Thanks Allen.Cliff, do you think it may be worth making a distinction, considering your earlier question about the operation of capacitors if they might become magnetised.. between the operation of components in the proximity of a fixed magnetic field, and the effect of operating components in the vicinity of ferrous material?

Being non technical and having no background in electronics I'm open to your suggestions.

My interest was in the pathway that analogue sound waves must travel along between an Analogue Amp and passive Loudspeakers.

Correct me if I'm wrong, but doesn't ferrous become magnetic or radiate a magnetic field when charged with current?

So rather than making the distinction which you're suggesting, as both magnets, and ferrous with a current running through it both radiate magnetism (correct me if I'm wrong) isn't it better just to refer to ferrous?

If ferrous can have adverse affects on an analogue signal, then, apart from wiring, posts, plugs, and solder, etc, crossover components such as iron core inductors & resistors which have ferrous components will also have an impact.

I don't know about electrolytic capacitors, but I thought poly caps being non metal are OK.

There is so much we don't know about HiFi audio that I'd say making components that sound good is as much an art as it is a science.

This is probably why there are literally millions of products out there all claiming to offer the best sound.

Atleast a couple of people I've met over time indicated to me that they've heard $500,000 systems that have sounded crap and others more moderately priced have been a joy to listen to.

I think the answer to what we can and needn't worry about is a little clearer than that, and when in doubt, much can be measured.

For example you can take advantage of this by coiling a conductor on its own, to make an inductor.. but the effect is further increased when an iron core is used. The presence of magnetic material between amps and speakers is most likely to only have a noticeable effect with the inductors used in a crossover. Using iron brackets and bolts for example might give unexpected results.

For the other case, the presence of a fixed magnetic field things would be different. Putting an air cored inductor near a speaker magnet might have no significant effect (notwithstanding that the speaker motor has iron in it). However put an iron cored inductor near a speaker magnet and maybe the core will become saturated in one direction.

Current will produce a field around a conductor regardless of what it is made of.between an Analogue Amp and passive Loudspeakers.

Correct me if I'm wrong, but doesn't ferrous become magnetic or radiate a magnetic field when charged with current?

For example you can take advantage of this by coiling a conductor on its own, to make an inductor.. but the effect is further increased when an iron core is used. The presence of magnetic material between amps and speakers is most likely to only have a noticeable effect with the inductors used in a crossover. Using iron brackets and bolts for example might give unexpected results.

For the other case, the presence of a fixed magnetic field things would be different. Putting an air cored inductor near a speaker magnet might have no significant effect (notwithstanding that the speaker motor has iron in it). However put an iron cored inductor near a speaker magnet and maybe the core will become saturated in one direction.

No, it isn't always a bad thing but you should know what is happening or you may have unexpected results, such as a variation in frequency response.If ferrous can have adverse affects on an analogue signal,

Poly caps do have metal plates, they're named that way to show what's between them.I don't know about electrolytic capacitors, but I thought poly caps being non metal are OK.

No, some alloys have magnetic properties even though none of their constituents is magnetic.Did you mean ferrous element? Some rare earth elements also have ferromagnetic properties. Gadolinium, samarium, neodymium are all examples of magnetic rare earth metals.

However, to avoid confusing the issue, these elements are used, in combination with iron, cobalt and nickel, in the manufacture of magnets - and not in the manufacture of binding posts and banana plugs. 🙂

A well-known one is the Heusler alloy: Heusler compound - Wikipedia

Those cables have a silver-plated core because only the outer skin actually conducts at >VHF frequencies, which is their intended use.What has me intrigued a bit is that there are coax-cables with a steel-core, which are said to be very suitable for audio-applications...

But this brings topic down to a dull level, sorry.

They are completely unsuitable for LF applications

This morning I saw a YouTube video with a fellow reworking a crossover in an older speaker, shaking his head, and showing him picking up screws with a magnet.

Amazingly, he doesn't show any support for his disapproval of this, not with his graphs, or listening annectotes.

He has some products he sells that I personally don't see a point of, aside from being in business for profit, which is natural.

Can a silver plated tellurium non magnetic quantum screw, nut, bolt, or fuse set of offerings be far behind?

Maybe differing ferrous %'d alloys to fine tune the magnetic qualities of one's speakers?😄

Amazingly, he doesn't show any support for his disapproval of this, not with his graphs, or listening annectotes.

He has some products he sells that I personally don't see a point of, aside from being in business for profit, which is natural.

Can a silver plated tellurium non magnetic quantum screw, nut, bolt, or fuse set of offerings be far behind?

Maybe differing ferrous %'d alloys to fine tune the magnetic qualities of one's speakers?😄

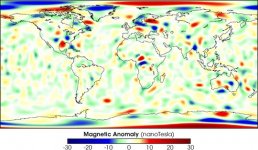

I'm concerned that the Earth’s surface magnetism may be having a deleterious effect on my listening pleasure. 😉

However, the concentrations of magnetic rocks and minerals in the Earth’s lithosphere are beyond my control.

Or perhaps a few nanotesla are nothing to worry about? After all, my fridge magnet is about 200 times stronger! 😊

However, the concentrations of magnetic rocks and minerals in the Earth’s lithosphere are beyond my control.

Or perhaps a few nanotesla are nothing to worry about? After all, my fridge magnet is about 200 times stronger! 😊

Attachments

Last edited:

When I lived in Tucson, there was a building in the middle of a park (and no, the building wasn't U shaped), for reasons unknown. A sign at the front of the building said that it was the 'Study of magnetics' or something of that reference. I wanted to go in but the doors were locked. I was repulsed ever since.

Magnetic capabilities and theories have been abused as an answer to just about anything that the public would buy. From fuel lines in cars to water lines in houses, and not at all surprisingly in audio (where it has the best chance of being considered), we stand in line for the latest thing. I do believe that there are possibilities in audio, but as mentioned before in this thread, just look at the number of resistors in almost any given circuit that have ferrous leads. This is not to mention a metal chassis that is made of highly magnetic material.

Maybe it should be better to consider a passive device that has its own magnetic ability to be more of a concern than whether the fact that it can be drawn by a magnet.

Magnetic capabilities and theories have been abused as an answer to just about anything that the public would buy. From fuel lines in cars to water lines in houses, and not at all surprisingly in audio (where it has the best chance of being considered), we stand in line for the latest thing. I do believe that there are possibilities in audio, but as mentioned before in this thread, just look at the number of resistors in almost any given circuit that have ferrous leads. This is not to mention a metal chassis that is made of highly magnetic material.

Maybe it should be better to consider a passive device that has its own magnetic ability to be more of a concern than whether the fact that it can be drawn by a magnet.

Anything, valid or not, will have those who exploit for profit.I'm concerned that the Earth’s surface magnetism may be having a deleterious effect on my listening pleasure. 😉

However, the concentrations of magnetic rocks and minerals in the Earth’s lithosphere are beyond my control.

Or perhaps a few nanotesla are nothing to worry about? After all, my fridge magnet is about 200 times stronger! 😊

For me, checking components with a magnet isn't about magnetism, but rather testing for iron content.

Other properties of iron include conductivity.

Copper can be 8 to 30 times more conductive than Iron depending on its composition.

Also brass, zinc & aluminium are all far better in conductance than iron.

A proponent against iron in the signal path indicated that iron tends to store energy or takes longer to dissipate or transfer it.

He adds that Iron Core Inductors tend to smudge the sonic signal.

They are a necessary evil in Bass driver applications due to the size & cost needed for an air core inductor of the same value, causing many builders to restrict air core inductors to tweeters & midrange where detail is of greater value.

Sound comparisons confirm that, in many applications, Iron Core Inductors affect sound reproduction in comparison to Air Core Inductors.

So, a general rule of thumb, is to remove iron from the signal path wherever economically possible.

It doesn't cost much to do, but may result in better sound.

Granted, there may be iron in other parts of the signal, but a system is only as good as its weakest link.

Silver plated tellurium non magnetic quantum screws is overkill.

I make choices when selecting parts I need.

For example, non iron banana plugs vs iron examples etc.

😉 🙂

Hope I haven't been controversial!

Member

Joined 2009

Paid Member

CliffR52,

I appreciate your answer here. Well stated and educational. If I were more concerned abouts magnetics, then it would be advisable for me to carefully route all signal cabling out of the way of all those power cords/products and concern myself less with the metallurgy of screws and other hardware. Probably not going to happen.

I appreciate your answer here. Well stated and educational. If I were more concerned abouts magnetics, then it would be advisable for me to carefully route all signal cabling out of the way of all those power cords/products and concern myself less with the metallurgy of screws and other hardware. Probably not going to happen.

Remove all the magnetic material from your (dynamic) speakers and you will not hear any distortion.

https://en.wikipedia.org/wiki/Royal_Observatory,_Greenwich#Magnetic_observations

"...made of non-magnetic materials."

Royal Observatory, Greenwich, Magnetic HouseWhen I lived in Tucson, there was a building in the middle of a park.... the 'Study of magnetics'

https://en.wikipedia.org/wiki/Royal_Observatory,_Greenwich#Magnetic_observations

"...made of non-magnetic materials."

Used such cable by mistake not so long ago. The amplifier just did not sound right. The cable was airplane cable with teflon isolation etc. but the core turned out to be iron/steel and magnetic. I obtained a spool of that cable intended for rewiring devices. A case of being convinced by the look of stuff. Now I did not have any other cable and it was in the middle of Covid so it was practically impossible to find anything else so I shipped the device and planned to let the owner tell me if the device performed well. The owner noticed it as well without being told!What has me intrigued a bit is that there are coax-cables with a steel-core, which are said to be very suitable for audio-applications...

But this brings topic down to a dull level, sorry.

*If one thinks the magnetic screw issue is exaggerated then just have a look at hard disks and what screws are used even for the PCB. Like CliffR52 I also avoid ferro parts as I learned decades ago that copper parts are to be preferred at certain spots. For binding posts and banana connectors my personal worry and experience is not so much that ferrous materials are used but a mix of metals with high zinc/aluminium content. These definitely sound worse than copper/brass based binding posts (please don't come up with academic blah blah "explaining" it should not matter but simply do the comparison instead). Industrial plated brass parts again outperform audio stuff but the latter has that nice looking ultra thin gold plating (over zamak 🙂)

Last edited:

zamak

I've appended Zamak (or Mazak) information here for reference. 🙂

https://en.wikipedia.org/wiki/Zamak

I have encountered unknown metals/alloys used in RCA connectors and even binding posts. Never thought to see if they were magnetic or not, but one thing was for sure, some of them were brittle.

When I rebuilt my speaker crossovers, I only used stainless steel for the fixings, except on the cross-over board cable eye mounts, where I used brass bolts. the big through bolt that fixed the into the rear of the mid/bass driver I remade in stainless steel also.

Binding posts were binned in favour of "less is more" & "test lead" sockets were used which have very little metal in them & the metal they do have is gold plated brass. Crimp eyes on the internal cables were tinned OFC, & the big connectors on the speaker cables into the back of the amp are now gold plated copper, & again have less metal in them.

Binding posts were binned in favour of "less is more" & "test lead" sockets were used which have very little metal in them & the metal they do have is gold plated brass. Crimp eyes on the internal cables were tinned OFC, & the big connectors on the speaker cables into the back of the amp are now gold plated copper, & again have less metal in them.

gold plated copper

Nickel is commonly used as a barrier layer between copper and gold.

The nickel prevents the copper diffusing into the gold, producing a corrosion resistant and durable coating.

The nickel layer can cause losses due to skin effect, but that need not be a concern at audio frequencies.

HiDave,

So that I understand correctly, you have shielded the crossover with stainless steel before mounting it directly onto the driver magnet?

eh???

The bolt that fixes the driver to the cabinet....the main mid/bass driver is not screwed to the front panel of the cabinet like normal....instead a bolt goes through from the rear panel of the cabinet into the rear of the driver magnet....

All info & photos in my thread here:-

https://www.diyaudio.com/community/...bronze-bx2-speakers-2010-2015yr-model.388989/

Nickel is commonly used as a barrier layer between copper and gold.

The nickel prevents the copper diffusing into the gold, producing a corrosion resistant and durable coating.

The nickel layer can cause losses due to skin effect, but that need not be a concern at audio frequencies.

Not in the case of the ones (WBT) that I bought.....quote:-

"Directly gold plated in a nickel-free finish to prevent oxidation. This ensures high conductivity and no magnetic interferences".

https://www.wbt.de/english/products...xtgenTM-bananenstecker-neu-muenchen-2008.html

Now I get it. I'm like that a lot. I read things differently than they were intended.eh???

The bolt that fixes the driver to the cabinet....the main mid/bass driver is not screwed to the front panel of the cabinet like normal....instead a bolt goes through from the rear panel of the cabinet into the rear of the driver magnet....

All info & photos in my thread here:-

https://www.diyaudio.com/community/...bronze-bx2-speakers-2010-2015yr-model.388989/

I actually used the idea of a long bolt from the back of a passive radiator to assist in mounting/bracing of a sub cabinet once. I do understand what you are referring to here, remembering KEF having done the same thing long ago... or was it Canton?

God, hardware, especially stainless and brass has become very high. Still I won't change unless there is an equal procedure that does the same thing, is convenient, and costs less.

- Home

- Design & Build

- Parts

- magnetic parts, and where to avoid them?