If I had the resources and tooling, I would search for the best material ply "layup" to create a highly damped, vibrationally dead panel.

Others are doing just that in the realm of cabinets; I think the panel ringing problem is even worse in OB, as an enclosed cab wall at least has all 4 edges bonded to the mass of the adjacent wall.

Others are doing just that in the realm of cabinets; I think the panel ringing problem is even worse in OB, as an enclosed cab wall at least has all 4 edges bonded to the mass of the adjacent wall.

I missed the chance to pick up a set of wharfdale sand filled baffles minus the drivers last year, much to my disappointment.

I recall a few builders mentioning that the wings across the tops bottoms and side add a lot of stiffness to the panel.

I recall a few builders mentioning that the wings across the tops bottoms and side add a lot of stiffness to the panel.

Out at the fringe of my thoughts, I was considering spending $60 at "Tractor Supply" for a

They do have thinner material that's cheaper. Actually possible for me to work with. You'd have to frame it, as it's flexible enough it would just fold right over if you tried to stand it up.

I have a set of 3, 24" X 24" smoke plexi panels 7/16" thick. I've been thinking a pair of those might make nice OB "top" panels, with the rest of it used for the base and any bracing structure. Of course, they make a sound when knocked on, but nothing like a wood panel.

I have a loose replica of Martins project 9 - but just a pair of H-frames with the 20 X 20" OB board (sporting the MA Pluvia 7(A) driver shown abobe) on top, versus the 4 H-frame setup he has.

4 ft. x 6 ft. x 3/4 in. Thick Rubber Stall Mat, 1202220

That sucker weighs 94 lbs, so I would not be able to maneuver it for transport nor fabrication. It stinks also, so it would need to be coated for indoor use. But that's what I'm talking about - a pair of 45 lb boards that you could whack with a hammer and just hear <thud>....They do have thinner material that's cheaper. Actually possible for me to work with. You'd have to frame it, as it's flexible enough it would just fold right over if you tried to stand it up.

I have a set of 3, 24" X 24" smoke plexi panels 7/16" thick. I've been thinking a pair of those might make nice OB "top" panels, with the rest of it used for the base and any bracing structure. Of course, they make a sound when knocked on, but nothing like a wood panel.

I have a loose replica of Martins project 9 - but just a pair of H-frames with the 20 X 20" OB board (sporting the MA Pluvia 7(A) driver shown abobe) on top, versus the 4 H-frame setup he has.

It's difficult to beat sand filled. It's low tech, but very effective. As a fringe benefit, it's also heavy. 😛best material ply "layup" to create a highly damped, vibrationally dead panel.

Searching the net now for sand filled baffle making as I had it planned before also when I came to know about Wharfedale speakers.It's difficult to beat sand filled. It's low tech, but very effective. As a fringe benefit, it's also heavy. 😛

May be I will give a try. Say two 12mm- 18mm plys sandwich the sand. Some bracing inside also to hold the plys together as the sand will pressurise the plys and may be it swells. Totally it may become 40mm or more in thickness. Is it as simple as that to make sand filled baffle? Has anyone here made?

Yes 12mm should be OK, but as you say it can swell under the pressure from the sand. Normally a few small wooden blocks are used to tie together front and back panels. Yes, the wood blocks do transmit some sound, but so do the baffle edges. In practice, the sand filled panel is so dead that the small connections are not a worry.

Thank you for the information. The below part is ok as there is the big circular bracing of the woofer hole. The problem is the place in between the full range and woofer and the opposite side of the full range as it's circular bracing is off center. Therefore other than the side bracing only two small (circular) wood blocks in slight diagonal fashion above the woofer will suffice. The picture in my mind is taking shape. Seems doable.

Yes the woofer ring will hold strongly in that area. And for sure the mid/tweeter mounting isn't going to be easy. Not only do you have to deal with the sand core, there is the baffle thickness and problems of resonances and diffraction around the opening. A thin one piece sub-baffle might work there, as it does in a solid baffle.

...humm maybe an old latex bed in a recycle plant to make the proof between the driver and the next hole panel ?

I wonder what Dynaudio use to glue the front panel of Confidence serie to the cabinet ? Really the front panel should not have theorically any link with the bass unit. Latex or rubber is what have the best damping while being enough solid to seal (sand is good too 🙂 but the coupling between the two layers is a problem in order the sand not to leak)

I wonder what Dynaudio use to glue the front panel of Confidence serie to the cabinet ? Really the front panel should not have theorically any link with the bass unit. Latex or rubber is what have the best damping while being enough solid to seal (sand is good too 🙂 but the coupling between the two layers is a problem in order the sand not to leak)

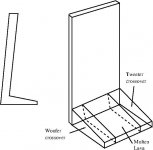

The shaded areas are the wooden blockes gluing the front and the back baffle together, other than the four sides bracing. The shade around the

full range (tweeter) hole is big compare to the ones around the woofer hole, so that 45 degree curving is possible on its rim. The white area is filled with sand.

full range (tweeter) hole is big compare to the ones around the woofer hole, so that 45 degree curving is possible on its rim. The white area is filled with sand.

Attachments

Last edited:

Good idea on the tweeter. You can use that large block of wood to smooth the edges of the hole.

Otherwise, it looks like the panel have support not too far in any direction.

Otherwise, it looks like the panel have support not too far in any direction.

Couple of more issues come to mind:

1. The bottom part of the baffle will be much less heavy compared to the top. This is because the woofer is large in size. So the baffle

will be unstable and may easily topple. A solution is that a heavy plinth (e.g. sand filled) must be attached at the base, to give stability to the whole structure. The plinth also may house the crossover network, hidden. Will look nice.

2. The type of sand. Searching the net, but no such information is available. There are sands which are almost dust like and there are

river sands with big granules. Scientifically, which one is more appropriate?

1. The bottom part of the baffle will be much less heavy compared to the top. This is because the woofer is large in size. So the baffle

will be unstable and may easily topple. A solution is that a heavy plinth (e.g. sand filled) must be attached at the base, to give stability to the whole structure. The plinth also may house the crossover network, hidden. Will look nice.

2. The type of sand. Searching the net, but no such information is available. There are sands which are almost dust like and there are

river sands with big granules. Scientifically, which one is more appropriate?

Does the woofer weigh more than the hole? Usually it does, but good point.

I don't know if there is any research on the size of the sand, but usually it's done with "play sand" which is medium fine, not dust. The way it's explained is that there is energy loss each time the sound has to move from one grain to the next, so you might think that more grains is better. But would power work? I don't think so. Does anyone else know?

I can tell you that standard construction grade sand sold in the US works well. But it needs to be dried out! It all does, of course, but the hobby or play sand comes dryer than construction sand.

I don't know if there is any research on the size of the sand, but usually it's done with "play sand" which is medium fine, not dust. The way it's explained is that there is energy loss each time the sound has to move from one grain to the next, so you might think that more grains is better. But would power work? I don't think so. Does anyone else know?

I can tell you that standard construction grade sand sold in the US works well. But it needs to be dried out! It all does, of course, but the hobby or play sand comes dryer than construction sand.

Thanks again Pano for following my thoughts and for the crucial information. The earlier baffle I built (35mm two ply glued) had this problem, the top part was much heavy, that is why I had to make the strong back support starting from the center. This this time I would like to avoide that, and keep the back of the woofer free from any obstacle. The Eminence Alpha 15A has small light magnet so does not give much of a weight. The sand part is understandable,. It should be dry, otherwise may affect the wood.Does the woofer weigh more than the hole? Usually it does, but good point.

I don't know if there is any research on the size of the sand, but usually it's done with "play sand" which is medium fine, not dust. The way it's explained is that there is energy loss each time the sound has to move from one grain to the next, so you might think that more grains is better. But would power work? I don't think so. Does anyone else know?

I can tell you that standard construction grade sand sold in the US works well. But it needs to be dried out! It all does, of course, but the hobby or play sand comes dryer than construction sand.

I have to now think how to build a heavy base.

I have to say, XRK's "The XSD Speaker" has a woofer design that puts quite a spine in place to hold up the rest of the baffle. I'm sure I've seen center spine designs that go over the back of the conventionally arranged woofer's magnet. Thinking of a structure that will give that tall board some rigidity, w/o getting in the way of the speaker cones rear emissions.

- Home

- Loudspeakers

- Multi-Way

- Martin King open baffle II