Hi everone and good day to all.

I am in the process of putting together a 2 channel amp with 6V6's in push pull. My chassis top side space is limited and the 4 6V6's will need to be close to each other. What is the minimum space I should have between tubes?

thanks

Bruce

I am in the process of putting together a 2 channel amp with 6V6's in push pull. My chassis top side space is limited and the 4 6V6's will need to be close to each other. What is the minimum space I should have between tubes?

thanks

Bruce

I would suggest one tube diameter as the minimum spacing, unless you have very good cooling arrangements.

One screw to tighten two tube sockets, I'd would say that's the minimum. No tube rolling with coke bottle 6V6's - keep that in mind.

I keep at least 2 inches between tubes. Remember they have to have room in order to cool themselves. Having tubes too close can cause hot spots due to radiating heat.

I think the OP was asking about the minimum he should have, not the minimum possible. The amp shown in post #3 is likely to lead to overheating and short valve life unless the 6V6 are run with rather cool bias.

Agree with earlier posts, one tube diameter is ok for smaller tubes up to, say, 10-15W Pa, high power tubes will usually require bigger spacing.

Edit:

The pic in post #3 says it all, i would never buy an amplifier where the constructor placed the tubes like this, this is clearly a sign to look for.

According to smallsignal tubes like the 12AX7, IMHO you can place them rather tight, as in 1/2 tube with or so.

Edit:

The pic in post #3 says it all, i would never buy an amplifier where the constructor placed the tubes like this, this is clearly a sign to look for.

According to smallsignal tubes like the 12AX7, IMHO you can place them rather tight, as in 1/2 tube with or so.

Last edited:

look at a Quad II, or any number of commercial highly regarded amps. Tight is fine imo as long as their is reasonable air movement possible. The valve doesn't operate unless its hot remember - warm is good. I'm not aware of any tube that melted from the outside in...

Having tubes too close can cause hot spots due to radiating heat.

Hot spots? They're everywhere, just don't touch them. 😀

I'd always choose good looks over longer tube life. Speaking of tube life, the glass won't crack so what else could go wrong? Melted parts? IMO 2 inches is too much for four 6V6s, doesn't look good to me - kinda like gapped teeth.😀

Mine is a DIY amp so I do what I want and I don't want a big chassis. 6V6's are cheap, who cares if they "could" last 6 months longer with a "proper" placement. I don't so less than an inch here. 😀

Morgen Jones recommends 1 1/2 times the tube diameter for spacing to keep one tube from heating the others

has anyone measured it? I mean, actually measured surface temps and then calculated the amount of radiated heat and figured out what the % difference is with regard to proximity? I have just done a quick search and, apart from stuff on VH output raiio and research tubes, I can't find any emperical data or advice on the subject.

This implies its not a significant issue...

This implies its not a significant issue...

Yeah, no data in the tube books that I've read either. Although common sense says tubes shouldn't touch each other. 😀

Morgan Jones? Never heard of him.

Morgen Jones recommends

Morgan Jones? Never heard of him.

i misspelled it sorry, Morgan Jones, has a few books out, Building valve amplifiers is where I read it. He was a long time engineer for the BBC

it's not about melting glas, it's about thermal radiation affecting other tubes, internal breakdown, tubes pushed out of operating points and possible crosstalk.

Some documnentation says that you have to take care of the tubes orientation, like the 6AS7, if mounted horizontally with one triode on top of the other you will have a sooner breakdown and affected operating point, logical, right?

Some documnentation says that you have to take care of the tubes orientation, like the 6AS7, if mounted horizontally with one triode on top of the other you will have a sooner breakdown and affected operating point, logical, right?

no, wrong as I understand it. You don't mount them horizontally because of the possible sagging of grids that are not designed to operate in that plane. THAT is the cause of shifted operating points.

The only reference I can find in data to operating ambient temperatures and cooling is around transmitter types where occasionally forced air cooling is suggested, but with no parameters.

The only reference I can find in data to operating ambient temperatures and cooling is around transmitter types where occasionally forced air cooling is suggested, but with no parameters.

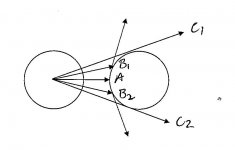

take a look at it this way - the two circles represent two adjascent tubes with a separation of around 1/2d

Only radiated heat in the vector A will pass largely unhindered from the left tube to the right. Vectors B1 and B2 have a % of reflection that reduces the heating, and anything further out that C1 or C2 is irrelevant.

Obviously the model is highly simplified, but what it signifies to me is that only a very small % of the total radiated heat from any tube will impact adjascent objects, and if hte objects themselves are cylindrical, the effect is further reduced.

I'm going to make the wild assumption that the manufacturers recommended operating points are conservatively set to allow for a wide range of applications. Hence any relatively minor external heating effect will have marginal impact on the actual operation of the device.

Got any evidence otherwise?

Only radiated heat in the vector A will pass largely unhindered from the left tube to the right. Vectors B1 and B2 have a % of reflection that reduces the heating, and anything further out that C1 or C2 is irrelevant.

Obviously the model is highly simplified, but what it signifies to me is that only a very small % of the total radiated heat from any tube will impact adjascent objects, and if hte objects themselves are cylindrical, the effect is further reduced.

I'm going to make the wild assumption that the manufacturers recommended operating points are conservatively set to allow for a wide range of applications. Hence any relatively minor external heating effect will have marginal impact on the actual operation of the device.

Got any evidence otherwise?

Attachments

Last edited:

Only radiated heat in the vector A will pass largely unhindered from the left tube to the right. Vectors B1 and B2 have a % of reflection that reduces the heating, and anything further out that C1 or C2 is irrelevant.

I'll buy that.

Some tubes cannot be operated horizontally. I'd imagine this is the case for most if not all directly heated tubes. In this case the hot filament will sag and might short out to the grid. In an indirectly heated tube, the heater is inside a cathode sleeve and sag is not an issue. Hence, indirectly heated tubes may be operated in any orientation.

Beam forming pentodes must be aligned a certain way to prevent their electron beams from interfering with each other. Typically, there will be a note in the data sheet along the lines of "if multiple tubes are within close proximity of another, align pins X and Y".

I would also imagine that mercury vapor rectifiers need to be upright...

~Tom

Somewhere in a datasheet I saw,they suggested that the spacing be (at least) the diameter of the tube(s).

No. For almost all of the valves we use, the only parts which need to be hot are the heater and cathode. If the other innards get too hot then they may outgas, which eventually kills the vacuum and may damage the cathode. If the glass gets too hot then seals may fail, and the glass itself may become slightly conductive. The glass is the main way of getting heat out, via convection and radiation, so the cooler the better.warm is good

Some high power valves need a hot getter, but these are usually ceramic types and rarely used for audio.

Your choice, of course, but I always thought an amplifier was for listening to rather than looking at. Remember that decent valves are a finite resource, so we don't want to use them up too quickly, otherwise only rich people will be able to enjoy valve audio.I'd always choose good looks over longer tube life

Heat is probably the most significant issue in valve life, after exceeding ratings (as some circuits do). Valves in radio and audio equipment generally last a long time, as they are fairly cool. Valves in TV sets could fail within a few years, because they were generally very hot.This implies its not a significant issue

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- Minimum space between 6V6 tube in Push-Pull Amp