Hello again

been away for a while but have sorted my missions got some good quality fuses in the crossovers and new foundation stands i put ebony cones in between stands and speaker an re bult my speaker cable with new qed spades and bannana plugs they sound loads better thanks for all the help ime hopeing to do more soon but for now they sound great.

Thanks

martin 🙂

Glad you enjoyed that. Not too hard was it? 🙂

I think you've got the hang of adjusting the new tweeter's level with that input resistor value. Your polycone bass has good natural rolloff so will work well on a simple coil. 😎

There's a fun thread here about 8" paper bass:

http://www.diyaudio.com/forums/multi-way/190129-8-1-two-way-diy-speakers-12.html#post4021066

sorry forgot to show you all the covers i made

and here are the stands i got and the spades and fuses seem to have made them sound much more even in terms of left to right imigeing much wider soundstage you can realy here where the players are in there now

thank you again for all ive lernt so far on this forum long way to go yet but finaly starting to get results

and here are the stands i got and the spades and fuses seem to have made them sound much more even in terms of left to right imigeing much wider soundstage you can realy here where the players are in there now

thank you again for all ive lernt so far on this forum long way to go yet but finaly starting to get results

Attachments

I use rubber feet myself. More out of practicality than anything. 🙂

Very good tweak is to stick something rubbery or carpety or underlayish to the sides of the panels. With reflex you leave the centre of the cabinet mostly clear, but it always helps to get the noise floor of the cabinet down.

http://www.diyaudio.com/forums/multi-way/223174-interesting-read-i-found-lossy-cabinet-designs-harbeth.html#post3234256

Very good tweak is to stick something rubbery or carpety or underlayish to the sides of the panels. With reflex you leave the centre of the cabinet mostly clear, but it always helps to get the noise floor of the cabinet down.

http://www.diyaudio.com/forums/multi-way/223174-interesting-read-i-found-lossy-cabinet-designs-harbeth.html#post3234256

They have big daming pads on all the walls and then lined with foam but ive neen thinking of getting some new foam in there cus that thats in there is getting on a bit at 33 year old so i dont think i will hurt to get some new even though it still feels ok i think it must be getting ready so i dont think it will hurt to get some new for them.

I do have a bit of a problem ive noticed there is some white corosion on the back of the basckets on the midbass drivers is there amything i can do to get rid of it and stop it coming back do you think.?

I do have a bit of a problem ive noticed there is some white corosion on the back of the basckets on the midbass drivers is there amything i can do to get rid of it and stop it coming back do you think.?

Just alloy rot, I'd think. Motorbike wheels and engines get it too. Big problem in the Far East where it is very damp. 🙂

I suppose you rub the chassis down with a cloth and some maintenance spray like WD 40. But I'm always a bit wary of solvents over applied. They can dissolve glues and attack surrounds...

Perhaps, if it ain't broke, don't fix it? 😀

I suppose you rub the chassis down with a cloth and some maintenance spray like WD 40. But I'm always a bit wary of solvents over applied. They can dissolve glues and attack surrounds...

Perhaps, if it ain't broke, don't fix it? 😀

Ye i was woried about using eny sprays on them i thought about replaveing them with a pair of poly vifas but ime woried it will spoil the balence ive got now what do you think do you think they would werk ok or leeve them alone.

Hardly any point swapping one polycone for another, is there?

I have a good idea how your speakers sound:

Have you tried that Zobel I suggested? That can make a lot of difference to the top end smoothness. Something modest like 7.5R and 0.68uF across the tweeter does a lot to tame the very top end. Makes a speaker a lot more listenable IMO.

0 68 fd SuperSound Capacitor

Ceramic Resistors

You can also get them at Maplin.

I have a good idea how your speakers sound:

An externally hosted image should be here but it was not working when we last tested it.

Have you tried that Zobel I suggested? That can make a lot of difference to the top end smoothness. Something modest like 7.5R and 0.68uF across the tweeter does a lot to tame the very top end. Makes a speaker a lot more listenable IMO.

0 68 fd SuperSound Capacitor

Ceramic Resistors

You can also get them at Maplin.

The top end is prety good now only wory i have is the damege the corosion could do to my drive units but if i can keep them cleen they should be ok i hope and i wont have to change them

Why don't we see a schematic of the 770 XO with all the values?

Adding some brightness to them is a very simple task though.

It's just a 1st order low pass and a 2nd order high pass + resistor,

similar to most early Mission XOs.

Just replace the (only) capacitor with an poly/MKP and swap the

resistor (you called it the "long black thing") for the next lower value.

For this you'd need to measure the current value. That's all.

I do not think increasing the low pass coil's resistance is any good

idea at all.

BTW, if it's bass reflex, increasing the port's length by 30 to 50 %

would make a less boomy but deeper bass.

If I remember correctly the midbass driver is a Seas, and the early

770's tweeter has been a Vifa unit. If the tweeters were blown, did

you try to obtain a Vifa replacement diaphragm? They're probably

cheap and easy to replace cos being self-cetered.

Adding some brightness to them is a very simple task though.

It's just a 1st order low pass and a 2nd order high pass + resistor,

similar to most early Mission XOs.

Just replace the (only) capacitor with an poly/MKP and swap the

resistor (you called it the "long black thing") for the next lower value.

For this you'd need to measure the current value. That's all.

I do not think increasing the low pass coil's resistance is any good

idea at all.

BTW, if it's bass reflex, increasing the port's length by 30 to 50 %

would make a less boomy but deeper bass.

If I remember correctly the midbass driver is a Seas, and the early

770's tweeter has been a Vifa unit. If the tweeters were blown, did

you try to obtain a Vifa replacement diaphragm? They're probably

cheap and easy to replace cos being self-cetered.

If I remember correctly the midbass driver is a Seas, and the early

770's tweeter has been a Vifa unit. If the tweeters were blown, did

you try to obtain a Vifa replacement diaphragm? They're probably

cheap and easy to replace cos being self-cetered.

That depends on when they were made, the Mission 770 went through a number of revisions. The first ones used a proprietary polypropylene woofer with a SEAS soft plastic dome tweeter, like the H107 or H254. The crossover was designed "by ear" by Farad Azima.

They are the mk2 the tweeters were seas units ive replaced them with morel cat 308 tweeters the midpace is a poly seas unit.

What setting on the meter will be needed to test the resister and the capacitor

from what ive been told the cap should be ok and wont degrade but the resister may need replaceing is this right ?

What setting on the meter will be needed to test the resister and the capacitor

from what ive been told the cap should be ok and wont degrade but the resister may need replaceing is this right ?

They are the mk2 the tweeters were seas units ive replaced them with morel cat 308 tweeters the midpace is a poly seas unit.

What setting on the meter will be needed to test the resister and the capacitor

from what ive been told the cap should be ok and wont degrade but the resister may need replaceing is this right ?

I should have guessed from you are new to this. 😀

So far you have replaced the fuses and the tweeter.

https://learn.sparkfun.com/tutorials/how-to-use-a-multimeter/measuring-resistance

You need the 200 ohm scale. To get the level right, you may now need to change the input resistor to the tweeter filter. Wirewound 7 Watt 2.2 Ohm Resistor | Maplin

Bigger like 3.3R makes it quieter. Smaller like 1R makes it louder. This involves soldering too.

40W Soldering Kit | Maplin

You apply solder to the soldering iron the first time it warms up. This is called "tinning the tip". Otherwise it turns black (oxidises) and is ruined.

Capacitors are always marked. Yours will be 2.2uF, 3.3uF or 4.7uF.

I strongly doubt there's any point in helping here. 🙄

fitted. It doesn't even matter.

You should measure the resistor only. Honestly, if you don't know how to do this

simple job, stop working on loudspeakers. 😉

BTW, Seas also make replacement diaphragms. The fabric domes are compatible

with the cheap plastic ones as they share the same voice coil. Way cheaper than

a pair of Morels and the Freedom will sound even better as the XO still works as

intended. Research first, then do the work.

Don't get me wrong, but I've read this topic and I know what tweeters you'veThey are the mk2 the tweeters were seas units ive replaced them with morel cat 308 tweeters the midpace is a poly seas unit.

What setting on the meter will be needed to test the resister and the capacitor

from what ive been told the cap should be ok and wont degrade but the resister may need replaceing is this right ?

fitted. It doesn't even matter.

You should measure the resistor only. Honestly, if you don't know how to do this

simple job, stop working on loudspeakers. 😉

BTW, Seas also make replacement diaphragms. The fabric domes are compatible

with the cheap plastic ones as they share the same voice coil. Way cheaper than

a pair of Morels and the Freedom will sound even better as the XO still works as

intended. Research first, then do the work.

I strongly doubt there's any point in helping here. 🙄

Don't get me wrong, but I've read this topic and I know what tweeters you've

fitted. It doesn't even matter.

You should measure the resistor only. Honestly, if you don't know how to do this

simple job, stop working on loudspeakers. 😉

BTW, Seas also make replacement diaphragms. The fabric domes are compatible

with the cheap plastic ones as they share the same voice coil. Way cheaper than

a pair of Morels and the Freedom will sound even better as the XO still works as

intended. Research first, then do the work.

Ok wont ask again i can sort it from the help ive bean given from system7

good bye an god bless 🙂

I realised that if you're new to this, most of what I say might as well be Greek, slipmyster! 😱

We were all new to this lovely hobby once. But it's amazing what you an do once you have a plan.

Here's some good sites to learn stuff:

DIY-Loudspeakers

The Art of Speaker Design

Here's a software simulator that I use:

Downloads

And some projects that you can put in the "projekte" folder and play with straightaway:

boxsim-db.de | Boxsim Projektdatenbank

I hope you can start building up a collection of tools and bits too. Sky's the limit then!

We were all new to this lovely hobby once. But it's amazing what you an do once you have a plan.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Here's some good sites to learn stuff:

DIY-Loudspeakers

The Art of Speaker Design

Here's a software simulator that I use:

Downloads

And some projects that you can put in the "projekte" folder and play with straightaway:

boxsim-db.de | Boxsim Projektdatenbank

I hope you can start building up a collection of tools and bits too. Sky's the limit then!

Attachments

Thank you steve your a star thats a lot of hel more than i could of wished.

Bye my freind

martin 🙂

Bye my freind

martin 🙂

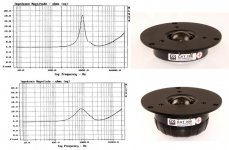

I nearly forgot. The difference between the Morel CAT 298 and the more expensive CAT 308 is interesting.

Essentially the same tweeter. Same voicecoil, replaceable dome and magnet with ferrofluid. Similar frequency response.

The CAT 308 has a bigger rear vented chamber. It's like a bass speaker in a bigger box.

So the low end issues might be less. The impedance peak is called the Fs of the driver. You usually try to get it well down in level with a steep crossover to avoid some ringing problems. Or notch it out with a LCR circuit tuned to 900Hz.

Essentially the same tweeter. Same voicecoil, replaceable dome and magnet with ferrofluid. Similar frequency response.

The CAT 308 has a bigger rear vented chamber. It's like a bass speaker in a bigger box.

So the low end issues might be less. The impedance peak is called the Fs of the driver. You usually try to get it well down in level with a steep crossover to avoid some ringing problems. Or notch it out with a LCR circuit tuned to 900Hz.

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- mission 770 crossover