Hello everyone!

I have recently bought a second hand Grace G707 to mount it on my Thorens deck. However, mounting distance for the Grace is 222mm against to 215.6mm of the TP-16mkII, the original Thorens tonearm. Due to the shape of the sub-platter around the arm-mount, I have to rotate the arm in order to mount it 222mm away from the spindle. Which means that when the arm stands, it won't be tangential to the platter. Is this ok?

If not, the only solution I think of is building a new plinth.

I have recently bought a second hand Grace G707 to mount it on my Thorens deck. However, mounting distance for the Grace is 222mm against to 215.6mm of the TP-16mkII, the original Thorens tonearm. Due to the shape of the sub-platter around the arm-mount, I have to rotate the arm in order to mount it 222mm away from the spindle. Which means that when the arm stands, it won't be tangential to the platter. Is this ok?

If not, the only solution I think of is building a new plinth.

The 222mm figure is all that matters so your plan is fine.

I remember fitting a Rega RB300 (which has the same mounting distance) to a TD160 and having to file away part of the subchassis to get the correct position.

sp

I remember fitting a Rega RB300 (which has the same mounting distance) to a TD160 and having to file away part of the subchassis to get the correct position.

sp

Another thought would be to mount the G707 on the original position of the TP-16(215.6mm) and then increase the overhang to reach 222mm. Would this be a correct solution?

P.S Stoolpigeon, thanks for your feedback!

P.S Stoolpigeon, thanks for your feedback!

I'm not sure what you mean but the arm to spindle distance is designed to be 222mm. This distance combined with the angle of the headshell will give you the best tracking performance. Assuming the cartridge is properly alligned that is.

If I remember the overhang for this setup is 18mm meaning the stylus tip will be 18mm further past the record spindle. This gives you what is called the effective length of the arm as 222 + 18 = 240.

My memory is fading so someone correct me if I'm wrong.

Bottom line is mount it at 222mm.

sp

If I remember the overhang for this setup is 18mm meaning the stylus tip will be 18mm further past the record spindle. This gives you what is called the effective length of the arm as 222 + 18 = 240.

My memory is fading so someone correct me if I'm wrong.

Bottom line is mount it at 222mm.

sp

What I mean is mounting the arm at 215.6, instead of 222mm. Would this be ok?

Then I would increase the overhang as much as possible to approach the effective length.

Then I would increase the overhang as much as possible to approach the effective length.

No, it has to be at 222mm. I just looked at a photo of a TD145 and it is essentially the same as a TD160. I have a TD160 I can check but not until the weekend.

I am also thinking I may have been mistaken when saying I mounted a Rega RB300 to a TD160 because I think it was a TD321 which is a different beast.

In any case I am happy to check my TD160 but not till the weekend.

sp

I am also thinking I may have been mistaken when saying I mounted a Rega RB300 to a TD160 because I think it was a TD321 which is a different beast.

In any case I am happy to check my TD160 but not till the weekend.

sp

busoni said:What I mean is mounting the arm at 215.6, instead of 222mm. Would this be ok?

Then I would increase the overhang as much as possible to approach the effective length.

Hi,

No.

If you reduce arm mounting length the actual arm becomes too long.

The problem becomes can you move the cartridge far back enough.

(The overhang 15mm (237 minus 222) does not change much)

If you understand arm geometry its not that intractable. Only when

you want the cartridge parallel to the headshell in the middle of the

headshell for the arms designed geomtery does the arm mounting

distance exactly matter.

Reducing arm mounting distance reduces the required effective

length and changes the optimum angle slightly (gets bigger).

What matters is getting a decent 2 point alignment within the

range of the headshell slots - cartridge angle does not matter.

Also note you can always set a null point near the record end,

what then is of interest is whether you get a null point at the

start of the record, as you move up and down the slots and

always setting the first point, the second one moves.

http://www.vinylengine.com/phpBB2/viewtopic.php?t=7141

Note that 15mm overhang is not part of the say Baerwald

alignment - its larger moving the cartridge forward which

would allow a shorter arm mounting distance (2mm or so).

# For Baerwald null points are 66.0 and 120.9 mm

# For Loefgren null points are 70.3 and 116.6 mm

Null points for the G-707 : 66.8 / 103.0 mm - not the best IMO.

Also I cannot see why the arm would not sit straight. You move it

backwards for the extra length and only sideways if you need to.

why twist it ?

🙂/sreten.

Hi,

Just now going through similar experience. I had a plate made to mount my Audio Technica AT1009 arm to my Thorens TD146. The arm length is 225mm. The person that made the plate stated that the length of 225 was all that was important. I dropped the plate off with my TT guy yesterday and hopefully will have unit next week. Both the guy who made my plate and my TT guy said would probably have to trim the sub-chassis a little below the arm mount to make fit. (The reason for me not to DIY)

Anyway, my TT guy knows what he is doing and I feel my Thorens is in good hands 🙂 Can't wait. I have been listening to my spare Marantz but really miss the Thorens. 🙁

ck

Just now going through similar experience. I had a plate made to mount my Audio Technica AT1009 arm to my Thorens TD146. The arm length is 225mm. The person that made the plate stated that the length of 225 was all that was important. I dropped the plate off with my TT guy yesterday and hopefully will have unit next week. Both the guy who made my plate and my TT guy said would probably have to trim the sub-chassis a little below the arm mount to make fit. (The reason for me not to DIY)

Anyway, my TT guy knows what he is doing and I feel my Thorens is in good hands 🙂 Can't wait. I have been listening to my spare Marantz but really miss the Thorens. 🙁

ck

stoolpigeon said:The 222mm figure is all that matters so your plan is fine.

I remember fitting a Rega RB300 (which has the same mounting distance) to a TD160 and having to file away part of the subchassis to get the correct position.

sp

I put quite a few 707s on Thorens TD 160, 165 & 145. The subchassis needed to be drilled/filed out a bit IIRC (it was 25+ years ago) to get the 222, but the grace came with 2 big washers that made mounting it up easy.

dave

@sreten

I cannot move the arm back and sideways because I have to trim the subchassis a little. I am trying to find a position without trimming but I doubt wether it's possible or not.

Thanks for your insights into arm geometry. I am not that familiar, but I understand that getting two null points is what matters. Anyway, I think I'll go conventional keeping the Grace specs. Actually I found some Rega mounting plate templates so I'll copy and build one of them as Regas have 222mm mounting distance too.

I cannot move the arm back and sideways because I have to trim the subchassis a little. I am trying to find a position without trimming but I doubt wether it's possible or not.

Thanks for your insights into arm geometry. I am not that familiar, but I understand that getting two null points is what matters. Anyway, I think I'll go conventional keeping the Grace specs. Actually I found some Rega mounting plate templates so I'll copy and build one of them as Regas have 222mm mounting distance too.

Ciskokid, I am not familiar with the AT1009 but I recall most arms being in old fashioned terms 9 or 9.5 inches effective length or in metric 229 or 240 mm.

229 mm is the Linn style and requires a mounting hole to spindle distance of 214 mm and overhang of 15 mm.

240 is the Rega style and equivalent figures are 222 mm and 18 mm.

These figures are all approximate but the point I am getting to is wondering where your 225 mm measurement come from?

sp

229 mm is the Linn style and requires a mounting hole to spindle distance of 214 mm and overhang of 15 mm.

240 is the Rega style and equivalent figures are 222 mm and 18 mm.

These figures are all approximate but the point I am getting to is wondering where your 225 mm measurement come from?

sp

stoolpigeon said:

Ciskokid, I am not familiar with the AT1009 .......... but the point I am

getting to is wondering where your 225 mm measurement come from ?

sp

Hi,

Numbers on the mounting template are 15mm overhang, 225mm mounting and 240mm effective length.

🙂/sreten.

stoolpigeon said:...am not familiar with the AT1009 ...

Hi sp,

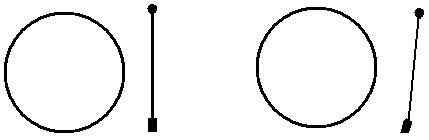

I got the measurements from the mounting template. Shows a mounting distance of 225mm and an effective length of 240mm. See attached picture.

An externally hosted image should be here but it was not working when we last tested it.

Kind regards,

ck

Hai Basoni.

Just slot in>

Grace is a great amp, which was my first tonearm with my first tt, thoren 150mk II. I missed alot due to chip in for upgrade to Denon 401 10 inch arm to suit my Oh mighty heavy lenco with 5 inch plinth build.

The allowance on the head shell as mention surely offers the fine tune to 15 mm overhang but provided mounting distance have to be around 222.

You must set to 222mm with the drilled hole have some acess of play and 15mm to get the geometry. The importance of ttb is different from cd. First is the ttb, rigid ++, the arm, then catridge at last. What do you think if the importance of setting it accordingly to hold your lovely catridge?? The frist problem will disturb the effective mass.

The td 147, some they widen the chassis and drill the sub to penetrate selected arm distance. Of cource will not look good but can be cover by bigger arm board screw on top of original one. Or try to go to Thoren site. They tell you everything from head to tole..

Looking at the picture of the arm not on vertical enough? Just the look. Or get a S shape arm and that will looks better on this problem.

Sometimes when having a tt doesn't mean it can fit all kinds of arms. Have to consider the mass, the lenght and the weight especially on suspension tt. Even height on low design platter like lenco. Or maybe my friend, other arms suit nicer, and better here. Sme 3009?

If you try to full with arm, alignment, setting ought be as precise as possible. This is the manually anolog world. Very fun.... Yet i have not complete mine. I would like to share this continously. Plinth building?? yeh!!! gotha.

Cheers!!

Wan.

from mALAYSIA.

Just slot in>

Grace is a great amp, which was my first tonearm with my first tt, thoren 150mk II. I missed alot due to chip in for upgrade to Denon 401 10 inch arm to suit my Oh mighty heavy lenco with 5 inch plinth build.

The allowance on the head shell as mention surely offers the fine tune to 15 mm overhang but provided mounting distance have to be around 222.

You must set to 222mm with the drilled hole have some acess of play and 15mm to get the geometry. The importance of ttb is different from cd. First is the ttb, rigid ++, the arm, then catridge at last. What do you think if the importance of setting it accordingly to hold your lovely catridge?? The frist problem will disturb the effective mass.

The td 147, some they widen the chassis and drill the sub to penetrate selected arm distance. Of cource will not look good but can be cover by bigger arm board screw on top of original one. Or try to go to Thoren site. They tell you everything from head to tole..

Looking at the picture of the arm not on vertical enough? Just the look. Or get a S shape arm and that will looks better on this problem.

Sometimes when having a tt doesn't mean it can fit all kinds of arms. Have to consider the mass, the lenght and the weight especially on suspension tt. Even height on low design platter like lenco. Or maybe my friend, other arms suit nicer, and better here. Sme 3009?

If you try to full with arm, alignment, setting ought be as precise as possible. This is the manually anolog world. Very fun.... Yet i have not complete mine. I would like to share this continously. Plinth building?? yeh!!! gotha.

Cheers!!

Wan.

from mALAYSIA.

busoni,

I checked one of my Thorens - an ATR TD160B Mk2 - and if I measure from the record spindle to the furthest edge of the subchassis arm cutout I get about 234mm.

I forgot to measure the radius of this cutout but I think the 707 should fit without modification.

Just Googled and 707 mounting hole is 19mm so furthest point from spindle should be 222 + 9.5 = 231.5.

sp

I checked one of my Thorens - an ATR TD160B Mk2 - and if I measure from the record spindle to the furthest edge of the subchassis arm cutout I get about 234mm.

I forgot to measure the radius of this cutout but I think the 707 should fit without modification.

Just Googled and 707 mounting hole is 19mm so furthest point from spindle should be 222 + 9.5 = 231.5.

sp

Slightly off topic, and a few months late, but out of interest which cartridge are you using with the 707? I have just got hold of one of these for my ancient Goldring Lenco GL55 rebuild, and it seems finding a suitable high compliance cartridge these days is the tricky part. I have been thinking of ACD XLM, and Shure V15, but both of these have been out of production for some time, and command high prices when they come up second hand.

Hi,

Audio Technica AT120E/T is a good match or AT440MLa.

Can be imported from the States at very silly prices.

http://www.garage-a-records.com/proddetail.php?prod=AT120E

🙂/sreten.

Audio Technica AT120E/T is a good match or AT440MLa.

Can be imported from the States at very silly prices.

http://www.garage-a-records.com/proddetail.php?prod=AT120E

🙂/sreten.

Perhaps a Grado would be another option, and aren't there a few Ortofons with relatively high compliance as well?

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Mounting a Grace G-707 on a Thorens TD-145mkII