for his neutrality, the result is the absence of resonance and rumble, a silence total with a LP in good condition !Thought of MDF too, but a lot of people think it's too 'dead' for that purpose. Dampens the liveliness of the music. What are your findings? Did you compare to other turntables?

Thanks You !Hi Roger,

congratulation for your work!!!

The DC motor comes from an old tape recorder !can you give some more details on the motor unit?

Where is it coming from?

adjustment speeds with 2 trimmer resistor connected to a double switch, look an example "chirurgie":

http://www.formgestalter.com/krishu/index_hifi_turn_motor.htm

I use a strobo (50Hz) to adjust speeds or a disc test (a track with 1000Hz) with a frequency meter (on the computer).

Yes, of course, I "stick" the ball with a thick grease so that it remains in its housing during the assemblyI suppose first you put oil, than the ball and at the end the "verin"

Platter material

But those subtle higher and lower harmonics (overtones), wich give the instrument its characteristic sound signature, were supressed.

Note, that the upper layer was directly coupled to subplatter, so no compliant material was introduced into vibration path (see the sketch below). CLD principle was implemented in purpose to kill "resudal" vibrations, aside of the main vibration path. So, I came to conclusion:

1. The platter material and its damping/vibration proterties are absolutely critical for good sound.

2. No compliant materials ("heavy absorbers") shall be placed invicinity of cartrige.

3. I must give the hardwood platter a try.🙂

I was quite happy with my constraint layer sandwich platter untill one day, being heavily affected by tweaking virus, I decided to pull the middle sorbothane layer out. Now I know what exactly "sucking the life from the music" means. With the soft layer in place, the color richness of the sound (primarily accoustical instruments and voices) was lost. I was foolished by the fact, that the high and low extremes were affected much less.Thought of MDF too, but a lot of people think it's too 'dead' for that purpose. Dampens the liveliness of the music.

But those subtle higher and lower harmonics (overtones), wich give the instrument its characteristic sound signature, were supressed.

Note, that the upper layer was directly coupled to subplatter, so no compliant material was introduced into vibration path (see the sketch below). CLD principle was implemented in purpose to kill "resudal" vibrations, aside of the main vibration path. So, I came to conclusion:

1. The platter material and its damping/vibration proterties are absolutely critical for good sound.

2. No compliant materials ("heavy absorbers") shall be placed invicinity of cartrige.

3. I must give the hardwood platter a try.🙂

Attachments

diy tt

dis donc roger, on est un forum d'adorateurs de LS3/5a, basé en france

on s'interresse au vinyl et ta platine nous intrigue

peux tu venir nous en parler un peu sur www.ls3-5a-forum.com

dis donc roger, on est un forum d'adorateurs de LS3/5a, basé en france

on s'interresse au vinyl et ta platine nous intrigue

peux tu venir nous en parler un peu sur www.ls3-5a-forum.com

Hey Joe !

Je connais un peu le Forum LS3/5A, il m'arrive de le parcourir, je l'ai connu car Pascal (PTSOUNDLAB.COM) l'avait mis en liens sur son excellent site !

J'avais posté la même chose qu'ici sur le site de Pascal :

http://www.ptsoundlab.com/forum/viewtopic.php?t=609

et le préamp à tubes fabriqué d'après les conseils de Pascal:

http://www.ptsoundlab.com/forum/viewtopic.php?t=751&postdays=0&postorder=asc&start=45

Depuis la platine a été équipé d'une cellule DECCA Garrott Microscanned acheté une fortune à un anglais sur ebay.uk, la platine a fait un bond en avant mais il faut que j'alourdisse le bras, il est trop léger pour cette cellule...

J'avais aussi une paire de blocs mono à tubes pushpull 845 en construction, mais c'est en standby cause travaux maison, je suis donc inactif au sein des forums par manque de temps (et je n'ose pas trop y mettre le nez car c'est un bouffe temps pas possible)

Il y a qlq temps j'avais essayé de m'inscrire sur le forum LS3/5A, mais ma boîte hotmail n'étant pas acceptée et étant déja inscrit sur pas mal de forum, je n'avais pas insisté...

Va falloir que je trouve une solution pour l'inscription car votre section vinyl est très active ! 🙂

Je connais un peu le Forum LS3/5A, il m'arrive de le parcourir, je l'ai connu car Pascal (PTSOUNDLAB.COM) l'avait mis en liens sur son excellent site !

J'avais posté la même chose qu'ici sur le site de Pascal :

http://www.ptsoundlab.com/forum/viewtopic.php?t=609

et le préamp à tubes fabriqué d'après les conseils de Pascal:

http://www.ptsoundlab.com/forum/viewtopic.php?t=751&postdays=0&postorder=asc&start=45

Depuis la platine a été équipé d'une cellule DECCA Garrott Microscanned acheté une fortune à un anglais sur ebay.uk, la platine a fait un bond en avant mais il faut que j'alourdisse le bras, il est trop léger pour cette cellule...

J'avais aussi une paire de blocs mono à tubes pushpull 845 en construction, mais c'est en standby cause travaux maison, je suis donc inactif au sein des forums par manque de temps (et je n'ose pas trop y mettre le nez car c'est un bouffe temps pas possible)

Il y a qlq temps j'avais essayé de m'inscrire sur le forum LS3/5A, mais ma boîte hotmail n'étant pas acceptée et étant déja inscrit sur pas mal de forum, je n'avais pas insisté...

Va falloir que je trouve une solution pour l'inscription car votre section vinyl est très active ! 🙂

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- my DIY Turntables and DIY tonearm