Yes Jan, it makes sense for everyone close to DE that can also wait weeks for delivery and has elaborated finished design. I can do that, and probably will for some cases, but we have people here from all around our planet, don't think it is sensible to order custom piece of metal from Germany if you are in I don't know where, New Zealand for example

Couldn't a palm router with some sort of template do it?

If you can get press tools, you could always use a vice as a press. I have used a chisel on brass (I think I copied the technique from clickspring on YouTube) I have used a handheld jigsaw on 4mm stainless, but it wasn't a pleasant exercise. Presumably you could get some sort of file to go in a jigsaw.

If you can get press tools, you could always use a vice as a press. I have used a chisel on brass (I think I copied the technique from clickspring on YouTube) I have used a handheld jigsaw on 4mm stainless, but it wasn't a pleasant exercise. Presumably you could get some sort of file to go in a jigsaw.

You talk without knowledge. They also produce in USA. Shipping times from receipt of order usually 5 days.Yes Jan, it makes sense for everyone close to DE that can also wait weeks for delivery and has elaborated finished design. I can do that, and probably will for some cases, but we have people here from all around our planet, don't think it is sensible to order custom piece of metal from Germany if you are in I don't know where, New Zealand for example

Drawing with the app takes half an hour tops. You can order directly from the app.

If you don't want to do this, fine.

But don't come up with BS.

Jan

Most time i am using The Greenlee tools, but i think 6mm Alu is too much for them

In soft aluminum front panels that were 1/4" thick, I have indeed cut a 1" dia hole with a Greenlee chassis punch.

Use a right angle ratchet wrench, and some oil for lubrication. Just go slow.

Always have the cutting edges of the punch against the visible side of the panel.

The other side may have marks from the punch unless you use masking tape to guard it.

This was not very polite dear Jan, period.You talk without knowledge. They also produce in USA. Shipping times from receipt of order usually 5 days.

Drawing with the app takes half an hour tops. You can order directly from the app.

If you don't want to do this, fine.

But don't come up with BS.

Jan

Besides , this is DIY forum, I asked about more effective DIY solution. Everyone with some money on credit card can order complete chassis to be CNC-ed That is not a question. We are crafters not people ordering from pro shops.

Correction, sorry, I call myself crafter, and probably many do, by all means I don't speak for many, so "we" above is mistake.

Still cheers,

Drazen

Digikey stocks many examples of panel-mount XLR connectors that only require the main center hole and mounting holes. Depending on the design, 2 or 4 mounting holes.

They reduce your problem to just accurately drilling a bunch of holes.

Simplicity of mounting is one of the reasons I often use DIN connectors for my electronic projects, particularly for power supply connections. Drill the center holes & two 3mm mounting holes. Done.

They reduce your problem to just accurately drilling a bunch of holes.

Simplicity of mounting is one of the reasons I often use DIN connectors for my electronic projects, particularly for power supply connections. Drill the center holes & two 3mm mounting holes. Done.

Drazen, 16 holes with slots is too much Zen indeed. I think Jans option then maybe is more attractive although I feel 50 Euro will not be enough with 6 mm aluminium panel!? I still like to do it myself. It is craftsmanship earned by doing it a lot.

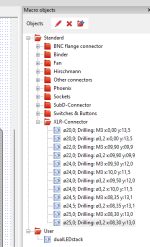

Downloaded FrontDesign by Schaeffer though. It runs on Mac. Cool.

Downloaded FrontDesign by Schaeffer though. It runs on Mac. Cool.

Last edited:

Hi Mark, I agree. As mentioned earlier, all Neutrik XLR sockets support back mounting that requires one big round 24mm hole, 2 small ones for screws and just one slot for female ones. Comprehended.Digikey stocks many examples of panel-mount XLR connectors that only require the main center hole and mounting holes. Depending on the design, 2 or 4 mounting holes.

They reduce your problem to just accurately drilling a bunch of holes.

Simplicity of mounting is one of the reasons I often use DIN connectors for my electronic projects, particularly for power supply connections. Drill the center holes & two 3mm mounting holes. Done.

I feel sorry that DIN sockets felt out of fashion in audio, today nobody bothers to produce good ones, and even when they do (for instance mini DIN for completely different purposes) , one needs to make cables to fit them... XLR is standard, I like it or don't....

Well there is always Lemo you can count on. Like you I like XLR technically but till a few years back I did not join the balanced/symmetrical club as I dislike(d) the Cannon connectors big time.

Lemo connectors however are a work of art but you will need an art broker with them 🙂

Lemo connectors however are a work of art but you will need an art broker with them 🙂

Last edited:

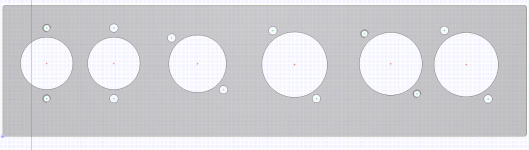

I did a quick one with 6 random XLR types on 3mm panel to keep cost under control. This one is 54 euro. Just an example.

You can also send them your own panel and they will machine it.

I have no connection to Front Panel Express, but find their service affordable, quick and perfect quality.

The attached panel was also around 50 euro, including the text engraving.

I had to modify the XLR hole as I changed my mind to the type of plug afterward. That's also diy ...

The square holes are for LED display stacks.

Jan

You can also send them your own panel and they will machine it.

I have no connection to Front Panel Express, but find their service affordable, quick and perfect quality.

The attached panel was also around 50 euro, including the text engraving.

I had to modify the XLR hole as I changed my mind to the type of plug afterward. That's also diy ...

The square holes are for LED display stacks.

Jan

Attachments

Last edited:

As thought. With 16 holes and 6 mm aluminium Drazen likely will be happily drilling and filing a few Zen hours 🙂

https://amzn.eu/d/6OrbXU0

US versions also available. Fine for 2mm aluminium, but 3mm or more gets tough!

US versions also available. Fine for 2mm aluminium, but 3mm or more gets tough!

Yeah, there are those , I also like Amphenol a lot, and most of all Ghielmetti patchbay contacts solution. But these are all together super darling and not standard. If I go and make system for out of this universe, it would not be with Neutrik 🙂Well there is always Lemo you can count on. Like you I like XLR technically but till a few years back I did not join the balanced/symmetrical club as I disliked the Cannon connectors. Lemo connectors however are a work of art but you will need an art broker with them 🙂

Yes, and yet I prefer front mounting practically always, but the related hole has to be about 26 mm in that case and you have to be careful because it becomes very close to the screw holes, but in my experience it can be easily done.As mentioned earlier, all Neutrik XLR sockets support back mounting that requires one big round 24mm hole, 2 small ones for screws and just one slot for female ones.

I must confess that at a certain point, I am not willing to try and produce 16 perfectly aligned holes for these sockets. It was enough to drill out the original RCA sockets so that the type of RCA that I wanted to use required a larger hole. A good friend in Washington state helped me along with his CNC machine. Now, I realize that this is close to apples and oranges because my front and rear panels were made of 7/16" thick wood. The point is that it would have been really shaky for to get all of that right. That is when you try and find maybe local help.

Attachments

Logon, that is a consequence of using a stepped drill. This does not occur with milling.

Hi Jan, these on picture are still for male back panel mounted ones 🙂 no slots that are the issue.

Just for fun, picture of what is laying around my man's cave: abandoned preamp experiment with 16 Neutriks, and on top experimental box for ultra low noise amps (this time I was smarter and went for back mounting)

On abandoned preamp there is hole for removed DIN (far left) that was DC power connector.

Just for fun, picture of what is laying around my man's cave: abandoned preamp experiment with 16 Neutriks, and on top experimental box for ultra low noise amps (this time I was smarter and went for back mounting)

On abandoned preamp there is hole for removed DIN (far left) that was DC power connector.

Jean-Paul. Not exactly. That was the first attempt (I had another panel) and I first did several successful tests.

I purposely countersunk the hole, the step bit has nothing to do with it.

The step bit, as the name suggests, is stepped, but you may want an intermediate diameter and therefore you have to use a bit of inventiveness.

After mounting the connectors, any possible smudge is obviously completely invisible.

I purposely countersunk the hole, the step bit has nothing to do with it.

The step bit, as the name suggests, is stepped, but you may want an intermediate diameter and therefore you have to use a bit of inventiveness.

After mounting the connectors, any possible smudge is obviously completely invisible.

If this would be only fetish I have, I would be all right 🤣

Need to invent smiley with 3 dots in a circle 🙂

Need to invent smiley with 3 dots in a circle 🙂

- Home

- Design & Build

- Construction Tips

- Making panel holes for XLR