Yeah...not going to do that for this amp. Might try this year. 6k resistor on the cathode of the sv83. Should give around 150VDC. Choke loaded 6N1P. Et Voila.

maybe a negative rail, then run the front end with the grid leak and cathode resistor down there instead of ground. If you bias the 6N1P right so the plate is at ground potential it should work, but may need some funky attention during warm up.

Already the first changes from the schematic. I had some other nice resistors lying around.

I spotted that junction 500R-220R was bad...so that is fixed already. Did not clip the ends because not sure I'm going to use these values.

I spotted that junction 500R-220R was bad...so that is fixed already. Did not clip the ends because not sure I'm going to use these values.

Thanks, I was not aware of this mod!shown here is the hazen mod in place.

source: https://www.decware.com/newsite/paper146.htmlI've listened to a fair numbers of triodes and triode wired EL34's over the past 20 years and each has it's strengths. The triode is not categorically superior to the triode wired EL34 as some would think. However when the suppressor grid of the EL34 is modified with the cap there is a huge difference in the presentation of the amplifier for the better, despite the fact that typical measurements show no substantial change has occurred. I think one of two events are taking place: A) the phase angle of the AC component on the suppressor is modified resulting in a deceleration of the electrons as they pass through this sparsely wound suppressor grid on their way to the plate resulting in less dislodged electrons in the first place. B) the electrons that are being dislodged from the plate are being absorbed by the suppressor grid. In case A, there are less electrons being dislodged from the plate so there are less secondary electrons being re-assembled on the plate. In case B, there are the same amount of electrons being dislodged from the plate, but less secondary electrons being re-assembled on the plate, giving us the same result as case A.

Does it work only for triodes?

Well actually just for pentodes with a suppressor grid that is not internally tied to the cathode. So SV83 and EL34 being 2 of them I know of. On or in the EL84 the suppressor grid is tied to the cathode internally.

Sorry, I meant if it works only for triode-connected pentodes, or also for pentode/UL connected pentodes.

Thanks

Thanks

Ah...I don't know actually. Good question! But whatever the answer. I asked tizman in this thread how big the effect is. And it's hardly audible if at all. So don't expect too much. I've never done a before and after test listening or otherwise.

Now with heater bias and ct drawn in. This is exactly how it will be started up within the next couple of days. Tonight glue in the transformers. And that's it.

Hello Bas:

Regarding the Hazen mod. I used it on a 6p15p in my RH84 circuit and really like. I had previously left the suppressor grid unconnected, the difference was night and day.

Nice design I hope it works out I am likely to follow in your footsteps on my next SE build.

I hope this helps

Regarding the Hazen mod. I used it on a 6p15p in my RH84 circuit and really like. I had previously left the suppressor grid unconnected, the difference was night and day.

Nice design I hope it works out I am likely to follow in your footsteps on my next SE build.

I hope this helps

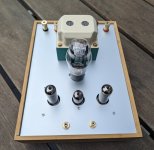

Needs some finessing in the corners...wood glue with sanddust to fill the gaps. To be continued. Next up some voltages to check...probably this weekend.

very lovely Bas:

I really like the juxtaposed contrast between the 5u4G and the novel tubes. Your presentation looks very good.

May I suggest you do not use glue and sand-dust for your filler. In stead use your finishing oil and very fine sand-dust as the filler. Reason being is the glue will not oxidize the same as the rest of the finish and will show more intensely as time goes on. I have done both and found great success in in using the same finishing oil I used on the sides mixed with 320 grit sanding dust as the best way to go. Make a wet paste rub it in leave it for a couple of days to harden then hand sand. I also sand out to 320 grit before spraying on the top coat of urethane. I have also used the top coat finish (urethane) as well to make a filler paste as it hardens the same as the sides if I am not using an oil to colour the wood.

Just an idea.

Or sometime wood is wood and does not need to look like anything at all. Leave it as is.

Looking forward to your impressions of the sound, and some voltage measurement once it settles down and stabilizes.

I hope this helps

I really like the juxtaposed contrast between the 5u4G and the novel tubes. Your presentation looks very good.

May I suggest you do not use glue and sand-dust for your filler. In stead use your finishing oil and very fine sand-dust as the filler. Reason being is the glue will not oxidize the same as the rest of the finish and will show more intensely as time goes on. I have done both and found great success in in using the same finishing oil I used on the sides mixed with 320 grit sanding dust as the best way to go. Make a wet paste rub it in leave it for a couple of days to harden then hand sand. I also sand out to 320 grit before spraying on the top coat of urethane. I have also used the top coat finish (urethane) as well to make a filler paste as it hardens the same as the sides if I am not using an oil to colour the wood.

Just an idea.

Or sometime wood is wood and does not need to look like anything at all. Leave it as is.

Looking forward to your impressions of the sound, and some voltage measurement once it settles down and stabilizes.

I hope this helps

Last edited:

- Home

- Amplifiers

- Tubes / Valves

- My Decware Zen "Clone"