Would rotating the HF lens 90 degrees be of any benefit? I am just not sure how it will play with the aperture on the inside of the enclosure.

Would rotating the HF lens 90 degrees be of any benefit? I am just not sure how it will play with the aperture on the inside of the enclosure.

While I have not played with a coax speaker in a Karlsonator, I have heard several vintage coaxials in full sized Karlsons. IME, it does make a difference which way the HF horn is oriented, but it is hard to predict which way sounds better. Best to try both vertical and horizontal, and go with what your ears tell you.

Hi all,

Here are some news of the fountek fr135ex karsonator 😀.

Final internal brassing :

With final lining stuff :

I did some test with thicker material and with material on the flank but it don't need to many lining .... maybe a better idea is to use 5mm felt on the floor, bottom and flanks.

Quick test setup to adjust the lining :

Accoustical tissu on the K apperture (visaton sc-50 and a stapler) :

(with a 10w LED COB lamp behind)

I was thinking about fixing the front baffle using threated nuts / steel screw-in socket (first vid here : Some shop solutions by Ron Walters) but the result was awfull ....

Those are perfect for real wood and plywood but with mdf 🙄. You hace to cut the hole a little bigger and fill it with diluated wood blue. The slice will absorb the blue and harden the MDF. Then make a new hole and try to set the insert ....

I choose to juste glue the front baffle ... after puted some coat of sealer close to the acoustical tissu. This explain the color difference on the pics (light aok varnish)

Some pics with the front glued (still a test setup):

I'm currently finishing the varnish (4/5 layers). Next is to make test about ground coupling / decoupling.

I'm happy about the sound. Directivity is outstanding. They are smooth/no fatiguing to listen to (I feel asleep at 5PM during classical music listening with a high sound level 😴 ...) and full of new details.

The (small) drawback is that the fréquency response fall at 70hz (nothing at 60hz 😕). During the test I don't used feet under them so I supposed it wiil disappeared next.

Right now they are way better than my previous fe85 builds and on par with the davis accoustics cadillac 1 mk2 I own (Davis Acoustics Kadillac 1 MK2). 😎

Xrk971 : if you still have the initial simulation, I'll need some more data 😛. I buy some informations plate :

I'll be so glad if you can give me a impedance curve and a max cone displacement/excursion curve (to set max power without high pass crossover) 😎

Here are some news of the fountek fr135ex karsonator 😀.

Final internal brassing :

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

With final lining stuff :

I did some test with thicker material and with material on the flank but it don't need to many lining .... maybe a better idea is to use 5mm felt on the floor, bottom and flanks.

An externally hosted image should be here but it was not working when we last tested it.

Quick test setup to adjust the lining :

An externally hosted image should be here but it was not working when we last tested it.

Accoustical tissu on the K apperture (visaton sc-50 and a stapler) :

An externally hosted image should be here but it was not working when we last tested it.

(with a 10w LED COB lamp behind)

An externally hosted image should be here but it was not working when we last tested it.

I was thinking about fixing the front baffle using threated nuts / steel screw-in socket (first vid here : Some shop solutions by Ron Walters) but the result was awfull ....

Those are perfect for real wood and plywood but with mdf 🙄. You hace to cut the hole a little bigger and fill it with diluated wood blue. The slice will absorb the blue and harden the MDF. Then make a new hole and try to set the insert ....

I choose to juste glue the front baffle ... after puted some coat of sealer close to the acoustical tissu. This explain the color difference on the pics (light aok varnish)

Some pics with the front glued (still a test setup):

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

I'm currently finishing the varnish (4/5 layers). Next is to make test about ground coupling / decoupling.

I'm happy about the sound. Directivity is outstanding. They are smooth/no fatiguing to listen to (I feel asleep at 5PM during classical music listening with a high sound level 😴 ...) and full of new details.

The (small) drawback is that the fréquency response fall at 70hz (nothing at 60hz 😕). During the test I don't used feet under them so I supposed it wiil disappeared next.

Right now they are way better than my previous fe85 builds and on par with the davis accoustics cadillac 1 mk2 I own (Davis Acoustics Kadillac 1 MK2). 😎

Xrk971 : if you still have the initial simulation, I'll need some more data 😛. I buy some informations plate :

An externally hosted image should be here but it was not working when we last tested it.

I'll be so glad if you can give me a impedance curve and a max cone displacement/excursion curve (to set max power without high pass crossover) 😎

Abusine,

Great looking build!

I am surprised you say there is nothing at 60Hz, the sim predicts F3 below 60Hz. Have you checked for air leaks? Perhaps a gasket on the driver bezel needed?

I will check Xmax and impedance curve etc for you.

I assume you are driving with the ACA amp? (Nice implementation btw) should make plenty of bass with that amp.

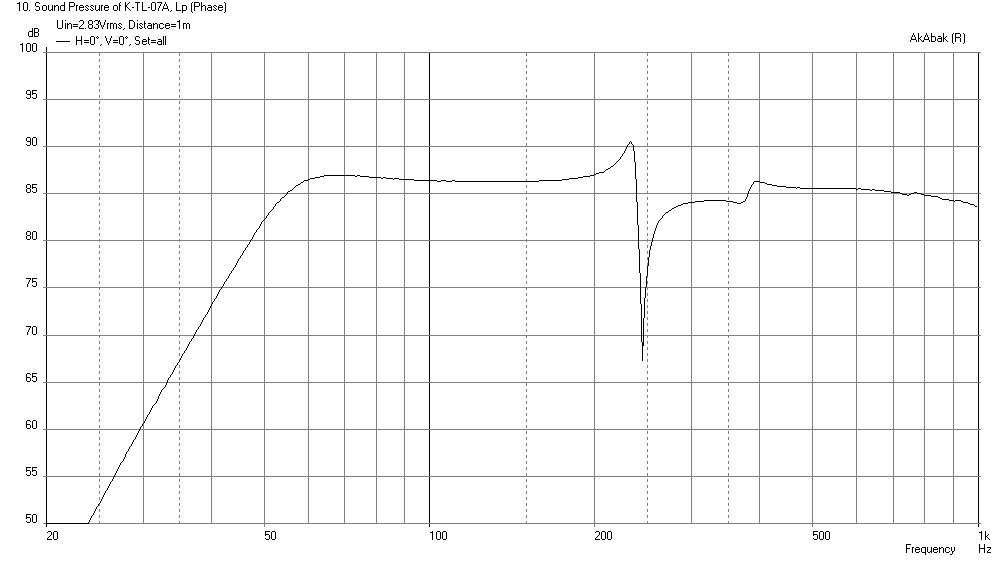

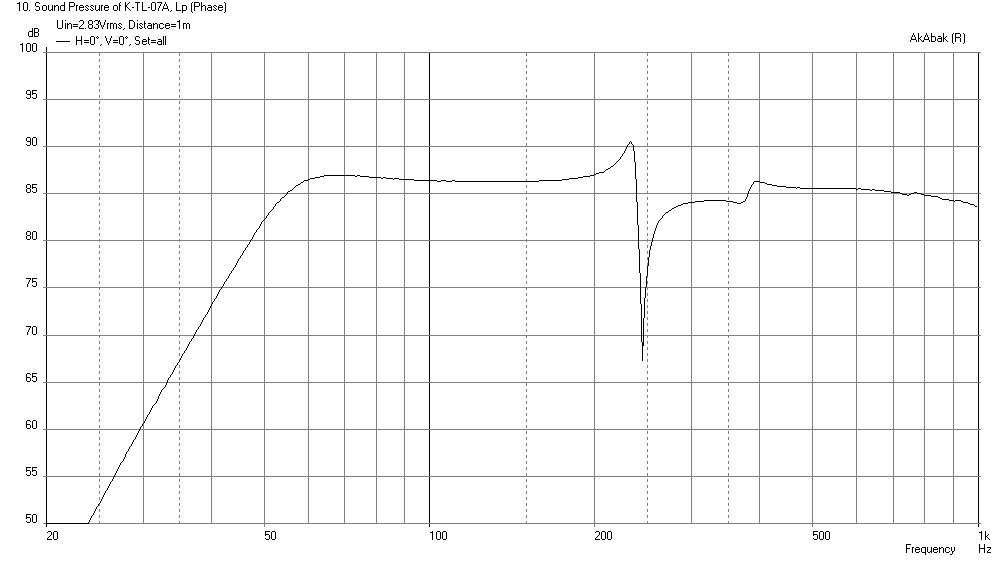

Here is sim again:

Great looking build!

I am surprised you say there is nothing at 60Hz, the sim predicts F3 below 60Hz. Have you checked for air leaks? Perhaps a gasket on the driver bezel needed?

I will check Xmax and impedance curve etc for you.

I assume you are driving with the ACA amp? (Nice implementation btw) should make plenty of bass with that amp.

Here is sim again:

All perfect : noob inside ...

Bass problem solved .... because there is none 😱

Test setup was using an android TV box as player and I quickly tested F3 using a "bass video tester" on youtube ....

. Big mistake from me to think this video was right

. Big mistake from me to think this video was right  .

.

Today I plugged to my PC and used WinISD as a frequence generator to check it again (with some varnish layers and rubber feet). This time every things is right and F3 is between 50 and 55Hz 😎.

Your simulation was done perfectly 😉.

They will be drived by an android box ==> Advance acoutics MDX600 DAC (pcm1796) until I make one 😀 ==> Objective2 as pre-amp (small box on the right) ==> ACA (23V).

Bass problem solved .... because there is none 😱

Test setup was using an android TV box as player and I quickly tested F3 using a "bass video tester" on youtube ....

. Big mistake from me to think this video was right

. Big mistake from me to think this video was right  .

.Today I plugged to my PC and used WinISD as a frequence generator to check it again (with some varnish layers and rubber feet). This time every things is right and F3 is between 50 and 55Hz 😎.

Your simulation was done perfectly 😉.

They will be drived by an android box ==> Advance acoutics MDX600 DAC (pcm1796) until I make one 😀 ==> Objective2 as pre-amp (small box on the right) ==> ACA (23V).

Glad all that worked out - great that the sims hold up 😀

I have heard great things about O2 as preamp. If you want to keep your preamp all class A, the JLH headphone amp is really good. Can drive speakers up to 1.6w too. $20 kit. I have this and it just makes my headphones sound incredible.

Online Shop 2016 NEW JLH HOOD1969 Class A Headphone Amplifier PRE AMP KIT DIY|Aliexpress Mobile

Will need a 15v 30va toroid from Antek ($11).

I have heard great things about O2 as preamp. If you want to keep your preamp all class A, the JLH headphone amp is really good. Can drive speakers up to 1.6w too. $20 kit. I have this and it just makes my headphones sound incredible.

Online Shop 2016 NEW JLH HOOD1969 Class A Headphone Amplifier PRE AMP KIT DIY|Aliexpress Mobile

Will need a 15v 30va toroid from Antek ($11).

- Great looking new Karlsonators - my Beta10cx/Karlsonator 12 has a LF corner of ~38Hz (its tuning fb)

1.6W is as good as those old cheap Norh triode-tied 6L6 amps - how warm will the heatsinks get? I had an Indeed hybrid starved triode/MOS SE amp which sounded very good with some headphones.

btw- the fellow with Nirvana Super 12 has finished his break-in run and published their specs - will they work in the Karlsonator12 without changing cabinet size ?

http://www.diyaudio.com/forums/full...anifold-horn-audio-nirvana-2.html#post4715072

1.6W is as good as those old cheap Norh triode-tied 6L6 amps - how warm will the heatsinks get? I had an Indeed hybrid starved triode/MOS SE amp which sounded very good with some headphones.

btw- the fellow with Nirvana Super 12 has finished his break-in run and published their specs - will they work in the Karlsonator12 without changing cabinet size ?

http://www.diyaudio.com/forums/full...anifold-horn-audio-nirvana-2.html#post4715072

Last edited:

- Great looking new Karlsonators - my Beta10cx/Karlsonator 12 has a LF corner of ~38Hz (its tuning fb)

1.6W is as good as those old cheap Norh triode-tied 6L6 amps - how warm will the heatsinks get? I had an Indeed hybrid starved triode/MOS SE amp which sounded very good with some headphones.

btw- the fellow with Nirvana Super 12 has finished his break-in run and published their specs - will they work in the Karlsonator12 without changing cabinet size ?

http://www.diyaudio.com/forums/full...anifold-horn-audio-nirvana-2.html#post4715072

Those heat sinks are small TO-220 ones and they are hot (can touch it for 8 seconds) but not excessive. If one were to mount the transistors and 7815/7915's to a larger finned heat sink 150mm x 60mm x 25mm ($5 from Ali) it would not be too warm at all.

I haven't had time to put the AN12 params in a sim yet. If he asks me directly I will but not going to run a sim of someone has not asked.

great work Albusine!

So new builder here and I'm about to try out the foam board .4x karlsonator with a single vifa tcd9fd. A couple of questions... how are you guys making the front aperture detachable; or at least the top two screws accessible.

Then I'm going to use BL21DE3's measurements for the box but noticed that the base measurements are an equal 17.5 cm. I was under the impression you should avoid a square base.

Any ideas?

Cheers

So new builder here and I'm about to try out the foam board .4x karlsonator with a single vifa tcd9fd. A couple of questions... how are you guys making the front aperture detachable; or at least the top two screws accessible.

Then I'm going to use BL21DE3's measurements for the box but noticed that the base measurements are an equal 17.5 cm. I was under the impression you should avoid a square base.

Any ideas?

Cheers

The base may be square but it's at the hairpin turn of TL so doesn't really matter. Also, a lot padding and damping is used at the bottom annealing the side walls to reduce reflections from the back cone.

The K aperture is screwed in place to small blocks of foam core (cleats) glued to the side wall of the front chamber. I stack 3 layers of foam core into a 0.75in x 1.0in cleat glued together with hot melt. Then use drywall screws to go through front into cleats. A double layer K aperture is probably best if you can make it.

The K aperture is screwed in place to small blocks of foam core (cleats) glued to the side wall of the front chamber. I stack 3 layers of foam core into a 0.75in x 1.0in cleat glued together with hot melt. Then use drywall screws to go through front into cleats. A double layer K aperture is probably best if you can make it.

Interesting, even when glued together, that the foam will be able to take dry walls. Thanks for the extra tips! Btw, I didn't want to bug you further you w/ pm's haha.

Idea throwing time. I used foam core to build the .4x's. Was thinking of using mod podge as a sealant to avoid warping when I use paint. Don't know what color yet but was wondering about chalk paint. The boxes aren't 100% perfect and hiding some imperfections would be ideal. Would chalk paint or any other method be a viable solution to essentially be a paint and filler?

Chalk paint, as I reckon atm, is just paint mixed in with powder/plaster that gives it a thicker consistency and a more antique look when finished; depending how you choose to finish it.

Do you have any suggestions for sealer --> paint that won't warp the foam?

Just started reading up on gesso. Seems to be a good sealer/primer and thick enough to be considered a filler. With enough sanding you could get a wood like finish before you start painting. This might be what I end up with using. Hopefully this is a little thing I can add to this huge thread 😉

Do you have any suggestions for sealer --> paint that won't warp the foam?

Just started reading up on gesso. Seems to be a good sealer/primer and thick enough to be considered a filler. With enough sanding you could get a wood like finish before you start painting. This might be what I end up with using. Hopefully this is a little thing I can add to this huge thread 😉

There is a spray on artwork sealer used to stabilize pastel drawings. It is light waterproof coating and smells like volatile based but because it is light and evaporates so quickly doesn't have time to melt the foam. I think modpodge is water based and may warp.

Yeah I had an edited response that didn't go through but, Mod podge is a no go. I'm going to try a little of this gesso stuff because its a sealer and is thick enough to hide all the numerous little creases and imperfections in the foam board. After this stuff and paint, you might be able to make a foam enclosure imitate a wooden one in appearances.

That's something to think about if you'd ever gift these speakers to a non enthusiast haha.

That's something to think about if you'd ever gift these speakers to a non enthusiast haha.

hi, im posting here the ts parameters for my driver- eminence beta8, which i started asking about in this thread.

http://www.diyaudio.com/forums/full-range/293050-straight-karlsonator.html

i'd like the karlsonator to be 90cm tall. (3 feet) and as narrow as possible. it can be bowling alley deep if it's going to get an extra octave in bass. 😀

thanks in advance for any guidance.

Resonant Frequency (Fs)65 Hz

DC Resistance (Re)5.99 ohms

Voice Coil Inductance (Le)0.49 mH

Mechanical Q (Qms)4.95

Electromagnetic Q (Qes)0.42

Total Q (Qts)0.38

Compliance Equivalent Volume (Vas)0.82 ft.³

Mechanical Compliance of Suspension (Cms)0.37 mm/N

BL Product (BL)9.60 TmDiaphragm Mass Inc.

Airload (Mms)16g

Maximum Linear Excursion (Xmax)3 mm

Surface Area of Cone (Sd)210 cm²

http://www.diyaudio.com/forums/full-range/293050-straight-karlsonator.html

i'd like the karlsonator to be 90cm tall. (3 feet) and as narrow as possible. it can be bowling alley deep if it's going to get an extra octave in bass. 😀

thanks in advance for any guidance.

Resonant Frequency (Fs)65 Hz

DC Resistance (Re)5.99 ohms

Voice Coil Inductance (Le)0.49 mH

Mechanical Q (Qms)4.95

Electromagnetic Q (Qes)0.42

Total Q (Qts)0.38

Compliance Equivalent Volume (Vas)0.82 ft.³

Mechanical Compliance of Suspension (Cms)0.37 mm/N

BL Product (BL)9.60 TmDiaphragm Mass Inc.

Airload (Mms)16g

Maximum Linear Excursion (Xmax)3 mm

Surface Area of Cone (Sd)210 cm²

In spirit of keeping this within a "budget" realm I used a cheap gesso with some left over cheap acrylic paint. The gesso is all in on sealer, glue and primer. After a couple coats dried you could tell that even though the paper kept some flexibility, so nothing will rattle, the box is significantly more rigid.

I'm running this A & B comparison with the untreated box and there is a clear difference in mid range clarity, etc. its ability to handle more aggressive guitar strums. Admittedly I didn't treat the inside of the boxes with much more than foam or extra bracing.

I had some leftover paint that ran out right when it splat all over one part of the front panel; hence why it just looks bad. With more even layers and foam brushes, the rest of the box surprisingly imitates wood grain pretty well.

I'm running this A & B comparison with the untreated box and there is a clear difference in mid range clarity, etc. its ability to handle more aggressive guitar strums. Admittedly I didn't treat the inside of the boxes with much more than foam or extra bracing.

An externally hosted image should be here but it was not working when we last tested it.

I had some leftover paint that ran out right when it splat all over one part of the front panel; hence why it just looks bad. With more even layers and foam brushes, the rest of the box surprisingly imitates wood grain pretty well.

Dozyproductions:

Nice work! Interesting that the paint improves the sound! Must be making it a bit more stiff. I have heard that gluing on a thin layer of aluminum foil will make a big difference in clarity.

Another happy build of an 0.40x K'nator

Nice work! Interesting that the paint improves the sound! Must be making it a bit more stiff. I have heard that gluing on a thin layer of aluminum foil will make a big difference in clarity.

Another happy build of an 0.40x K'nator

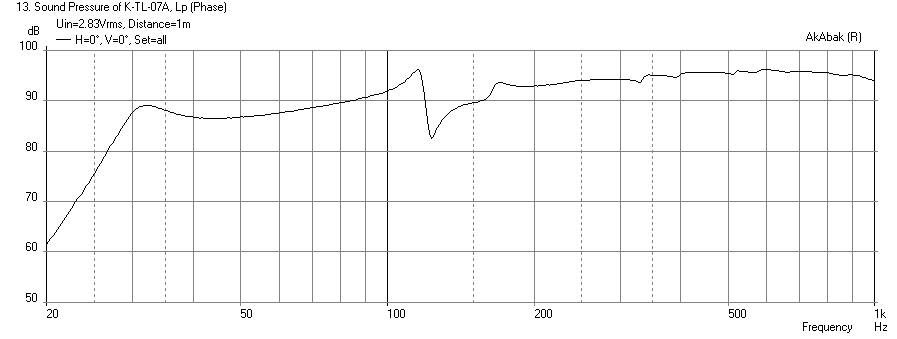

Beta 8A simulation

It looks like scaling the Karlsonator 12 plans by 1.20x in height and depth,and 0.63x in width allows the Beta 8A to have some pretty deep bass extension down to F3 of 28Hz with a sensitivity of 86dB. It's quite a bit down from nominal 95dB sensitivity but requirement of 3ft tall imposed a rather deep bass extension that suffers in sensitivity. Ideally, if you made am 0.80x scale by height and depth and 0.75x scale in width you would get a 92dB sensitive speaker with F3 of 43Hz.

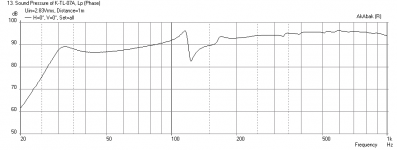

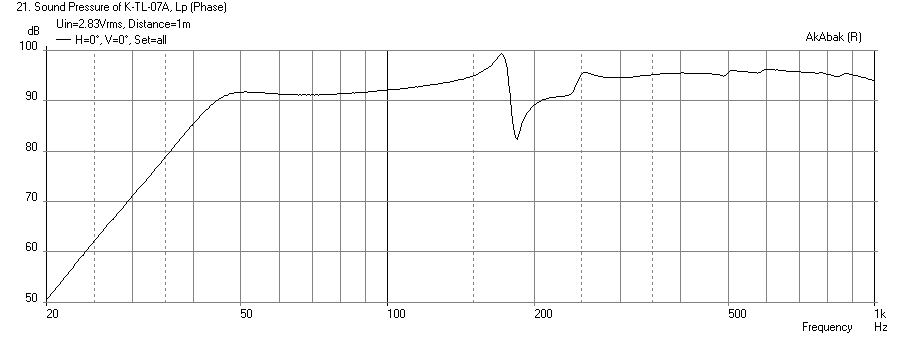

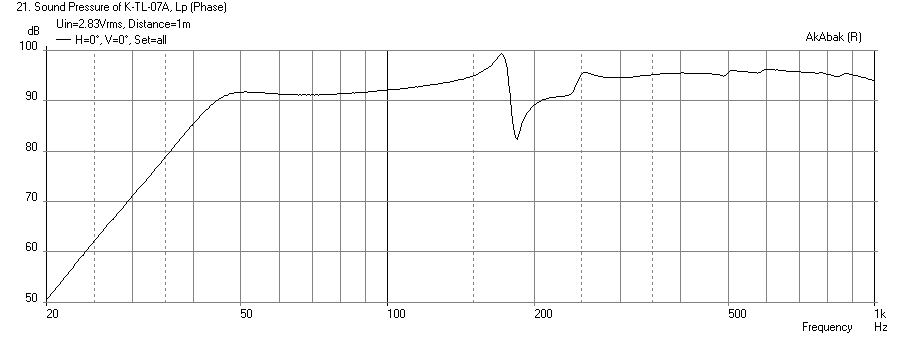

Here are sims for 3ft tall variant - frequency response (sags a bit due to too much volume):

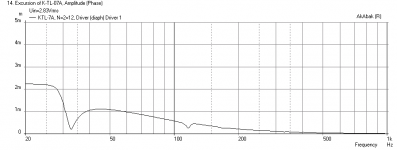

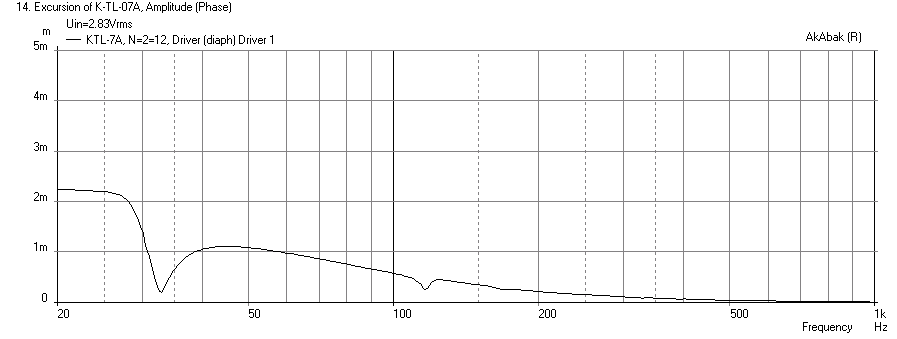

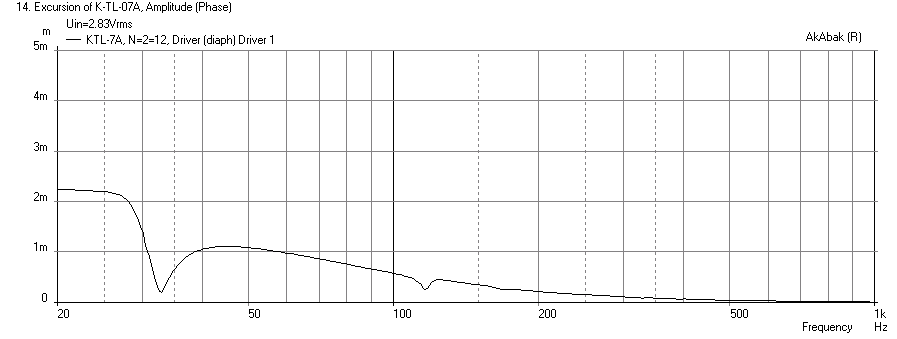

cone displacement:

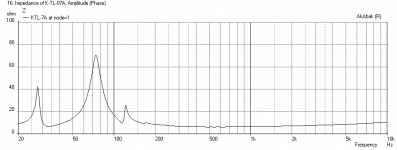

Impedance:

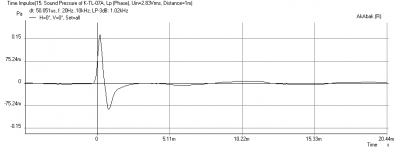

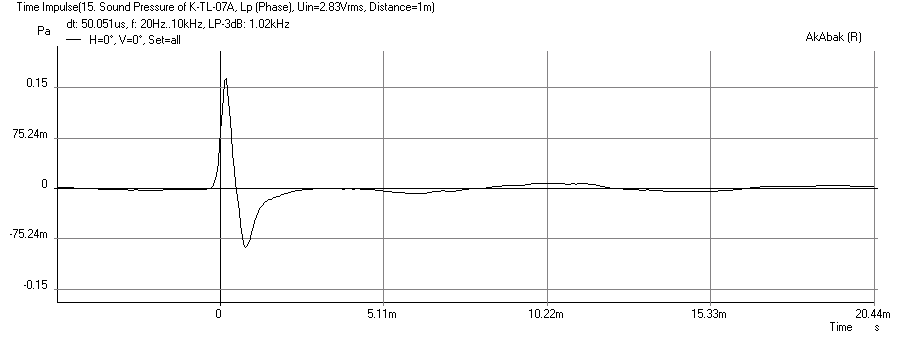

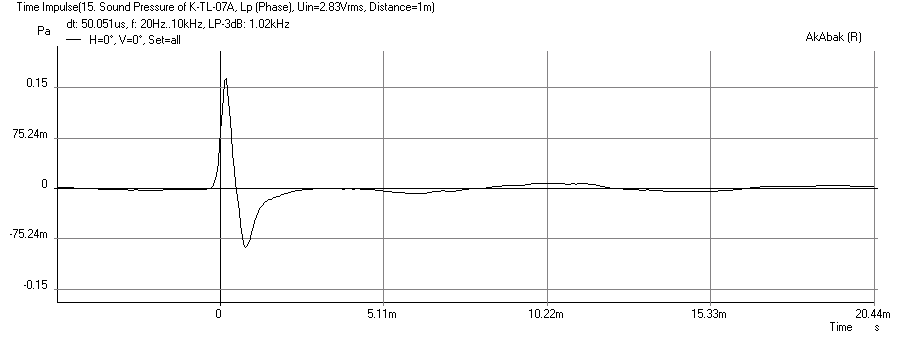

Impulse response:

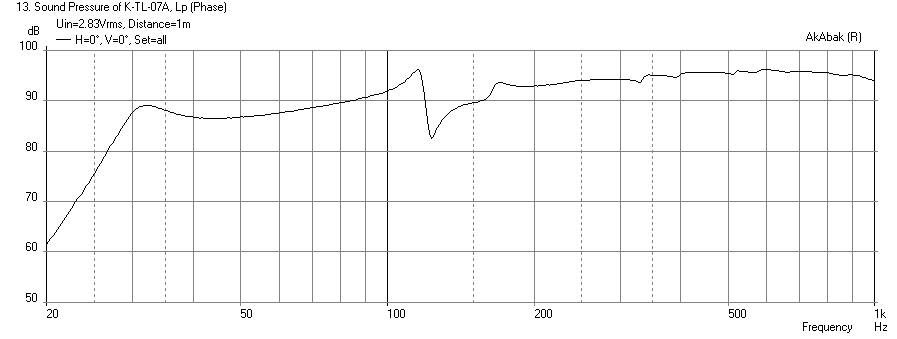

Here is the frequency response for 0.80x (24in) tall speaker:

hi, im posting here the ts parameters for my driver- eminence beta8, which i started asking about in this thread.

http://www.diyaudio.com/forums/full-range/293050-straight-karlsonator.html

i'd like the karlsonator to be 90cm tall. (3 feet) and as narrow as possible. it can be bowling alley deep if it's going to get an extra octave in bass. 😀

thanks in advance for any guidance.

Resonant Frequency (Fs)65 Hz

DC Resistance (Re)5.99 ohms

Voice Coil Inductance (Le)0.49 mH

Mechanical Q (Qms)4.95

Electromagnetic Q (Qes)0.42

Total Q (Qts)0.38

Compliance Equivalent Volume (Vas)0.82 ft.³

Mechanical Compliance of Suspension (Cms)0.37 mm/N

BL Product (BL)9.60 TmDiaphragm Mass Inc.

Airload (Mms)16g

Maximum Linear Excursion (Xmax)3 mm

Surface Area of Cone (Sd)210 cm²

It looks like scaling the Karlsonator 12 plans by 1.20x in height and depth,and 0.63x in width allows the Beta 8A to have some pretty deep bass extension down to F3 of 28Hz with a sensitivity of 86dB. It's quite a bit down from nominal 95dB sensitivity but requirement of 3ft tall imposed a rather deep bass extension that suffers in sensitivity. Ideally, if you made am 0.80x scale by height and depth and 0.75x scale in width you would get a 92dB sensitive speaker with F3 of 43Hz.

Here are sims for 3ft tall variant - frequency response (sags a bit due to too much volume):

cone displacement:

Impedance:

Impulse response:

Here is the frequency response for 0.80x (24in) tall speaker:

Attachments

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs