The suggestion that a square horn won't produce a spherical wavefront is wrong. It will, just with a square cross section. A square throat, however makes it much harder at high frequencies without a phase plug, which is harder to do for square, but POOH is specifically referring to low frequency horns..Here's someone who emphatically prefers rectangular.

http://www.diyaudio.com/forums/multi-way/100392-beyond-ariel-952.html#post3687058

While a non-round horn can obscure the dip, it isn't necesarily a cure. Nor is the on-axis dip necessarily a problem.Also, in some applications, a round horn will give an on-axis dip.

Here's someone who emphatically prefers rectangular.

http://www.diyaudio.com/forums/multi-way/100392-beyond-ariel-952.html#post3687058

Thanks for chiming in!

I believe, as AllenB mentions in a later post, Pooh was referring to bass horns. He uses round midrange and treble horns as far as I know. He was actually a key contributor to my horn 101 thread, and in my choice of Faital M5N12-80 as the driver for this application.

Would you mind sharing some of that, or pointing me to a thread?I did a lot of trials with 4" wideband drivers in 2015, and got a similar (huge) on-axis dip with a round horn, better results with a rectangular one - but my horns were also different sizes, so not a perfect comparison.

I noticed Bruce Edgar started with his rectangular tractrix midrange horn, but eventually moved onto circular midrange horns. Not sure, though, if the circular horns were operating at the same frequencies as the 400Hz rectangular tractrix.

Looking to DIY rather than buying off-the shelf horns. Logistics of large and light objects to Argentina is a pain. Plus DIY is a lot more fun.If you have deep pockets, the large Iwata horns (as made by Auto-Tech of Poland) look like the best of both worlds. For a couple thousand $ less, you can just start with standard biradial horns and extend them to have whatever mouth shape you fancy.

I have. Actually Manninen has tried that with a TPL and a (I think) JBL midrange horn. Results were not good and he dropped the idea. At the time I thought his approach was a bit unoptimized as he simply placed the TPL-150H in front of a midrange horn without any sort of aerodynamic cover to the back of the TPL, in my mind leading to many unwanted reflections. It appears to me the size of the TPL is just too big for this to work well, and the fact people are doing synergy horns but not this kind also suggest something, I think.As a final thought: since you are using DSP and can use digital delay, have you considered mounting the TPL coaxially, in the midhorn's mouth?

I realise the TPL is huge (by tweeter standards), and would "shade" the mid horn considerably, so you'd have to streamline it / design around it.

There are three ways to go with a straight axis horn. 1 ) Make the back chamber sealed.

That is what I'm going with. Thanks for the other clarifications.

Correct. For the time being my drafted system includes a pair of 10" woofers per side, each in its sealed box, running from 80Hz to the xo pint of the midrange horn, which as of now is 350/400Hz. Lately I've been further intrigued by replacing that with a midbass horn with its own driver, but let's not get into that here/now.As the topic of the thread is about constructing a mid-range horn I assume there would be some sort of bass cabinet used in addition to the system. It is my opinion in this case, that the speaker chamber for the mid horn should be sealed. An educated guess tells me the speaker chamber for the Faital driver is going to be quite small, so venting is not only unnecessary, but out of the question unless the vent is just a hole.

I am going with a sealed rear chamber. The rear chamber that sets the electrical impedance peak 10Hz above fc si 1.3 liter (or 79 cubic inches). Small indeed. I should have dummy chambers built out of 6" PVC pipes done this week. Lined with fiberglass.

Let's explore rectangular horns further. What kind of profile would you suggest for the width, and which one for the height?

So far I have decided on the driver, have set a sealed rear chamber with tuned electrical impedance. The throat size will equal Sd. The mouth size is set such that fc=215Hz, while the intended xo point is 400Hz. I believe I should now decide the profile and that will dictate the length, and then I can build something 🙂

Let's explore rectangular horns further. What kind of profile would you suggest for the width, and which one for the height?

I will leave to mouth dimensions to you. There are plenty articles published on directivity index based on horn mouth geometry. You probably know this, but be sure to adjust the volume of the camber to accommodate the added volume of the driver assembly.

The length of your horn will be based on the mouth dimensions you decide on, whether it be Exponential or Tractrix.

BTW - You may want to experiment with the amount of damping material you use. Too much will affect the sound of the cone.

Good luck with your project.

Last edited:

Here's someone who emphatically prefers rectangular.

I've seen the Iwata being discussed in the large JMLC horn thread, is there a difference between Iwata and Iwata-JMLC horns?

Edgar Style and Great sound !!

My 2 cents:

For an Edgar Tractrix, there is no reactance nulling, but I really do think it is still a very good idea to use a flare rate one octave lower than your Fcx. Your choice of 215 Hz is just fine. With a driver such as the Faital having a relatively stiff suspension AND the fact that Bruce found the best results with an open back, I would recommend that a box for the back wave may not be the best solution for optimum sound quality. Then again, I would not use an open back, either. Just my own personal choice, because I don't like a back wave splaying about the room. It adds a false rear wave reflection that some think is added "depth", but it is indeed false. What I use is an "acoustic tunnel". Even though I am currently using round horns; I would do the same for rectangular. The tunnel does not raise the driver's free air resonance, but does absorb just enough of the back wave, so as not to be bothersome. The inner circumference of said tube is lined with pink panther (non-faced, one inch) and the rest of the volume void is filled with acoustic fiber-fill. This is only what has worked well for me, and in no way do I mean that my method is some sort of holy gospel that all others should follow. I just wanted to share the info. Happy Listening to all.

My 2 cents:

For an Edgar Tractrix, there is no reactance nulling, but I really do think it is still a very good idea to use a flare rate one octave lower than your Fcx. Your choice of 215 Hz is just fine. With a driver such as the Faital having a relatively stiff suspension AND the fact that Bruce found the best results with an open back, I would recommend that a box for the back wave may not be the best solution for optimum sound quality. Then again, I would not use an open back, either. Just my own personal choice, because I don't like a back wave splaying about the room. It adds a false rear wave reflection that some think is added "depth", but it is indeed false. What I use is an "acoustic tunnel". Even though I am currently using round horns; I would do the same for rectangular. The tunnel does not raise the driver's free air resonance, but does absorb just enough of the back wave, so as not to be bothersome. The inner circumference of said tube is lined with pink panther (non-faced, one inch) and the rest of the volume void is filled with acoustic fiber-fill. This is only what has worked well for me, and in no way do I mean that my method is some sort of holy gospel that all others should follow. I just wanted to share the info. Happy Listening to all.

Attachments

sort huge variovant or at least cardioid ?

MaYbe a short closed thick foam back chamber can cancell enough the backwave aswell.

MaYbe a short closed thick foam back chamber can cancell enough the backwave aswell.

... to illustrate the spatial significance of an on-axis measurement on a round horn.

Attachments

Last edited:

My 2 cents:

Scott,

Thanks for remainding me about Bruce's (Pooh) experience with this driver and without a sealed back chamber. Actually, the way I'm building my dummy back chamber with a PVC pipe and the corresponding cap, I can test a sealed chamber and an open end as you do with ease.

What are your crossover points between the AMT and midrange horn, and to the midbass? What are your thoughts about lobbing, considering the spacing between your AMT and midrange horn?

Cheers

Thanks for chiming in!

I believe, as AllenB mentions in a later post, Pooh was referring to bass horns.

You are right - silly oversight on my part.

Would you mind sharing some of that, or pointing me to a thread?

This thread is some of my rambling, for what it's worth.

1) My measurements are a bit sketchy (room effects etc)

2) It's hard to know what's a driver effect and whats a horn effect

The on-axis HF garbage was pretty repeatable, and fiddling with throat size and mounting gaskets didn't fix it. Mind you, the conical horns sound better than they measure - a bad measurement at only one location is not the end of the world (I think this is what AllenB is getting at). It just happens to be the location spec sheets use most often.

http://www.diyaudio.com/forums/full-range/280220-fostex-ff105wk-conical-horn-2.html#post4501868

Looking to DIY rather than buying off-the shelf horns. Logistics of large and light objects to Argentina is a pain. Plus DIY is a lot more fun.

Of course, whatever works for you. I like DIY, but I chose to modify some off the shelf horns, to avoid two of my bad habits:

1) scrapping projects, usually with only one channel built, and starting over. Less likely to do this if I started with two.

2) staying stuck in the planning phase forever. Having a good core to work from narrowed the design space in a good way (for me).

I have. Actually Manninen has tried that with a TPL and a (I think) JBL midrange horn. Results were not good and he dropped the idea. At the time I thought his approach was a bit unoptimized as he simply placed the TPL-150H in front of a midrange horn without any sort of aerodynamic cover to the back of the TPL, in my mind leading to many unwanted reflections. It appears to me the size of the TPL is just too big for this to work well

23cm is indeed a big tweeter.

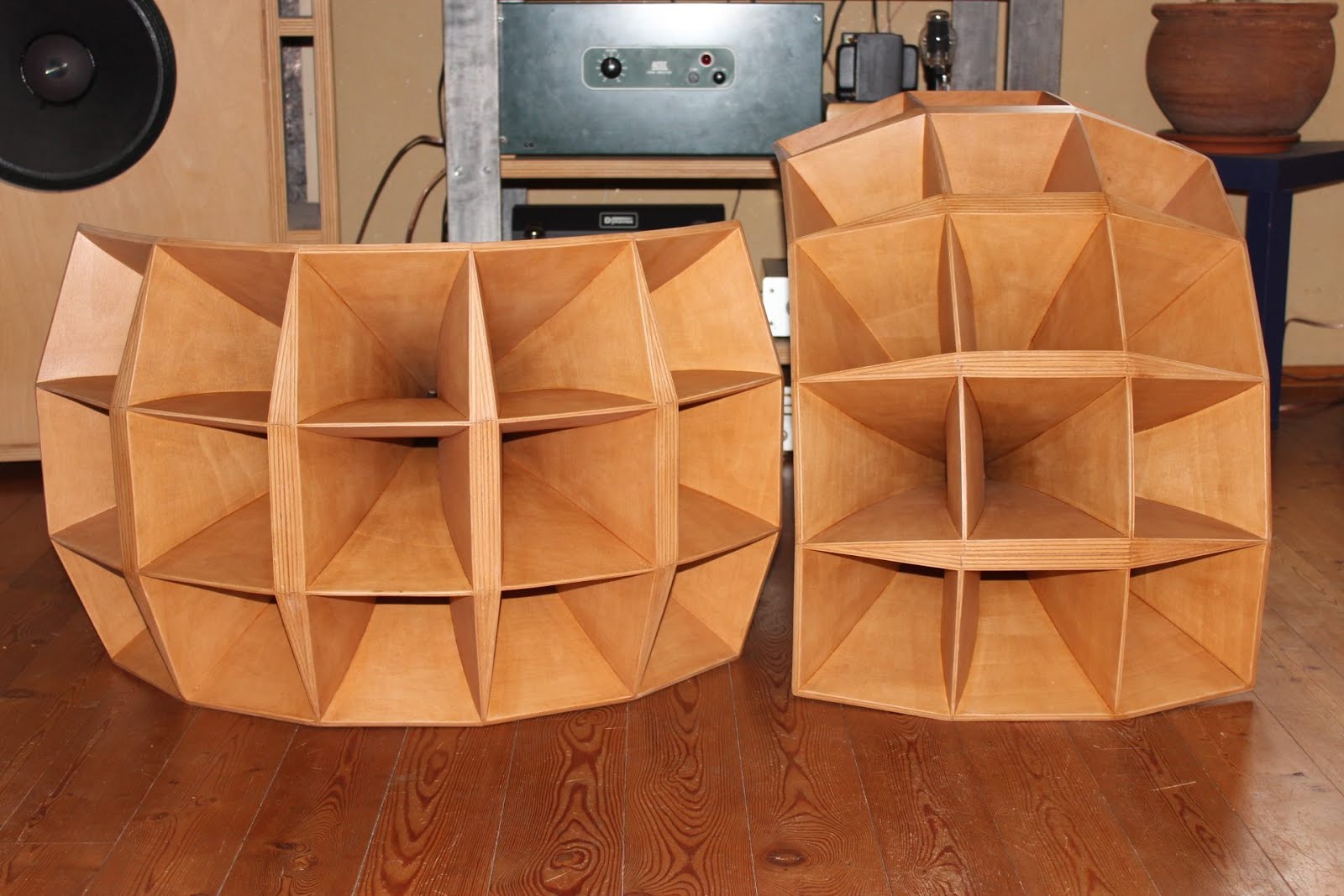

Looking at the pictured multicell: imagine if one built only the centre cell, and used that as the TPL mount. That's the sort of thing I'm envisaging as the 'aerodynamic cover'. Like mounting the TPL in a huge phase plug.

and the fact people are doing synergy horns but not this kind also suggest something, I think.

How loose a definition of 'this kind of thing' would you allow?

What I'm suggesting is basically the same layout as a ye olde coaxial driver, like the Altec 604.

http://www.greatplainsaudio.com/downloads/604_8H_III.pdf

These have their fans. I enjoy listening to P-Audio copies of this driver 🙂

The existence of the Danley SM100 shows that Mr Danley still finds a coaxial to be a good solution, in some instances.

Scott,

Thanks for remainding me about Bruce's (Pooh) experience with this driver and without a sealed back chamber. Actually, the way I'm building my dummy back chamber with a PVC pipe and the corresponding cap, I can test a sealed chamber and an open end as you do with ease.

What are your crossover points between the AMT and midrange horn, and to the midbass? What are your thoughts about lobbing, considering the spacing between your AMT and midrange horn?

Cheers

I have had the misfortune not once, but twice to audition the Bruce Edgar system. Once at a trade show where he was present, and the other in home of one of his customers. Never before have I heard such a horrid sounding system. That round Tractrix horn of his with the 2 inch compression driver sounded like broken glass.

sort huge variovant or at least cardioid ?

MaYbe a short closed thick foam back chamber can cancell enough the backwave aswell.

Only at wavelengths that are much less than the dimensions of the enclosure. Where the wavelengths are greater than any dimension of the box there will be no cancellation.

What damping material does in a loud speaker enclosure, is attenuate high frequencies, and reduces the velocity of sound at low frequencies. Meaning, the acoustical tangle results in a situation where it takes the longer waves more time to pass through the material, then upon returning to their origin, again taking the waves longer to pass through the material a second time before it reaches the speaker. In essence, damping material 'fools' the speaker when producing low frequencies into behaving as if it is in a larger enclosure.

This is a routine I used to use, showing the weighting I applied to angular measurements from 0 to 90 degrees (for combining into a power response).a bad measurement at only one location is not the end of the world (I think this is what AllenB is getting at).

This is showing wider measurement angles being geometrically more significant, in that they represent a larger area of the wavefront.. On the other hand the wider angles may also show lower pressures so that the angle most representative of the nature of the power response is most likely an intermediate angle.

Attachments

Good answer, thanks.

Checking that I understand / thinking 'out loud'

Checking that I understand / thinking 'out loud'

on-axis (the 0-10 degree region) is 0.00349 / 1 of the total area of the hemisphere

The 10-90 degree region is thus 1-0.00349 or 99.651% of the area of the hemisphere that a driver is firing into, hence matters a bunch (technical term) more than the on-axis

The power calculation is multiplying the area of each region by its relative SPL

They do. Diffraction effects are widely spread, but with a round horn they tend to focus when on axis, as may standing waves whereas a less regular shape may promote a wider but less intense focus. Fortunately, good optimum listening angles are found elsewhere with a round conical.Mind you, the conical horns sound better than they measure - <snip> It just happens to be the location spec sheets use most often.

Essentially. Looking back I may have used 0-5, then 5-15, 15-25 etc. At the time of that screen shot they were out by 0.4% but the point remains the same.

- on-axis (the 0-10 degree region) is 0.00349 / 1 of the total area of the hemisphere

- The 10-90 degree region is thus 1-0.00349 or 99.651% of the area of the hemisphere that a driver is firing into, hence matters a bunch (technical term) more than the on-axis

- The power calculation is multiplying the area of each region by its relative SPL

As for the power response yes that's correct, but also taking into account that power is 10*log(magnitude) and pressure is 20*log(magnitude).

Last edited:

I have had the misfortune not once, but twice to audition the Bruce Edgar system. Once at a trade show where he was present, and the other in home of one of his customers. Never before have I heard such a horrid sounding system. That round Tractrix horn of his with the 2 inch compression driver sounded like broken glass.

Quick clarification, FWIW: The Bruce referred to above is the forum member Pooh and not Bruce Edgar. Nevertheless it is interesting you didn't like Edgarhorn sound. I never hear any myself, but about everything I read suggest they sounded good. Goes to show taste is a big part of the equation.

This thread is some of my rambling, for what it's worth.

1) My measurements are a bit sketchy (room effects etc)

2) It's hard to know what's a driver effect and whats a horn effect

The on-axis HF garbage was pretty repeatable, and fiddling with throat size and mounting gaskets didn't fix it. Mind you, the conical horns sound better than they measure - a bad measurement at only one location is not the end of the world (I think this is what AllenB is getting at). It just happens to be the location spec sheets use most often.

http://www.diyaudio.com/forums/full-range/280220-fostex-ff105wk-conical-horn-2.html#post4501868

Thanks for providing the link. From what I can gather from the graphs you posted, the round vs oval horn produced very similar results, especially within the band I'm interested in.

BTW, going through the thread I saw again Xrk's Edgar Tractrix with the PRV driver, which measures rather good and he says it sounds good. Good remainder for me.

Nice multicell! I see what you mean now. And it might work. But I seriously doubt the multicell would be allowed in the living room by my wife 😱. I'm skating on thin ice when it comes to horns!Looking at the pictured multicell: imagine if one built only the centre cell, and used that as the TPL mount. That's the sort of thing I'm envisaging as the 'aerodynamic cover'. Like mounting the TPL in a huge phase plug.

Scott,

Thanks for reminding me about Bruce's experience with this driver and without a sealed back chamber. Actually, the way I'm building my dummy back chamber with a PVC pipe and the corresponding cap, I can test a sealed chamber and an open end as you do with ease.

What are your crossover points between the AMT and midrange horn, and to the midbass? What are your thoughts about lobbing, considering the spacing between your AMT and midrange horn?

Cheers

I realize it might look like it shouldn't work, but, it does, and sounds marvelous ! Mid range horn to tweeter @ 6kHz, down to mid bass @ 250Hz. I love this sound. The only thing I might try, is to horn loaded the mid bass slot exit. As far as lobbing is concerned, I don't hear any. Please note the acoustic "pillow" I have placed on top of the red horn to absorb any possible reflections from the tweeter, even though it is largely directional, I figured it couldn't hurt.

Attachments

Thanks for providing the link. From what I can gather from the graphs you posted, the round vs oval horn produced very similar results, especially within the band I'm interested in.

Yep. Most drivers were OK to ~4kHz and above when I used a big throat (no compression).

I tried various drivers (a Fostex, domestic midbass drivers) on a 2" throat, and most had a big dip at ~2kHz. The only pro driver I used, P Audio 4" (SN4-60F) was good to 4kHz.

http://www.diyaudio.com/forums/mult...compression-drivers-budget-3.html#post4623542

Nice multicell! I see what you mean now. And it might work. But I seriously doubt the multicell would be allowed in the living room by my wife 😱. I'm skating on thin ice when it comes to horns!

This was just a pic I found in a quick search, to illustrate the idea. I don't think you'd need to go that big. The horns I was using in the above link had 30*45cm mouths. I've extended them a little since then, but they are still light and petite compared to that multicell.

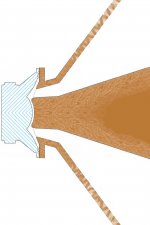

Here's another illustration of the TPL-on-huge-phase-plug idea (modified pic from centauriaudio.com.au). Only a little bit crazier than a normal big DIY horn 🙂

Attachments

- Home

- Loudspeakers

- Multi-Way

- Midrange horn design, cone-driven - 201