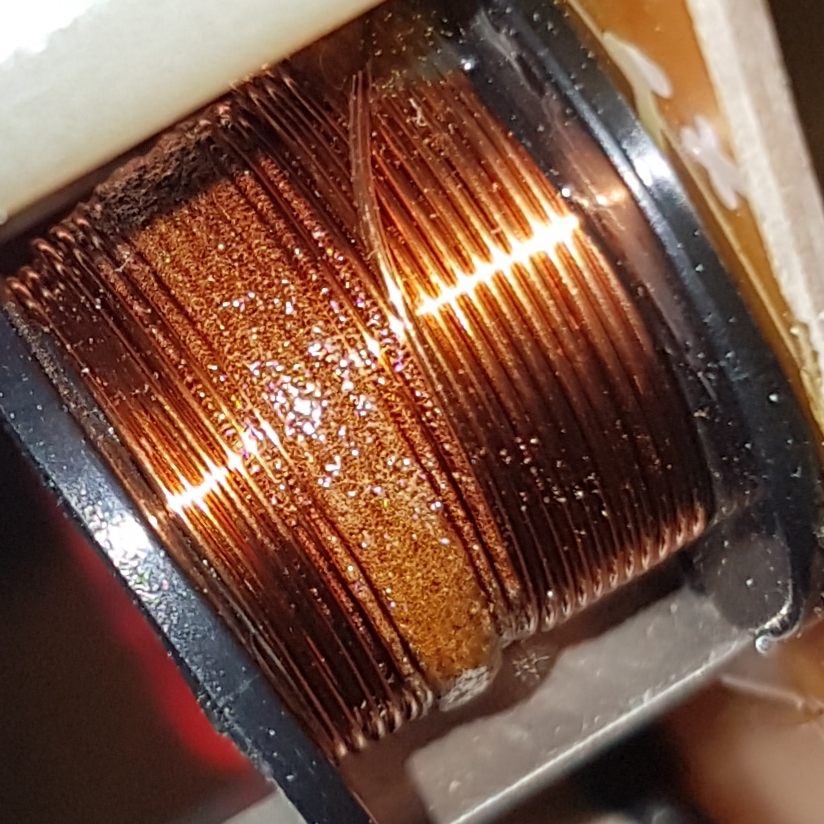

The core is going to assist the inductor, making it smaller. Less wire means less resistance if that is an issue in your crossover because the resistance is sometimes unwanted. However, at higher levels the core runs out and fails temporarily, upsetting operation.

Solution, use air core or size you iron properly.

Solution, use air core or size you iron properly.

I was asking because 24awg does seem relatively small gauge and given the fact they've overheated I could see a benefit to buying higher gauge wire for the inductor. But does lowering the resistance if the inductor effect the frequency response of the speaker? For instance van the tweeter then draw more power and would be louder?

24 gauge is fairly small, but importantly it's too small to be used the way it was. I'd definitely go larger, no need to get carried away though.

You can always add some resistance. Did you establish which one it was on the diagram of post #9?

You can always add some resistance. Did you establish which one it was on the diagram of post #9?

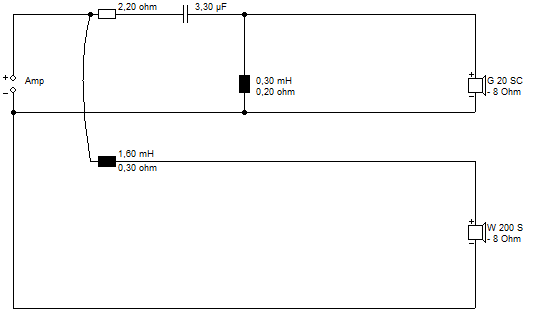

Is it not r1 c2 and l4?

So the resistance of the inductor does make a difference to frequency response?

So the resistance of the inductor does make a difference to frequency response?

Not a lot in this case.

Anyway, I'm going to go out on a limb here. An 18g air core probably has a similar resistance to a 24g ferrite core. (system7 knows a thing or two about ferrite cores).

Anyway, I'm going to go out on a limb here. An 18g air core probably has a similar resistance to a 24g ferrite core. (system7 knows a thing or two about ferrite cores).

Is that an invitation to chip in, Allen? 😱

I do mess around with these things. Ferrite increases inductance 4 fold. Doubling the number of turns also increases inductance 4 fold. Thing is, coils have such small resistance relative to a driver, it's not a biggie.

Still, maybe we need a review here. A quiet tweeter and a possibly overheated tweeter filter.

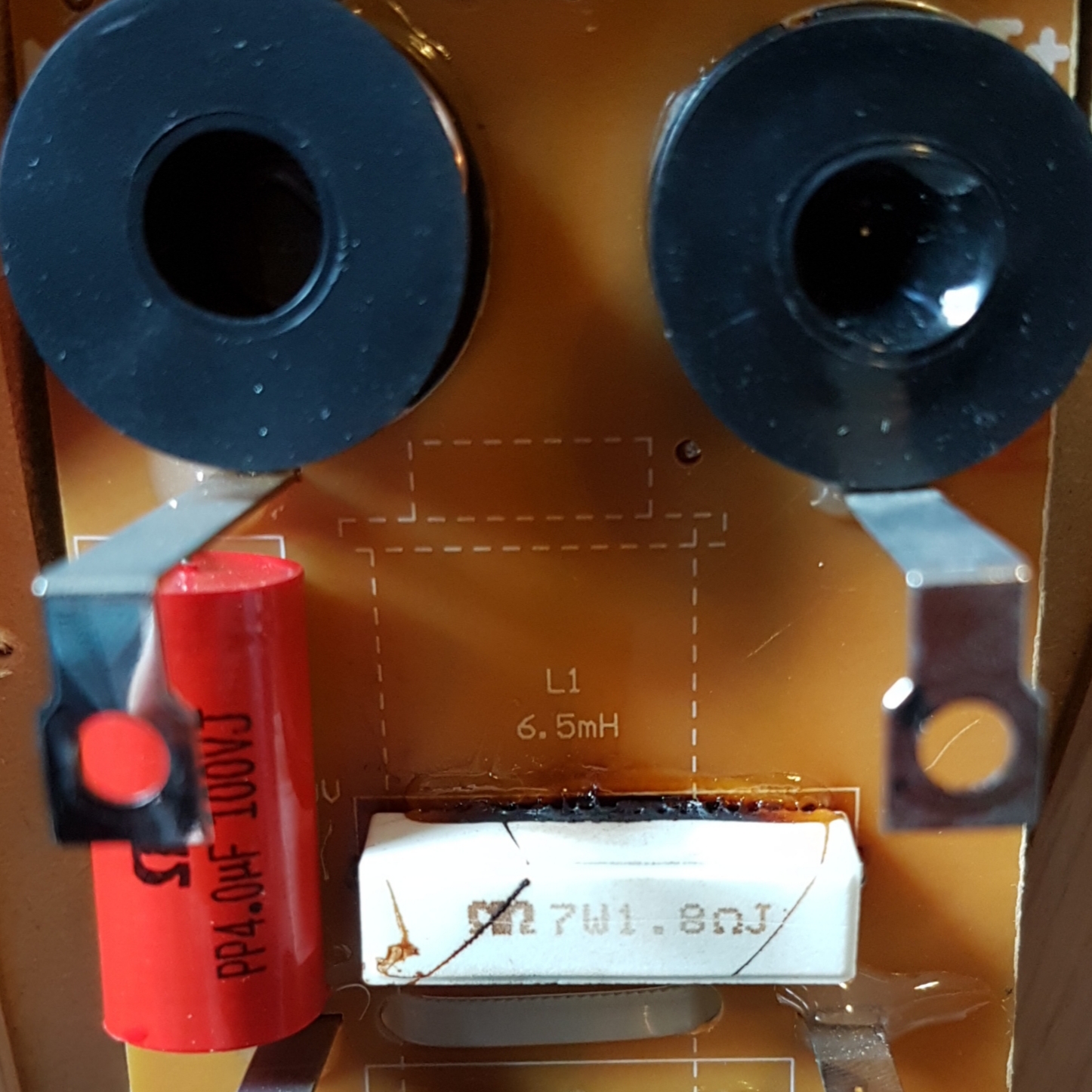

The coil and resistor do look as though they could have let out the magic smoke at a party.

It all goes horribly wrong when a tweeter blows, and then the crossover goes undamped and resonant at high volume.

Circuit a bit like this at 1.8R, 6uF and 0.2mH.

All quite replaceable. Components and accessories

Might as well do the capacitor at the same time. 5.6uF 250V will do.

I do mess around with these things. Ferrite increases inductance 4 fold. Doubling the number of turns also increases inductance 4 fold. Thing is, coils have such small resistance relative to a driver, it's not a biggie.

Still, maybe we need a review here. A quiet tweeter and a possibly overheated tweeter filter.

The coil and resistor do look as though they could have let out the magic smoke at a party.

It all goes horribly wrong when a tweeter blows, and then the crossover goes undamped and resonant at high volume.

Circuit a bit like this at 1.8R, 6uF and 0.2mH.

All quite replaceable. Components and accessories

Might as well do the capacitor at the same time. 5.6uF 250V will do.

Last edited:

Hi Guys,

My 1st post as I have just joined after a google search about my issue.

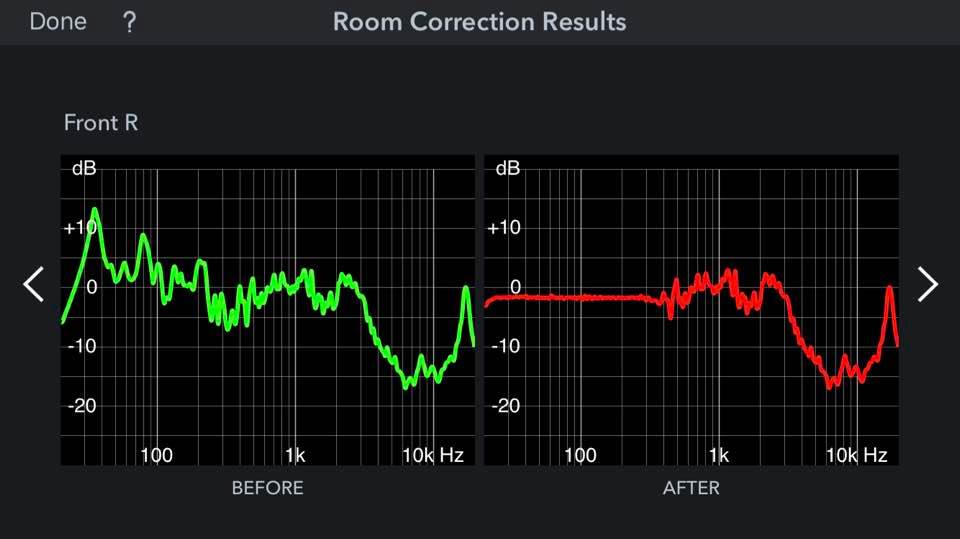

I seem to be in the exact position. My right front RS8 seems to have gone slightly quieter and sounds a a bit flat. I noticed it when I was doing some measurements using Audyssey. I have read through the thread and its been really helpful so far although some of it goes over my head but im learning : ) I removed all my drivers and tweeter yesterday and they all gave a reading close to the Ohms stated for it. Would that indicate there are all ok? After reading through this im now thinking its time to start looking at the crossover? This is the frequency response graph taken from the speaker. What does the bit missing around 2k mean?

Many Thanks 🙂

My 1st post as I have just joined after a google search about my issue.

I seem to be in the exact position. My right front RS8 seems to have gone slightly quieter and sounds a a bit flat. I noticed it when I was doing some measurements using Audyssey. I have read through the thread and its been really helpful so far although some of it goes over my head but im learning : ) I removed all my drivers and tweeter yesterday and they all gave a reading close to the Ohms stated for it. Would that indicate there are all ok? After reading through this im now thinking its time to start looking at the crossover? This is the frequency response graph taken from the speaker. What does the bit missing around 2k mean?

Many Thanks 🙂

Attachments

I'm not sure the speaker in this very unsatisfactory thread was a Monitor Audio RS8 at all, but we have spent time on the RS8.

Main quality you need to fix stuff is a willingness to delve into the innards of what are quite simple speakers. You seem to have that, but why not trust your ears?

Broken connections, broken components. Poor sound.

Simple diagnostics like putting a 1.5V penlight battery and paperclip across the drivers tells you whether they work in some fashion. Inspect solder joints for cracks, called a dry-joint. Crossover components like resistors can be measured with a £5 multimeter. Capacitors don't often go wrong, especially plastic foil types. Coils are hard to break too, being essentially just enamelled copper wire.

A bad woofer with rubbing voicecoil will distort. Quiet tweeters might have clogged up ferrofluid, which needs replacement or removal. Flat sounding speaker sounds like no or reduced tweeter output to me.

Main quality you need to fix stuff is a willingness to delve into the innards of what are quite simple speakers. You seem to have that, but why not trust your ears?

Broken connections, broken components. Poor sound.

Simple diagnostics like putting a 1.5V penlight battery and paperclip across the drivers tells you whether they work in some fashion. Inspect solder joints for cracks, called a dry-joint. Crossover components like resistors can be measured with a £5 multimeter. Capacitors don't often go wrong, especially plastic foil types. Coils are hard to break too, being essentially just enamelled copper wire.

A bad woofer with rubbing voicecoil will distort. Quiet tweeters might have clogged up ferrofluid, which needs replacement or removal. Flat sounding speaker sounds like no or reduced tweeter output to me.

The thread is titled Monitor Audio RS8 Crossover repair/upgrade. I have tested them using each driver unit with my multimeter already. I can see and hear them working, just abit flat , quieter on the right speaker. With your advice im thinking check the resistors next then or as you said ferrofluid clogged up. Who can i check the fluid? Would a clogged up tweeter show a different reading on my multimeter?

Just for the record, tweeters are terribly simple things when you (very carefully...) lift them apart:

H0414-08 19TAF/G

Fresh ferrofluid is applied to the gap before reassembly:

Blue Aran - The UK's no.1 Loudspeaker Component Stockist > Sonitus Audio > High Frequency Drivers > Ferrofluid

Hope that helps.

H0414-08 19TAF/G

Fresh ferrofluid is applied to the gap before reassembly:

Blue Aran - The UK's no.1 Loudspeaker Component Stockist > Sonitus Audio > High Frequency Drivers > Ferrofluid

Hope that helps.

Would a clogged up tweeter show a different reading on my multi meter?Just for the record, tweeters are terribly simple things when you (very carefully...) lift them apart:

H0414-08 19TAF/G

Fresh ferrofluid is applied to the gap before reassembly:

Blue Aran - The UK's no.1 Loudspeaker Component Stockist > Sonitus Audio > High Frequency Drivers > Ferrofluid

Hope that helps.

No it wouldn't. The multimeter just tells you the voicecoil has continuity in some fashion. That doen't mean it is any good though. Could have fried into a birdsnest which is irrepairable. Expect 3 to 7 ohms.

I found the 1.5V battery test was good enough to identify dried up ferrofluid. The bad one hardly crackled or sounded at all. The better one made more noise.

Ferrofluid is essentially kerosene oil and ferric oxide. If the oil evaporates, the voice coil is stuck in sludge resembling Marmite. Easy enough to clean the residue out with WD40 and blotting paper.

Don't forget you have a balance control on an amp. Comparing left and right tells you something about the tweeters, which make the fizzy top end. You can easily just put your hand over a tweeter and listen to the bassy woofers contribution too.

I found the 1.5V battery test was good enough to identify dried up ferrofluid. The bad one hardly crackled or sounded at all. The better one made more noise.

Ferrofluid is essentially kerosene oil and ferric oxide. If the oil evaporates, the voice coil is stuck in sludge resembling Marmite. Easy enough to clean the residue out with WD40 and blotting paper.

Don't forget you have a balance control on an amp. Comparing left and right tells you something about the tweeters, which make the fizzy top end. You can easily just put your hand over a tweeter and listen to the bassy woofers contribution too.

Thanks. Thats some great info and advice. Ive spent the afternoon reading about what the big dip in my graph is. 2k - 20k hz upper midrange to brilliance. this is what my ears are hearing. Would that mean testing the mid driver again as well? ThanksNo it wouldn't. The multimeter just tells you the voicecoil has continuity in some fashion. That doen't mean it is any good though. Could have fried into a birdsnest which is irrepairable. Expect 3 to 7 ohms.

I found the 1.5V battery test was good enough to identify dried up ferrofluid. The bad one hardly crackled or sounded at all. The better one made more noise.

Ferrofluid is essentially kerosene oil and ferric oxide. If the oil evaporates, the voice coil is stuck in sludge resembling Marmite. Easy enough to clean the residue out with WD40 and blotting paper.

Don't forget you have a balance control on an amp. Comparing left and right tells you something about the tweeters, which make the fizzy top end. You can easily just put your hand over a tweeter and listen to the bassy woofers contribution too.

No it wouldn't. The multimeter just tells you the voicecoil has continuity in some fashion. That doen't mean it is any good though. Could have fried into a birdsnest which is irrepairable. Expect 3 to 7 ohms.

I found the 1.5V battery test was good enough to identify dried up ferrofluid. The bad one hardly crackled or sounded at all. The better one made more noise.

Ferrofluid is essentially kerosene oil and ferric oxide. If the oil evaporates, the voice coil is stuck in sludge resembling Marmite. Easy enough to clean the residue out with WD40 and blotting paper.

Don't forget you have a balance control on an amp. Comparing left and right tells you something about the tweeters, which make the fizzy top end. You can easily just put your hand over a tweeter and listen to the bassy woofers contribution too.

Thank you for the good info and advice. Please excuse some of my terminology as Im still learning. Ive been reading up today about the missing bit in my graph. The huge null from 2000 - 20000hz. The upper mid range to brilliance. This is what my ears seen to notice. Shall I also check the mid-driver again? Or would the tweeter problem be the sole problem of the missing 2000hz - 20000hz. My goal is to replace what needs be, unless its an easy fix im happy to try myself.

RS8

It looks like a tweeter problem to me. I'd expect the big 6" metal midrange unit to be crossing over at about 3 kHz here. You should measure on axis.

I find Sweepgen occasionally useful. If only to learn what various frequencies actually sound like on the musical scale. Audio Tools - from David Taylor, Edinburgh

RS8

It looks like a tweeter problem to me. I'd expect the big 6" metal midrange unit to be crossing over at about 3 kHz here. You should measure on axis.

I find Sweepgen occasionally useful. If only to learn what various frequencies actually sound like on the musical scale. Audio Tools - from David Taylor, Edinburgh

Thank you very much for your replies Steve. Much appreciated. Im going to take the tweeter back out tomorrow and check the fluid and also what you suggested. Thats more great information. Im enjoying learning about it all and find it quite fascinating the science and logic behind it all. Ive been fascinated by Music/speakers since a very early age but never got into the technical side until I got into surround sound and room treatment at home. I dragged the filter to around 500hz on that graph, thats why its only been corrected to around 500hz as recommended by Audioholics videos.

You only need to learn about speakers when they go wrong, IMO! 😀

But a very good and interesting hobby.

3 ways tend to work like this:

You can have a bash yourself with a simulator:

Software | Visaton

Try importing a project a bit like your RS8 speakers to the projekte folder:

Atlantis – Boxsim Projektdatenbank

Seen one metal driver and you've seen em all IMO:

AL 170 - 8 Ohm | Visaton

You always have to deal with metal cone breakup around 6kHz. So they need more complex filters. Called notches to stop the shrieking sound.

But a very good and interesting hobby.

3 ways tend to work like this:

You can have a bash yourself with a simulator:

Software | Visaton

Try importing a project a bit like your RS8 speakers to the projekte folder:

Atlantis – Boxsim Projektdatenbank

Seen one metal driver and you've seen em all IMO:

AL 170 - 8 Ohm | Visaton

You always have to deal with metal cone breakup around 6kHz. So they need more complex filters. Called notches to stop the shrieking sound.

Hi all,

Due to the incredibly long lead times of hifi collective I got them fixed up last week and the tweeters appear to be working. The only thing I've noticed is they do seem to be fairly noisy and sometimes distort. With no signal through them there is a fair amount of noise from the tweeter, not audible unless close to them but I'm sure I didn't notice that before.

I'm wondering if this is my poor soldering or something more serious? Thinking about it now I didn't clean anything with contact cleaner or something before I soldered them I just took the old ones out and stuck the new ones in.

The only thing I did differently was that I noticed that in the old crossover both inductors were flush to the PCB and I read that they should be 90° relative to each other so I spun it round so it was sat on its circumference.

Any thoughts?

Due to the incredibly long lead times of hifi collective I got them fixed up last week and the tweeters appear to be working. The only thing I've noticed is they do seem to be fairly noisy and sometimes distort. With no signal through them there is a fair amount of noise from the tweeter, not audible unless close to them but I'm sure I didn't notice that before.

I'm wondering if this is my poor soldering or something more serious? Thinking about it now I didn't clean anything with contact cleaner or something before I soldered them I just took the old ones out and stuck the new ones in.

The only thing I did differently was that I noticed that in the old crossover both inductors were flush to the PCB and I read that they should be 90° relative to each other so I spun it round so it was sat on its circumference.

Any thoughts?

Thanks for your advice. I ordered a new RS8 tweeter. It came today and my speakers are back to sounded great again. ThanksRS8

It looks like a tweeter problem to me. I'd expect the big 6" metal midrange unit to be crossing over at about 3 kHz here. You should measure on axis.

I find Sweepgen occasionally useful. If only to learn what various frequencies actually sound like on the musical scale. Audio Tools - from David Taylor, Edinburgh

- Home

- Loudspeakers

- Multi-Way

- Monitor Audio RS8 Crossover Repair/Upgrade