Digging through that thread makes me uncomfortably sweaty and antsy, i might stop to look at plywood on the way home from work....

Get it while supplies last! You never know! Black market ply is going to be expensive! ;-)

I also like to walk past and have a look at materials. Some shops have many different types of ply, lots of nice textures or whatyoucallit.

Question.....I calculate the 0.47x inside width at a little over 7 inches for the EL70. Is this correct? There was a build on here where 5 inches was recommended for the CHR70, but 0.42x calculates to 6.4 inches. Or am I referencing the wrong original drawing (GregB's Karlsonator)?

What thickness foam board for Mudjester 0.53x mini karlsonator with dual tc9fd. The thickest I can find in the uk is 10mm

Typical foam core in USA is 3/16in. But you should not worry about exact dimensions. If needed be build to internal dimensions. Don’t worry about being 5mm to even 10mm off. It’s very forgiving as a speaker design.

Question.....I calculate the 0.47x inside width at a little over 7 inches for the EL70. Is this correct? There was a build on here where 5 inches was recommended for the CHR70, but 0.42x calculates to 6.4 inches. Or am I referencing the wrong original drawing (GregB's Karlsonator)?

Nominal 1.0x scale internal width is 15in.

0.47x is about 7.05in and 0.42x is 6.3in. But don’t worry if you have to make it 1/8in up or down.

Hi All,

This may be a bit of a tangent, please let me know if I should be posting this elsewhere.

I just bought a somewhat large-volume 3D printer at 300x300x400mm. I have a couple TC9FD's kicking around from foamboard spiral horn builds a couple years ago, and I've wanted to print something for them.

I was browsing TC9FD ideas and came to this thread, and I've been working on modifying the design to be 3D printable with minimal supports.

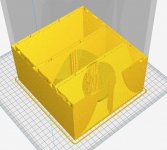

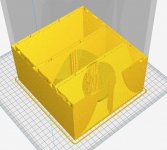

Here's what I Have so far. I've modified the bottom opening so that it's printable, but with the same area as the original design. It would be printed upright, including the sides, but not the top as it isn't printable in this orientation.

I welcome any thoughts, criticism, feedback etc before I start printing. I've smoothed some of the edges/etc, but is there anything else I could/should do since I'm not constrained by foamboard?

Thanks in advance!

(would be happy to provide the Solidworks files for anyone who'd like them)

The design:

![2018-03-18 16_08_46-SOLIDWORKS Premium 2017 x64 Edition - [printable.SLDPRT _].png 2018-03-18 16_08_46-SOLIDWORKS Premium 2017 x64 Edition - [printable.SLDPRT _].png](https://www.diyaudio.com/community/data/attachments/601/601090-db17b40f81a1ed58d2fbc1a2dd918894.jpg?hash=2xe0D4Gh7V)

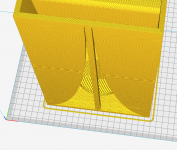

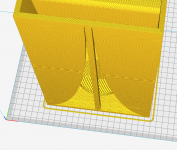

The slicer view (note the supports for the arcs and front panel:

This may be a bit of a tangent, please let me know if I should be posting this elsewhere.

I just bought a somewhat large-volume 3D printer at 300x300x400mm. I have a couple TC9FD's kicking around from foamboard spiral horn builds a couple years ago, and I've wanted to print something for them.

I was browsing TC9FD ideas and came to this thread, and I've been working on modifying the design to be 3D printable with minimal supports.

Here's what I Have so far. I've modified the bottom opening so that it's printable, but with the same area as the original design. It would be printed upright, including the sides, but not the top as it isn't printable in this orientation.

I welcome any thoughts, criticism, feedback etc before I start printing. I've smoothed some of the edges/etc, but is there anything else I could/should do since I'm not constrained by foamboard?

Thanks in advance!

(would be happy to provide the Solidworks files for anyone who'd like them)

The design:

![2018-03-18 16_08_46-SOLIDWORKS Premium 2017 x64 Edition - [printable.SLDPRT _].png 2018-03-18 16_08_46-SOLIDWORKS Premium 2017 x64 Edition - [printable.SLDPRT _].png](https://www.diyaudio.com/community/data/attachments/601/601090-db17b40f81a1ed58d2fbc1a2dd918894.jpg?hash=2xe0D4Gh7V)

The slicer view (note the supports for the arcs and front panel:

Last edited:

Great idea - but you need to add braces between the large panels. There should not be any span larger than 2-3in without a brace. Since printing - I would print “foam” panels by making interior porous - maybe 30% fill and sheathed by 3 layers of solid to make airtight. This saves filament and makes it faster to print and gives property similar to foam core which sounds better than plywood.

Great idea - but you need to add braces between the large panels. There should not be any span larger than 2-3in without a brace. Since printing - I would print “foam” panels by making interior porous - maybe 30% fill and sheathed by 3 layers of solid to make airtight. This saves filament and makes it faster to print and gives property similar to foam core which sounds better than plywood.

Thank you for the reply and helpful information.

If my understanding is correct, the braces are to prevent flex and especially resonance?

If this is the case, out of curiosity would non-uniform panels resolve the issues? Something like this (smooth on the inside):

![2018-03-18 17_13_08-SOLIDWORKS Premium 2017 x64 Edition - [ribbed.SLDPRT _].png 2018-03-18 17_13_08-SOLIDWORKS Premium 2017 x64 Edition - [ribbed.SLDPRT _].png](https://www.diyaudio.com/community/data/attachments/601/601210-92c9aacbcb60108c2ddb931f1b492638.jpg?hash=ksmqy8tgEI)

![2018-03-18 17_15_21-SOLIDWORKS Premium 2017 x64 Edition - [ribbed.SLDPRT _].png 2018-03-18 17_15_21-SOLIDWORKS Premium 2017 x64 Edition - [ribbed.SLDPRT _].png](https://www.diyaudio.com/community/data/attachments/601/601229-bcb9ed55e5af27ce496ef258101b8b84.jpg?hash=vLntVeWvJ8)

So, if I did my math correctly (scaling up from a 0.53), a 1.0 Karlsonator is 31" tall by 16.75" wide and 17.75 deep.

My thought was to make a sub about that size, and put it as the bottom of my 19" rack. However that means it will be close to the back wall and on the ground (or very close to it).

Two questions:

1) how bad a position would that be for a Karlsonator? I know some bass boxes like to be in corners, but I thought I remembered that Karlsonators prefer some breathing room.

2) if it's not too bad a position for the sub, what are some of the parameters I'm looking for in a single sub to put in the box? In a different thread (MOAK?), xrk971 mentioned 'moderate Qts w/ paper cone, 10" or 12" in diam' (or so my notes say), and referenced a DC 250-8, which has a Qts of 0.38... Anything else to look for to help make this a better fit? Looking for low bass, as the dual 3FE25-16s should handle everything else.

I'm not dead set on a K-box, but some of them have been drop-dead gaaaw-jus! I really like the idea of a two tone, sides dark, and the K panel in a light tone, possibly with a fabric insert (cats in the house). However, the location (in or adjacent to the rack) is a fairly solid requirement. If not a Karlsonator, what might live in such a space and go fairly low (ideally 25-30Hz up to about 100-120Hz for the crossover to the 3FE25-16s)?

My thought was to make a sub about that size, and put it as the bottom of my 19" rack. However that means it will be close to the back wall and on the ground (or very close to it).

Two questions:

1) how bad a position would that be for a Karlsonator? I know some bass boxes like to be in corners, but I thought I remembered that Karlsonators prefer some breathing room.

2) if it's not too bad a position for the sub, what are some of the parameters I'm looking for in a single sub to put in the box? In a different thread (MOAK?), xrk971 mentioned 'moderate Qts w/ paper cone, 10" or 12" in diam' (or so my notes say), and referenced a DC 250-8, which has a Qts of 0.38... Anything else to look for to help make this a better fit? Looking for low bass, as the dual 3FE25-16s should handle everything else.

I'm not dead set on a K-box, but some of them have been drop-dead gaaaw-jus! I really like the idea of a two tone, sides dark, and the K panel in a light tone, possibly with a fabric insert (cats in the house). However, the location (in or adjacent to the rack) is a fairly solid requirement. If not a Karlsonator, what might live in such a space and go fairly low (ideally 25-30Hz up to about 100-120Hz for the crossover to the 3FE25-16s)?

What thickness foam board for Mudjester 0.53x mini karlsonator with dual tc9fd. The thickest I can find in the uk is 10mm

Where do you buy your 10mm in UK? I'd like to try that.

I get my 5mm from The Range (UK) which is the cheapest I've found at £10 for 4 sheets A1 size.

a Karlsonator12 would probably be ok as a sub with a moderate Q 12" speaker. When built to the original plan below, tuning is ~37Hz

https://lh6.googleusercontent.com/-.../AAAAAAAABik/txissf4J4PI/s800/Karlsonator.png

MMJ could suggest a Karlflex , and xrk971, either XKi or Karlsonator

https://lh6.googleusercontent.com/-.../AAAAAAAABik/txissf4J4PI/s800/Karlsonator.png

MMJ could suggest a Karlflex , and xrk971, either XKi or Karlsonator

What thickness foam board for Mudjester 0.53x mini karlsonator with dual tc9fd. The thickest I can find in the uk is 10mm

Oh geez, that's a mistake. I should have included the thickness in the drawing. Thanks for pointing that out. If you find any other mistakes, please let me know.

As XRK said, the design is for 3/16" foam core boards that are easy to find here in the USA. That's pretty close to 5 mm.

foam core boards that are easy to find here in the USA.

I really wonder what this stuff is called in german speaking countries like Austria.

In France. they call it carton de mousse, and it is plentiful at arts and crafts stores.

carton de mousse chez Rougier & Ple

In Germany try here:

Attention Required! | Cloudflare

Attention Required! | Cloudflare

carton de mousse chez Rougier & Ple

In Germany try here:

Attention Required! | Cloudflare

Attention Required! | Cloudflare

Hello!

After the recommendation in my noob asking thread, I about to build my first DIY speakers: 0.53X Karlsonator with dual 3fe25 16ohm. Very excited about the project and listen to them 🙂

Right now I am getting everything to build them, I have already ordered the 3fe25 and I am looking for the foam core boards (not so easy to buy here in Spain, and definitely no so cheap!). Question about them, 5mm is the right thickness, is it?

About the stuffing, it looks like more an art than a science, and that troubles me because I could be good in science but not in arts... I have seen over the thread pillow foam and some black dense foam in some walls. I have around some 2mm cork sheet, would it be OK as panel stuffing? Any advice on this?

I'll keep you informed with my building progress as soon I have something built 🙂

After the recommendation in my noob asking thread, I about to build my first DIY speakers: 0.53X Karlsonator with dual 3fe25 16ohm. Very excited about the project and listen to them 🙂

Right now I am getting everything to build them, I have already ordered the 3fe25 and I am looking for the foam core boards (not so easy to buy here in Spain, and definitely no so cheap!). Question about them, 5mm is the right thickness, is it?

About the stuffing, it looks like more an art than a science, and that troubles me because I could be good in science but not in arts... I have seen over the thread pillow foam and some black dense foam in some walls. I have around some 2mm cork sheet, would it be OK as panel stuffing? Any advice on this?

I'll keep you informed with my building progress as soon I have something built 🙂

In France. they call it carton de mousse, and it is plentiful at arts and crafts stores.

carton de mousse chez Rougier & Ple

In Germany try here:

Attention Required! | Cloudflare

Attention Required! | Cloudflare

Thank you, XRK! I found a dealer here in Vienna.

Foamcore is called KapaLine hereabouts...

Foamcore is called KapaLine hereabouts...Hello!

After the recommendation in my noob asking thread, I about to build my first DIY speakers: 0.53X Karlsonator with dual 3fe25 16ohm. Very excited about the project and listen to them 🙂

Right now I am getting everything to build them, I have already ordered the 3fe25 and I am looking for the foam core boards (not so easy to buy here in Spain, and definitely no so cheap!). Question about them, 5mm is the right thickness, is it?

About the stuffing, it looks like more an art than a science, and that troubles me because I could be good in science but not in arts... I have seen over the thread pillow foam and some black dense foam in some walls. I have around some 2mm cork sheet, would it be OK as panel stuffing? Any advice on this?

I'll keep you informed with my building progress as soon I have something built 🙂

You don’t need cork. Felt lining behind drivers is good idea. Don’t worry about the stuffing too much. Just put some in the closed end (more dense) and pull some apart to make less dense (loosely packed) for stuffing right behind the drivers all the way to the bottom. The back divider behind drivers should have a layer of felt or open cell foam to reduce direct back reflection.

So yesterday i finished the first 0.53 with the dual 3fe25, i messed up a few things during cutting and glueing so it ended up a bit ugly, will redo this one and make it prettier.

However, i don't know whether it is because of expectations or if the things i messed up made it worse but i am not impressed so far.

Without BSC it doesn't go very low at all and sounds a bit boxy(to little/too much stuffing?) and with bsc it goes a bit lower but it sounds like it is missing something and it sounds distorted.

i used a 1.2ohm 10w resistor and a 0.82mh inductor for the bsc, will try ordering a 0.9mh inductor with less resistance because the one i'm using is taken from a slaughtered pioneer speaker and it has thin copper wire on it.

I expected them to sound atleast as good as my current speakers but i think they are quite far from it right now (current speakers are Omage av21).

I am also considering building it in Liteply instead of foamboard, the foamboard is 5mm and the liteply is 4mm, do you think that could work?

I have found lite ply for the same price as foamboard, all sheets are a bit deformed and not 100% flat, do you think i could use it and make it straight with some bracing (which would be needed anyways)?

However, i don't know whether it is because of expectations or if the things i messed up made it worse but i am not impressed so far.

Without BSC it doesn't go very low at all and sounds a bit boxy(to little/too much stuffing?) and with bsc it goes a bit lower but it sounds like it is missing something and it sounds distorted.

i used a 1.2ohm 10w resistor and a 0.82mh inductor for the bsc, will try ordering a 0.9mh inductor with less resistance because the one i'm using is taken from a slaughtered pioneer speaker and it has thin copper wire on it.

I expected them to sound atleast as good as my current speakers but i think they are quite far from it right now (current speakers are Omage av21).

I am also considering building it in Liteply instead of foamboard, the foamboard is 5mm and the liteply is 4mm, do you think that could work?

I have found lite ply for the same price as foamboard, all sheets are a bit deformed and not 100% flat, do you think i could use it and make it straight with some bracing (which would be needed anyways)?

Last edited:

So yesterday i finished the first 0.53 with the dual 3fe25, i messed up a few things during cutting and glueing so it ended up a bit ugly, will redo this one and make it prettier.

However, i don't know whether it is because of expectations or if the things i messed up made it worse but i am not impressed so far.

Without BSC it doesn't go very low at all and sounds a bit boxy(to little/too much stuffing?) and with bsc it goes a bit lower but it sounds like it is missing something and it sounds distorted.

i used a 1.2ohm 10w resistor and a 0.82mh inductor for the bsc, will try ordering a 0.9mh inductor with less resistance because the one i'm using is taken from a slaughtered pioneer speaker and it has thin copper wire on it.

I expected them to sound atleast as good as my current speakers but i think they are quite far from it right now (current speakers are Omage av21).

I am also considering building it in Liteply instead of foamboard, the foamboard is 5mm and the liteply is 4mm, do you think that could work?

I have found lite ply for the same price as foamboard, all sheets are a bit deformed and not 100% flat, do you think i could use it and make it straight with some bracing (which would be needed anyways)?

Hi hehejaa - sorry to hear your first speaker sounds disappointing. Forget about Liteply - first try to get the foamboard speaker to sound as it should. Post some photos (stuffing, speaker wiring etc), then we can help you to solve possible issues.

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs