Hi Tom,

Excellent advice, and I would recommend a coupling capacitor for sure. You can get a nice film capacitor for not much money.

Not using a coupling capacitor is just inviting trouble. Maybe not right now, but down the road for sure.

-Chris

Excellent advice, and I would recommend a coupling capacitor for sure. You can get a nice film capacitor for not much money.

Not using a coupling capacitor is just inviting trouble. Maybe not right now, but down the road for sure.

-Chris

I also do not need balanced input. How will I have connect the input?

To pin 1 and pin 2 on the input connector. Just as you would with the THAT1200 in place. You can ground pin 3 if you want, but without the THAT1200 it serves no purpose.

You can use a coupling cap if you wish. As Chris says above, it's generally a good idea to include one. 2.2-10 uF would be reasonable. I'd use a polypropylene one or get one of the Nichicon UES-series bipolar caps.

Tom

Parallel 86 build question

Hi Tom,

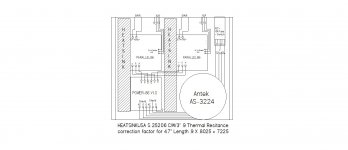

I hope you are well. I haven’t posted in a long time…just been enjoying my Modulus 86 for the last five years. I’m posting because I’m finally ready to build the Parallel 86 I bought from you in 2017 and would appreciate your thoughts and recommendations on my attached designs.

Specifically, one design has two chips on one heatsink with a 0.7012 thermal resistance. The other has each chip on its own heatsink, each with a 0.7225 thermal resistance. Is the two heatsink design overkill?

Thanks,

henrylrjr

Hi Tom,

I hope you are well. I haven’t posted in a long time…just been enjoying my Modulus 86 for the last five years. I’m posting because I’m finally ready to build the Parallel 86 I bought from you in 2017 and would appreciate your thoughts and recommendations on my attached designs.

Specifically, one design has two chips on one heatsink with a 0.7012 thermal resistance. The other has each chip on its own heatsink, each with a 0.7225 thermal resistance. Is the two heatsink design overkill?

Thanks,

henrylrjr

Attachments

TL;DR: I like the layout with the single heat sink, but the single heat sink might not be enough. Consider the 8.000" profile from HS USA or adding a thermal cutoff switch.

Note that in addition to the length correction factor, you'll need to apply a temperature correction factor (see attached). Heat sinks are commonly specified for 70 ºC temperature rise, which would make the heat sink close to 100 ºC at room temperature. That's way too hot. I generally recommend staying at 60-65 ºC or below so you don't get burns if you touch your amp after a 'spirited' listening session. The 65 ºC comes from a standard for external temperature of kitchen appliances. Controls (knobs) are allowed to reach 55 ºC and external surfaces 65 ºC. I find it reasonable to apply the same standard to amps.

So you're probably looking at either the 1.170 or 1.257 correction factor. This brings you to 0.7012 * 1.257 = 0.88 K/W for the single heat sink or 0.91 K/W per heat sink for the dual heat sink layout.

The Parallel-86 (and Modulus-286) will dissipate 50.2 W when running on ±36 V with music played at near clipping levels with a 4 Ω load. If you want to keep the heat sink below 65 ºC with 25 ºC ambient you need a heat sink with a thermal resistance below (65-25)/50.2 = 0.80 ºC/W = 0.80 K/W.

So technically neither heat sink is sufficient. Technically... Here's where it gets fuzzy, i.e., where experience takes over because engineering got us stuck. 🙂

Some (including most commercial hifi companies) choose to punt. Heat sinks are expensive, large, and heavy. So they skimp and add a temperature sensor (they still have to meet the safety standards after all). That's fair. And that works well enough for the reasons listed above.

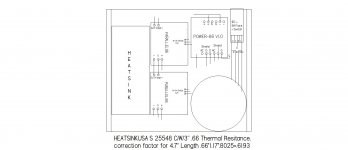

One option that could work very well for you would be the 8.00" profile from HeatSinkUSA. It has serrated fins so it's more efficient. It's rated at 0.66 K/W (3"), so you'd be looking at 0.68 K/W for 4.5", 30 ºC give/take. That could be attractive.

Do note that I have found errors/typos in HeatSinkUSA's thermal numbers. For example they claim their 2.00" profile with serrated fins has a thermal resistance of 1.5 K/W. It's more like 2.5 K/W in my measurements.

As a sanity check it may be worthwhile to compare with a similar profile elsewhere. For example HeatSinkOnline. If the profile is similar (roughly same base thickness, same fin geometry, etc.) the thermal resistance should be similar.

Note that I spec things conservatively. You will likely find that if you build the amp according to my recommendations it won't get much beyond lukewarm even after a 'spirited' listening session. Some seem disappointed in that. I see it as a good design. I'm building amps not hot plates. 🙂

All math above assumes music reproduction with 14 dB CF. I guarantee you that the amp will overheat if you run it for hours with a sine wave at the worst case power dissipation into a 4 Ω load.

Tom

Note that in addition to the length correction factor, you'll need to apply a temperature correction factor (see attached). Heat sinks are commonly specified for 70 ºC temperature rise, which would make the heat sink close to 100 ºC at room temperature. That's way too hot. I generally recommend staying at 60-65 ºC or below so you don't get burns if you touch your amp after a 'spirited' listening session. The 65 ºC comes from a standard for external temperature of kitchen appliances. Controls (knobs) are allowed to reach 55 ºC and external surfaces 65 ºC. I find it reasonable to apply the same standard to amps.

So you're probably looking at either the 1.170 or 1.257 correction factor. This brings you to 0.7012 * 1.257 = 0.88 K/W for the single heat sink or 0.91 K/W per heat sink for the dual heat sink layout.

The Parallel-86 (and Modulus-286) will dissipate 50.2 W when running on ±36 V with music played at near clipping levels with a 4 Ω load. If you want to keep the heat sink below 65 ºC with 25 ºC ambient you need a heat sink with a thermal resistance below (65-25)/50.2 = 0.80 ºC/W = 0.80 K/W.

So technically neither heat sink is sufficient. Technically... Here's where it gets fuzzy, i.e., where experience takes over because engineering got us stuck. 🙂

- With the Power-86 (or any other 'linear' power supply) you will have some sag when the amp draws high current, i.e. on the near-clipping peaks into that 4 Ω load. So you don't get ±36 V at the amp chip, you probably get ±33-34 V. That means the power dissipated in the LM4780 will drop correspondingly.

- No "4 Ω" speaker is 4 Ω across the entire audio band. This could work with or against you, but tends to work with you.

- Few ever play music that loud for any length of time, so what you really need is thermal mass (as well as a way to get rid of the heat).

- Music doesn't have a constant crest factor throughout each track, so even if you do load that 14.00 dB CF track (I assumed 14 dB CF in my math) and play it with the peaks exactly at clipping, odds are that the actual power dissipated will be less than what the math says. Then again, depending on your musical tastes it could also be higher.

Some (including most commercial hifi companies) choose to punt. Heat sinks are expensive, large, and heavy. So they skimp and add a temperature sensor (they still have to meet the safety standards after all). That's fair. And that works well enough for the reasons listed above.

One option that could work very well for you would be the 8.00" profile from HeatSinkUSA. It has serrated fins so it's more efficient. It's rated at 0.66 K/W (3"), so you'd be looking at 0.68 K/W for 4.5", 30 ºC give/take. That could be attractive.

Do note that I have found errors/typos in HeatSinkUSA's thermal numbers. For example they claim their 2.00" profile with serrated fins has a thermal resistance of 1.5 K/W. It's more like 2.5 K/W in my measurements.

As a sanity check it may be worthwhile to compare with a similar profile elsewhere. For example HeatSinkOnline. If the profile is similar (roughly same base thickness, same fin geometry, etc.) the thermal resistance should be similar.

Note that I spec things conservatively. You will likely find that if you build the amp according to my recommendations it won't get much beyond lukewarm even after a 'spirited' listening session. Some seem disappointed in that. I see it as a good design. I'm building amps not hot plates. 🙂

All math above assumes music reproduction with 14 dB CF. I guarantee you that the amp will overheat if you run it for hours with a sine wave at the worst case power dissipation into a 4 Ω load.

Tom

Attachments

So the Parallel 86 TR, (.7128), will be 36% lower than my cool running Mod86 TR, (1.1228). Would over 1/3 reduction in TR, while not ideal, work in the Parallel 86?

From Post #5505. Emphasis added.

So neither is technically low enough. For what to do about it, see the four bullets in Post #5505. You can always add a thermal switch that turns the amp off if the temperature of the heat sink exceeds 60-65 ºC.

If you use high-efficiency speakers (say 90 dB SPL @ 1W, 1m) you'll likely never push the amp hard enough that it'll get more than lukewarm. So accepting it as-is and just keeping an eye on the temperature is a valid approach too.

Tom

So you're probably looking at either the 1.170 or 1.257 correction factor. This brings you to 0.7012 * 1.257 = 0.88 K/W for the single heat sink or 0.91 K/W per heat sink for the dual heat sink layout.

The Parallel-86 (and Modulus-286) will dissipate 50.2 W when running on ±36 V with music played at near clipping levels with a 4 Ω load. If you want to keep the heat sink below 65 ºC with 25 ºC ambient you need a heat sink with a thermal resistance below (65-25)/50.2 = 0.80 ºC/W = 0.80 K/W.

So neither is technically low enough. For what to do about it, see the four bullets in Post #5505. You can always add a thermal switch that turns the amp off if the temperature of the heat sink exceeds 60-65 ºC.

If you use high-efficiency speakers (say 90 dB SPL @ 1W, 1m) you'll likely never push the amp hard enough that it'll get more than lukewarm. So accepting it as-is and just keeping an eye on the temperature is a valid approach too.

Tom

Last edited:

I’m a bit confused. The parallel 86 designdocumentation.pdf states “A good candidate for a suitable heat sink would be a 3” section of Heatsink USA 12.000“profile”. That heatsink has a C/W/3” .85 thermal resistance. Based on that it would seem any heatsink with a TR of .85 or lower would work.

So based on that it seems, applying the correction factor for 4.7” length to heatsinkusa 24300 and 25206, with a C/W/3” 0 .9 thermal resistance, should result in a more than sufficient thermal resistance of 0.7218. Why wouldn’t that meet “the good candidate requirement?

So based on that it seems, applying the correction factor for 4.7” length to heatsinkusa 24300 and 25206, with a C/W/3” 0 .9 thermal resistance, should result in a more than sufficient thermal resistance of 0.7218. Why wouldn’t that meet “the good candidate requirement?

That documentation was last updated in January of 2016. I've learned a lot since then. One of the many things I've learned is the compensation factors for length and temperature. I have no plans to update the documentation as the Parallel-86 was discontinued 3-4 years ago when TI killed the LM4780.

Heat sinks are commonly specified for 70 ºC temperature rise. Heat sinks are more efficient when they're hotter than the ambient air (i.e., a hot heat sink will have a lower thermal resistance than a cold one when operated at the same ambient temperature). I recommend staying at a heat sink temperature of 65 ºC or below, so unless you keep your listening room at -5 ºC you will need to apply the temperature correction factor. I gave the relevant factors in Post #5505.

Assuming 25 ºC ambient and 65 ºC maximum heat sink temperature, you're looking at 65-25 = 40 ºC temperature rise, so you need to multiply the specified thermal resistance by 1.170 to get the thermal resistance at 40 ºC temperature rise.

So a 3" chunk of 12" profile from HeatSink USA (specified at 0.85 K/W @ 70 ºC temperature rise) has a thermal resistance of 0.85*1.170 = 0.99 K/W @ 40 ºC temperature rise.

Then compensate for the 4.5" length. 4.5" is not specified in the table. It looks like you took the average of the 4" and 5" numbers. That's probably close enough, so you need to multiply by (0.87+0.78)/2 = 0.825. That gets you to 0.99*0.825 = 0.82 K/W.

So the heat sink profile specified for 0.85 K/W @ Trise = 70 ºC, L = 3" is 0.85*1.170*0.825 = 0.82 K/W @ Trise = 40 ºC, L = 4.5".

Last I checked 0.82 > 0.80, so technically the 4.5" heat sink is a bit too small. I've provided suggestions for what to do about that (including doing nothing) in Posts #5505 and #5507.

Tom

Heat sinks are commonly specified for 70 ºC temperature rise. Heat sinks are more efficient when they're hotter than the ambient air (i.e., a hot heat sink will have a lower thermal resistance than a cold one when operated at the same ambient temperature). I recommend staying at a heat sink temperature of 65 ºC or below, so unless you keep your listening room at -5 ºC you will need to apply the temperature correction factor. I gave the relevant factors in Post #5505.

Assuming 25 ºC ambient and 65 ºC maximum heat sink temperature, you're looking at 65-25 = 40 ºC temperature rise, so you need to multiply the specified thermal resistance by 1.170 to get the thermal resistance at 40 ºC temperature rise.

So a 3" chunk of 12" profile from HeatSink USA (specified at 0.85 K/W @ 70 ºC temperature rise) has a thermal resistance of 0.85*1.170 = 0.99 K/W @ 40 ºC temperature rise.

Then compensate for the 4.5" length. 4.5" is not specified in the table. It looks like you took the average of the 4" and 5" numbers. That's probably close enough, so you need to multiply by (0.87+0.78)/2 = 0.825. That gets you to 0.99*0.825 = 0.82 K/W.

So the heat sink profile specified for 0.85 K/W @ Trise = 70 ºC, L = 3" is 0.85*1.170*0.825 = 0.82 K/W @ Trise = 40 ºC, L = 4.5".

Last I checked 0.82 > 0.80, so technically the 4.5" heat sink is a bit too small. I've provided suggestions for what to do about that (including doing nothing) in Posts #5505 and #5507.

Tom

Last edited:

Last edited:

I have a funny issue with my Modulus 86. Im a lazy guy so when I put the 86 into my TV system I used a simple chinese preamp (relay volume and inputs - no gain) in front of my valve preamp which was connected to the Mod86. I put the volum ( ladder) on my preamp to max and got some hum, then I put the volume a step down and no hum. Didnt think much of it as it might be som issue from my preamp build. I then used the Mod86 like this for a long time and had no issues with it. Today I put the Mod86 into a system with a B1 Korg and got loud hum. I also tried it directly from dac and got the same hum. What could be wrong? Is this some impedance matching issue ( as it works ok with my valve pre vith the volume one step down from straight through )

between +wire and terminal I think.

OK. Let's put this cap coupling to bed once and for all.

Add a 470 kΩ from the RCA centre to RCA ground.

Add 2.2-10 uF from RCA centre to pin 2 on the input of the MOD86.

Add 47 kΩ from pin 2 to pin 1 on the input of the MOD86.

Pluck the THAT1200 from the MOD86.

Connect pin 3 to pin 6 on the (now empty) THAT1200 socket.

Connect RCA ground to pin 1 on the MOD86 input.

Done.

Note that you lose all benefits of the balanced input (and some of the benefit of the EMI/RFI filtering) with this approach, but you do get a slight reduction in noise.

Tom

Tom I have no idea how two chips on one heatsink will be affected by a heatsink thermal resistance.

Each LM4780 will dissipate 50.2 W when operated with music (14 dB CF) at clipping levels into a 4 Ω load.

If you have one Parallel-86 on each heat sink, each heat sink will have to dissipate 50.2 W.

If the heat sink temperature is to stay below 65 ºC at 25 ºC ambient, this requires a thermal resistance of: (65-25)/50.2 = 0.80 K/W.

If you have two Parallel-86 on one heat sink and each Parallel-86 dissipates 50.2 W, the heat sink will have to dissipate 2*50.2 = 100.4 W.

If the heat sink temperature is to stay below 65 ºC at 25 ºC ambient, this requires a thermal resistance of: (65-25)/100.4 = 0.40 K/W.

Given that you operate the heat sink at (65-25) = 40 ºC temperature rise, you need to look for a heat sink specified for:

- One Parallel-86 per heat sink: 0.80/1.170 = 0.68 K/W (@ 70 ºC temperature rise).

- Two Parallel-86 per heat sink: 0.40/1.170 = 0.34 K/W (@ 70 ºC temperature rise).

Applying factors to HSUSA 8" .66 TR heatsink results in .619 (.66X1.17X.802=.619). Would that work?

That would be quite comfortable for one Parallel-86 (0.62 < 0.80), yes. It would not be enough for two Parallel-86 (0.62 > 0.40).

Tom

Last edited:

I have a funny issue with my Modulus 86.

Yeah, that's an interesting one. Did you build the MOD86 as described in the instructions (i.e. kept the balanced input, etc.) or did you colour outside the lines a bit? It's fine either way, but to provide the best help I need to know what you have.

I'm assuming your sources are single-ended. In that case, you need to connect pin 1 to pin 3 on the MOD86 input. Take this connection to the RCA ground. The RCA centre goes to pin 2 of the MOD86 input.

If the MOD86 is built per the instructions and you have the input connected as described above, it should be plug-n-play. An interesting experiment to try would be to add a largish resistor from RCA centre to RCA ground. Anything in the 100-500 kΩ would work. It shouldn't be necessary, but I'm intrigued that the hum goes away as soon as you dial the volume down by one step. That adds a resistor to ground at the input of the MOD86, so that could be a quick and easy fix.

Tom

Last edited:

I did everything by the book, and yes my sources are single ended and connected as described. Ill try with the resistor this evening.

Initially if you rember my post I connectet the components in a wrong way and some of the chips got hot before I turned off and fixed the error. Could some of the chips be damaged ( I get a relativly loud on-off thump, my speakers are over 100db/w).

Initially if you rember my post I connectet the components in a wrong way and some of the chips got hot before I turned off and fixed the error. Could some of the chips be damaged ( I get a relativly loud on-off thump, my speakers are over 100db/w).

Last edited:

The LM3886 is pretty rugged, so damage is unlikely but not impossible.

That said, one proven way to damage the LM3886 is to reverse the polarity of the power supply (as a couple of Modulus-686 builders have found out the hard way 😱). So connect the supply correctly. 🙂

The thump is likely due to the single-ended connection. I've seen that before. It's caused by the THAT1200. You can reduce the thump drastically by adding a resistor 10-47 kΩ from RCA centre to RCA ground.

You could also eliminate the thump (and gain speaker protection) by using the Guardian-686 or Guardian-86 speaker protection circuit.

Tom

That said, one proven way to damage the LM3886 is to reverse the polarity of the power supply (as a couple of Modulus-686 builders have found out the hard way 😱). So connect the supply correctly. 🙂

The thump is likely due to the single-ended connection. I've seen that before. It's caused by the THAT1200. You can reduce the thump drastically by adding a resistor 10-47 kΩ from RCA centre to RCA ground.

You could also eliminate the thump (and gain speaker protection) by using the Guardian-686 or Guardian-86 speaker protection circuit.

Tom

- Home

- Amplifiers

- Chip Amps

- Modulus-86 build thread